@Circuitsoft said:

I have had plenty of designs using 10ppm crystals get 150ppm out because the loading capacitors aren't quite right. This really becomes an issue when you have a ground plane (which is a very good idea) because the loading caps then parallel/add to the ground-plane caps, so the frequency can wind up very wrong.

I don't have much choice there because the loading caps are internal to the P2. The pads of the XI/XO pins are 1.2x1.3mm so the area including traces is something around 2mm². With a 0.3mm FR4 prepreg between the top and upper inner layer this results in around 0.2pF and can be safely ignored compared with the much larger load capacitance of 15pF in the P2.

The data sheet of the crystal specifies 12pF load capacitance while the P2 has only offers 15 and 30pF. So the frequency will surely be some 10+ppm off. Nevertheless I'm quite sure this will be still perfectly OK for standard applications like serial comm, HDMI/VGA pixel clock and general timing. If anybody want's to build a precision clock he can always replace the crystal with an oscillator (if he finds one that fits...). While I already had some problems with crystals not starting up using FPGAs I've never seen such problems with the P1 or P2.

But thanks for the info about USB powering. I'll keep the mini USB connector, though. I use them a lot and never had any problems. Even if micro or type C connectors are more common theese days I think using a power supply with a type A receptacle and exchangable cable is the way to go.

@jmg said:

You may need more parallel vias in the high current and thermal paths, especially around the 1v8 switcher ?

Good point. But I don't want larger copper areas connected to the inductor pads because of the risk of parasitic capacitance causing EMI problems. I've added a ground plane on the top layer below the inductor and some more vias to the inner ground plane. I've successfully used this practice to transfer more heat to a big inductor for soldering (convection reflow oven) so this should also work to transfer heat away from the inductor.

As there is a certain demand for a simple and cheap board, and to bridge the time to start a P2D2 production and for many other reasons @ManAtWork redesigned the KISS board. I'm ready to distribute the boards in EU.

Questions:

When can we expect the board to be ready?

Will the old board be dumped in favour of having unique hardware and so reduce upcoming questions?

What is the expected price point?

From my side the main interest is to bring the board as cheap as possible to those that invest time and effort to contribute to the forum and develop KISS applications, TAQOZ favored ;-)

I'm curious as to what the answers will be too but until @ManAtWork assembles and tests first board we should be patient, i guess.

On the other hand the KISS board, both revisions, do not require hardware support, imho. The board is professionally made, the schematic is available. I know that first hand from the experience.

The question is not if you need support, but if support may be needed. Like in sumo: if there is a tiny little handle, you are out of game ;-) Criticism is about the easiest exercise in a forum.

I think I have not expressed myself clearly then, if it got understood as criticism.

All I meant was to say that hardware support is, in my opinion, not necessary. But of course, you are right. Some users may need it. However, hardware support, as I understand it, would require time and effort and quite possibly induce some associated costs and that doesn't help with making the board sufficiently financially attractive. Unless you meant "best effort" support here on the forum.

Again, this is just a clarification of my subjective view and not the criticism.

Good questions... The PCBs are already produced and ready to ship. They should be here the next week. Propellers are also ordered and should also arrive in one or two weeks. As soon as they are here I'll start assembly. However, I'm on holiday from August 15th to 22nd so if the parcels are delayed due to covid or customs trouble it could happen that I can't make the boards before August 23rd.

I still have 100 boards of the old layout without SD card. Normally, I try to avoid wasting something that is not broken. But if the main application is TAQOZ it probably makes more sense to have all boards with the same features and revision. Do you think anybody would still buy the old ones if I sell them for €20 and the new ones for €25?

I can't imagine to buy an older version if the newer is available. If not there is an application that definitely doesn't need those features. So I would produce the old version only on demand..

@ManAtWork said:

Good questions... The PCBs are already produced and ready to ship. They should be here the next week. Propellers are also ordered and should also arrive in one or two weeks. As soon as they are here I'll start assembly. However, I'm on holiday from August 15th to 22nd so if the parcels are delayed due to covid or customs trouble it could happen that I can't make the boards before August 23rd.

