Right-angle drive for the Parallax Servo360

Phil Pilgrim (PhiPi)

Posts: 23,514

Phil Pilgrim (PhiPi)

Posts: 23,514

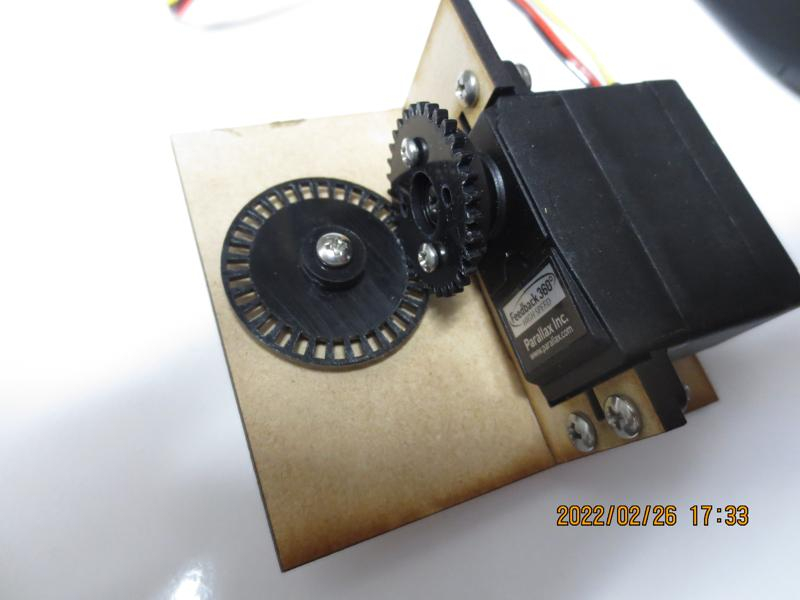

I'm working on an instrument that involves a large dial with a pointer. I cannibalized a wall clock for its bezel, but the bezel has limited depth in which to mount components. I wanted to use the Servo360, due to its accuracy and repeatability, but it's too tall to fit in the bezel and drive the pointer directly. What I needed was a right-angle drive for it to lower its profile. I considered bevel gears, but didn't want to spend the time waiting for them to build on my 3D printer. So I came up with a 2D design that I could make with my laser cutter.

For the moving parts, I'm using 1/16" black acetal copolymer (similar to Delrin). For the supports, I'm using 1/8" MDF. Here's a photo of the completed prototype assembly:

The drive gear is just a normal 32-tooth involute gear with a 1" pitch diameter. It's completely captured by the slotted disk that drives the pointer through a bulkhead. That way it can't become uncoupled and slip. The shaft is a 3/16" x 7/16" x 4-40 hex threaded standoff. The hexagonal shape prevents the pointer from spinning relative to the disk. The thru-hull bearing is a round acetal disk with a hexagonal hole that rides in a hexagonal acetal disk with a round hole. The hexagonal disk is mounted in a hexagonal hole in the MDF.

Thankfully, the parts mesh smoothly with no noticeable backlash. Soon I hope to post here about the instrument I'm building.

-Phil

Comments

That's pretty cool Phil !

Beautimous! I can see that meshing smoothly. Nyce use of laser cutter!

Phil,

Wouldn't one of those little 28BYJ48 Stepper Motors do the job?

The FLiP module board I'm using this with has headers for a servo and no stepper driver circuitry.

The 28BYJ48 has 64 steps per revolution; the Servo360, 1000 "steps" per revolution. I could microstep the stepper to get more resolution and add a peg at the low end of the dial to zero it on power-up. The Servo360, by comparison, always knows where it's "pointing" without an external physical reference.

Another advantage of the Servo360 is that it draws very little current when it's not moving. A micro-stepped stepper is always drawing holding current to keep it located between macro steps. (I did try a much smaller servo but, oddly, it drew more current than the FLiP module's USB 5V could handle. Plus, it had a limited range of 180 degrees or less. I need 260 degrees of rotation.)

The stepper does have a price advantage, certainly, which is something to consider if I build my devices to sell.

-Phil

Phil,

I wasn't thinking so much of price but size.

The 28BYJ48 is small enough that you could couple it directly without all the extra mechanics.

Erco may know of some low priced gizmos that you would be worthy for production.