I get busy for a while and the Stingray is gone ????

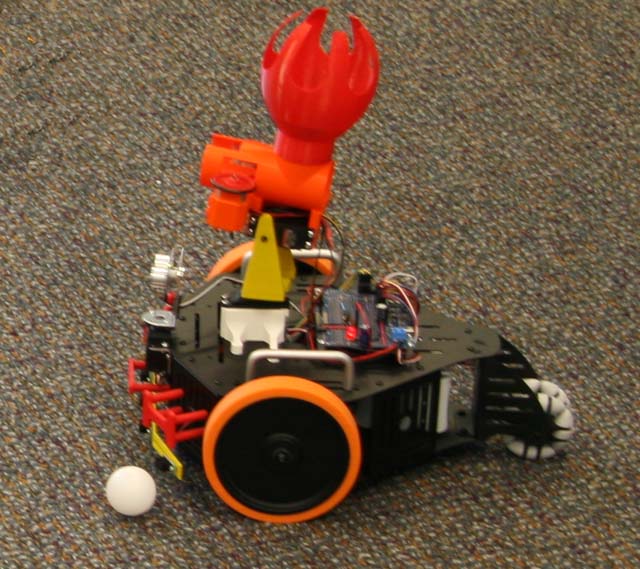

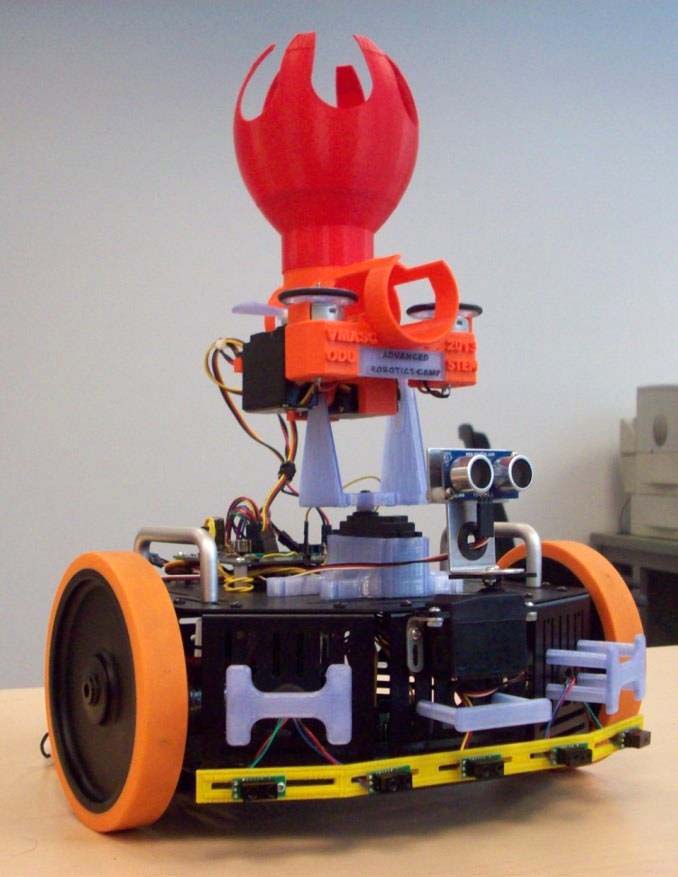

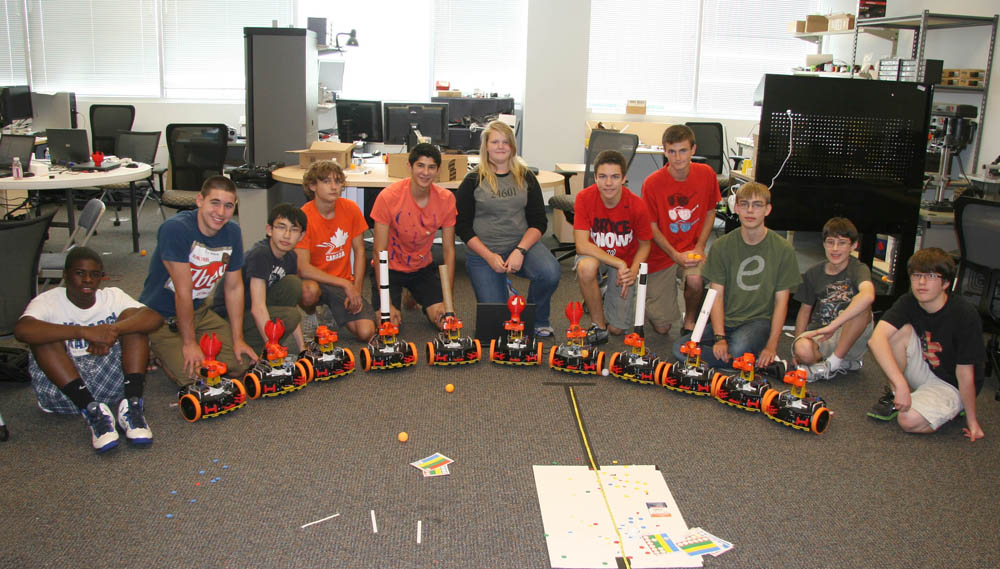

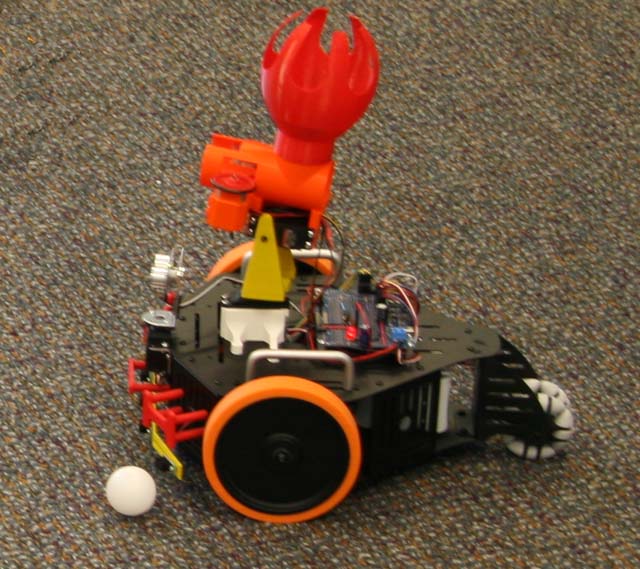

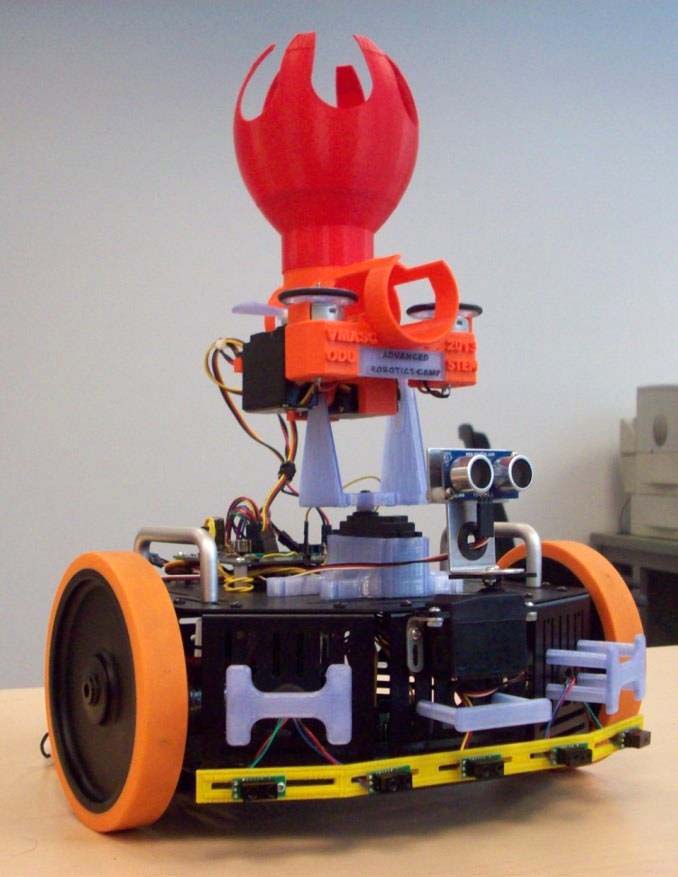

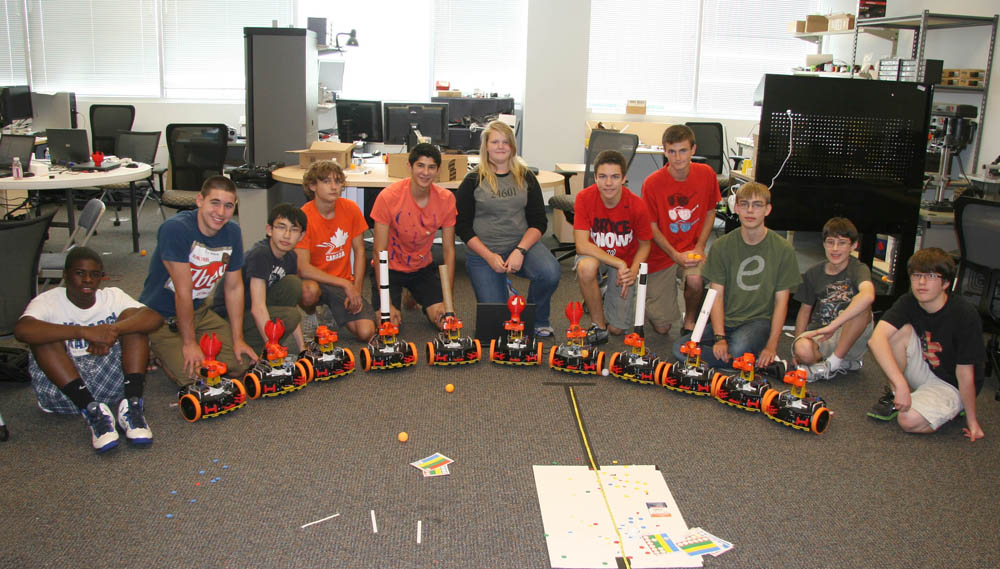

I have been using the Stingray on an increasing basis for a variety of activities in our University over the last two years. It is the standard platform for our "Design of Autonomous Robotic Systems" course, as well as a platform we have used for several man-machine interface experiments. All in all, a tremendous amount of effort has gone into building upon the basic chassis with the addition of sensor, electronics, alternative control boards, simulations etc. Most recently, we used it in our summer robotics camp, after adding a ping-pong ball launcher on it, which consisted of a variety of parts we designed and printed in our 3D printer. The launcher itself has two degree of freedom (azimuth/pitch) and an automatic ball feeder.

I have attached some photos of the activities below, but I am really disappointed to find out Parallax has end-lifed the Stingray. I understand the original controller card had quirks and the motor gearing is not perfect but why discontinue the chassis itself? I am really stuck at this point, and dread having to re-work all of this on a different platform. Definitely not a happy camper - no pun intended. By the way, I am using the Boe-Bot for the introductory robotics camp, is it safe or is it going to disappear as well?

Is there any chance Parallax would consider bringing back the chassis alone as it was sold before its demise? Even the chassis without the motors would be useful, although including the wheels and the old motors would be a welcomed addition. Given the CAD drawings, we could probably just print it in plastic, but again, without some help from Parallax, I am stuck.

Photos of the various Stingray incarnations are below.

