mArlo Debut - UPDATE with Video Tour

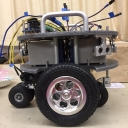

mArlo, my mid-size Arlo robot platform, is complete and running as of today - Memorial Day, May28, 2018. mArlo uses the components of the Parallax Arlo Complete Robot System in more compact configuration - just under 12" in diameter. Many of my parts are from previous versions of the current Arlo.

Below are build photos of the final assembly and a quickly shot video of the mArlo running some BlocklyProp Code written for the Arlo using Ping))) ultrasonic detectors for obstacle avoidance. It is called Arlo Roaming with Ping))) Obstacle Detection. The code is at this link - http://blockly.parallax.com/blockly/editor/blocklyc.jsp?project=15424 Notice the addition of an additional breadboard area in the final photo.

Below are build photos of the final assembly and a quickly shot video of the mArlo running some BlocklyProp Code written for the Arlo using Ping))) ultrasonic detectors for obstacle avoidance. It is called Arlo Roaming with Ping))) Obstacle Detection. The code is at this link - http://blockly.parallax.com/blockly/editor/blocklyc.jsp?project=15424 Notice the addition of an additional breadboard area in the final photo.

Comments

Man! You've got some serious battery power on that thing!

BTW, I like the photos from your shop. Can you show us around some more, please?

-Phil

@"Ken Gracey" - You got that right!

Set up with two SLA batteries, mArlo weieghs about the same amount as Aron, but because of its size - it feels much heavier!

If I didn't know better I'd say you cut up the counter top from your kitchen. Now *that* is dedication to robotics!

@AwesomeCronk- No issues here - and these are the very first 12V motor and wheel sets Parallax sold - long faithful service.

I think some folks needed to update the firmware on their DHB-10 motor control board. Easy to do - see the Arlo section at learn.parallax.com

There's some mighty fine chamfering on those edges. Almost like you have the right tool for the right job.

That is a terrific idea for a bot platform, going to have to hunt down a few for my Slammer project. My plywood is starting to get a little weak from all the holes I drilled. Would you happen to know what kind of material yours is? Did it require any special tools for cutting?

@"Hal Albach" - My prototype was cut using a bandsaw - drilled a center hole, made a pivot and spun the board to make the circles - then cut the wheel notches on the middle platform, the bottom is just a rectangle.

Once I had everything figured out - I used a CNC router to cut the final boards after making drawings. All edges are just hand sanded.

@Martin_H - Thanks!

Spent some time troubleshooting an IR Remote issue with Parallax.

We are still working on it, but...

Parallax customer/technical support is SECOND TO NONE!

Thanks to you all!

UPDATE: The rest of this story is here - http://forums.parallax.com/discussion/168600/sony-ir-with-m-arlo-bug-solved#latest

BTW, does your mini Arlo burp like this one?

Easy peasy - m-Arlo will be burping in now time. See http://learn.parallax.com/tutorials/robot/activitybot/remote-control-rock-talk-and-roll-activitybot on learn.parallax.com - This ActivityBot sounds just like Stephanie!

What tool did you use to cut out your cutting boards?

Jim

Once I had everything figured out - I used a CNC router to cut the final boards after making drawings on AutoCAD. My sister teaches at Louisiana Tech and has access to some very sophisticated tools! Below is a video of the mid-deck being cut. All edges are just hand sanded to smooth them and slightly round the edges.

1. What is the diameter of MArlo?

2. Any ideas for a very small DC Motor Driver?(2-channel)

I think using the ActivityBot 360 servos and wheels would make a great t-Arlo, especially since the 360 servos include the encoder function with on extra wire. You could use a Propeller Activity Board WX too. The diameter of t-Arlo would be about 6" - I may make one too! This is a super idea.

My parts list would include:

2 - Parallax Feedback 360° High Speed Servos - https://www.parallax.com/product/900-00360 - $50

1 - Propeller Activity Board WX - https://www.parallax.com/product/32912 - $80

1 - Battery Holder 5-AA Barrel Jack - https://www.parallax.com/product/753-00007 - $4

Better yet...

1 - Small Robot to ActivityBot 360° Upgrade Kit - https://www.parallax.com/product/32603 - $100 (save $25!)

2 - Small Robot Wheel and Tire - https://www.parallax.com/product/28114 - $8

All you need then is a base (cut like m-Alro's mid-deck, a top deck, way to mount the servos and the "tail" wheels - front and back - I might even use a

1 - Small Robot Chassis - https://www.parallax.com/product/700-00022 - $25 (and another ball wheel mount) and

2 - 1" Tail Wheel Ball(s) - https://www.parallax.com/product/700-00009 - $8

You could make the whole thing for around $150.

I am on a shoestring budget, here, so I was actually looking at double wall cardboard.

I would roll with your first list, but have a bs2 on a breadboard instead.(or something like the picture)