Suggestion for mounting BOE-Bot servos

Phil Pilgrim (PhiPi)

Posts: 23,514

Phil Pilgrim (PhiPi)

Posts: 23,514

Anyone who's ever assembled a bot on the BOE-Bot/ActivityBot chassis knows how aggravating it can be to install nuts on the screws that hold the wheel servos in place. And once you get one started, it's tempting to stop tightening when the nut starts to spin, just because it's so hard to get a wrench or pliers in there to hold it. As a consequence, many servos do not get tightened down as well as they could be. The latter could become an issue with the ActivityBot especially, since those same screws also hold the encoder bracket, which should be held tight to get the best results.

To address this issue, I've designed a self-threading backing plate to replace the nuts entirely:

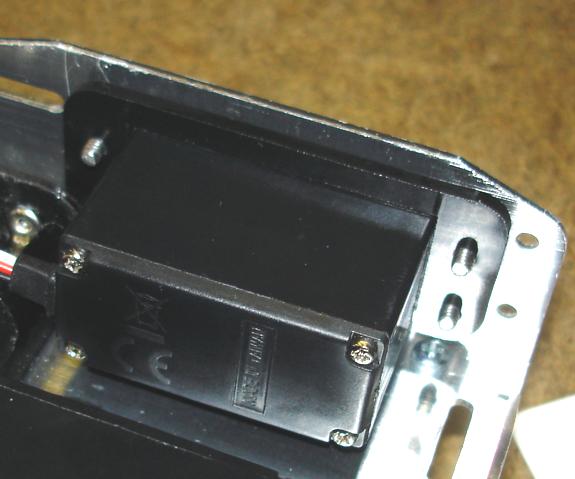

It's laser-cut from 3/32" acetal copolymer with 0.096" holes (thanks, Matt!) into which 4-40 screws thread neatly and hold tightly. To install a servo, it's necessary only to position the backing plate over the back of the servo and start turning screws. No needle-nosed pliers or tiny fingers are needed. Here's a photo of the plate installed:

Attached is a DXF file so that Matt can try one out on Parallax's laser cutter.

-Phil

To address this issue, I've designed a self-threading backing plate to replace the nuts entirely:

It's laser-cut from 3/32" acetal copolymer with 0.096" holes (thanks, Matt!) into which 4-40 screws thread neatly and hold tightly. To install a servo, it's necessary only to position the backing plate over the back of the servo and start turning screws. No needle-nosed pliers or tiny fingers are needed. Here's a photo of the plate installed:

Attached is a DXF file so that Matt can try one out on Parallax's laser cutter.

-Phil

Comments

I have an aversion to self threading plastic holes. My S2 screws barely stay in place since I've opened it up so many times.

What if instead of holes, you cut hexagons to hold the nuts in place (so they don't spin when tightened)?

According to Matt G, even if the holes do strip, the Delrin is self-healing and can hold a screw again. The 3/32" material holds really tight, BTW. It would be hard to strip it. As a bonus, it acts almost like a Nylok nut, keeping the screw from coming loose.

-Phil

-Phil

Thanks for the information Phil.

-Phil