Robotics Base for the 12V Motor Mount Wheel Kit (27971) and Caster Wheel (28971

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

Hey all,

Over the Christmas holidays I made a number of revisions (6-7) of a round robot base from high-quality, 9-layer solid wood core finish-grade plywood (the best plywood I could find within 100 miles of here). These were cut on an older ShopBot I found on Craig's List. It's a direct gear/pinion stepper arrangement so the resolution is about .003" which is fine for this kind of work. I made these bases because I think our customers need a quicker method of getting started (for a low cost) with the motor mount and wheel kits / caster wheels.

Why marry such fine aluminum machined products to a wooden base? Robotics is a personal hobby and everybody has their own preferences. As much as I'm an all-metal kind of crafter, maybe wood has a place in this application. It's one material that's easily workable with only minimal tools. It can be drilled without chipping, sanded and painted nicely with minimal skills, and produced at a very low cost. Within a few minutes you could have a robot platform ready to roll. Acrylic chips when drilled, metal isn't easy to work with, etc.

And what's with this round shape? Goofy-looking, I agree. But, round robots can free themselves more easily from chairs and other obstructions.

Some of the features of the robot base:

- 18" diameter

- 1/8" rounded bevel on all edges

- 12V Motor Mount and Wheel Kit + Encoders (27971) mount underneath the base with 1/4 x 20 stainless steel button head screws

- Drill patterns for one (or two) Caster Wheels (28971)

- Drill patterns for up to 10 Ping))) sensors using the Ping Protector Stand (725-28015)

- Battery platform for 12V 7AHr batteries mounts underneath motor mount bearing block with 1/4 x 20 stainless steel button head screws

The battery platform holds the battery in place, but doesn't prohibit it from fore/aft movement. You can secure the battery by mounting a small piece of angle aluminum on either side of the platform.

The goal was to provide the minimal number of holes and decisions necessary, leaving plenty of customizing and work for the robo-head. For example, no holes were drilled for HB-25s, Parallax 3x4 boards (BOE, Prop Proto Board, BASIC Stamp Super Carrier, etc.). There is plenty of room underneath to mount CCFL tubes for full-on 'bot pimping, too. This is certainly not an attempt to make a new standard in robot bases, as your craftsmanship and experimentation is what the hobby is all about. But, I hope that these bases will at least get people started more quickly.

Until we put a professional ShopBot or ShopSabre CNC router in Parallax, these platforms are coming from my garage (limited production capacity). We'll set up a gantry mill at Parallax as soon as we clear out a storage space (our former chip programming room). For now, we have 20 sets available at $29.99 and I can make another run as necessary. Until the marketeers get this on the web you'll just need to call our Sales staff and ask for one of "Ken's wooden robot platforms from his office desk" and tell them to sell it to you "non-stock". They should get these on-line by the end of the week at which time they'll have a part number.

What you get in the kit:

- 18" round robot base

- Battery pack platform

- (4) 1/4 x 20 3/4" stainless steel cap screws for mounting the motor mount bearing blocks to robot base

- (4) 1/4 x 20 1/2" stainless steel cap screws for mounting the battery pack platform to bottom of motor mount bearing blocks

- (6) 6-32 x 7/8" socket cap screws + nylon lock nuts for mounting two caster wheels to robot base

The drawings are provided under Creative Commons 3.0 license - use them freely and cut your own robot base if you wish.

