NEVER say NEVER --> DIY PCB's

I read somewhere that it was nearly impoosible to get good results with Gootee's Toner Transfer method (http://www.fullnet.com/~tomg/gooteepc.htm)·for fabricating DIY pc boards.· Well, I just wanted to see if my 8 year old Lexmark Laser Printer and my PCB software·(Sprint Layout) http://www.abacom-online.de/uk/html/sprint-layout.html·could do it.

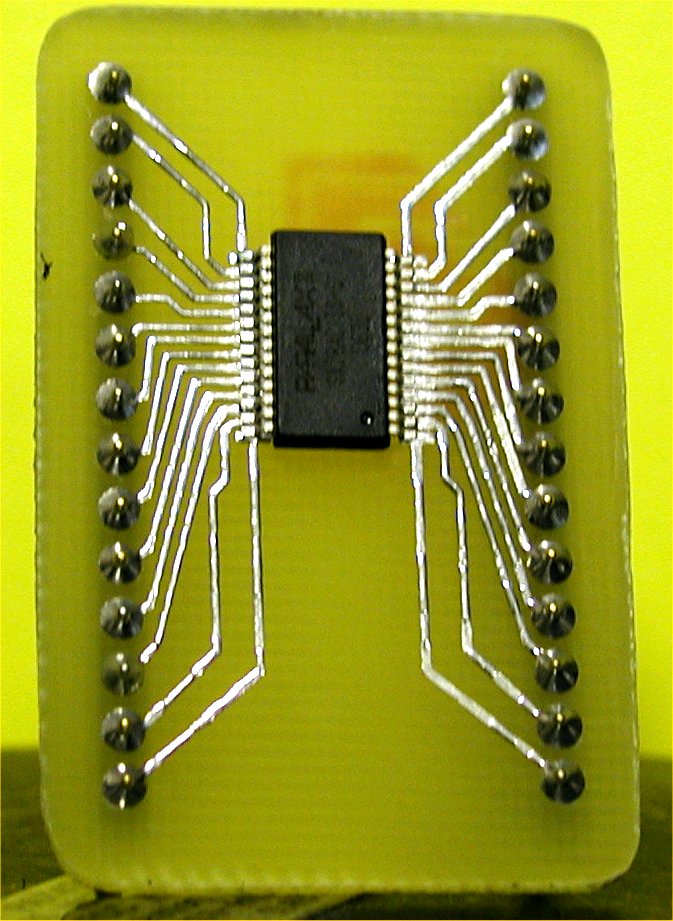

So what was I·doing?··· --> SSOP .65mm·pitch·SX28

How did I do?

Take a look.· Note: Due to shine and close up focus, some traces look like they touch... but that's just an optical illusion.· It works just fine.

Total Expense?·· About a $1.50 in materials.

BTW: I have much better results using Muriatic Acid (Cement etcher from Home Depot)· and Hydrogen peroxide (Pharmacy).· It etches much faster than Ferric chloride and it's not opaque.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

So what was I·doing?··· --> SSOP .65mm·pitch·SX28

How did I do?

Take a look.· Note: Due to shine and close up focus, some traces look like they touch... but that's just an optical illusion.· It works just fine.

Total Expense?·· About a $1.50 in materials.

BTW: I have much better results using Muriatic Acid (Cement etcher from Home Depot)· and Hydrogen peroxide (Pharmacy).· It etches much faster than Ferric chloride and it's not opaque.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

Comments

I am curious if you can provide some more info on the muriatic acid and H²O². do you mix the two together, or one after the other? some insite. before hitting Google would be preferred.

thanks

oops been a while since chemistry, Hydrogen per oxide isn't HO

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

A complex design is the sign of an inferior designer. - Jamie Hyneman, Myth Buster

Post Edited (Dgswaner) : 8/13/2007 1:53:50 PM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

D FAUST: I use a clean, fine point tip on my ancient (Circa 1977) Weller WTCP200 and magic flux ---> Qualitek - Water Soluble Flux - HIGHLY NASTY... finger pump spray liquid... must wash off RIGHT after soldering. I'm not sure I'd have done as well without it. I just tacked a quick blob on each column of surface mount pads ans used the layer of liquid flux to thin coat solder from the pads out to the edges. The flux made it easy.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

-Phil

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Making your own PCBs does take some time, but it is very rewarding. Almost anyone can do it, heck I was 16 at the time and was able to do it with little previous experience.

Harrison

Post Edited (Harrison.) : 8/13/2007 12:21:11 AM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

Sparkfun Tutorials

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Rick

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

Post Edited (pwillard) : 8/13/2007 4:55:40 AM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

I have used 3% before, it works very well. When you're done with the acid/H2O2 mixture, you can save it for a couple weeks. However, be sure that you put it in a light opaque container. Once I put 1.5 liters of the etch solution in a clear soda bottle with the cap on it. I came back in two weeks to find that several parts of my storage room had been damaged by shrapnel from an exploding soda bottle and that the shelf had been damaged from the etch solution pouring out of the bottle after it exploded.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

My Blog: Prog | Electro | Mech

I would love to change the world, but they won't give me the source code

People say that if you play Microsoft CD's backwards, you hear satanic things, but that's nothing, because if you play them forwards, they install Windows.

I spent a minute looking at my own code by accident. I was thinking "What the heck is this guy doing?"

Lots of great info, techniques and quite an active community!

Steve

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

I'm new to this, and am thinking of trying to make my own pcboard. What type of material do you use with your printer to transfer the traces to the bare board that are resistent to the etching solution?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

David

There are 10 types of people in this world,...

