Robot Base Kit - eDrawings and sample images

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

Hello,

You may recall a thread I posted over a year ago about the use of a CNC router inside of Parallax to cut wood material and collect the dust from the machining process. Although we're not cutting any plywood materials in the office, we've still designed a very functional enclosure and dust collection system around the Haas SR-100.

Now we're set up to cut all kinds of plastic material on the Haas CNC Router, such as solar panels kits, solar add-ons for the Boe-Bot, and of course the Robot Base Kit.

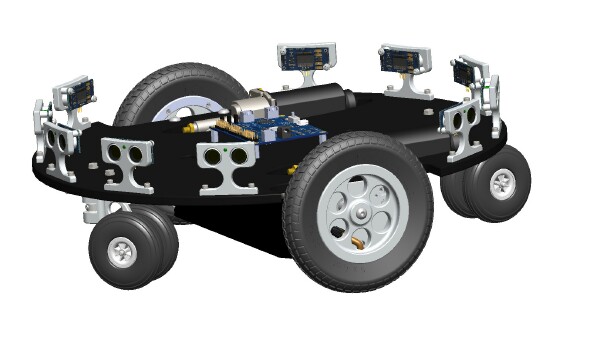

We will soon be switching the Robot Base Kit from 1/2" Apple Ply to 3/8" black HDPE. This is a far more sleek design and offers the same easy workability as a quality plywood.

If you have the plywood kit but prefer the black HDPE, I'll either provide you with the black HDPE version or provide it at a discount.

Some pictures are shown below, or if you prefer the eDrawing I've attached that as well.

Ken Gracey

Parallax Inc.

You may recall a thread I posted over a year ago about the use of a CNC router inside of Parallax to cut wood material and collect the dust from the machining process. Although we're not cutting any plywood materials in the office, we've still designed a very functional enclosure and dust collection system around the Haas SR-100.

Now we're set up to cut all kinds of plastic material on the Haas CNC Router, such as solar panels kits, solar add-ons for the Boe-Bot, and of course the Robot Base Kit.

We will soon be switching the Robot Base Kit from 1/2" Apple Ply to 3/8" black HDPE. This is a far more sleek design and offers the same easy workability as a quality plywood.

If you have the plywood kit but prefer the black HDPE, I'll either provide you with the black HDPE version or provide it at a discount.

Some pictures are shown below, or if you prefer the eDrawing I've attached that as well.

Ken Gracey

Parallax Inc.

Comments

I had recently purchased a couple extra of the plywood bases but these new ones out of black HDPE would probably work out much better for the robot. How much are the news ones going to cost?

Robert

Ken Gracey

Hey Robert, we're shooting for the same retail price. I haven't seen the actual costs of production yet, but we'll do our best to keep these reasonably-priced.

Ken Gracey

Thanks Ken!

You can't glue to HDPE! Black material isn't virgin, it's cheap regrind with lots of impurities! Bad mojo! Bad for your health! Makes your hair fall out in clumps!

But it matches my robot.....

Erco, Poor Cousin's manufacturing facility is your garage - open it up and blow the 10-micron dust right out in the 'hood! One aspect of the Dark Side is that it's also the Clean Side - aside from a few smells here and there the dust is mostly chips that are pleasantly collected.

One of the uses of HDPE is for plastic lumber. Just think of it as man-made lumber [with pigment] and you'll be more accepting of the whole idea. Or, how about those water bottles on your bicycle? Are they some kind of HDPE? Try making those out of plywood.

Poor Cousin, evolution comes naturally and you can't stop it. You and I need to put away our bell bottom pants sooner or later.

... I do not sense much "wood" in your Avatar...

-Matt

(and a little birdie told me that, for all you purists out there (Erco!) - white may be available too)...

Behold! - The Black HDPE Robot Base...

(available Real Soon Now)

Robert

Good afternoon Robert,

Available pretty quickly at this point. The CNC operator (AKA Scott) is trying to find a tool that can be used to automate the brushed finish. Once he's got that under control to the satisfaction of the internal Product Owner (Matt) we'll do a production run and replace all existing wooden bases in stock with the black HDPE.

If I had to guess, we can get one or two of these in your hands within a week.