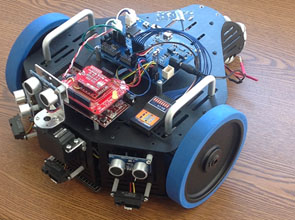

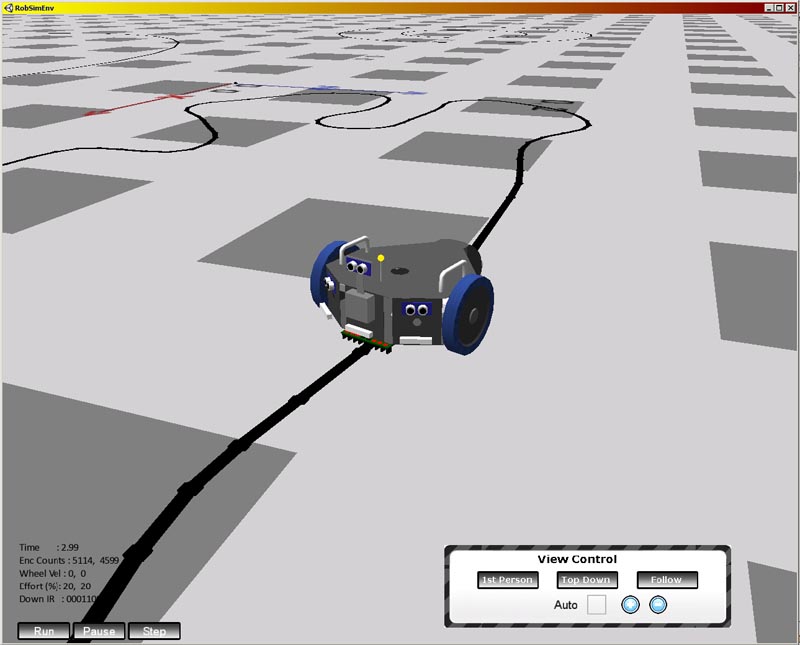

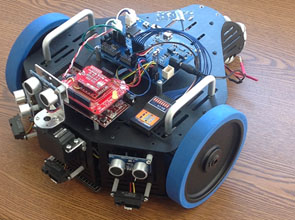

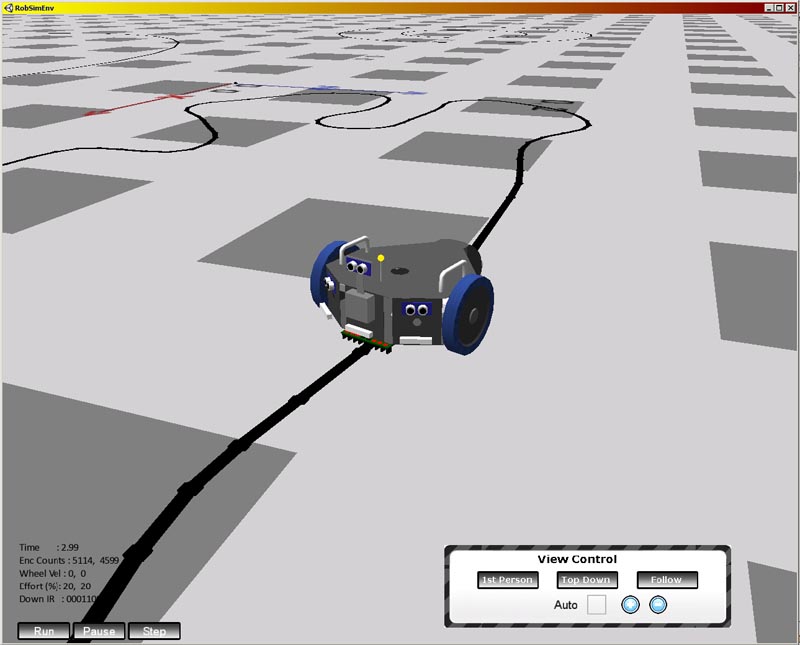

This is the configuration used in my Robotics class - it uses the old controller, a second propeller board (mounted inside) to handle the sensors and a third PIC board to run the student's code. This one is loaded with sensors, 3 front looking IR, the 8-IR down looking sensor for line following, 2 fixed pings and a servo mounted ping, an IMU inside the chassis, a remote control receiver and a roving networks wifi module for telemetry and multi-robot interaction projects. It is powered with the Parallax Li-Ion module. The second photo is a screen shot of the simulation environment; it contains a high-fidelity simulation of the stingray in which you can run the same code as you run on the PIC processor; the rest of the robot and its sensors are simulated in the environment.

This is the version used in the STEM robotics camp from this summer - great success by the way! We used the $30 MC33926 dual driver and a propeller USB project board, along with some basic electronics for controlling the launcher DC motors. We now have a group of young men and women who consider parallel micro-controller programming in C a normal activity!

I have attached some photos of the activities below, but I am really disappointed to find out Parallax has end-lifed the Stingray. I understand the original controller card had quirks and the motor gearing is not perfect but why discontinue the chassis itself? I am really stuck at this point, and dread having to re-work all of this on a different platform. Definitely not a happy camper - no pun intended. By the way, I am using the Boe-Bot for the introductory robotics camp, is it safe or is it going to disappear as well?

Is there any chance Parallax would consider bringing back the chassis alone as it was sold before its demise? Even the chassis without the motors would be useful, although including the wheels and the old motors would be a welcomed addition. Given the CAD drawings, we could probably just print it in plastic, but again, without some help from Parallax, I am stuck.

Photos of the various Stingray incarnations are below.