Those that understand binary numbers, and those that don't!!!

This comes from the first linked site.

FYI·injet printers don't work, for reasons why, see pwillard's first link.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

I agree with the assessment. I use that paper now too.· The paper, once soaked for a few minutes in water, rubs·off from the backside by just using your thumb and some pressure.· You do not need to rub all of the paper off where·the toner is, just where·the toner·*isn't* since a little may stick to the toner. You are protecting the copper with the toner so paper on the backside of the toner has no impact.· When you can see all the copper that is not covered·by toner shining without paper over it, you are done and ready to etch.· I use light brushing with an old toothbrush to get the last stubborn bits.· The whole process of removing the paper from the backside just takes a few minutes.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

Twisted Pair....

Thanks for the info.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

David

There are 10 types of people in this world,...

Those that understand binary numbers, and those that don't!!!

Watered Down Hydrochloric acid is known as Muriatic Acid.

FYI: The stuff from Radio Shack --Ferric Chloride Solution-- (FECL) is in my opinion the waste product from a Steel Mill pickling process. What is that? It's a checmical process to prepare steel for fabrication after it's been in storage for a few days. They use Hyrdrochloric Acid baths to remove "RUST" from the sheet steel. The RUST becomes a solution with the HCL that eventually becomes FECL. You see, a side effect of Muriatic Acid solution, apart from etching concrete (being watered down HCL) is that it's really good at removing rust.

I'm assuming that Radio Shack buys this Steel Mill Pickling WASTE product and ships it to stores as FECL as a less active acid for copper etching.

See why I think that the two chemicals are not so far removed from each other?

Muriatic Acid is cheaper... and See Through... Much better for etching. It is, however, much stronger... and etches in 1/4 to 1/2 the time of FECL.

This conclusion is merely a product of my own active imagination and some online research.

pw

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

Post Edited (pwillard) : 8/20/2007 10:16:21 PM GMT

That's very interesting. I always thought that the ferric Chloride was a new mix made for consumers and etc. If we the consumers only knew how things were made we could make it ourselves and not have to buy it from the people that do know....I will try the solution. This solution will cut down on my etch times and as you mentioned, the cost....What could be better....By the way, what role does the Hydrogen peroxide play in the mix ? Agitation ?

Thanks....

Twisted Pair....

But from what I understand, as long as you have an acid and an oxidizer the·mixture will eat the copper metal. The peroxide is the oxidizer and you just add a bit more peroxide·if the reaction·seems slow because if you get it wrong, it will not eat the copper and may even attack the toner.

In my case, I get best results with 2 parts oxidizer (peroxide) to 1 part acid.· If the mixture is not quite right, it will produce no bubbles as all.· When it's right, it will produce a few bubbles... it may bubble quite a bit when you wipe with a paper towel.· That's all I do, by the way... wipe the surface with a paper towel a few times.· It's reacting to the paper towel, from what I can tell.

Always wear protection.· I wear rubber gloves, and everything else is plastic.· I use a small diameter (1") short plastic tube with a wad pf paper towel in the end as a wiper.· I only ever wipe a board about 3-4 times during the etching process.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

I will give it a try....I noticed in the photo of your PCB, that the copper traces had a solder coating on them to allow for easier soldering of components to the board. What do you use to accomplish that ?

Twisted Pair....

As I said in the thread, I used a good flux and let the iron flow coat the small amount of solder I added to the IC chip pads.· I know people have mentioned blobbing solder on and then using solder wick to clean up, but I just haven't had to do that, nor do I want to.

---

There was a company (now sadly out of the business) called KEPRO that made a great·product called "room temperature immersion tin plating" solution.· It came pre-mixed and ready to use.· I much preferred that method of plating the the copper but if done carefully, solder can work too.

I've tried the heat and·mix tinning·crystals but·either·I must have done it wrong or it's just that nasty to use.· My results were bad.

I really dislike bare copper on DIY boards but I haven't figured out how to do a·solder mask·with conformal coating.

FYI: My very first job out of high school was a summer job operating a wave flow solder machine.· That was as closeset I ever got to an EE job but have remained a die hard hobbyist regardless of the current trends.· There is something about the beauty of flowing molten solder that has stuck with me to this day.· I'm dating myself by·saying that FREON was·the preferred board cleaner... can you figure out about when that was?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

Post Edited (pwillard) : 8/21/2007 2:27:00 AM GMT

You did a nice job laying on the solder to the traces. I have seen dry powder tin plate mixes on the market but haven't tried them or done any research on them. I'm not sure if the tin plating would be worth the extra time and cost. I use a silicon conformal coating called Final-L-Coat on my PCB's. It works fine but the bare copper is still visible as this coating is clear. I remember the company Kepro. To bad there gone now. I have ordered a few things from them in the past. I guess all good things must come to an end. In regard to the Freon dating, I think that I read an article in 1969 that talked about how the Saturn V rocket (the moon shot), components were made and in particular, how the Nasa designed computers were built. This article mentioned the PCB's and the freon that was used in the cleaning process. Now, who's dating who ?

Thanks PW....

Twisted Pair....

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Noli nothis permittere te terere

It works great. Just put the board in it and it almost instantly turns silver (color). No mixing or anything, it's ready to use.

It is very strong though. ALWAYS WEAR GOGGLES AND GLOVES.

Bean.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

I know what I know, don't confuse me with the facts...

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

www.hittconsulting.com

·