NonaProp, Inspired by TetraProp

Duane Degn

Posts: 10,588

Duane Degn

Posts: 10,588

A few years ago jazzed made a really cool board with four Propeller chips on it called the TetraProp.

I purchased several of these boards and while I populated a few with four Propellers, the PCBs which have seen the most use are the ones I cut into double or single Propeller boards.

I have half of a TetraProp in my Robot Remote project.

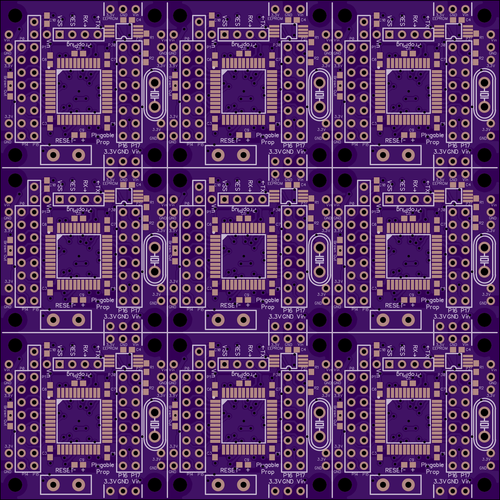

Out of a desire for inexpensive Propeller boards, I've decided to take jazzed idea a step further and place nine Propellers on one PCB.

While I'm not using OSH Park for this board, I did submit the zip file to their website to see what the boards would look like.

You're right, it does look cool.

A lot of board houses have deals on 10cm x 10cm PCBs. I wanted to take advantage of the price of the 10cm x 10cm boards and fit as many Propeller boards as I could on one.

I've ordered a set of ten boards (which could hold 90 Props) and I should get them back in a couple of weeks.

I'm reasonably confident I haven't made the same mistake on this board as I made on my Hex Caster board. I made sure current flowing into the Prop is only the current being used by the Prop and not passing through the chip to continue on to other parts of the board. This is the mistake I make with the Hex Caster. Having current flow through the Prop is a quick way of burning out the PLL circuit.

I don't know if I'll be selling these or not yet. If I do decide to sell them (or parts of them) I'll update this thread with price information.

I also ordered a solder paste stencil and plan to cook some of these up in a modified toaster oven.

While I'm calling this board NonaProp, it's really just a panelized MonoProp board. Again the idea is to be able to inexpensively add a Propeller to a project.

I thought seeing nine Prop (footprints) on a single PCB was fun to see and I thought some of you might also get a kick out of seeing these renders.

I purchased several of these boards and while I populated a few with four Propellers, the PCBs which have seen the most use are the ones I cut into double or single Propeller boards.

I have half of a TetraProp in my Robot Remote project.

Out of a desire for inexpensive Propeller boards, I've decided to take jazzed idea a step further and place nine Propellers on one PCB.

While I'm not using OSH Park for this board, I did submit the zip file to their website to see what the boards would look like.

You're right, it does look cool.

A lot of board houses have deals on 10cm x 10cm PCBs. I wanted to take advantage of the price of the 10cm x 10cm boards and fit as many Propeller boards as I could on one.

I've ordered a set of ten boards (which could hold 90 Props) and I should get them back in a couple of weeks.

I'm reasonably confident I haven't made the same mistake on this board as I made on my Hex Caster board. I made sure current flowing into the Prop is only the current being used by the Prop and not passing through the chip to continue on to other parts of the board. This is the mistake I make with the Hex Caster. Having current flow through the Prop is a quick way of burning out the PLL circuit.

I don't know if I'll be selling these or not yet. If I do decide to sell them (or parts of them) I'll update this thread with price information.

I also ordered a solder paste stencil and plan to cook some of these up in a modified toaster oven.

While I'm calling this board NonaProp, it's really just a panelized MonoProp board. Again the idea is to be able to inexpensively add a Propeller to a project.

I thought seeing nine Prop (footprints) on a single PCB was fun to see and I thought some of you might also get a kick out of seeing these renders.

Comments

I want some. If you can sell me one or two complete populated I am happy ...

Enjoy!

Mike

As I mentioned in the other thread, I'm still not sure how I like the yellow PCB. I decided to try yellow since it doesn't seem like a common PCB color. I think the yellow color makes the places where there isn't copper look kind of greenish.

