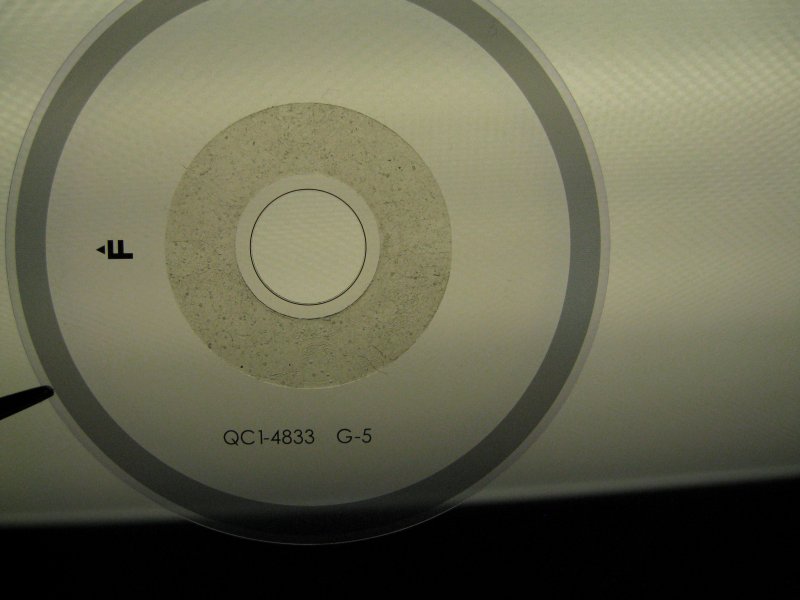

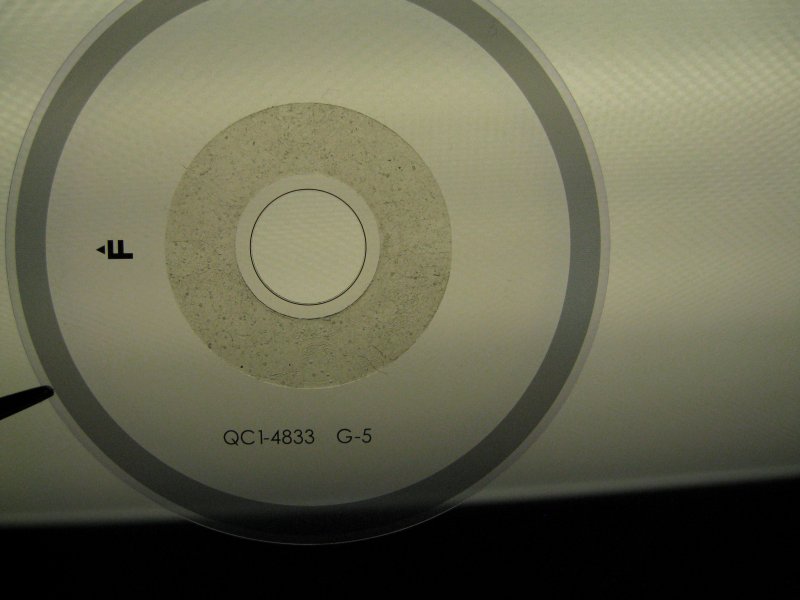

Mysterious rotation sensor disk

I had an old Canon iP4000 inkjet printer that quit working.

Thinking that I might be able to scavange some stepper motors and other parts, I took it apart.

I was surprised to see that there were no steppers - just various regular DC permanent magnet motors and IR/photoresistor sensors to precisely move the paper and inkjet carriage.

There are transparent disks glued to the gears and sensors positioned to monitor the track on the disks.

The strange part is that the track appears to be consistently the same darkness instead of alternate light and dark segments.

So how can this setup work???

Thinking that I might be able to scavange some stepper motors and other parts, I took it apart.

I was surprised to see that there were no steppers - just various regular DC permanent magnet motors and IR/photoresistor sensors to precisely move the paper and inkjet carriage.

There are transparent disks glued to the gears and sensors positioned to monitor the track on the disks.

The strange part is that the track appears to be consistently the same darkness instead of alternate light and dark segments.

So how can this setup work???

Comments

EDIT: a Google search for that part number in the Photo indicates a 'FILM, TIMING SLIT DISK" ... there may be fine marks in the grey area that you can not see. It produces a very fine quadrature signal to the receiver.

I looked at using a bright six Sony IR video camcorder light and could not detect any variation.

I thought maybe it had a dye that reacted to infrared light...