I still have 100 boards of the old layout without SD card. Normally, I try to avoid wasting something that is not broken. But if the main application is TAQOZ it probably makes more sense to have all boards with the same features and revision. Do you think anybody would still buy the old ones if I sell them for €20 and the new ones for €25?

Do you mean assembled boards with that price tag ? That would be really something spectacular.

I agree with Erna in that the assembling the v1 on demand is a good idea and I, for one, would consider buying both variants (but you have enough EU stock to satisfy my current needs for the v1 board anyway ).

I could certainly go for an original or two, possibly even without the flash. I mostly want to use it as a pc i/o expander, so having to bootload from the host is fine, and a prop-plug is plenty easy to hack out of an ftdi-compatible cable.

If there's any feature it's missing, for me, it's mounting holes, but it's easy enough to tie down with zip ties or scotch dualock tape.

@Circuitsoft said:

I could certainly go for an original or two, possibly even without the flash. I mostly want to use it as a pc i/o expander, so having to bootload from the host is fine, and a prop-plug is plenty easy to hack out of an ftdi-compatible cable.

If there's any feature it's missing, for me, it's mounting holes, but it's easy enough to tie down with zip ties or scotch dualock tape.

@Circuitsoft said:

I could certainly go for an original or two, possibly even without the flash. I mostly want to use it as a pc i/o expander, so having to bootload from the host is fine, and a prop-plug is plenty easy to hack out of an ftdi-compatible cable.

If there's any feature it's missing, for me, it's mounting holes, but it's easy enough to tie down with zip ties or scotch dualock tape.

I can accommodate shipments to US as I have them in stock. See first post in this thread for payment instructions.

The old boards are not obsolete. We just have to make them cheaper so that anyone who doesn't need the SD card can buy those. I can't promise a particular price at the moment. When all problems are solved I'll have to add all costs together.

There are no old boards. There are boards with slightly different features.

It is not for me to decide but I can see at least two more pricing strategies possible here:

sell them at the same price - might be a new price but the same for both boards. This way one can pick the board based on features one likes without the guilt syndrome or hesitation or

sell the v1 (the original KISS board) at the original price and the v2 at the new price, whatever that might be. This way the owners of the original v1 boards might feel somewhat special, like they were supporting the KISS board development for example, and the customers for the v2 board will enjoy it at its price.

There are more options but I will save them for the next occasion .

Just get rid of that old versus new terminology. Old doesn't sell well unless it's really ancient.

The GD25Q64ET ("T" means SO-8 150mil) is still not available. And it's not clear if it would work without additional pulldown resistor. The SD card is working on the new layout (or should I say "extended version").

So here is my decision: I'll keep the AT25SF321 and add pulldowns to all boards. But time is short. I'll leave for holidays, tomorrow. I'll assemble the rest of the boards when I'm back.

BTW, the SD card seems to have priority over the SPI flash chip and even over the serial ProgPlug. So the SD card has to be removed if the latter are to be used. Is this a problem? I don't think so. "keep it simple" means no room for DIP switches, sorry.

Update: If a boot image ("_BOOT_P2.PIX") is present on the SD card it takes priority. If an SD card is inserted without a valid boot image the normal programming with a ProgPlug or booting from SPI flash is possible. I think this is the perfect behaviour for most cases. So a data logger that boots from SPI flash but saves data on an SD card can also be implemented, for example.

..."keep it simple" means no room for DIP switches...

+1

Lack of DIP switches is a feature. And a good one.

Allow users to have them on board and you get hundreds of questions on how to set them to get "x" or "y" behaviour. Fortunately, there is no room for them on the board.

IIRC Flash boot comes before SD provided there is a pull-up on P61. If there is not valid code (checksum) in the Flash and P62 contains a pull-up (provided from the SD cards internals) the the SD Rom code initialises the SD card and then searches for the MBR, VOL and _BOOT_P2.BIX and _BOOT_P2.BIY files in that order and if not found (can take up to 1/2s or more depending on the SD card). If not found, the Rom code will try the serial next.

@ManAtWork said:

BTW, the SD card seems to have priority over the SPI flash chip and even over the serial ProgPlug. So the SD card has to be removed if the latter are to be used.