Some board houses charge more if you want a different color than their standard color. I was pleasantly surprised to see Dirty PCBs offer a variety of colors without charging extra.

Beside posting the above photo to this thread, I also wanted to reply to Jim's question here.

The bargain basement houses I've used require you to panelize them yourself. This isn't always easy. This board had too many pins for my version of Diptrace (not the free version). I could get around the pin limit by deleting the headers and adding them individually by hand after all nine Propellers had been copied to the board.

I'm pretty sure it's possible to panelize a board using the gerber files but I don't know how to do this.

Since I used the full 10cm x 10cm area of the board, I had a little bit of room around the outside edge of the board which I debated moving to the panel lines. I decided against increase the inter-panel space so all the header pins remained on a 0.1" grid.

I'm still trying to figure out the best way to make a v-groove in the boards.

I've been so busy lately, I haven't had a chance to solder a Prop to a PCB to see if the board is laid out correctly. I'm hoping to test one today.

Never seen this before.....Where can we buy them

Thanks. I admit, I think it's cool too.

I'm hoping to sell them if there's interest.

I'm not sure what people will be interested in, the bare boards, the board with components as a DIY kit or a finished board. Obviously there will be significant price differences for these various options.

I'm not making any promises yet but my guess is the bare board (9 squares) would be $10, A DIY kit would between $15 and $20 per single square (1/9 of the board) and a completed square (again 1/9 of the board) would be between $20 and $25 (hopefully closer to $20).

I was pleasantly surprised how easy it was to solder the Prop and EEPROM using solder paste and a stencil.

I'll upload some photos I took of a populated square in a few minutes.

Did any of you know this? (That's of course a joke.)

So I used an expired credit card as a squeegee and pressed solder paste into the little holes on the stencil. I then placed the components on the solder paste and used hot air to melt the solder. It was so easy!

And best of all, the Propeller works. I ran some code using the 5MHz crystal and 16xPLL and blinked an LED on each I/O pin to make sure they were working.

Here's the board with the surface mount components added.

Below is a photo of the boards and the (slightly used) stencil.

I added a crystal, programming headers and wire jumper to pull the brownout enable pin low.

I'm using a small 3.3V regulator on the back of the board. (I didn't use the stencil on these components.)

The jumper on the left is for use when a PropPlug is used to program the board. Lots of the inexpensive USB to serial boards require a capacitor on the reset line. With the jumper removed, the reset pin is capacitively coupled to the reset line on the PropPlug header. This way I can use this USB to serial board which cost less than $3. The UART board also provides 5V power to the Propeller board.

I'll add a link to the USB/serial board soon.

Did I mention using the solder paste stencil was easy? This is so darn cool!

Darn. ElectroDragon no longer sells these devices.

ElectroDragon does have this adapter which looks like should also work as a PropPlug type device.

The adapter shown above costs less than the one I'm using now. The price is $1.60 (+shipping).

There are lots of other inexpensive USB to serial adapters available. Be careful when purchasing one of these cheap adapters. Not all of them can be used to program the Propeller. The board should have a "DTR" pin or at least a "CTS" "RTS" pin. If you use a board with only the CTS RTS broken out, you will need to change the "Propeller Reset Signal" from "DTR" to "CTS" "RTS" in the "Operation" tab in the Propeller Tool's "Preferences" section in the "Edit" menu.

There are a zillion USB to serial adapters on ebay. It looks like this one should probably work with the Propeller.

Another PropPlug alternative is Pololu's Wixel. With two of these, it's possible to program the Propeller wirelessly.

Edit: See post #11 for a link to the USB to serial adapter I used.

Edit again: As mentioned by Cluso99 in post #17 I was using "CTS" where I should have been using "RTS".

Awesome!

If you want to sell them, I will gladly buy a 9 prop DIY board and a 1 prop DIY board.

This is especially great for beginners ( like me ) who are just learning to use solder paste and a stencil. I hope others have interest in this as well....otherwise I don't get one

I thought you had pointed us to this one http://www.electrodragon.com/product/cp2102-usb-ttl-uart-module-v2/ from ElectroDragon a while back. IT is CP2102 V2 and goes for $2.20 each. I bought 5 of them for some reason, I'm sure it was your idea!

I haven't tried them yet. I haven't looked into details about the cap needed on DTR.