I also looked a crystal wine glass thru it - couldn't see anything there.

Curious...

Robert

If you have a flat bed scanner, place it on the scanner and set it for the finest resolution... I bet then you can see the marks... maybe.

Lawson

I did not find a strip type encoder. The sensors only have three wires - ground, v+ for the emitter and the wire to the photo sensor. If it was a quadrature setup it would need two emitter-sensor pairs.

It must really be high resolution! I need a microscope...

That disk looks just like the ones HP uses. Maybe Cannon is using something different. Do you have any pictures of the sensor that has the slot for this encoder disk? Maybe they were only using one channel. Very odd.

Robert

Since the same circuitry that reads the pulses from the encoder also controls the motor it does not need a quadrature signal to tell it what direction the motor is going.

I was thinking that exact thing before I saw your reply.

I set my scanner software to scan Positive Film and removed the back panel so the light would shine thru from the scanner cover.

I had a hard time getting the scanner software to recognize the "film" but finally scanned it at 1600 dpi.

You can see the lines now! Wow!!

"Since the same circuitry that reads the pulses from the encoder also controls the motor it does not need a quadrature signal to tell it what direction the motor is going." - True, but the same sensor can have two detectors built into one unit and have a single 'mask' with two sections one section purposefully aligned 90 deg out of Phase. The result is a high precision quadrature output ... available when it's needed. depends on the application.

It seems that a standard IR LED and sensor can handle such high resolution with the right firmware.

"I do believe that you guys are talking about Moir

Whatever the actual sensing these double-graters rely on diffraction and fringe effects to measure optical displacement. Because of the fineness of the optics, the encoder discs are virtually useless without their corresponding sensor. Good luck getting any information on the sensor.

-- Gordon

Have you tried shining a laser pointer through that grid? Just wondering if it's fine enough to get a diffraction pattern out of.

Then I made some small aluminum brackets and mounted the sensor next to it.

I identified the IR emitter leads ans have it working but I haven't hooked up the sensor yet.

The sensor has transparent windows on the top and bottom halves so you can see thru it.

There is a 100 ohm resistor in series with the IR emitter and capacitor

(which looks like a resistor with colored rings like a resistor) across the power and ground.

The sensor has four connections GND, V+ and two others I assume to be the sensor output(s).

More later...

It might be - I was looking at some other sensors when I stated that there were only three wires - there were actually five optical sensors in the printer.

Look up polaroid diffractive encoder and you'll find numerous patents from the late 80s onward regarding this stuff.

The industrial side of Canon makes/made a sensor of this type, but using a laser for its collimated beam. They are capable of over 75,000 transitions per revolution. Maybe there's a small picowatt laser in that thing, though more likely it's just an LED. In the high-end Canon encoders the output is a bi-phase sine wave -- a bit more work to interface than standard digital quadrature pulses.

This may be neither here nor there, but as yours was a Canon printer it makes sense they're using Canon sensors.

-- Gordon

Gordon,

I think you may be right.

I usually use my digital camera to view IR emitters since the camera sensor will pick up the IR frequencies, but I could actually see a red glow in the sensors with the naked eye - probably an LED.

I don't think I'm going to pursue it now. I was mainly interested in disk's characteristics.

I had no idea that such a high resolution was possible with these devices.

The other two disks are lower resolution - the lines are clearly visible.

In fact, they are marked 150 lpi - 150 lines-per-inch I assume...

I think I was trying to use the wrong sensor with the high resolution disk. Two of the modules are identical so they probably match the low resolution disks.

Thanks for everyone's input!

- Ron

I turned the disk slowly by hand and grabbed the image.

It does look like a quadrature encoder

If you can see a red glow it could be a near-IR laser -- they're not that expensive these days -- or it could be an LED with a very narrow output wavelength. The more coherent the light output the better. My money would be on a laser. They're actually cheaper in the long run.

Though I can't imagine many robotic applications would benefit from this resolution you've got a pretty nice encoder there!

-- Gordon

I used a BS2 to count pulses on one channel over a 2 second interval and tried to do 1 revolution.

It looks like approx 2500 pulses in 360 degrees!

'

I have the need for a high resolution encoder.

'

Now I know where to find one.(I have a couple old printers laying around I kept for parts)

'

Thanks for the thread and info.

With quadrature that'll resolve to 10,000 cpr. Great for your inkjet printing bot!

-- Gordon

That may be a bit of overkill for a robot wheel sensor but sounds great for a precision cnc system.

I'm going to start looking through some of my old printers for these. Thanks for posting the information.

Duane