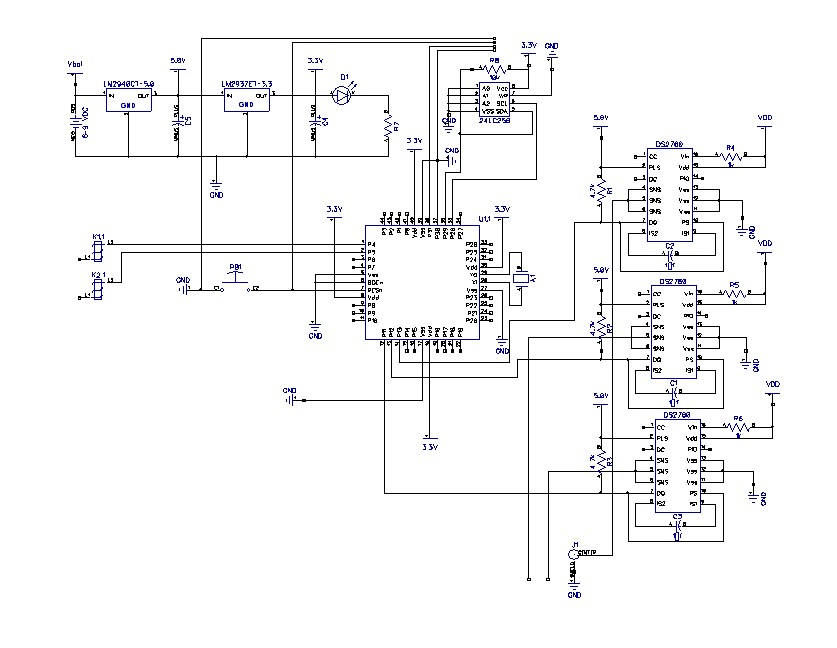

First Attempt at a schematic

I have been playing around with Diptrace and ExpressPCB. I think I am going to settle on diptrace. Anyways, attached is a my first attempt at a schematic. there are a few little things missing still as I haven't found/made the symbols I need. I would like to know if I am on the right track. This layout basically will use 2 thermocouples, and an inline ph meter to take readings which will be used to control 2 relays one runs a pump, the other runs a gas valve to control heat.

Greg

-edit

added a higher res jpeg

Post Edited (Greg LaPolla) : 2/26/2009 6:32:08 AM GMT

Greg

-edit

added a higher res jpeg

Post Edited (Greg LaPolla) : 2/26/2009 6:32:08 AM GMT

Comments

Greg

As mctrivia said it's good practice to add those decoupling caps but make sure that they are as intimate to the supply pins of the IC as possible. It cost nothing to design them in even if you don't need them all.

*Peter*

http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=PCC1762TR-ND

Thanks for the reply. The relays are solid state with and led circuit that can be driven by as little as 3 volts. Its safe as far as I can see. I posted about it earlier here

*Peter*

May even produce enough noise to get the FCC's attention ... pure speculation of course [noparse]:)[/noparse]

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

--Steve

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

are you saying that caps should be placed between the crystal and the prop? on XO or XI or both? or should caps just be placed on the VDD's on the prop?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

A note on your schematics. Positive supplies should always be to the top and ground to the bottom (not sideways or upside down). When you ave multiple supplies, always label the voltage (not Vdd) as it makes your circuit easy to follow. And you should always have decoupling capacitors close to the power pins on each IC. Hobbyists often get away without them, but if you get strange results it can be a pain to debug.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Links to other interesting threads:

· Home of the MultiBladeProps (SixBladeProp)

· Prop Tools under Development or Completed (Index)

· Emulators (Micros eg Altair, and Terminals eg VT100) - index

· Search the Propeller forums (via Google)

My cruising website is: ·www.bluemagic.biz

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"I have always wished that my computer would be as easy to use as my telephone.· My wish has come true.· I no longer know how to use my telephone."

- Bjarne Stroustrup

is 0403 a type of cap ? also should this cap go between vss & vdd or just vdd to gnd ?

0403 is a size of surface mount component very small. I normally work with 0603 components as they are easy to work with and still very small. you still need twezers though

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

Round 2. I made some changes. Regarding the feedback. See attached.

My next item to attack is surface mount. I an kinda old school when it comes electronics. I learned from my Grandfather on tube TV's and ham radio's back in the seventies.

Is there some documentation or websites with data relating to this as to determining what is needed? I assume since they are so damn small they don't use color codes anymore.

I have been watching ebay and seeing small soldering ovens and rework stations in the 300-400 dollar range. That seems to be a fair price. Is surface mount somthing that is easy to do with the right equipment or should I just contract the whole thing out? I would like to keep the cost of this little project as low as possible. However there is a small possibility that what I am creating could spark some interest in my little circle of friends so there may be a need to make a few more than what I need.

Greg

If you are doing a lot of surface mount I highly recomend spending the extra money and buying the JBC AD2700 its ability to heat up instantly and change tips while hot is a life saver. With surface mount you need to change tips for different size and shaped components. The tips are very expensive but I have not had to replace one yet. Unlike welers tips that i use to change weekly.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

Do you work solely with this or do you also use an oven ?

Greg

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod $50CAN has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module.

I need to do some research about smt before I take the next step.

Post Edited (Greg LaPolla) : 2/27/2009 5:21:32 AM GMT