8 pin prop?

Hello,

Just an idea... I would love to see a mini-prop.

I work on many projects where space is everything... currently working on a controller where maximum allowed width is 12mm!

For this the QFN or QFP chip is the only available solution, and I have to run traces under the chip and cross other unused pins to allow the traces to fit.

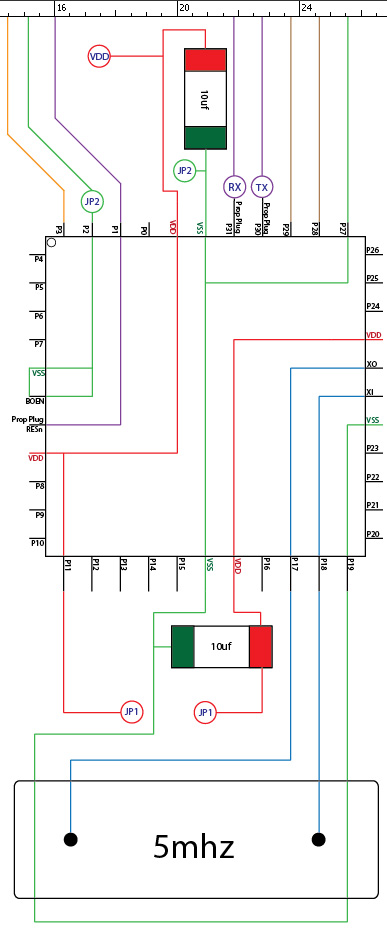

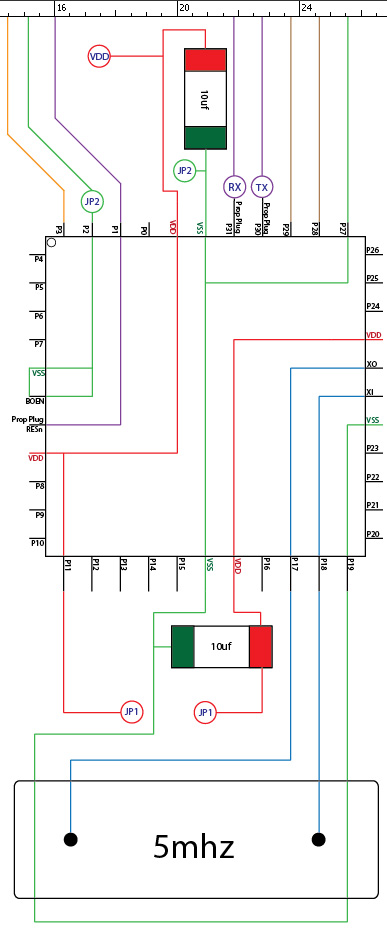

Here's a pic of how I am accomplishing this challenging width constraint.

I would love to see something like a micro-prop.

Maybe 4-8 useable pins, only would need 2-4 cogs... and make it as thin as possible such as 5mm.

Just an idea... I would love to see a mini-prop.

I work on many projects where space is everything... currently working on a controller where maximum allowed width is 12mm!

For this the QFN or QFP chip is the only available solution, and I have to run traces under the chip and cross other unused pins to allow the traces to fit.

Here's a pic of how I am accomplishing this challenging width constraint.

I would love to see something like a micro-prop.

Maybe 4-8 useable pins, only would need 2-4 cogs... and make it as thin as possible such as 5mm.

Comments

-Phil

Hand soldering that is going to suck. Especially if you're like me and have shaky, large hands. I can't hand solder anything SMD unless it's about 1206 size. 0805 is quite hard for me to do. This is where the 8-pin DIP idea I think the OP is getting at would come in. Of course if you got a reflow oven none of the sizes really matter. Just solder paste, place parts, stick in oven and good to go.

-Phil

When you apply yours do you let it reheat to room temp (the paste that is)? Awhile back I was really into making my own PCBs and what not, but I got sick of the ferric-acid stuff from RadioShack. Absolutely ruins everything it touches. Which, is not surprising to be honest. However recently (last week) I did pick up some Liquid Tin. So I am itching to try that out. I might try to use the ol' solder paste again but I had serious problems with it. The paste would not hold the components down properly and it wouldn't stay/stick where I wanted. It was horrible. That's why I asked about the room temperature thing. Also, stencils I hear are good, but I don't see why you need to make this custom thing for a custom PCB just to put the solder paste on when all you would need to do is just apply with syringe. Then again, my method failed so maybe a stencil is worth a shot, who knows?