I'd try a NonaProp or two (sounds like SMD is too easy from your experience!)

I have my TetraProp running PropForth (x4) (Steve disowned me). The chance to run PropForth(x9) sounds too good to resist!

Yes, that's the one. I didn't see it when I searched ElectroDragon for "USB". Thanks for reminding me which one it was.

I notice there's a jumper on the back of the board to change the voltage of the Vdd line from 5V to 3.3V. I think the trace to the 5V pad has to be cut and a jumper of some sort added to the 3.3V pad.

I like the 5V source being available. The MCP1700 on the back of the NanoProp drops this down to 3.3V.

I connect 5V from the USB/serial device to the Vin position next to the PropPlug header. All 5 Vin positions on the board are linked together with a wide trace but the Vin bus does no extend beyond a single square unless linked with one of several headers.

The 3.3V and ground buses are all linked from board to board but I'm pretty sure any current flowing in these buses won't pass through a Prop chip (I think I've learned my lesson about frying Props with current through the chip).

This is one thing to consider before adding a v-cut. Scoring the boards to make them easy to separate will also cut the power and ground copper pours.

I've started adding caps to the reset line on my Propeller PCB designs. I also add a jumper to return the reset to its usual configuration.

An easy way to add a cap to the CP2102 board is to place on inline with the wire connection the DTR to Reset (the blue wire on my cable).

SMD is easy with a solder paste stencil. I'll need to provide a way to have the SMD components added and let the user add the through hole parts.

And rightfully so.

I foresee a great disturbance in the Force if such an action is carried out. But hey, if you've got the money. . .

Thanks Don.

That adapter looks almost identical to the one I'm using but the silkscreen appears a little different than the ElectroDragon board.

Yes. That's the main reason I purchased the nice stainless steel stencil.

I don't have enough components on hand to assemble a full board. I'll place a Digi-Key order today to purchase the parts I need (mainly the TSSOP EEPROM).

While I'm waiting for the parts to arrive, I'll get my toaster oven converted to a reflow oven.

Once I have the parts and tools lined up, I can time myself to see how long it takes to make and test a board. I'll also have a better idea what my BOM will cost. Once I have this information I can finalize the price of boards with the added smt parts.

In post #9 you refer to CTS as an alternative to DTR. This should be RTS as CTS is an input.

Thank you. I'll fix post #9 (again).

As for SMT with a stencil.... it's the only way!. My PowerTwigs and M44D40+ module are both built by hand with stencils and they are fairly easy.

From my adventure with my Propeller BSC module that use the FT230, all of my Propeller Tool loads on various computers have the reset preference set to "DTR & RTS" since the FT230 doesn't have DTR. Still works perfectly with Propeller tool.

That's what I'm hoping. I've had too many blown PLL circuits for my liking and I tried to be extra careful with how the power and ground connect to the Prop (I used lessons learned from Cluso99 and others).

I haven't tried it yet, but I think the Props on these boards should survive a stunt like this.

I keep hoping to hold some sort of "robotics school" and I keep looking for inexpensive Propeller boards to use. Before the QuickStart's price went up, I planned on using it. Now I'll probably make my own boards.

Yes I am. It works but I think there's a better solution. I'm just not aware of it.

Yes, but as I'm sure you know, there are plenty of tricks to do it correctly. I've been reading the forum for years and I've paid attention when people like yourself tell us how you do this sort of stuff.

I remember reading with interest what you shared about both these projects.

This is good to know. It will make it easier to use the inexpensive USB to serial devices available. I love Parallax but I don't love paying $15 for a PropPlug (though it's not obvious since I'm sure I have more than 5 of them).

ED5037-ND from DigiKey

Those look a lot better than using machined pin sockets. The machined sockets are just a tad too big to hold the crystals securely.

Thank you. I'll try them.

When you come out with a price for your packages, please post them.

I have need of three propellers in line, in the future, and the boards

provide a neat way of completing the project. The other propeller

part of the board, I can use for my "Huminoid" project I am working on.

Thanks!

Before I started adding components, I attempted to make my own v-grooves. I used a X-acto knife and it was pretty hard to keep the lines straight. I know I'll want to figure out a better way to cut these groove than with a X-acto knife.

Once the v-grooves were cut, I added the voltage regulator on the back of the board. The solder paste was pretty easy to apply to the back of the board. I monitored the temperature of the oven with a thermocouple on my DMM.