This is the configuration used in my Robotics class - it uses the old controller, a second propeller board (mounted inside) to handle the sensors and a third PIC board to run the student's code. This one is loaded with sensors, 3 front looking IR, the 8-IR down looking sensor for line following, 2 fixed pings and a servo mounted ping, an IMU inside the chassis, a remote control receiver and a roving networks wifi module for telemetry and multi-robot interaction projects. It is powered with the Parallax Li-Ion module. The second photo is a screen shot of the simulation environment; it contains a high-fidelity simulation of the stingray in which you can run the same code as you run on the PIC processor; the rest of the robot and its sensors are simulated in the environment.

This is the version used in the STEM robotics camp from this summer - great success by the way! We used the $30 MC33926 dual driver and a propeller USB project board, along with some basic electronics for controlling the launcher DC motors. We now have a group of young men and women who consider parallel micro-controller programming in C a normal activity!

Comments

Now, as for the Stingray. Comparing it to the BoE-Bot isn't really a fair comparison in terms of longevity. The BoE-Bot has been around for more years than I have been at Parallax and is a core part of our educational curriculum and used in many schools. I don't think we're likely to see the end of the BoE-Bot chassis any time soon. By comparison the Stingray had a number of issues from the standpoint of our customers and we failed to meet customer expectations within a reasonable time to keep the product viable. The Stingray was rather expensive compared to the BoE-Bot and therefore didn't sell nearly as well. In order to keep having the chassis manufactured we had to have to be able to sell a certain number of units in a certain amount of time and since our MOQ for the chassis was 1,000 pieces for each part. A considerable amount of resources were committed to this product, but once source issues started, factored with those who would wait until we had everything worked out, we had no choice but to discontinue it. Products are discontinued sometimes for various reasons, and while some people will not be happy when a product is discontinued, it allows us to keep moving forward.

