Propeller Proto Board Enclosures from Parallax

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

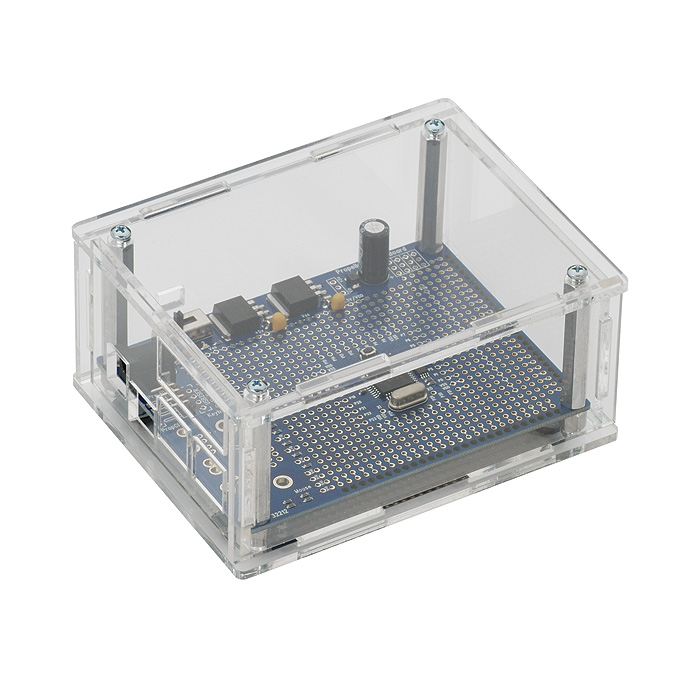

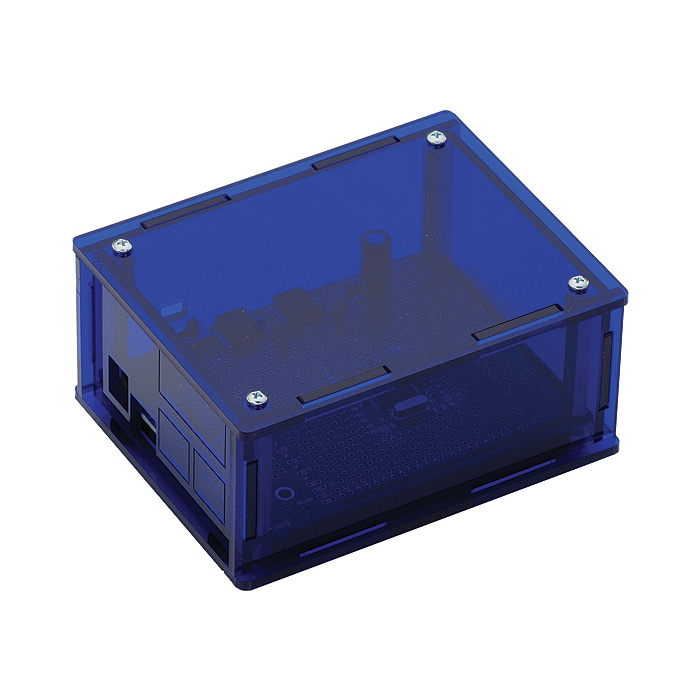

Hey all, we've just made three new products available - Propeller Proto Board enclosures in blue, clear and opaque red for $19.99. These were made on our new Epilog 75W 24x36 Laser Cutter.

Clear http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/enclosure/List/0/SortField/4/ProductID/706/Default.aspx

Red Opaque http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/enclosure/List/0/SortField/4/ProductID/707/Default.aspx

Blue http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/enclosure/List/0/SortField/4/ProductID/708/Default.aspx

The idea? We got it from Chuck George of Mountain King. And we are paying Chuck for his idea so we have his blessing to make these, too. Improvements were made to manufacture the Parallax design, and it fits together really precisely with only the most minimal slop.

The products will be enabled for on-line ordering on Thursday. It looks like the web team is still setting things up, but we certainly have inventory of all three colors.

Of all the tools we recently purchased, the laser cutter gets the most use! No less than six of our staff have installed the print driver and regularly use this tool - it seems to be used more often than any tool in our office! The total absence of CAM software, simplicity of the printer driver, and minimal training required all contribute to making the laser cutter an awesome tool in our office. It's become a real generator of fun and ideas, so much that we sometimes have to tone down the enthusiasm else we'll be selling parts for R/C cars, Christmas ornaments and custom-engraved Leatherman tools.