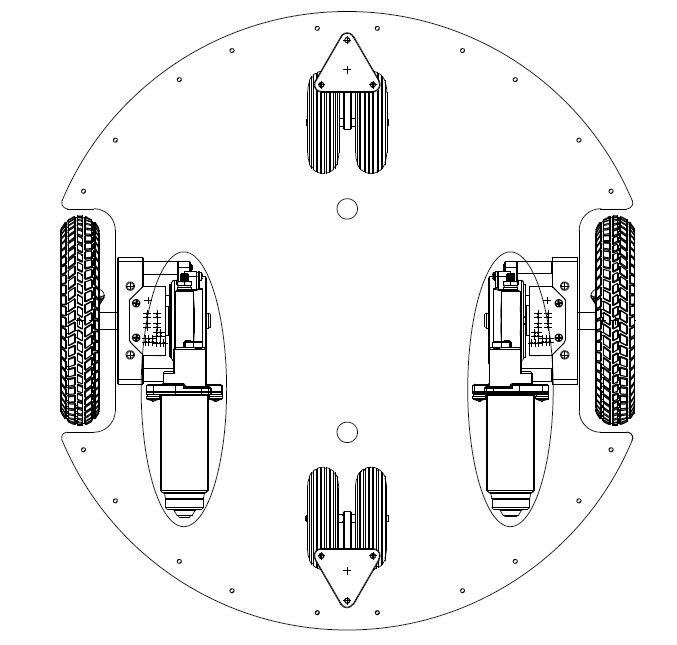

I know you'll want a photo of a built-up robot. I can't wait to build one from these bases so it shouldn't be too long before I provide more photos. But for now you can get a general idea of what this looks like from an older photo I have attached (a smaller, 16" diameter base).

Hope some people find this useful.

Sincerely,

Ken Gracey

Parallax Inc.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Ken Gracey

Parallax Inc.

Follow me at http://twitter.com/ParallaxKen for some insider news.

Post Edited (Ken Gracey (Parallax)) : 3/26/2010 2:01:35 AM GMT

Over the Christmas holidays I made a number of revisions (6-7) of a round robot base from high-quality, 9-layer solid wood core finish-grade plywood (the best plywood I could find within 100 miles of here). These were cut on an older ShopBot I found on Craig's List. It's a direct gear/pinion stepper arrangement so the resolution is about .003" which is fine for this kind of work. I made these bases because I think our customers need a quicker method of getting started (for a low cost) with the motor mount and wheel kits / caster wheels.

Why marry such fine aluminum machined products to a wooden base? Robotics is a personal hobby and everybody has their own preferences. As much as I'm an all-metal kind of crafter, maybe wood has a place in this application. It's one material that's easily workable with only minimal tools. It can be drilled without chipping, sanded and painted nicely with minimal skills, and produced at a very low cost. Within a few minutes you could have a robot platform ready to roll. Acrylic chips when drilled, metal isn't easy to work with, etc.

And what's with this round shape? Goofy-looking, I agree. But, round robots can free themselves more easily from chairs and other obstructions.

Some of the features of the robot base:

- 18" diameter

- 1/8" rounded bevel on all edges

- 12V Motor Mount and Wheel Kit + Encoders (27971) mount underneath the base with 1/4 x 20 stainless steel button head screws

- Drill patterns for one (or two) Caster Wheels (28971)

- Drill patterns for up to 10 Ping))) sensors using the Ping Protector Stand (725-28015)

- Battery platform for 12V 7AHr batteries mounts underneath motor mount bearing block with 1/4 x 20 stainless steel button head screws

The battery platform holds the battery in place, but doesn't prohibit it from fore/aft movement. You can secure the battery by mounting a small piece of angle aluminum on either side of the platform.

The goal was to provide the minimal number of holes and decisions necessary, leaving plenty of customizing and work for the robo-head. For example, no holes were drilled for HB-25s, Parallax 3x4 boards (BOE, Prop Proto Board, BASIC Stamp Super Carrier, etc.). There is plenty of room underneath to mount CCFL tubes for full-on 'bot pimping, too. This is certainly not an attempt to make a new standard in robot bases, as your craftsmanship and experimentation is what the hobby is all about. But, I hope that these bases will at least get people started more quickly.

Until we put a professional ShopBot or ShopSabre CNC router in Parallax, these platforms are coming from my garage (limited production capacity). We'll set up a gantry mill at Parallax as soon as we clear out a storage space (our former chip programming room). For now, we have 20 sets available at $29.99 and I can make another run as necessary. Until the marketeers get this on the web you'll just need to call our Sales staff and ask for one of "Ken's wooden robot platforms from his office desk" and tell them to sell it to you "non-stock". They should get these on-line by the end of the week at which time they'll have a part number.

