Considerations for putting your design into production.

Have you ever considered taking your small project from your own use, and putting on the market to sell?

Well if you have, here are a few things to consider.

The above are good references to anyone thinking about production. It is a good habit to put fiducials on your boards. It is much easier to put them on early and avoid them, rather than trying to fit them later.

The only other consideration is lead or no-lead. Any board which could be sold to overseas customers should comply with RoHS. This would mean the board, plating, solder and parts must comply with RoHS. If working to sell items, it is easier to start in the beginning with RoHS and not try to convert later. Some components are not available in all packages(QFN,QFP,DIP, etc) to comply with RoHS.

I post this information for everyone. Anyone can create a gadget that others may want, and if you do, pre-planning can save a lot of headaches.

James L

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

James L

Partner/Designer

Lil Brother SMT Assembly Services

Well if you have, here are a few things to consider.

- 1. Everyone doesn't think a like, so when preparing your board, make sure you mark the parts with polarity (Silk screen is not an absolute necessity, an assembly file can accompany your board which contains an image of the board with parts and polarity). Make sure the assembler knows the method of marking (positive, negative, or both depending on the component)

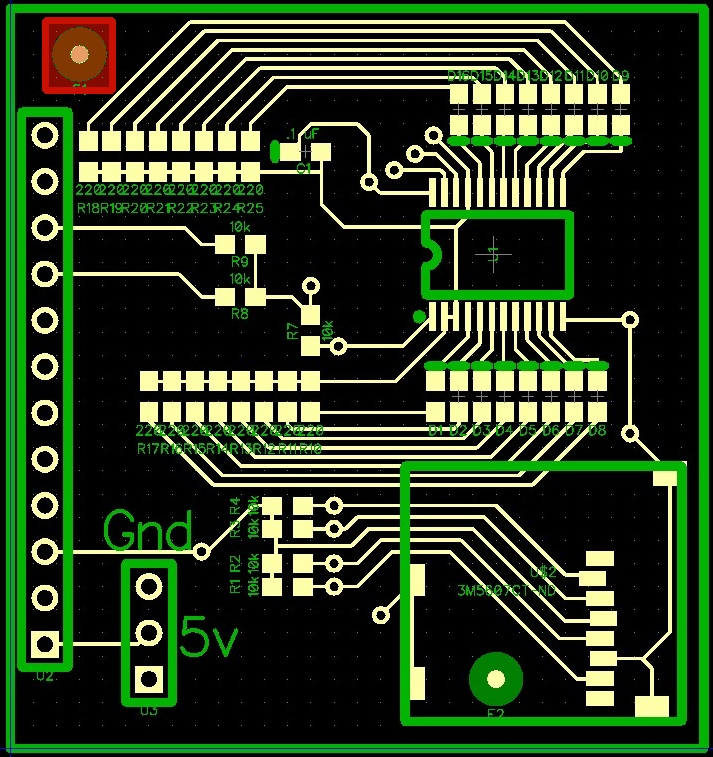

- 2. If you want to have the boards assembled with a "Pick & Place", the machine needs to have a reference to the board. This is done with fiducials (red highlighted part of the image included). Different companies use different sizes, you may need to ask your assembler what sizes that accept.

- 3.Decided if you want to participate in any part of the process. Different companies offer different levels of service, from basic assembly to full turn key items.

The above are good references to anyone thinking about production. It is a good habit to put fiducials on your boards. It is much easier to put them on early and avoid them, rather than trying to fit them later.

The only other consideration is lead or no-lead. Any board which could be sold to overseas customers should comply with RoHS. This would mean the board, plating, solder and parts must comply with RoHS. If working to sell items, it is easier to start in the beginning with RoHS and not try to convert later. Some components are not available in all packages(QFN,QFP,DIP, etc) to comply with RoHS.

I post this information for everyone. Anyone can create a gadget that others may want, and if you do, pre-planning can save a lot of headaches.

James L

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

James L

Partner/Designer

Lil Brother SMT Assembly Services

doc

41K

Comments

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

As I understand it, and I may not fully, an item only needs to be tested if it uses voltage between 50 and 1,000 volts AC or 75 and 1,500 volts DC. Or if the item uses the radio frequency spectrum.

I may be wrong, but this is what the CE regulatory website states.

James L

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

James L

Partner/Designer

Lil Brother SMT Assembly Services

www.berr.gov.uk/whatwedo/sectors/sustainability/regulations/cemark/page11646.html

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

Thanks for the information. I have an associate in the UK checking on the regulations to our newest design. He will be able to wade through the regulations better than I. He deals with them everyday.

James L

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

James L

Partner/Designer

Lil Brother SMT Assembly Services

I was talking with an old friend one time about hobbies and the toys people pride themselves on. He said a lot of people talk about their possesions, but most people where actually slaves to their possesions. And these things actually owned them!

Yes, I hope to have a product some day that's desirable. Build a better mouse trap and all that! But if you don't prepare to let it take care of you[noparse]:([/noparse] ie: by·making it a turn-Key product that you simply place an order for.) then your days will be spent constantly taking care of it!

It's nice to look on the forum and get answers to my questions, but it's shear grace to find the questions I didn't know to ask!

There is a larger amount of money invested in parts, boards, and the cost of assembly. There are assembly companies that will help out the customer to understand all the small issues, but some assume you understand the whole process. An assembler that will take time to help a customer or explain the requirements is what a new comer really needs. There are documents that can be read to understand, but even then, sometimes it's like reading a different language.

We try to help anyone, even if they end up using someone else. There is no need to be intimidated of the process.

I find the biggest intimidation for myself (even I have apprehension), I may have made a mistake on the board. I would be assembling a large number of paperweights. Unfortunately, at times this will happen. We recommend at least a few production prototyped be built (at home) by the customer before having an assembly run done.

Also, many have issues with trust when it comes to assembly. It is a fact, any assembler which did something untrustworthy (copied or shared your design), wouldn't be in business very long. Word can spread fast if a customer has been wronged in the trust department.

So, anyone who reads, don't be afraid to think about entering the market place with your design. You only need a project someone else will buy.

James L

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

James L

Partner/Designer

Lil Brother SMT Assembly Services