Wire Wrapping

Whit

Posts: 4,191

Whit

Posts: 4,191

Hey All,

I was just reading up on Wire Wrapping for prototyping - the tools, materials, etc...

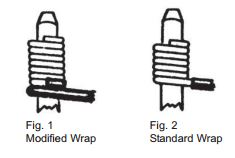

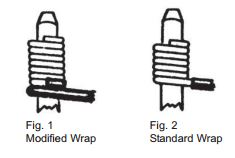

Do any of you use wire wrapping for your projects? If you do, what are your thoughts on modified (that is wrapping with a couple of turns of insulated wire) vs. regular wire wrapping (i.e., wrapping only the stripped wire). I understand that the modified method is for situation where there is vibration.

I didn't know if the amount of vibration in robotics applications would be enough to warrant the modified method.

Any advice from those who are more experienced would be appreciated.

I was just reading up on Wire Wrapping for prototyping - the tools, materials, etc...

Do any of you use wire wrapping for your projects? If you do, what are your thoughts on modified (that is wrapping with a couple of turns of insulated wire) vs. regular wire wrapping (i.e., wrapping only the stripped wire). I understand that the modified method is for situation where there is vibration.

I didn't know if the amount of vibration in robotics applications would be enough to warrant the modified method.

Any advice from those who are more experienced would be appreciated.

Comments

I wire wrap the majority of my projects if the conditions allow (i.e. never for 120V AC or multi-amp stuff).

Modified vs regular? Never gave it any thought. When I learned how to W/W in the early '70s, the wire wrapping tool was always set up for modified. A nice benefit for modified is if you goof and wire to an incorrect adjacent pin, there is probably enough un-wrapped wire to re-wrap on the new pin.

Advice? The only thing I'd caution against is making the wires too tight. It may look pretty, but they are a bugger to troubleshoot. Being able to tug on one end of a wire to see movement through the rats nest really helps tracking the connections.

Wire wrapping is great. I did a lot of it back in the early 1980's. When you want to prototype a ten inch by ten inch board with some 40 pin DIP microprocessor, some RAM and ROM, some UARTS and timers and a bunch of DIP TTL, you can pull up you schematic or net list and settle down to "stitching". You have to get into the "zone" because it's going to take a working week.

I was surprised to find there are traffic light controllers around that still have wire wrapped back-planes for their processor cards. They are still working well after being out in the heat and cold for thirty years!

I would still use wire wrapping for some prototypes. Preferably simpler circuits. But there are many down sides to wire wrapping in this modern world.

Those wire wrap sockets are expensive, as are the tools and the wires and the boards.

Most interesting devices now a days don't come in DIP packages.

All in all this leads to the fact that it's simpler and quicker to design a PCB layout and get one made. Now a days that is very quick and cheap which was not the case in the hey day of wire wrap.

Notice how AdaFruit, SparkFun, even Parallax and other places basically make a business out of providing easy to use break out boards for tiny surface mount parts: micro-controllers, sensors etc. Those things can be connected using a couple of jumpers or solder connections for I2C, SPI and PWM etc. The need for wire wrap is not there. The wire wrap sockets would cost more than the brake out boards.

Bottom line for me is that if the thing you want to prototype is complex it's easier quicker and cheaper to get a board made than set about wire wrapping it. If you just want to stitch together a couple of DIP parts, go for it. Although a good old strip board solution is normally what I end up with.

Now I'm probably not out of the woods because I made a parallel eepom programmer that is a rats nets of wires on my breadboard. So I'm going to need to transfer it to a more permanent home. I also want to build an add on card for interfacing with the physical world. So I may yet wire wrap something.

Eventually the retro computing and robots will converge because I plan to interface the retro computer with sensors and servos. Basically I'm doing a nostalgia project.

I do all my prototyping with WW. When I was in the Navy (20 years worth) wire wrapping was the ONLY mil-spec method of back plane wiring for main frame computers. I've never heard of the so called modified method of WW, I have always used the standard method of a turn or two to mechanically anchor the wire to the pin.