Strange, I can't reproduce this any more. Now, with the pullup at P61 and pulldown at P58 the SPI flash always takes priority over the SD card. So even if the SPI ROM is erased you can't boot from SD card unless you remove either the pullup or the pulldown resistor. So the options are:

load into RAM only with progplug, SD card has to be removed, pullup/down don't matter

load into flash and boot from flash, pullup+pulldown have both to be present, SD card can be used for data storage but not for booting

boot from SD card, pullup or pulldown has to be removed

This is somehow inconvenient and not how it was meant to be. However, it is too late for a PCB layout change. I think, for a completely free choice of SD vs. SPI booting it would be indeed neccessary to add a DIP switch. Unfortunatelly, the "card inserted" switch of the SD socket can't be used as it is of the wrong polarity. A NC instead of a NO switch would be required to automatically disable the pulldown resistor. And even then the "SD card for data only" option wouldn't work.

Comments

I don't have much choice there because the loading caps are internal to the P2. The pads of the XI/XO pins are 1.2x1.3mm so the area including traces is something around 2mm². With a 0.3mm FR4 prepreg between the top and upper inner layer this results in around 0.2pF and can be safely ignored compared with the much larger load capacitance of 15pF in the P2.

The data sheet of the crystal specifies 12pF load capacitance while the P2 has only offers 15 and 30pF. So the frequency will surely be some 10+ppm off. Nevertheless I'm quite sure this will be still perfectly OK for standard applications like serial comm, HDMI/VGA pixel clock and general timing. If anybody want's to build a precision clock he can always replace the crystal with an oscillator (if he finds one that fits...). While I already had some problems with crystals not starting up using FPGAs I've never seen such problems with the P1 or P2.

But thanks for the info about USB powering. I'll keep the mini USB connector, though. I use them a lot and never had any problems. Even if micro or type C connectors are more common theese days I think using a power supply with a type A receptacle and exchangable cable is the way to go.

Good point. But I don't want larger copper areas connected to the inductor pads because of the risk of parasitic capacitance causing EMI problems. I've added a ground plane on the top layer below the inductor and some more vias to the inner ground plane. I've successfully used this practice to transfer more heat to a big inductor for soldering (convection reflow oven) so this should also work to transfer heat away from the inductor.

OK, PCB is in production. P2 chips are ordered. Everything else is already in stock.

A reminder, there a 11 units available for immediate shipment in the US for shipping to North American locations.

@Publison If you don't mind saying... Are you still asking $50 for these? I assume that is before shipping, right?

See first post here for payment options. I have them here in the US,

https://forums.parallax.com/discussion/172391/kiss-eval-board-ready-to-ship-taking-orders/p1

As there is a certain demand for a simple and cheap board, and to bridge the time to start a P2D2 production and for many other reasons @ManAtWork redesigned the KISS board. I'm ready to distribute the boards in EU.

Questions:

When can we expect the board to be ready?

Will the old board be dumped in favour of having unique hardware and so reduce upcoming questions?

What is the expected price point?

From my side the main interest is to bring the board as cheap as possible to those that invest time and effort to contribute to the forum and develop KISS applications, TAQOZ favored ;-)

I'm curious as to what the answers will be too but until @ManAtWork assembles and tests first board we should be patient, i guess.

On the other hand the KISS board, both revisions, do not require hardware support, imho. The board is professionally made, the schematic is available. I know that first hand from the experience.

The question is not if you need support, but if support may be needed. Like in sumo: if there is a tiny little handle, you are out of game ;-) Criticism is about the easiest exercise in a forum.

I think I have not expressed myself clearly then, if it got understood as criticism.

All I meant was to say that hardware support is, in my opinion, not necessary. But of course, you are right. Some users may need it. However, hardware support, as I understand it, would require time and effort and quite possibly induce some associated costs and that doesn't help with making the board sufficiently financially attractive. Unless you meant "best effort" support here on the forum.

Again, this is just a clarification of my subjective view and not the criticism.