Now, speaking of moving forward. Losing the motors for the Stingray was already a problem, and while we may have that issue solved, the fact is those motors affected more than one product, so we're currently down by two products as a consequence. So we're looking at multiple options to get the motors we want to carry and open the option to replace the Stingray with a more viable platform. I haven't ruled out laser-cut, though that has generated mixed feedback already. Just as many people love it as hate it. And so we're back at trying to please everyone on a platform that just doesn't sell enough units to be in that position again. So I am not making any promises, but I am looking at options. I'm not saying the Stingray will ever come back in any way, shape or form. But if it does it will be more complete and include what we originally wanted for it before we released the units you purchased. Hopefully something can be saved out of this. But only time will tell. One thing is sure, something was learned.

Thank you Chris, and no problem - in retrospect, I should have done that too.

Please understand that my comparison to the BoE-Bot is simply from my naive standpoint, as an outsider. I have seen the Boe-Bot used in several universities and high schools, but I have also seen the Stingray, mostly at Universities; from my limited viewing window they are similar, in the sense that they are a Parallax product. The BB is smaller/simpler in terms of a 'product', and I always considered the Stingray the next step-up, both in terms of capabilities and complexity. Which is why the 'issues' with it were moot; I have quit using the original board a while ago and dealing with the motor gearing is simple, just don't drive it as hard; and true, the motors have a lot of inertia and effectively no braking but this is what makes it a great platform to teach closed loop controls. But the chassis size makes it rather unique; I don't know of another differential drive robot, at that size in that price range. Now, if the issues you are having with it have to do with supply chain, that's another story. I did not mean to be unfair, I just have a simple view into it as just another product.

Having said that, I really appreciate the information you provided about the BB.

All true - and as always your openness to the company's internals is greatly appreciated and respected. I also understand as a vendor you are trying to please everyone, but I never understood why people would 'hate' a product, and furthermore why that matters. If someone hates a product, just don't buy it; others may. I guess it's just an issue of numbers at the end.

I noticed the Stingray inventory at $100 went really quick (something like from hundreds to out of stock in a couple of months); a smarter person in my position may have realized something was up - a whole other story. In any case, I suspect at a reasonable price point, the chassis, even without motors would sell reasonably well hopefully making the 1000 MOQ feasible. Something to consider.

Again, thanks for the information and visibility into your thought process.

We have used the Wild Thumper in my lab before; it is a completely different platform. The Stingray is a differential drive robot that can be driven with no slip on the wheels and is reasonably precise. The WT, in both the 4 and 6 wheel configuration can only steer with wheel slip, which prevents any reasonable odometry estimation or demonstration of closed loop kinematics. It is also too rough for indoor use. Pretty solid though, we have used it mostly outside.

First, I understand and share in your frustration. We hate to discontinue products, and do everything in our power to prevent it.

In the case of the Stingray, there were many things that lead to it's retirement. The main factor, as Chris mentioned, was that we had a 1000-piece MOQ of the metal pieces. Unfortunately purchasing at this quantity caused us to have excess inventory of the product, something that doesn't resolve well on income statements. We looked into other suppliers and purchasing at lower quantities. This, in turn, increased the cost significantly and would have required us to raise the retail price. When looking at the current sales volume, we knew this wasn't an option.

However, you are correct, you can make the chassis out of other material. Kenneth in our machine shop actually made his own custom version out of acrylic. MattG has also experimented with acrylic solutions. We're discussing ways internally to make this happen, though nothing has been decided on.

I've attached the manufacturing files for the Stingray chassis plates. Hopefully you can use them for your class, and please do let me know let me know if you need anything else!

Now, if you'll allow me, I'd like to insert a plug for our new Propeller C learning system....

As you mentioned, the Stingray was intended to be the "next step" from the Boe-Bot. However, we found that the transition from PBASIC to Spin was fairly tough for many people. Instead, we've been working on our new Propeller C learning system, which includes simple libraries to make programming the Propeller as easy as programming the BASIC Stamp! The intention is that people will be able to progress through robotics platforms using a common language.

The first robot, the ActivityBot, will be released later this fall. In the meantime, we have a whole host of circuits and devices tutorials available on learn.parallax.com. Let me know if you're interested in a robot when it's released, I'd be happy to send one your way!