The only problem with the tool is that it emits some fumes. . .which can be smelled all the way over in the offices. We've got a giant cyclone sucking air from the laser cutter, but we still have a smell problem on "big cut days" in the office. We're now designing an enclosure for the laser cutter to fix this problem. Workmen's comp situations and environmental regulations are significant business issues in California so we've got to address the smells fast and seriously before they become a real problem.

Please visit our web store and buy yourself an enclosure for your Prop Proto Board!

Thank you!

Ken Gracey

Parallax Inc.

Clear http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/enclosure/List/0/SortField/4/ProductID/706/Default.aspx

Red Opaque http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/enclosure/List/0/SortField/4/ProductID/707/Default.aspx

Blue http://www.parallax.com/StoreSearchResults/tabid/768/txtSearch/enclosure/List/0/SortField/4/ProductID/708/Default.aspx

The idea? We got it from Chuck George of Mountain King. And we are paying Chuck for his idea so we have his blessing to make these, too. Improvements were made to manufacture the Parallax design, and it fits together really precisely with only the most minimal slop.

The products will be enabled for on-line ordering on Thursday. It looks like the web team is still setting things up, but we certainly have inventory of all three colors.

Of all the tools we recently purchased, the laser cutter gets the most use! No less than six of our staff have installed the print driver and regularly use this tool - it seems to be used more often than any tool in our office! The total absence of CAM software, simplicity of the printer driver, and minimal training required all contribute to making the laser cutter an awesome tool in our office. It's become a real generator of fun and ideas, so much that we sometimes have to tone down the enthusiasm else we'll be selling parts for R/C cars, Christmas ornaments and custom-engraved Leatherman tools.

The only problem with the tool is that it emits some fumes. . .which can be smelled all the way over in the offices. We've got a giant cyclone sucking air from the laser cutter, but we still have a smell problem on "big cut days" in the office. We're now designing an enclosure for the laser cutter to fix this problem. Workmen's comp situations and environmental regulations are significant business issues in California so we've got to address the smells fast and seriously before they become a real problem.

Please visit our web store and buy yourself an enclosure for your Prop Proto Board!

Thank you!

Ken Gracey

Parallax Inc.

Comments

As an alternative to the "possibly expensive" and "possibly perspex cracking" metal mounting hardware, maybe something like this could also be used:

Richco CRLCBSR-8-01...

http://uk.rs-online.com/web/search/searchBrowseAction.html?method=getProduct&R=3035201

They come in a variety of lengths etc... Push to fit, very fast to use.

.... Oopps... Just noticed, the metal standoffs might be dual purposed to hold the lid on...? In that case, the above pcb holder would only be good for projects that desire a removable lid (might actually be useful in some cases?)

Or, if there is concern with using metal standoffs/screws against the perspex, I guess plastic (polyamide) standoffs with plastic screws could be used instead of those pictured metal ones. Maybe on the laser cutter, matching coloured polyamide standoffs could be machined if the standard white ones are not acceptable ?

Would the sides be strong rnough to handle the torque of a 1/4th inch audio jack? If not, I could build it up with another layer....maybe get some of your scraps.

I wonder if raymans displays will fit in there.

Thanks,

Doug

Bill

@Ken,

Would it be possible to get one (or more) which had cut outs for adding one of your NES heads, RCA plug, and micro SD adapter? I understand that it would require some pre-planning on the Protoboard, but would make a very interesting kit. I'm willing to do the instructions for such a thing.

OBC

If super glue is incompatible, what adhesive is recommendeed?

Thanks,

Doug

Bill

transparent (like the blue one), or opaque (like the red)?

And on the jack question: Yes, no problem on support. The trick with acrylic is to drill a small pilot hole and then ream it out with the larger bit. Go slow with the "push" speed - if you push too hard you can crack it, go slow and be patient, and you'll get a really nice, clean hole.

Please excuse me now, I'm gonna go enjoy some more "aroma therapy" in the laser room...

-Matt

Mike B.

He's right. I have used acetone to build some acriclic parts and something like a hypo needle works great for glueing the parts together. Put the needle in the joint and it just gets sucked into the joint. Works great.

Mike B.

Hey Mike, unfortunately we can't do custom work. Nobody would want to pay for the true costs of dealing with us. Parallax is designed around product manufacturing - we make an initial investment and start to recover our tooling/NRE/design/documentation costs.'

Many companies do custom parts, however. I'm sure there are some in your region - or you can call Pololu and they'll do it over the net.

