Acrylic enclosures for P2 EVAL - Available now

W9GFO

Posts: 4,010

W9GFO

Posts: 4,010

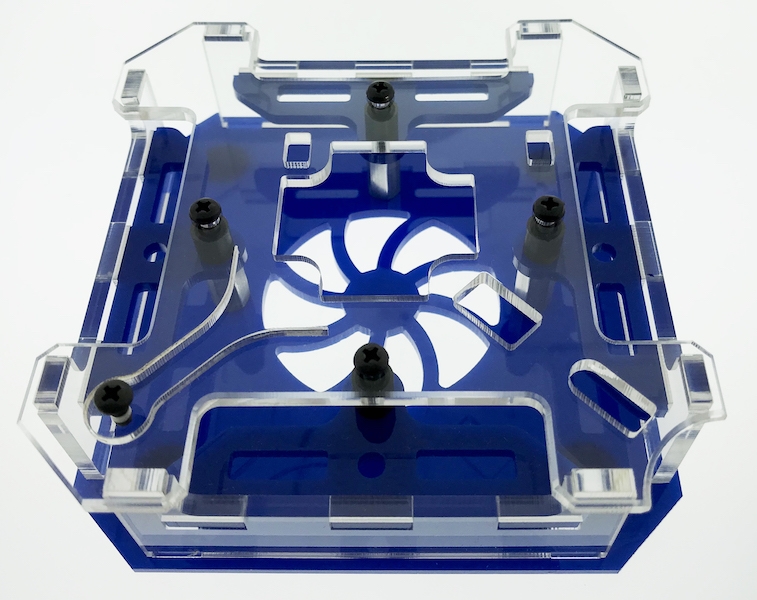

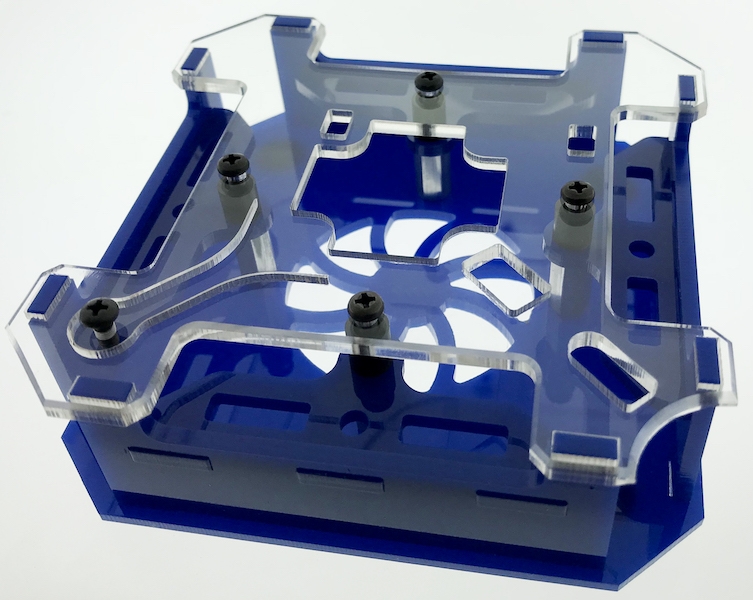

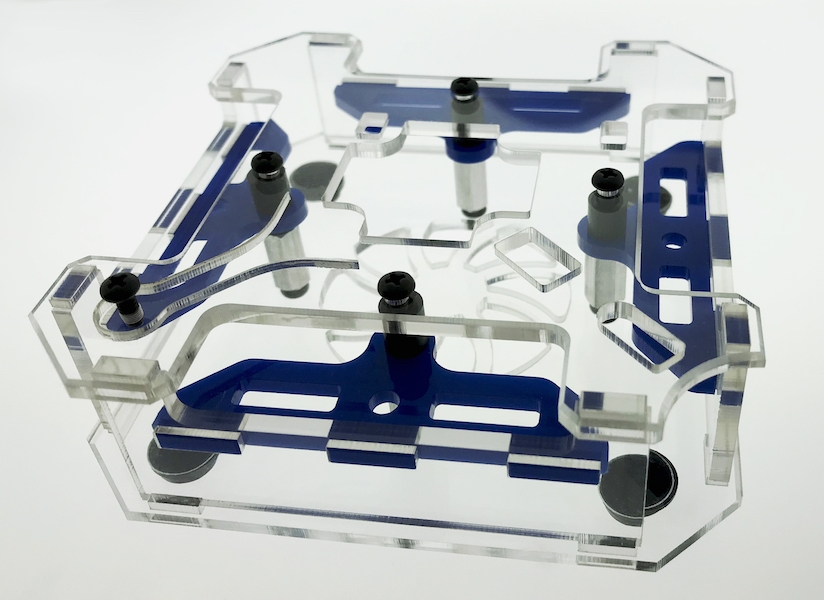

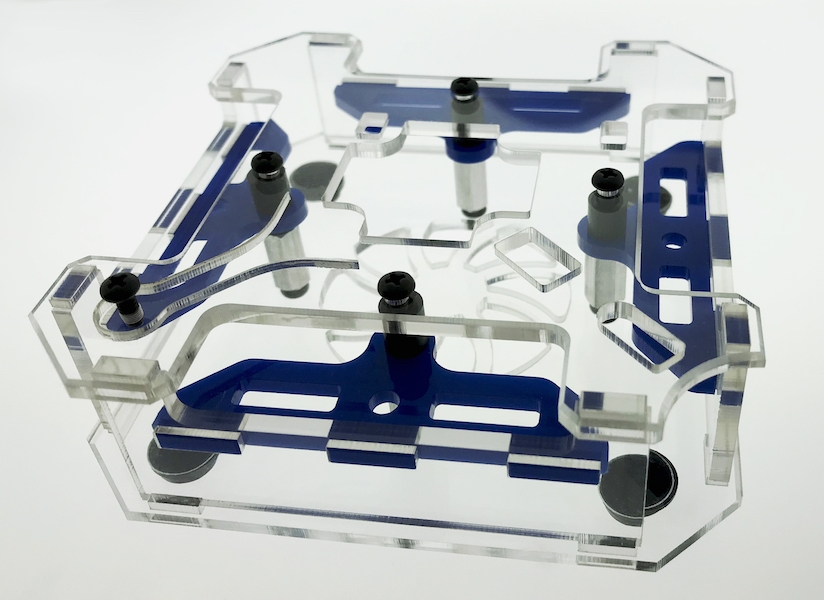

The P2EVAL Board Enclosures are now available to order.