Good questions... The PCBs are already produced and ready to ship. They should be here the next week. Propellers are also ordered and should also arrive in one or two weeks. As soon as they are here I'll start assembly. However, I'm on holiday from August 15th to 22nd so if the parcels are delayed due to covid or customs trouble it could happen that I can't make the boards before August 23rd.

I still have 100 boards of the old layout without SD card. Normally, I try to avoid wasting something that is not broken. But if the main application is TAQOZ it probably makes more sense to have all boards with the same features and revision. Do you think anybody would still buy the old ones if I sell them for €20 and the new ones for €25?

I can't imagine to buy an older version if the newer is available. If not there is an application that definitely doesn't need those features. So I would produce the old version only on demand..

Do you mean assembled boards with that price tag ? That would be really something spectacular.

I agree with Erna in that the assembling the v1 on demand is a good idea and I, for one, would consider buying both variants (but you have enough EU stock to satisfy my current needs for the v1 board anyway ).

).

I could certainly go for an original or two, possibly even without the flash. I mostly want to use it as a pc i/o expander, so having to bootload from the host is fine, and a prop-plug is plenty easy to hack out of an ftdi-compatible cable.

If there's any feature it's missing, for me, it's mounting holes, but it's easy enough to tie down with zip ties or scotch dualock tape.

I like the original, especially that I don't need to use a USB connector for power and for most if my uses I don't need a SDcard slot.

I can accommodate shipments to US as I have them in stock. See first post in this thread for payment instructions.

Ummm. I don't see payment instructions in the first post of this thread....

I guess it is in here: https://forums.parallax.com/discussion/172391/kiss-eval-board-ready-to-ship-taking-orders

Sorry, It should have been first post of this thread,

https://forums.parallax.com/discussion/172391/kiss-eval-board-ready-to-ship-taking-orders/p1

Wow, that was fast. Today, the 270 P2 chips have arrived.

The new PCBs and the SD sockets will take at least another week.

