Well I removed the brake drum, and got the errors at 30 seconds. With the drum in at 50 Hz, error starts around around 60-90 seconds. At 30Hz maybe 90-120 seconds. I only need this thing to work a reliable 15 seconds at a time. Under a 400lb load, only testing will determine if the errors are consistent as mentioned or if more load means errors coming sooner. Working on a test rig to lift the weight this week.

It appears the power to the brake comes from the same wires to the motor. Somehow they get forward and reverse with red blue and black and also the break turns on.

I mentioned this before post 7. I had assumed the round coil of wire that surrounds the brake drum was doing the work.

It appears the power to the brake comes from the same wires to the motor. Somehow they get forward and reverse with red blue and black and also the break turns on.

I mentioned this before post 7. I had assumed the round coil of wire that surrounds the brake drum was doing the work.

"Wires to the motor" is not even the motor windings. There's nothing in that that says the brake is pulled by the motor magnetics. Anyway, not vital info in the end. Just me trying to understand the workings now.

I'm afraid I don't have the knowledge nor experience to solidly guide you further. There will be an imbalance in the phases, because one of the three is missing and those two are at 90 degrees rather than the ideal 120 degrees. That will be adding stress but I would have though the VSD had the strength to easily handle. I'm not confident in that VSD but then I'm not confident in myself now either.

Thanks Evan for the valuable tips! What I have is probably workable as is, I'll find a better vfd and see what happens. At least now I have some understanding to connect real 3 phase motors to the propeller projects in the future.

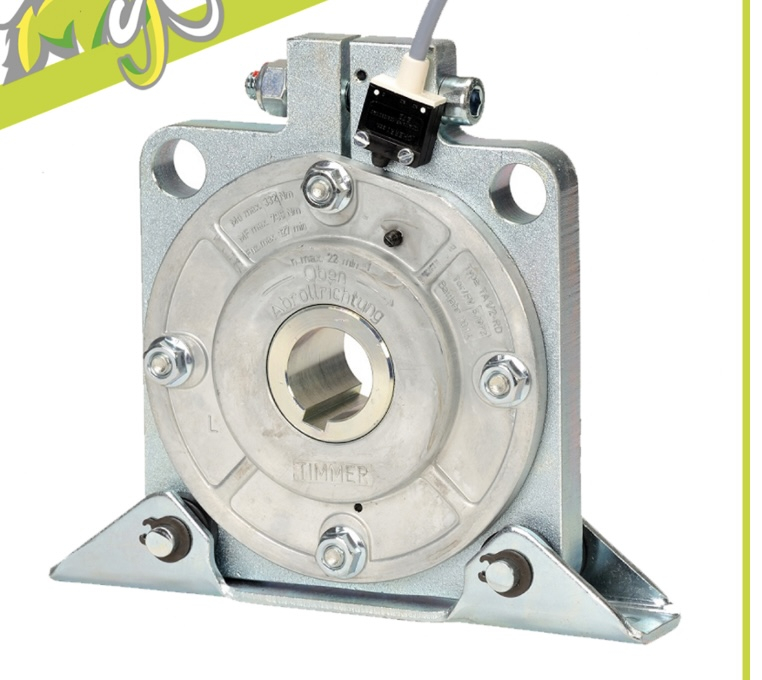

I found these inertia brakes that kick on the brake at 22 rpm, no electronics involved to set the brake. They have various braking forces. The brake releases when you reverse the shaft. A switch on the brake can be used to cut AC to motors. This will prevent a free fall if the gears break in the hoist.

Yeah, I first speculated on something like that but it's reasonably clear that T Chap is right, the motor magnetics pulls the brake drum, disengaging it upon every use of the motor. And it's a simple spring engage when the motor is not powered.

PS: Here's the non-tracking link extracted from your link -

Comments

Well I removed the brake drum, and got the errors at 30 seconds. With the drum in at 50 Hz, error starts around around 60-90 seconds. At 30Hz maybe 90-120 seconds. I only need this thing to work a reliable 15 seconds at a time. Under a 400lb load, only testing will determine if the errors are consistent as mentioned or if more load means errors coming sooner. Working on a test rig to lift the weight this week.

I mentioned this before post 7. I had assumed the round coil of wire that surrounds the brake drum was doing the work.

"Wires to the motor" is not even the motor windings. There's nothing in that that says the brake is pulled by the motor magnetics. Anyway, not vital info in the end. Just me trying to understand the workings now.

I'm afraid I don't have the knowledge nor experience to solidly guide you further. There will be an imbalance in the phases, because one of the three is missing and those two are at 90 degrees rather than the ideal 120 degrees. That will be adding stress but I would have though the VSD had the strength to easily handle. I'm not confident in that VSD but then I'm not confident in myself now either.

Thanks Evan for the valuable tips! What I have is probably workable as is, I'll find a better vfd and see what happens. At least now I have some understanding to connect real 3 phase motors to the propeller projects in the future.

I found these inertia brakes that kick on the brake at 22 rpm, no electronics involved to set the brake. They have various braking forces. The brake releases when you reverse the shaft. A switch on the brake can be used to cut AC to motors. This will prevent a free fall if the gears break in the hoist.

Probably this is why no wires to the brake.

https://google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwj-x6Kdy9aCAxUOLEQIHVlgDKAQwqsBegQIJRAG&url=https%3A%2F%2Fwww.youtube.com%2Fwatch%3Fv%3DptafWt9kbzk&usg=AOvVaw1bb4yg93EjzELM62VHyZVE&opi=89978449

Yeah, I first speculated on something like that but it's reasonably clear that T Chap is right, the motor magnetics pulls the brake drum, disengaging it upon every use of the motor. And it's a simple spring engage when the motor is not powered.

PS: Here's the non-tracking link extracted from your link -