For reference this is the circuit I used for the SD on this board - it follows the same pin order as initially given in the SD card thread, although I didn't add the SD power LED to the 8th pin in this case as it is hidden inside the cartridge but I did include the general purpose LED on the 7th pin (also useful for debugging when standalone - eg. to find the xtal osc problem I had). Because I didn't have the power LED I just included a 1k8 to ground from the SD power supply to discharge the caps faster when the FET is turned off.

The V_USB and SENSE signals are not part of the SD stuff, they just happened to make use of a spare 22k resistor I had nearby for sensing 5V on the USB-C cable that can be optionally plugged-in.

Discharge resistor isn't needed. The power LED stops conducting very early in discharge curve. The driver software pulls all the DAT and CMD pins low to drain caps. It takes about 37 28 milliseconds via the five 22 kR resistor paths.

PS: The level is monitored on the CLK pin so if it takes longer then no issue.

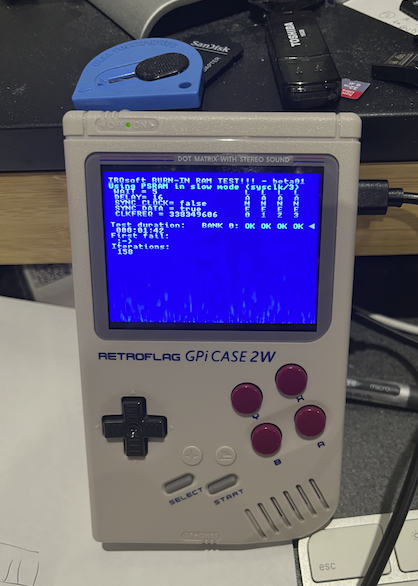

Our external power feed resistor has now been cut and it runs the SD card test from inside the GPi case on it's internal Lipo powered 5V supply, with USB-C plugged directly into the cartridge. No more external supply shorting risk.

Now I just need to context switch back to messing with all the prior NeoYume settings etc - am a bit rusty for all that as it was several weeks ago now and I've been in HW mode since.

@evanh said:

Actually, if you turn on -D SD_DEBUG it'll report how quickly the power-down happened.

Just ran it again. But I see it did report some CMD10 errors before things ultimately worked, are they important?

( Entering terminal mode. Press Ctrl-] or Ctrl-Z to exit. )

clkfreq = 128000000 clkmode = 0x10001fb

SD card driver (4-bit SD mode) v1.12

sdsd_open: using pins: 53 52 48 55 54

Card detected ... power cycle of SD card

power-down threshold = 37 pin state = 1

power-down slope = 29633 us pin state = 0

SD clock-divider set to sysclock/320 (400 kHz)

Card idle OK

OCR register 80ff8000 - SDSC Card

Data Transfer Mode entered - Published RCA 1ff30000

CID register backed up

4-bit data interface engaged

Speed Class = C4 UHS Grade = U0

Video Class = V0 App Class = A0

Cache = 0 Queue = 0

TRIM = 0 FULE = 0

Card User Capacity = 1920 MB (1.88 GB)

High-Speed access mode engaged

SD clock-divider set to sysclock/4 (32.0 MHz)

. CMD10 error!

. CMD10 error!

. CMD10 error!

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

rxlag=8 selected Lowest=4 Highest=11

CID decode: ManID=02 OEMID=TM Name=SD02G

Ver=3.2 Serial=a8ab6696 Date=2008-4

SD Card Init Successful

/sd1 handle = 105f0 ... mounted

@rogloh said:

Just ran it again. But I see it did report some CMD10 errors before things ultimately worked, are they important?

Thanks. Those errors are complete normal, it's the calibration routine making use of the regular command/response functions to find the good/bad boundaries of rxlag setting.