I probably wouldn't want to design an enclosure for the Propeller Demo Board for the following reasons:

(a) Usage (how many we sell) of the Propeller Demo Board is far less than the Propeller Proto Board - perhaps 1/5th the volume.

(b) Propeller Demo Board is a one-per-customer type of product whereas many customers need several Propeller Proto Boards.

(c) The Propeller Demo Board has a breadboard so it may be less accessible to the user with a lid.

(d) Mountain King makes one that fits the Propeller Demo Board.

Even for something as simple as this enclosure our design, documentation and production startup costs exceed $3-5K to do it professionally and correctly. You can figure out the Bill of Materials costs on your own - at least $5 of parts. With labor and kitting the cost is nearly $10/unit. With an average selling price of about $15 each we have a gross profit of $5/unit. Ammortize that over the higher end of our startup costs and you'll see that we need to sell a thousand units to break even.

Change any of the parameters for lower volume and the equation looks worse.

I realize this is much more information than you wanted to know. I am comfortable providing it because it helps you understand why we couldn't do what you asked us to do. My Parallax life is mostly business - while you get to have many fascinating discussions about your projects I toil in spreadsheets and business software. However, without a doubt my most personally rewarding work occurs when I get to use our own products in a project of my choice.

Ken Gracey

Parallax Inc.

That's a currency to us and you are most welcome.

Ken Gracey

YOU WHAT!!???

What the heck is happening with everyone going all ethical and everything! Next thing you know, once somebody works for you for 10 years you'll give 'em a month off.

It's reasons like this that folks love working with Parallax and the Parallax Community!

John R.

But that will also mean I will have to buy a proto board to go inside

Anyway we can fit a Propeller Platform USB from Gadget Gangster inside? It that the same size?

JM

I've had parts cut by Pololu. I'm happy with the results, the parts arrived quickly, and Pololu was easy to work with. In fact, I just submitted another job for a quote a few hours ago. I got the quote back already and there was some confusion because of the drawings I sent, not something on their side. I'm waiting for the updated quote now.

An update: I just received a final quote for my parts and have approved the order. It's for 10 identical plates, each about 2.5 x 3.8 inches but not quite rectangular and with 24 round holes of varying sizes. They are made from 3mm smoked gray acrylic. The total (without shipping) for a 3 day turnaround (at their end, before shipping) was under $40 (or about $4 per board). Not too bad for custom parts.

The large GG Prop Platform boards are 2.5 x 3.8 inches. The proto boards are 3 x 4 inches. The GG boards should fit inside with room to spare.

But the metal parts are not going to land anymore at the right place

So I think I will really have to understant how to use a protoboard. So far, it's a mystery for me

Still more to learn

Chuck, over at Mountain King has done some very nice custom work for me. In fact, I just received another batch of his craftmanship... they're perfect.

Bill

One of them will, I guess

Matt,

Opaque!!! Sometimes, I don't want people to see the gizzards of my beast!!!

Bill

I think opaque black looks really nice - until it gets fingerprints/smudges on it. I have stuff I've made using black for front panels (with all sorts of switches, jacks, etc.). It never looks clean.

Sure - I'll have Matt post the DXF/DWG formats on the product pages in case you want to make your own or work from our files.

Ken Gracey

I second the vote to have an enclosure kit that would accommodate those parts (should be a matter of a few cutouts on one or more panels).

Wow. Impressed. I found the question courageous, and the response very open

Thanks for sharing those documents!

Might be usefull if we want to replace a broken peace, or if we want to customize some parts.

JM

I don't see any reason to put you through an exercise with your calipers. Last time I checked we didn't own the concept of making acrylic enclosures, either. The value we add in this case is actually manufacturing and supplying the product. Although we're proud of our design and Matt put a significant effort into the drawing and prototype process to get the most from our laser cutter there are no trade secrets.

So, if it helps you it helps us! Creative Commons 3.0 Attribution is applied to the drawings.

Ken Gracey

Parallax Inc.

Per (courageous!) Ken's request, the .dxf drawing should be up shortly. In the interest of expediency, the dimensions are not shown because this .dxf is derived from our actual cut file (which has no visible dimension information).

You can, however, *pick/measure* the dimensions with a .dxf viewer.

I'll post the link to the file when it's up.

-Matt

What that guy said, but now with links:

http://www.parallax.com/Portals/0/Downloads/docs/prod/prop/PropellerProtoBoardEnclosureDXF.zip

Also, they're up on the product pages as well.

Enjoy!