Next I tried the front. The first time I attempted to add solder paste I ended up smearing the paste a lot. I cleaned off the board and tried again.

Can you tell were the solder bridges are going to occur? It was interesting to look at these photos after the board had been through the oven because the areas with nice clean solder paste, had nice clean solder joints. The areas where the solder paste overlapped ended up being areas with lots of solder bridges.

One of the 0 ohm resistor tombstoned on me. I know from past experience these issues will be easy to fix.

I still need add crystals in order to proper test the boards. I'm hoping they all work alright.

I thought it was interesting to see how much the board changed color from being heated.

I'm still wondering why you call it a NonaProp when it's just 9 independent Prop boards on a mini-panel, except that you did your own Vgroove. It's fairly normal to do boards this way but we don't count the panel itself as a "board"

However I can see you are applying way too much solder paste, half of that would be more than sufficient, perhaps less than a quarter would be better. You'd be surprised as to how little is needed. But rather than individually paste each pad on the Prop I just run an even bead all the way down the center of the pads complete with "bridges". As long as you don't have too much solder and you run hot enough for long enough the solder will wick away back to the pads and you wouldn't even know they were so pasted the way they were. Toaster ovens are not ovens to profile, I just run mine on full, pop the boards in on folded foil on a center tray with another tray just above the bottom element which all helps to prevent hot spots. Run this for exactly 4 minutes, carefully remove the tray and let it cool. Perfect every time unless I have stuffed it up somehow or I have let the paste dry too much between pasting and baking, in which case you can get tombstoning as you observed.

How about 50 Props then!

Oh, now I see your original post:

"While I'm calling this board NonaProp, it's really just a panelized MonoProp board. Again the idea is to be able to inexpensively add a Propeller to a project."

I see you found my original reasoning.

It may be normal to panelize small boards but this is all pretty new to me.

I had toyed with the idea of finding some application for nine Propellers working together but I have yet to find an application which uses the four Propellers in a TetraProp board. I do have lots of two Prop projects.

I think your 50 Prop board looks amazing.

Thank you very much for your suggestions. I'll try it this way next time.

Do you have anything between the top element and the board?

While my little oven have several levels the rack may be placed, there is only one rack. I'll need to rig something to hold the foil.

I cringe a bit about all the money in a 9 Propeller board. I imagine cooking 50 at a time is not for the faint of heart.

And Parallax likes purchase of P1 chips x 50.

Did that fit in your toaster oven?

In case anyone is looking for Peter's board, he has a thread here about it.

Sure looks like a nice board.

I personally want easy access to all the I/O pins.

I also wanted a socket for the crystal. The little one on your board sure makes your board look nice and tidy.

You can modify a basic ceramic tile cutter for cutting straight V grooves by replacing the cutting wheel with a V blade used for scoring plastic or a metal lathe bit. Tungsten carbide bits work best.

I was thinking of something like this.

http://www.amazon.com/Milescraft-2214-4-Inch-Groove-Designs/dp/B002YD7ZJK/ref=pd_sim_hi_5?ie=UTF8&refRID=1RYESHBRKX6MS73PM5S4

While I was drafting a reply about the solder paste I thought I'd have a bit of fun and do a one-upmansship thing so as a bit of a lark I had pushed these Prop strips together to make it look like one panel. Looks good but it would all be so terribly useless!

The reality is that I have 10 sets of these modules along with 10 sets of the Ethernet modules on the one mini-panel which is much more manageable and also fits in the toaster oven.

The foil is just placed between the pcb and the tray and the top element ends up doing most of the work. I will take some shots later to give you an idea. This also lets the boards cool down much faster than if they were in direct contact with the tray.

That tiny SMD crystal is actually a cheap oscillator as I normally use 10Mhz 5x3mm crystals but I wanted to push the Prop a bit harder but still within safe limits so I choose 6Mhz to give me 96MHz but small SMT crystals aren't to be had at 6Mhz so I found these oscillators for just over a buck. BTW, those SMT HC49 crystals are an abomination and if you must use HC49 then use the standard TH part. I've commented quite a few times about the ridiculousness of the huge pads that comes about from deforming a TH part into an SMT part. Those pads are huge antennas and get in the way of all the I/O etc.