Ken Gracey

Can we buy just the HDPE Base and Battery holder? I have all the fastners and want to keep my beautiful plywood too.

And I honestly need to order something anyway so I didn't have to pay a shipping charge on just my 99 cent Propeller Christmas Tree Ornament!

Oh, I must admit, it does look sharp, and per the responses here, you'll sell plenty.

I'm just a cranky old guy who's mired in my plywood & bandsaw ways. Plus, I enjoy the thrill of the hunt at Home Despot: trying to find a piece of plywood that isn't warped too badly.

So whatever you do, Bre'r Ken, don't even THINK about sending me one of these for Christmas with motors, wheels, and controllers. I couldn't take that!

erco, Matt tells me that the white version is approved for food use. Maybe I could send you one with a sizzling Christmas Steak, or a fruitcake and a knife. Ever had a real fortified, pressed-in-a-tin fruitcake?

As for what passes for commercial fruitcakes these days, they are the ultimate in recycling and regifting. No one ever eats them or even opens them, they just get put into the pile of emergency gifts, next to the bulk bag o' tube socks and all-in-one tools.

Not only Balance, but you could also carve a Turkey on it !

"Ebony and Ivory, live together in perfect harmony..."

Robert

Send me an e-mail and I'll get you what you need ASAP.

I agree about having a great project to do over Christmas break. I'm planning ahead as well.

Thanks, Ken Gracey

Sorry for the delay - I had to figure out how to get big pictures uploaded to the new Forums.

We've been working on the production methods of the Base Plates and I think we're there. One of the biggest challenges has been to get a consistent finish on both the top and bottom of the HDPE plates. The HDPE comes from the factory with blemishes, dings, and scratches which we need to minimize without removing too much material (like surfacing the entire surfaces with a large end-mill).

So we decided on a "brushed" finish that you can see below. The brushing gives the entire surface a texture that I call "consistent inconsistencies" - that is to say the whole thing is lightly *scratched*, giving it a slightly matte finish that minimizes the incoming defects, yet maintains full dimemsion. This results in a thicker platform - stronger - and less expensive blank, which means we can keep the cost down too.

We're in the middle of the first (limited) production run, and we should have the necessary hardware in by Tuesday, Dec. 7th.

What do you all think?

-Matt

Wow! Even I, the ultimate RYOR (roll your own robot) guy, think that looks good! All it needs is a Parallax WiFi module! (Ok. Excuuuuse me!

--Bill

It's laser-cut 1/4" thick transparent black acrylic. We've added some pre-drilled holes for mounting SLA batteries, as well as many of our standard 3"x4" pcb's.

The SLA that we're using is rated @ 12vdc @ 7.5ah.

The closely spaced groups of holes act as an "adjustable mounting system" for some slight dimensional variations between different brands of batteries.

The screw heads you see, go into 1/2" tall threaded stand-offs which hold the battery in place (visible below). The view below is "robot top-side up"...

and this is bottom side up.

The hardware is in, and we're trying to get some *early units* out the door in the next day or two.

Our *cracker-jack* machinest Scott came up with a way to improve the brushed finished even more than what the earlier pictures (above) reveal. -Matt

Is this in the store now so I can order one?

What size battery are you'all using?, and are you mounting it on the "battery shelf", and if so, how?

I use two 12V 7ah batterys mounted on the base. They are sideways with the terminals sticking out toward the motors. It's a tight fit but I can get both in there for twice the capacity. They are offset toward the rear a little bit to favor the rear castor being on the ground. After all, the wheel kit / base are heavy duty and can carry a lot. Why skimp on the battery and just use one. It really isn't that much more weight so go for it. Be bold and let it carry some more fuel for the motors and Propeller brain!

Since I'm still expanding my robot (moving to multiple Propellers and more sensors) I may still add another battery or two in order to ensure it has a nice heathly power source before it needs to feed again. Besides the extra weight in the base helps ensure my 5' tall beast stays upright and won't decide to topple over.

Robert

Robert

Click to see larger image.

That's my battery setup for the wood version. I have a separate small 7.2v R/C type battery that just "sits" on the top surface to power my robot controller board.

Anyway, here's a couple photos of mine: