Output current of gate driver

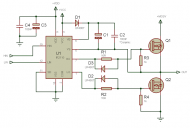

I am trying 3-phase inverter circuit.

I am using IR2110 to switch high and low side MOSFETs. Each MOSFET's gate is connected to the high/low side pins of driver IC. When I apply the PWM input to the gate driver, the MOSFET switches and the circuit works fine. I connected to the load (motor), the motor runs OK.

When I try to check the gate current of the MOSFET (that is, from driver IC output pin to the MOSFET's gate), I notice that zero amps is flowing to the gate. But how?

I am biasing the gate driver IC with 12 volts and I used a 30 ohm resistor in the gate terminal,

I = 12V/30 = 400mA

But when I measure the current it shows "0 amp". I also changed the value from 30 ohms to 10 ohms. But no change, so I think I am wrong somewhere.

Please correct me.

I am using IR2110 to switch high and low side MOSFETs. Each MOSFET's gate is connected to the high/low side pins of driver IC. When I apply the PWM input to the gate driver, the MOSFET switches and the circuit works fine. I connected to the load (motor), the motor runs OK.

When I try to check the gate current of the MOSFET (that is, from driver IC output pin to the MOSFET's gate), I notice that zero amps is flowing to the gate. But how?

I am biasing the gate driver IC with 12 volts and I used a 30 ohm resistor in the gate terminal,

I = 12V/30 = 400mA

But when I measure the current it shows "0 amp". I also changed the value from 30 ohms to 10 ohms. But no change, so I think I am wrong somewhere.

Please correct me.

Comments

This reminds me of the time a qualified EE thought he found a problem. He said "it must be this NPN transistor, there's only 0.6V on the base"

Those gate drives are pulled down with 1K resistors (R3 and R4) so we can expect 12ma of DC current there.

Sounds like your circuit is working fine.

Using a current probe and a high speed oscilloscope ?

Average DC current into a Cap load is Zero, but peaks or RMS current will be > 0.

But that helps with charging and discharing the mosfets capacitive (pF) gate charge very fast

so the mosfet's transition in the resistive region goes over very fast.

When turning on/off something like a light/solenoid every other seconds, it does not really matter.

But a smps powersupply that runs at 1MHz, it does, and also mosfets with low gate charge as the charging and discharging is wasted energy.

Boot strapping the floating highside does rely on a minimum switching freq, as the mosfets gate charge does dissipates.

Unlike a dedicated chargepump, boot-strapping needs its capacitor to go from +- to ++ at a minimum external freq to be recharged faster than the mosfets gate field leakage.

I am trying to build a 1KW bldc inverter circuit.

I used atmel328p processor, gate driver and 12 mosfets. The mosfets swiches good, but when i connected to 1kW motor (at 20v and 10amp supply) the mosfet gets heated up above 60C. The circuit work fine for low watts motors but not for high power motor(1KW).

I attached the schematic below, correct me friends.

mosfet=irf3205

Mosfet=irf3205, gate driver=ir2110 & switchign freq= 10Khz. I am controlling the speed by changing the duty cycle.

The voltage from the diode is insufficient to turn on the high side MOSFET, it simply charges the cap so that when the cap switches it now puts it's voltage in series with the output which if at full voltage would effectively be twice the voltage. It takes a bit of pumping via switching to get there hence the term "charge-pump".

BTW - a scope is indispensable for anyone designing and testing circuits. Even a pocket scope or a USB scope is affordable.

Then you disconnected the battery. The capacitor will store the charge for some time. So if you were to measure the voltage across it's terminals you would see about 9 volts.

Now connect one end of the capacitor to the positive terminal of the battery. Now if you measure the voltage from the other end of the capacitor to the negative end of the battery you will see 18 volts.

Why?

Well, the battery delivers 9 volts and the capacitor is charged to 9 volts, in series connection that adds up to 18 volts.

By making that parallel then series connection you have "pumped" up the voltage available to twice that you started with.

If you look at the diode capacitor arrangement in your circuit long enough and think about how the voltages change over time and which way currents can or cannot flow you will see that it also pumps up the voltage on the capacitor.

It's worthwhile doing this experiment for real with a 10uF capacitor and a battery, just to really convince yourself. (Be sure to get electrolytic capacitors the right way around)

That makes the process very clear to me. You learn something new every day!

Sandy

BTW Budd - none of us are dudes here on the forum but "Friends" is an ok term although you can even skip that and get straight to what you want to say without embellishments

Sandy - yeah, and when you put that in series with another cap, and another cap etc you end up "multiplying" the voltage - search "voltage multipliers", they are very similar to charge pumps. Most EEPROM and Flash chips have charge pumps on-chip.

That is what actually bootstrap in gate driver does right? , Your are saying that to reduce 100uf to 10uf.

No, I'm not suggesting you change component values in the circuit. They all depend on the actual situation, which I have not analysed at all.