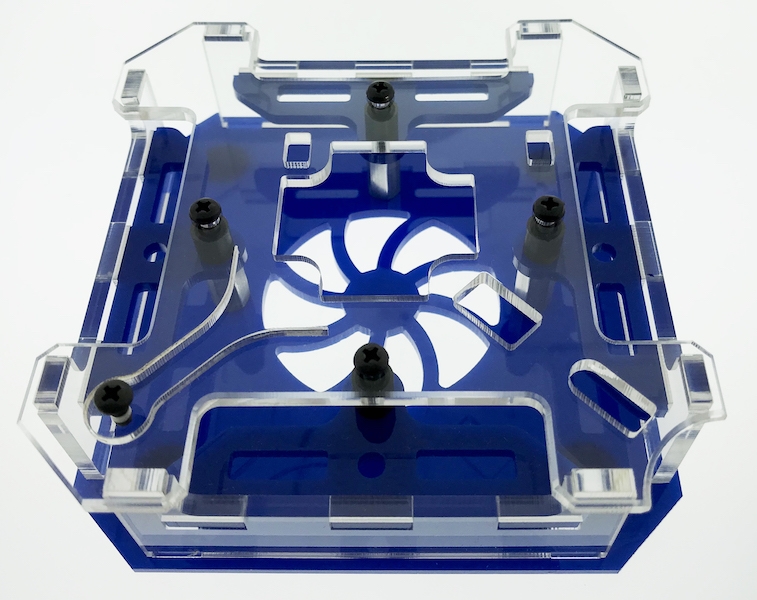

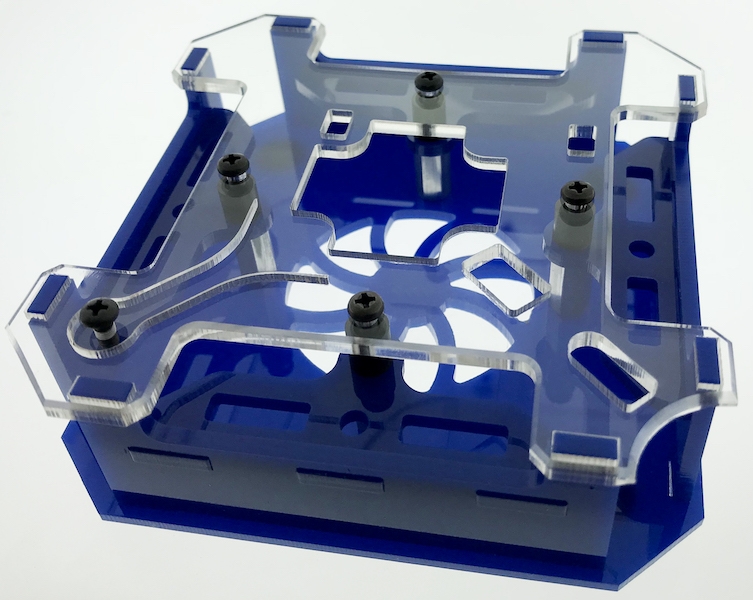

The standard enclosure is 100mm x 100 mm x 35mm high. The Overclocker's version is 50mm high and includes a 12V fan. Both versions will include the hardware to assemble and rubber feet. P2EVAL board is not included.

You can choose the colors of the sides and bottom for the acrylic enclosures. Choices are clear, blue, and orange.

P2EVAL Board Enclosure

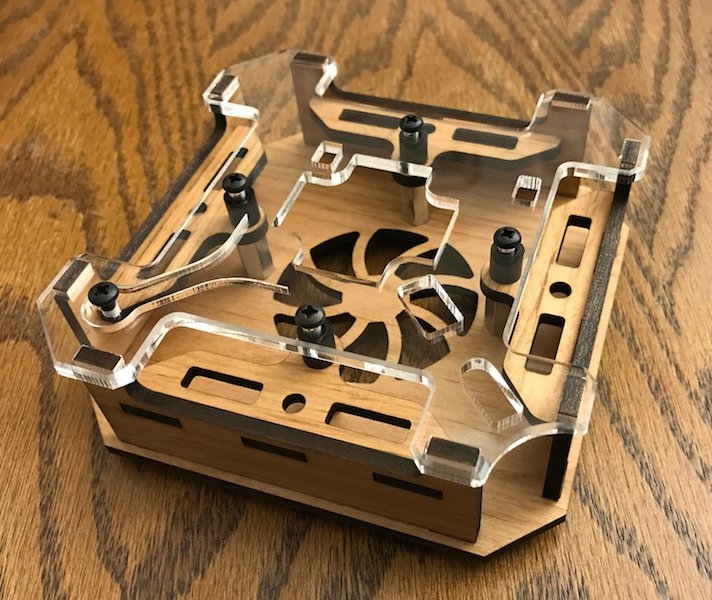

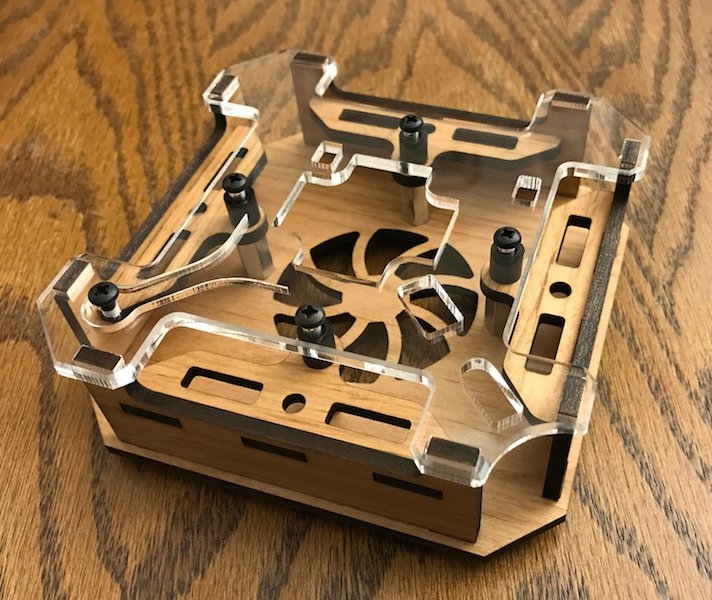

P2 EVAL Board Enclosure - Red Alder

P2EVAL Board Enclosure w/Fan - Overclocker's version

*note, anyone ordering the Overclocker's Enclosure that do not want a fan, just leave a note and you'll be refunded $6. I'll also include a spacer to take place of the fan so it can be assembled properly.

*note 2: Exploded views/assy instructions attached.

The standard enclosure is 100mm x 100 mm x 35mm high. The Overclocker's version is 50mm high and includes a 12V fan. Both versions will include the hardware to assemble and rubber feet. P2EVAL board is not included.

You can choose the colors of the sides and bottom for the acrylic enclosures. Choices are clear, blue, and orange.

P2EVAL Board Enclosure

P2 EVAL Board Enclosure - Red Alder

P2EVAL Board Enclosure w/Fan - Overclocker's version

*note, anyone ordering the Overclocker's Enclosure that do not want a fan, just leave a note and you'll be refunded $6. I'll also include a spacer to take place of the fan so it can be assembled properly.

*note 2: Exploded views/assy instructions attached.

Comments

For the fanless one, I'd do with a much thinner variant.

Roy, and anyone else with their own laser that has been active in the P2 development is welcome to my files, just PM me.

Is the secondary operation still done with the laser, or is it s CNC or something else?

I was going to make mine out of hardwood, except for the top which would be clear acrylic.

It is done with a router table and a 45 degree bit.

I have some red alder that looks really nice. I might see how that looks on the sides and bottom.

NRE My estimate is you'll have 12 hours of NRE into this before you cut the first production model. Let's just call it $1200 that needs to be amortized over some units (or time).

BOM costs for the acrylic and any fasteners is probably about $6.

Laser cutter runtime is perhaps five minutes, let's say $5 per unit since machine time must be accounted for. Laser cutting shops charge $60/hr for machine time.

Kitting and shipping will cost you another $2 in supplies and time, even if one of your boys does the job in exchange for room and board - allowing you to exclude labor for this step.

We won't count your labor for loading and harvesting parts from the laser cutter since you enjoy this process and want to contribute something for free.

$6 BOM costs

$5 machine runtime

$2 kitting and bag for ship

=================

$13/unit total costs + NRE

We still have to account for recovering the NRE. You're going to sell 60 sets quite quickly to half of the P2 Eval Board consumers (pretty aggressive estimate but works well with the NRE). $1200/60 units = $20 NRE per unit.

Let's just assume that your NRE is your profit, so you're really selling your design time.

$13+$20 and you're somewhere around $33/unit costs with design time recovery and a 60-unit lifespan.

Since you can't sell these for $40, just sell them for $29 and enjoy the project. After all, that's your intent in doing this anyway. Assuming we don't change the layout of the P2 EB in a future revision and you sell hundreds it will become financially productive too!

$29 is the price I suggest

Ken Gracey

I'm still getting a grip on how you're making these things.

Ken Gracey

Ken Gracey

That's a pretty good assessment of the costs involved, it's like you've done it before...

The BOM cost is going to be more than $6, mostly because of the fan. The hardware is $2.00 (half of that in the four threaded standoffs) and I am not sure how many sets I can get out of a sheet of acrylic yet. Last time I bought 1/8" clear cast acrylic it was ~$55 a sheet, but that was from a friend/customer that purchased in volume. Not sure what it will cost me now and I do not have enough on hand - unless you like blue and translucent orange.

I'll send you five, don't want you to pay though.

Cheapest available is about $5, cheapest with ball bearings is about $9.

Which voltage?

A 12V fan running on 5V is super quiet and should be more than adequate for all but the hard core overclocker. Especially considering that a fan shouldn't even be needed for most use cases.

A 5V fan will move more air, but you'll hear it.

Most people won't need it.

And I would do the 12v running off of 5v.

Also, even if I get the files from you (I'll send a PM later), I'll still buy one full kit from you (whatever that ends up being).

If I substituted spacers, the price difference is only about $4.

If I offered a thinner enclosure with room for a fan, it would probably be about $7 or so cheaper.

The question is then; is there enough interest in a thinner no-fan version to justify spending the time to design one or should the enclosure size remain the same and just make the fan optional? At least then you could add a fan later if you changed your mind.

Your design seems to be so versatile that, even without the inside mounted fan, it could be left at the table top, standing by one of its sides (sure, the logos are not meant to be upside down viewed).

For the ones don't intending to constantly try any overclocking, a good heat sink can be bonded to the solder side of the board, thus it makes sense having the extra height unit, since there will be plenty of space for the heat sink and also a good convection air flow.

In my POV, at the 'vertical' position it ressembles one of the long gone, 'classic', alarm clocks from the 70'.

Just a good piezo speaker, and it could tell you when "Iiiiiit's P2 Time!"

Ken Gracey

If I had to guess, only a small number of people are going to want to run the significant overclocking that requires a fan. So you could probably plan on like 90% fanless, at least.

I will probably only do the "tamer" overclocking that Chip has been doing without any fan, so I'd go with a fanless one. Especially since this eval board will dissipate the heat away from the chip much better.

The monstrous fan, massive copper, heat sinks, all send the wrong message to prospective customers.

Preferably fanless, but either is fine with me.

And would prefer the version with ability to mount a fan and/or heatsink.

Enjoy!

Mike