I used a program back in the day called "Wire Master" (a DOS program) that would take as input a text file listing all the connections in a network (ie: all the connections to say pin 1 of IC23) and generate several lists. There would be a wiring list telling you which pins to wire and in what order, a wrap count list to show you if there were the correct number of turns on each pin. (NEVER more than 2 wraps per pin!) a continuity list for the individual networks and last but not least, an "unwrap list" to make changes to your design.

If you passed all the check lists, assuming your design was valid, it WILL work. I built MANY S100 buss computers and cards for customers using Wire Master and they all worked as advertised.

Go forth young man and fear not the Wire Wrap tool for it is your friend...

Mike B.

Stangely I had never heard of this "normal" and "modified" styles. We just did what was appropriate at the time, never knew these things had names.

Martin,

We'd love to hear about your retro-robot controller efforts.

to handle. For ordinary robotics I wouldn't worry, wire-wrap is a strong technique especially as

the wires tend to hold each other down.

Have done a little in the dim and distance past and hated it, staring at hundreds of metal

spikes seems to promote eye-strain like nothing else.

Wire wrap is bulkier, uglier, costs more, harder to modify, probably slower construction. What's the great appeal?

When wiring the address bus and data bus of a computer you tend to have many connections to the same pin on the microprocessor. This becomes awkward with point to point soldering, but the length of a wire wrap pin allows for many connections. I've also heard people claim that the circuits have less noise at higher frequencies than point to point soldering, but I can't confirm that.

@Heater, OK I'll post some details about what I'm up to soon.

-Phil

Phew. I figured I had a dogpile coming my way.

#30 wire-wrap wire for point-to-point soldering +1

Feel free to park the wire-wrap tools and sockets next to the churn and the spinning wheel.

:-) - Alright PJ, erco and Phil - I get the message.

Thanks for all the answers everybody - I guess since I kept seeing tools and info about wire wrapping and never used it myself - I was afraid I was missing a skill-set. Guess not. Still might try it on something simple if I find the supplies on sale.

If you've already got the tools (strip, wrap, unwrap), I'd say give it a try just to see for yourself what it offers. But if you don't already have the tools, I seriously wouldn't bother. Even the simplest hand wrap tools are grotesquely expensive, and the meager benefits they offer do not justify the cost, IMO.

-Phil

They come handy for some modifications of an existing board, and I think it's nice to have this option. Sometimes it's the neater solution.

Massimo

There are people that make entire circuits on wire wrap sockets only. Sort of a takeoff on the dead-bug technique. They use the 30ga wire and solder to the post, gluing the sockets side by side and not even using perf board. It's whatever works, so I wouldn't go by what anyone tells you is good or bad, the right way or the wrong way. eBay has cheap(er) wire wrapping tools, and as someone else mentioned, the wire and the basic tool are also handy for making fixes in traditionally soldered projects. Buy one OK wire wrap tool for $15 or $20, and that'll set you up for life.

Because of how I use wire wrapping, I don't like the modified method.

I never could trust the wrapped wire SO

when I've completed wrapping, I test the circuit as I would on a breadboard THEN

I permanently connect the wrapped terminal with solder.

I actually wire wrap most of my stuff without wire wrapping sockets.

Using standard DIP sockets, two turns usually holds the wire wrap in place, if insulation has been stripped.

I only fabricate a few projects per year, but I haven't had any failures as yet.

I know, Sounds peculiar, I guess I'm a bit odd.

It cost but a few bucks back then (1980's). Today, they're more than $30 from DigiKey! -- for this little freaking handheld piece of metal.

-Phil

Welcome to the club. We will add your distinctiveness to our own.

How dare you say wire wrap is uglier. A nice big board covered in logic and wire wrapped neatly is a thing of beauty. Like for example the ALU board of the Magic-1 homebrew computer. See below:

As for "bulkier" I'm not sure one could layout a double sided PCB for a design like this that would be smaller in area. This will also be easier to modify if you make the odd mis-connection or minor design revision.

...now THAT is a beautiful thing!!!

One drop is not rain.

One taco is not dinner.

One post is not a dogpile.

That sounds so deep. Too bad it didn't work into a nice Haiku.

I must admit, that's a great example of a beautiful professional wire wrap job. I suspect there are some ugly ones out there by hacks like me.

Nor one taco a dinner.

One post? No dogpile.