What you get in the kit:

- 18" round robot base

- Battery pack platform

- (4) 1/4 x 20 3/4" stainless steel cap screws for mounting the motor mount bearing blocks to robot base

- (4) 1/4 x 20 1/2" stainless steel cap screws for mounting the battery pack platform to bottom of motor mount bearing blocks

- (6) 6-32 x 7/8" socket cap screws + nylon lock nuts for mounting two caster wheels to robot base

The drawings are provided under Creative Commons 3.0 license - use them freely and cut your own robot base if you wish.

I know you'll want a photo of a built-up robot. I can't wait to build one from these bases so it shouldn't be too long before I provide more photos. But for now you can get a general idea of what this looks like from an older photo I have attached (a smaller, 16" diameter base).

Hope some people find this useful.

Sincerely,

Ken Gracey

Parallax Inc.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Ken Gracey

Parallax Inc.

Follow me at http://twitter.com/ParallaxKen for some insider news.

Post Edited (Ken Gracey (Parallax)) : 3/26/2010 2:01:35 AM GMT

Comments

- Ken

I think it would be pretty cool if you guys made a kit for this that had the motors, wheels, castors, HB25s, and a controller board. Sort of like a big brother to the Stringray.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Check out the Propeller Wiki·and contribute if you can.

12V Motor Mount and Wheel Kit $279.99

HB-25s 2@ $49.99

Caster Wheels 2@79.99

That's $540 and the Ping))) are not added.

With ten (10) Ping))) sensors and Ping Mounting Bracket the cost could climb to $700.

And then we could offer a discount, of course.

Still not much compared to R/C toys, and there's often a heck of a lot more satisfaction and learning from a quality robot.

Ken Gracey

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Check out the Propeller Wiki·and contribute if you can.

Looks great!

I was going to make a base out of Dupont Corian. But it turns out you can't buy unless it is intalled by factory authorized companies.

I like your wooden platform and I like the zero turning radius design too.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Whit+

"We keep moving forward, opening new doors, and doing new things, because we're curious and curiosity keeps leading us down new paths." - Walt Disney

Post Edited (Whit) : 1/3/2010 12:52:52 AM GMT

What you describe is a a real racket - anybody should be able to buy that stuff. Have you checked eBay?

I bet we can find some. . . wonder if it would cut well on the CNC router [noparse]:)[/noparse]

Ken

http://www.cuttingboardcompany.com/cuttingboards.asp?id=3

Also, talk about "pinping your bot", imagine how those CCFL tubes would look under that translucent HDPE deck or in routed grooves cut into the top of the deck!

Duffer

Post Edited (Duffer) : 1/3/2010 3:18:42 AM GMT

Thanks for the ideas! Ken, I did know that you could get scraps, but the closest to me is about 100 miles away. I should not have been so easily put off. Duffer, I did think about cutting boards, but I couldn't find a color I like or a big enough board. I should have googled it! Thanks for the link.

I like the idea of either for several reasons. I thing it would be easy to work with saw, drill and route. They use a router to round the corners of countertop and at sinks. I like the color through the material, non-condutivity, rigidity but slight flexibiltiy. Look at the cool colors of the Corian here - http://www2.dupont.com/Surfaces/en_US/products/corian/new_colors.html I was thinking Nocturne, Cobalt, or even Mardi Gras,·but lots of colors would work including some of the bright solid colors.

Duffer - these cutting boards are really good option with all the advantages of the Corian. I like the thickness too. I think that 1/2 would be a minimum - this is also available in the Corian.

Thanks for getting me excited again. I start working and then get distracted, till something gets me fired up again. I got the 12 volt motors for something really cool - robotic wise -·and wanted the platform to be equally as neat as the wheels. I probably should have built a test platform in something quick and easy to work our other issues, but I didn't.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Whit+

"We keep moving forward, opening new doors, and doing new things, because we're curious and curiosity keeps leading us down new paths." - Walt Disney

Post Edited (Whit) : 1/3/2010 1:42:36 PM GMT

If you send me the material of your choice I'll cut whatever you want on my CNC router. Or, if you prefer one of the wooden bases above just make the request and I'll get one off to you quickly. I didn't realize you were still sitting on a set of 12V Motor Mount + Wheel kits - we need to put those to use so you have a great demo for the kids.