My 10uf value for an experiment with a capacitor and battery was just an example for such an experiment. Too small and you won't see the effect. To big is not necessary.

Really, try it for yourself.

This is the circuit I found but there is also another test circuit attached.

It takes one complete cycle to charge up, so you can not start with high side on and leave it there.

Its voltage doubling buildup dissipates slowly-but-steadily so you need to switch faster than just 1Hz.

These have build-in bootstrap diode:

https://www.mouser.com/ProductDetail/STMicroelectronics/L6494LD?qs=sGAEpiMZZMvQcoNRkxSQkrbSyqzE5%2bUqQz2J046wl0c=

https://www.mouser.com/ProductDetail/Infineon-Technologies/2EDL05N06PJXUMA1?qs=sGAEpiMZZMvQcoNRkxSQkjKGCqEdeY3WnxzpIxXsfEA=

Nearly all 2-driver IC's use boot strap, it's the 4-driver full h-bridge that I have seen with charge pump to drive N-mosfets on the highside.

I replaced my 1n4007 with 1n4148(fast swtching diode) and tested for second time, mosfet continue to heats as before.

- Replaced 1n4007 with 1n4148 across mosfets drain and source.(image attached)

- But i didn't replace near ic, is it necessary to change near gate driver and mosfet gate.

- I checked the high side voltage = 10v(between HO pin and gnd) and Vb=20v (@60%duty cycle).

But what are you doing trying to get a complicated power circuit working when you're only guessing and you don't even have a scope? No really, I don't understand how you are attempting this and substituting almost any parts like tiny 1N4148 signal diodes in 3-phase inverted circuit, it boggles the mind.

- Ok i will replace with the fast recovery diode

- DO you think any other cause which leads my fet to heat.

Friend can you guide me to solve this issue.

I'm no great shakes electronics guy but I first observed this back in the early 1980's as an apprentice in a department that did nothing but motor controls.

Later I myself had a pile of dead MOSFETs whilst trying to build a class D amplifier is a project in technical school.

So do take the advice that has been offered here. Personally I would start by getting an oscilloscope. It's amazing the capability one can get in a scope for very little money now a days.

I would struggle with the "small small" problem of checking a waveform if I didn't have a scope.

If I look at the speedo on my car dash I can tell how fast I am going but I need to look out the windscreen to see where I'm going.

You can't drive a car just by looking at the speedo, you will crash and burn.

Likewise you can't design and test drive 3-phase inverter switching circuits just by using a meter, because likewise you will crash and burn.

Beg, borrow, or buy a scope so you can see where you are going wrong or right.

Some observations:

- The hand drawings have problems: 22R resistor between VS and motor phase shouldn't exist. Looks like it's changed to 10R on the other drawing. Get rid of that resistor, the phase wire should be directly to VS (pin 5).

- Don't use 1N4148 for power rectification! They're only signal diodes. Make sure you use "ultra fast" rectifiers, ie: The UF4007 in the original diagram.

- As well as gate drive voltage and load current, the gate (dis)charge time is also a major factor in heating consideration. The driver IC (IR2110) is spec'd for 2 A drive strength but the 10R gate series resistors reduce it to maybe 600 mA. That might be a limiting factor for switching speed. It has to overcoming the gate capacitances to perform the switching rapidly.

PS: This is the important Vgs voltage for calculating drive current at.

EDIT: Added word "supply" to load supply voltage.

- Can you explain me how 600mA will flow, If i use 10R.

(i,e) I = V/R

= 12v/10 = 1.2A

correct me friend if i am wrong.

Imagine that you removed the MOSFETs from the circuit. Now ask yourself what would be the current flowing out of LO?

The only current path is down to ground through R2 and R4 in series. That is 10 ohms + 1K ohms = 1010 ohms (this is not just the 10 ohms as you assumed above).

If LO is high at 12v the the current is I = V/R = 12 /1010 = 11.8811.. ma. Might as well call it 12ma.

Now put the MOSFETs back into the circuit. The MOSFET gates have very high input impedance, they are effectively just capacitors. So in the DC case they make no difference. The current is still 12ma.

What about the AC case? Well, those gate capacitors will need current to charge and discharge them as the LO transitions from low to high and high to low respectively. That current is only present during the very brief transition time.

How big is that current? One could work it out from knowledge of the gate capacitance value. Which I will not get into here. I suspect that the result would be very approximate as that gate capacitance is no doubt changing with voltage and/or current through the device. Also any inductance in the circuit traces will limit the amount of current during these high speed pulses.

One could measure the gate pulse current by monitoring the voltage across R1 and using Ohms law (We can ignore R4 in this case). For this one will need an oscilloscope. Be sure to make sure the scope is not grounded though.

Perhaps evanh's guesstimate of 600ma is about correct. I have never looked at this in such detail.

By the way, in general there is a little trick here to remember. When analyzing a circuit imagine the DC paths and the AC signal paths separately. For the DC paths simply imagine all the capacitors removed. This is what you need to do when assessing bias conditions.