Kicad P2 Stuff

R Baggett

Posts: 234

R Baggett

Posts: 234

I needed a multipart model in order to design P2 into some inspection fixtures.

Here is the model. I hope it is found to be useful, and I know it will at least get a thorough review. Feel free to comment on any errors or improvements and I will fix them.

If you fix some errors, or improve it, please post a copy here!

Thanks everyone.

Here is an updated version, It fixes the unfinished part Q, and I added a PDF of a drawing containing the component for easy viewing.

OK, Fixed the labels on part A

OK, again fixed the labels on part L

Here is the model. I hope it is found to be useful, and I know it will at least get a thorough review. Feel free to comment on any errors or improvements and I will fix them.

If you fix some errors, or improve it, please post a copy here!

Thanks everyone.

Here is an updated version, It fixes the unfinished part Q, and I added a PDF of a drawing containing the component for easy viewing.

OK, Fixed the labels on part A

OK, again fixed the labels on part L

pdf

37K

Comments

You should try KiCAD. You'll never want to go back once you get used to it! It's really gotten very good since CERN started putting lots of work into it.

I have a copy of KiCAD but I use DipTrace because that is what parallax uses and it makes it easier to view their new boards.

I agree KiCAD is a great program!

Hope you dont't mind me posting to your thread. I thought it may be beneficial to try and keep the KiCad P2 stuff in one thread.

What footprint did you use? (I didn't load the library)

Yesterday was my first attempt with KiCad. I've previously used Protel 95 & 99SE. KiCad has improved dramatically since I took a brief look years ago.

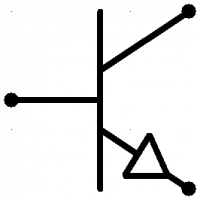

So, here is my first attempt at a P2 symbol and footprint. Beware, it's untested!

Note 1: I based the footprint on that used for the TQFP100 using a 5x5 thermal relief pad, with corrections to use a 9.6x9.6mm pad. The vias were/are currently specified as 0.2mm (~0.008") but I think I will need to change them to 0.3mm (~0.012") for manufacture and I may need to adjust the paste mask accordingly.

Note 2: The footprint uses a slightly modified pad size (1.475x0.3mm) from the recommended OnSemi (in P2 specs) pad size of 1.49x0.28mm. This was the

Note 3: Notice the paste mask are rounded style pads of 0.890668mm. This is what was used in the original TQFP footprint I copied. It is a recommended practice to use a series of paste "blobs" rather than a single large paste "blob" but I'm not certain of the recommended sizes without further research.

Note 4: I'm not totally happy about the thremal ground pad 101 reference in the symbol. Maybe I need to see if I can get that to come out from the block on a 45 degree angle at one corner. Just not sure how to do it yet.

pad size used in the KiCad standard library and should work just fine.

The symbol now has pin 101 (thermal pad) in the top left corner at 45 degrees to make it a little more obvious that it's not a normal pin.

The footprint now uses the thermal vias as pad 0.55mm and hole 0.3mm.

If anyone uses KiCad, can you tell me how to do a global (whole footprint) edit on a footprint to change the hole sizes and pad sizes?

I had to edit the source file with Notepad++ to do this as I couldn't find any alternative. This was simple enough tho.

Thanks! I plan to import your footprint. As far as blob size, I suspect the vias will steal a lot of the solder, so maybe a little extra is indicated? (My experience in this facet is limited.)

I have found Notepad++ often is faster than finding the 'correct' way to modify some things in Kicad.

I’ll check later today if there’s a penalty for using 0.2mm (~0.008”) vias - expect pcb mfr to be more expensive.

KiCad can import PCAD-ASCII files, which Peter can export from Protel 99, so there is also a P2 footprint available via that pathway.

That works quite well, it's a while since I tried it, but ISTR P2D2 imported fine, with some copper pour ordering/priority edits needed.

KiCad is also finishing a native Altium importer.

Someone mentioned Diptrace can import/export already ?

I see they claim this for pcb-layout

"Import / Export

Exchange layouts and libraries with DXF, Eagle, Altium, P-CAD, PADS, KiCAD and OrCAD. Import netlists from Accel, Allegro, Mentor, PADS, P-CAD, Protel, and Tango formats."

Has anyone tried any of those paths ?

Options B good....

I don't know the answer to you question but you can set those type's of option's with the design rules.

These holes were already defined in a footprint that I copied, and then copied and pasted more pads for a new part so it wasn’t the default that required changing. There doesn’t seem to be a way to change all in a footprint that I can find.

However, since the footprint file is an easy text format it was simple enough to do a global change in Notepad++. Much better than the hidden format of so many software packages. In the floppy days size mattered but no so any more.

Having fun watching KiCad YouTube tutorials. John’s Basement has a great, if somewhat low level, series.

Thanks for the heads up on John’s Basement YouTube channel- Really helpful.

Dave

I'm trying to get a bitmap into a footprint for including on a pcb overlay (done). Here is my Clusos icon redrawn from a png file found on the internet

A schematic is there to aid in describing the function of the circuit - it's not meant to be a graphical means for netlist entry, even though most people these days seem to use it this way. That's the downside of the schematics never reaching the customers anymore - eventually what happens is that nobody in the company can quite read it either

In my practice, after the layout is complete, generic symbols like FPGAs and P1/P2 are redone in a form that has the pins grouped to best fit with the flow of the schematic, the symbol is broken up into as many constituent parts as needed to best convey the information graphically, and all pins get application-specific names in addition to generic ones, i.e. `CLK_PP/P40` vs just `P40`.

In other words: the generic symbol should at the very least have two parts: power and generic pins, and then the part with the generic pins should have pins on at most two sides of the rectangle, i.e. left and right, since that is easier to deal with in terms of label-slinging while the layout is underway. While the layout is being done, having the flexibility of just moving signal labels around can't be beat. But once the layout is stable, it's time to actually make the schematic human-readable, and not merely machine-readable, and such generic symbols give the human signaling that directly opposes this IMHO noble goal. That's my 2c.

However the other thing is that I like to draw symbols for clarity but I also position the value into the component if possible. Those old style zigzag resistors are a waste of space and the same too with caps. This was all fine back in the tube/valve/transistor days when there were very few components in a circuit, but that was another age.

IMHO it's a dog's breakfast! You cannot easily work out what is connected to what.

Very clear schematic! The techs would burn me at at the stake if I changed the symbols for resistor and caps, but I really like that compactness. May adopt something like that for personal projects!

If I am cramped for space I do move the part IDs inside the square, but If it is too cramped I risk the whole stake thing again... My average tester is 15 or so sheets 11X17 minimum.

What is the significance of the color?

May I shamelessly rip off your SD power switch?

+1

That schematic reminds me of one from the manual of instruments I installed and serviced back in the mid to late 70's. Between the schematic, the netlist, and a clear description of the operation one could troubleshoot and make repairs with no training on the instrument, only basic electronics knowledge. Best manual and schematic I had seen until now. Really like this idea, and will use it on a project I am about to start.

How did you get the 101 in the corner at a 45 degree angle?

I want to make this

I have the png file for the top layer but I just cannot get Freecad to merge the 3d TQFP100 with the layer even tho I have it on the surface correctly. ie I cannot combine the surface with the object no matter how I try this - and the freecad forum was no help. Perhaps there's another 3d package?