- Ken

Thanks for the kind offer! I will be in touch...

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Whit+

"We keep moving forward, opening new doors, and doing new things, because we're curious and curiosity keeps leading us down new paths." - Walt Disney

Ken Gracey

They bases are beautiful. I like the wood and the paint looks fantastic!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Whit+

"We keep moving forward, opening new doors, and doing new things, because we're curious and curiosity keeps leading us down new paths." - Walt Disney

Hmmm. Maybe my Poor Cousin robot needs a duct-tape racing stripe to "keep up with the Graceys".

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

This particular robot is going to Phil Pilgrim when it is finished (except for wiring, which I'll leave for him to do). The hope is that Phil will write us some useful and simple GPS waypoint navigation code for this robot. Knowing him, he'll probably write a sweet little Perl GUI to download the waypoints to the robot. We'll see what he does in a couple of months.

Ken Gracey

Parallax Inc.

-Phil

That bot is looking great. I can't wait to see what Phil does with this. Sounds like he is already thinking...

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Whit+

"We keep moving forward, opening new doors, and doing new things, because we're curious and curiosity keeps leading us down new paths." - Walt Disney

I live in N. California in the Sierra Nevada mountains at 6,700 feet. About 12 miles from my home is the regularly recorded deepest annual snowpack in the continental USA at Donner Summit along I-80. Snow covers the ground for more than half of the year in a strong winter. While you sweat it out in the storage locker I'm probably freezing in the mountains.

The CCFL tubes haven't posed a problem for any of my electronics. Aside from the 12V 300 mA current draw they only generate a little bit of warmth.

Poor cousin could be outfitted with CCFL tubes, too. I'll contact erco and see what he wants to add some flair to his robot.

Ken Gracey

Post Edited (Ken Gracey (Parallax)) : 1/5/2010 5:47:11 AM GMT

Price is $29.99.

Preliminary documentation is attached, too.

Ken Gracey

Parallax Inc.

300 mA@12V to power the CCFLs? That's more power than one of PC's drive motors uses at 12V! Stall current is just 500 mA. Efficiency-wise, my PC is more like a Prius.

I gotta have something on SuperBot. [noparse]:)[/noparse]

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

Ken Gracey

Parallax Inc.

www.parallax.com/tabid/145/ProductID/635/Default.aspx

All your base are belong to us.

Have a great weekend.

Cheers, JJ

You go ahead and bump this thread all you want. Your CNC'ed platform is gorgeous, but my homebuilt robot thread is gaining momentum. People are sharing photos and details of their handmade creations and they are amazing! I hope everyone who has ever built their own robot posts there. I think the homemade crowd thread may surpass you in total views and posts over the weekend. Let the games begin! [noparse]:)[/noparse]

erco

PS: Did you see the centerfold someone posted at http://forums.parallax.com/showthread.php?p=869446·???

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

Post Edited (erco) : 1/9/2010 12:06:34 AM GMT

Maybe by then you guys can work out a package for the motor/wheel kit, 2x HB-25s, 2x casters, and 10 pings with brackets? [noparse]:)[/noparse]

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Check out the Propeller Wiki·and contribute if you can.

This particular robot is destined for Phil Pilgrim, in hopes that he does some GPS work for us using the robot base kit. Lucky guy, isn't he?

Ken Gracey

Parallax Inc.

Now the onus will be on me to meet Ken's expectations for this project. Oh, the pressure! [noparse][[/noparse]hyperventilates]

Seriously, this will be some major fun. Thanks, Ken!

-Phil

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Check out the Propeller Wiki·and contribute if you can.

Thanks for the interest!

Ken

I am also glad to see the base up on the Parallax site too.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Whit+

"We keep moving forward, opening new doors, and doing new things, because we're curious and curiosity keeps leading us down new paths." - Walt Disney

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Check out the Propeller Wiki·and contribute if you can.