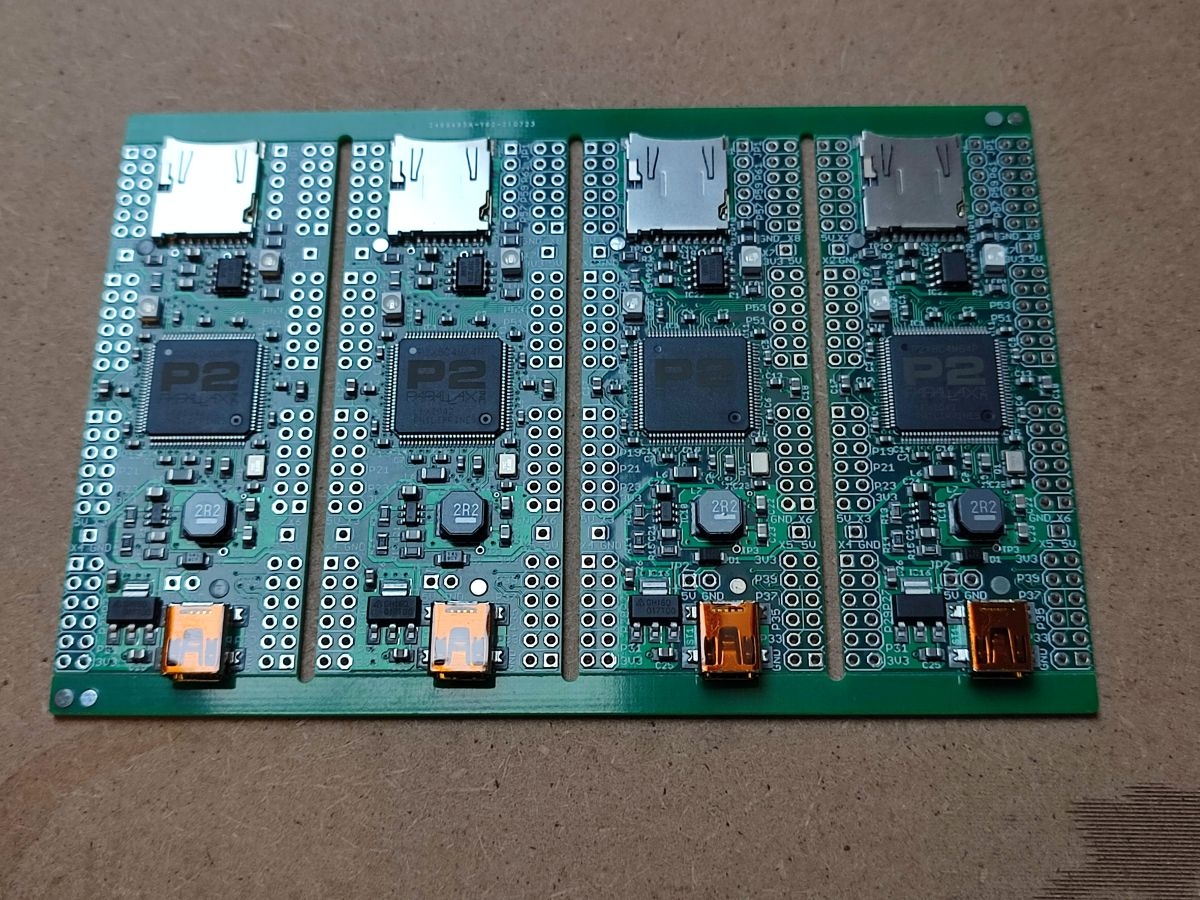

First panel assembled:

I wait with the others until flash ROM and SD card are fully tested. (I've burnt my fingers so I stay away from the fire....)

Looks good @ManAtWork. Guess we may have them coming to North America? Still need to sell old boards.

The old boards are not obsolete. We just have to make them cheaper so that anyone who doesn't need the SD card can buy those. I can't promise a particular price at the moment. When all problems are solved I'll have to add all costs together.

Lets get together to get the old boards sold.

What old boards are you guys talking about ?

There are no old boards. There are boards with slightly different features.

It is not for me to decide but I can see at least two more pricing strategies possible here:

There are more options but I will save them for the next occasion .

.

Just get rid of that old versus new terminology. Old doesn't sell well unless it's really ancient.

Ok, I see. I'm not good at marketing.

The GD25Q64ET ("T" means SO-8 150mil) is still not available. And it's not clear if it would work without additional pulldown resistor. The SD card is working on the new layout (or should I say "extended version").

So here is my decision: I'll keep the AT25SF321 and add pulldowns to all boards. But time is short. I'll leave for holidays, tomorrow. I'll assemble the rest of the boards when I'm back.

BTW, the SD card seems to have priority over the SPI flash chip and even over the serial ProgPlug. So the SD card has to be removed if the latter are to be used. Is this a problem? I don't think so. "keep it simple" means no room for DIP switches, sorry.

Update: If a boot image ("_BOOT_P2.PIX") is present on the SD card it takes priority. If an SD card is inserted without a valid boot image the normal programming with a ProgPlug or booting from SPI flash is possible. I think this is the perfect behaviour for most cases. So a data logger that boots from SPI flash but saves data on an SD card can also be implemented, for example.

+1

Lack of DIP switches is a feature. And a good one.

Allow users to have them on board and you get hundreds of questions on how to set them to get "x" or "y" behaviour. Fortunately, there is no room for them on the board.

IIRC Flash boot comes before SD provided there is a pull-up on P61. If there is not valid code (checksum) in the Flash and P62 contains a pull-up (provided from the SD cards internals) the the SD Rom code initialises the SD card and then searches for the MBR, VOL and _BOOT_P2.BIX and _BOOT_P2.BIY files in that order and if not found (can take up to 1/2s or more depending on the SD card). If not found, the Rom code will try the serial next.

Looking good! :-)

This is somehow inconvenient and not how it was meant to be. However, it is too late for a PCB layout change. I think, for a completely free choice of SD vs. SPI booting it would be indeed neccessary to add a DIP switch. Unfortunatelly, the "card inserted" switch of the SD socket can't be used as it is of the wrong polarity. A NC instead of a NO switch would be required to automatically disable the pulldown resistor. And even then the "SD card for data only" option wouldn't work.