Ya, it takes a bit of practice and patience but goes quick enough.

Duane J

PoundSign2

My hands are huge but, perhaps, not so beefy, in fact, they can easily cover a full octave, from a regular piano keyboard, tip to tip, from thumb to pinky finger.

Due to the fact I use to do electronics solder joints since I was twelve, its easier to me; My muscle memory was very well trained from the beggining.

I use to rely on it (muscle memory), and ever try to relax the feedback mechanism, between the eyes and the hands.

SMD sizes 1008 and 0805 were always doable, but 0603 required much more training, before I could master it.

In the absence of epoxy adhesive to hold parts in place, I rely on some of Mrs. Yanomani's emergency sewing kit needles, after rounding their tips against fine grain sandpaper, to avoid excessive contact pressure against fragile/vitreous parts.

I must admit, departing from size 0402, the time spent in place and solder tasks increases to unacceptable limits, so does rework/refurbish issues.

If you are addicted to your eyes, why don't giving yourself some usefull gift:

http://hackaday.com/2012/12/30/usb-microscope-used-for-soldering-very-small-things/

Or try getting some Tiger Woods eyes equiped intern.

Yanomani

I have an AOYUE 968 SMD station... very good cost for the effect, highly recommend one.

Soldering is not a problem for me, I have many decades of experience... just need a smaller prop chip

And no, a mini-Prop would not be "easier" to make by any significant margin just because it is less powerful. (feel free to correct me here if I'm wrong) There's still a LOT of work that would go into it for a market that honestly isn't very significant. Maybe in the future Parallax will start expanding their line of Propellers to such a degree, but I doubt that will happen any time soon.

-Phil

The problem, IMO, with the QFN package is you can't run traces or vias under the chip. I think the QFP package makes smaller PCBs easier to route than trying to use the QFN.

I can also hand solder the QFP. I'm too chicken to try soldering a QFN package.

I posted a few attempts at making a small Prop board to fit inside a servo.

I originally tried to route traces for a QFN chip but soon found it was easier to find paths with a QFP chip.

I want a 144 Pin DIP Propeller 2 please.

I much prefer SIP for those narrow boards.

Yeah but a 40 Pin DIP is about the size of a Twix bar. Imagine the size of a 144 Pin DIP? Hersey's bar? lol

Would it be possible to design a slim package requiring only one VDD/VSS by reducing the amount of cogs & output pins?

This may seem counterproductive to some I assume... however, I believe most can agree that for simple projects such as a sensor, 8 cogs & 30+ addressable pins is overkill.

a 'barebones' package would be of great use to those of us who need to make a large quantity of devices that only utilize 1 or 2 pins/cogs and must be as small as possible.

Just thought there might be others with similar needs

Microc: That was a terrible analogy. I'm not sure where the misquoted 'easier' rant came from, effort is never easy. I love progress and appreciate the amount of work invested by parallax, I too am looking forward to the prop2... but you'll just have to accept that sometimes people might ask for things that may make no sense to you at all. I dont think it's crazy to ask for a chip with reduced size at the sacrifice of capability.. a great example would be the micro-atx motherboard. So please, instead of the 'how dare you' attitude, think happy thoughts.

All VDD/VSS pins on the Prop must be properly connected together and decoupled.

If not done the Prop can be damaged even if only 1 cog is running.

Duane J

Duane J

Use the SAME die ! the 2 non DIP ones do The die is what constrains the package .

Just dont wirebond the pads to the pins

Yes it means some retooling but not a die change .

The Prop 1 die determines the package size, and the QFN40 has larger than usual pitch because of this.

A completely new die is very expensive, and cannot happen before P2 is done, but there are some example modules out there, which show what Parallax could do.

eg the UMFT234XF from FTDI, lists at $5.95 1+, $5.23 100+ and is low profile and small.

With the pcb-edge connections it can direct SMD mount in moderate volumes, or solder onto a pin-frame.

A prop 1 version would have EEPROM, decoupling, Xtal all in smallest-available basis.

Inclusion of USB link is going to impact size and price, so could push to two modules, one with USB, and a minimals-size one with just a working Prop

I like the SiLabs Si504 as a small, any-frequency clock, comes down to 2.5 x 2mm so could be a fit option for 'any frequency' model.

http://forums.parallax.com/showthread.php/149255-P8X16A-DIP24-16xI-O-Propeller-now-working-)?highlight=p8x16a