Jessica

Thank you Jessica; I understand the issues, wish I knew about it sooner. I do appreciate having the files, we will for sure look into the possibility of re-creating enough of the chassis to meet our needs in the short term.

No problem with the plug - always on the look-out for new robots and platforms. I also agree about the PBASIC to Spin transition, which is why in my advanced robotics camp, Spin was skipped and we used C using the beta version of the SimpleIDE (I have used SimpleIDE for several projects and was rather familiar with it). In fact, I found C easier to explain than PBASIC, especially when having to explain why numbers can't get negative in PBASIC. I also like the idea of support libraries, as during this go around I had to build these myself.

The new robot looks interesting, like a Boe-Bot on steroids. Of course I would love having when the time comes! And hopefully, you are also looking towards a larger differential drive chassis that can fill the gap between the Boe-Bot and the Eddie. Will be on the look-out!

-Yiannis

For the sample just drop Jessica your shipping information.

There's another robot base coming that'll likely be able to leverage some of the Propeller C resources - a lower-cost MadeUSA base with molded plastic wheels. More on this to follow.

-MattG

On the other hand, a 1/4" MDF Stingray kit could be lasercut and would work quite nicely at asignificantly lower cost. I may have to try one..............

I went ahead and spun one off the laser out of 1/4" MDF to see how it would look. Here are some pics:

The lasercut "stingray chassis" from the previously posted zip file. Took almost 9 minutes to cut.

My Stingray, "Manta", with his new upper and lower decks. He is officially a "hybrid"

Due to the thicker chassis, I had to use new screws. 3/8" 4-40 would be perfect, all I had was 1" 4-40s leftover from the Rocka experiments.

Close-up showing the thicker chassis, 1/4" MDF versus the original 1/16" Anodized Aluminum

All in all, I think the 1/4" MDF option is definitely valid. Since MDF could be easily modified by the end user, you could reduce the amount of holes/slots to reduce laser time, which in turn would reduce cost.

edit: You could also make one from Delrin which should allow an 1/8" thickness and it would still be very sturdy. Laser time would improve as well. Material for a single Delrin plate would be $6-10 depending on 1/16" or 1/8". Not sure if you could go to 1/16" though.

Amanda

Cherry with maple accents and brass fittings would look mighty sporty, too!

I agree with Ken. If someone like yourself wants to create a kit we'd be happy to link to it and provide what support we can to get you going.

Speaking of which...:nerd:

I did just get back a quote for the metal. At a 100 piece MOQ, a full set of metal, grained and anodized per the drawing, would run an end user about $160 delivered (pure cost plus US shipping, no profit). Since the full Stingray chassis kit (that included motors, wheels, hardware) was being sold for $150, I don't think that would be an option of interest, except for die-hard Stingray enthusiasts. I also had them quote the parts as bare metal, thinking that the graining and anodizing was a large portion of the cost. That comes out to a full set of metal parts for $110 delivered. (again, pure cost plus US shipping, no profit). Much less, but the semi-shiny uncoated aluminum may not be of much interest either.

So, I am working with the place I had quote these to determine where costs can be cut, yet a cosmetically functional product will still be supplied. First item on the chopping block are the PEM nuts on the motor and sensor brackets. The install process for them is done manually and requires additional manual cleanup before anodizing. The PEM nuts can be replaced with KEP nuts at a much lower cost and yet achieve the same final result. I hope to have some more updates on a metal set in this manner by next Friday.

It's very kind of you to share Stingray drawings with us "Stingray Fans"

Would it be too much if I ask DWG versions of the files? I've been trying to find a way of converting these files to DWG format but to no avail.

Cheers,

Should work with most cad programs (verified with Autodesk Inventor and DraftSight).

Nice job, Kerry. That's a big help to everybody who wants to make their own Stingray, or if somebody chooses to start up some small manufacturing runs.

Dave