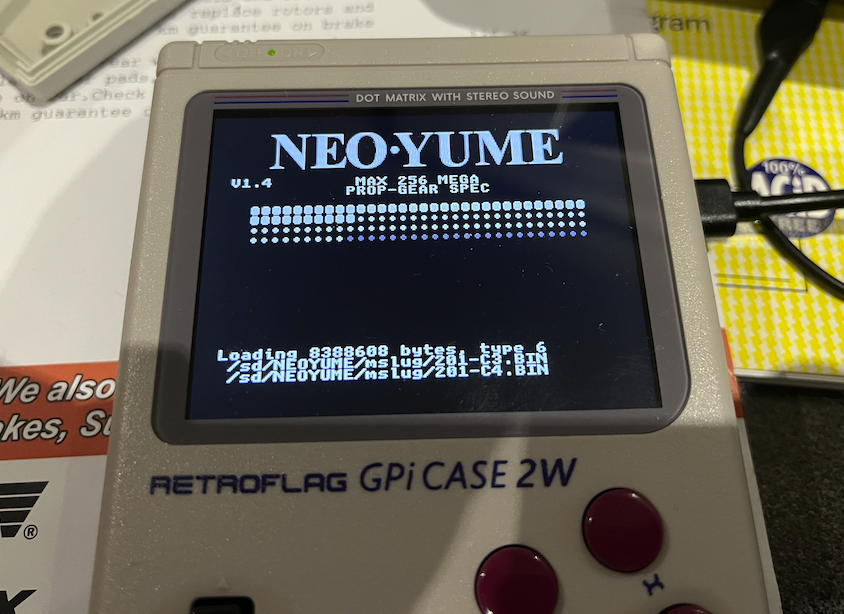

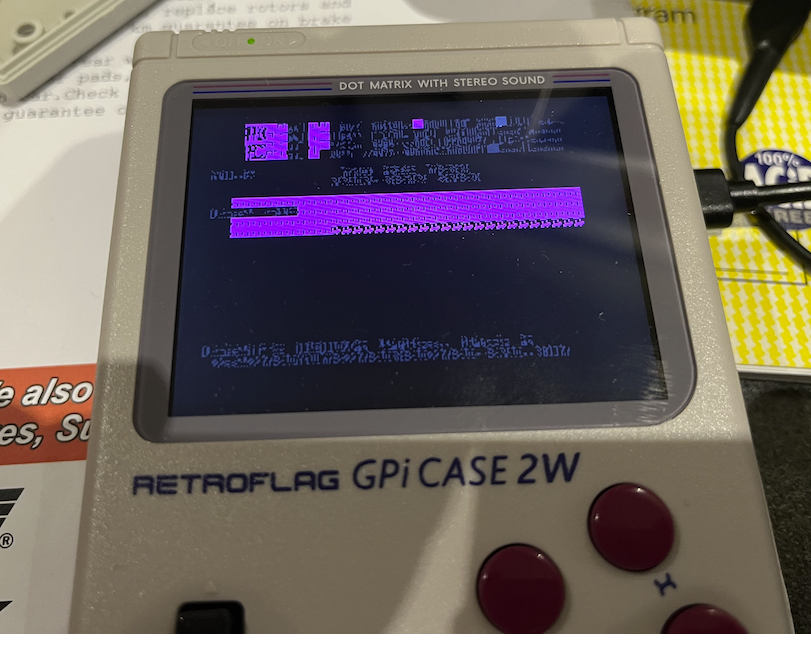

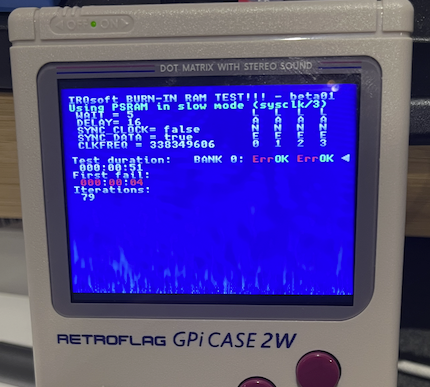

@Wuerfel_21 I have ported your emulators to my updated HW and ran into some issue after loading screen. Screen changes and freezes and looks like this once MSLug gets loaded. I tried with 4 bit SD initially then backed off to original SPI mode but effect is the same. Using PSRAM timing same as edge but also tweaked up and down a few clocks without help.

It did load up once the very first time and let me get into the initial in-game MSlug menu and played sound fx etc but locked up just before it would have started actual gameplay when I wanted to start it.

Wondering if PSRAM settings might cause this, or actual overheating...?

Didn't you have a RAM test app that ran when the other Cogs were running sprite stuff at rated game clock speed? That could potentially be useful to debug this issue.

EDIT: wow the boards are HOT. Just took them out of the case to see how warm. Would be worth adding a thermocouple into the housing if I can fit it in while game is running. Even though my board is transferring some P2 heat too, I think an actual heatsink plate is going to be needed. Might also explain why it seemed to work the first time but not afterwards (once it had warmed up a lot). Also when I ran the memory test again now when things were warm I got worse values vs prior run.

@rogloh said:

@Wuerfel_21 I have ported your emulators to my updated HW and ran into some issue after loading screen. Screen changes and freezes and looks like this once MSLug gets loaded. I tried with 4 bit SD initially then backed off to original SPI mode but effect is the same. Using PSRAM timing same as edge but also tweaked up and down a few clocks without help.

You did try tweaking the sync/async settings, right?

It did load up once the very first time and let me get into the initial in-game MSlug menu and played sound fx etc but locked up just before it would have started actual gameplay when I wanted to start it.

Wondering if PSRAM settings might cause this, or actual overheating...?

Hard to decisively distinguish. But looks to me moreso like PSRAM fail rather than P2 core fail.

That the screen changes when trying to boot is normal, on startup the menu fix graphics are kicked out in favor of the game's fix graphics.

Didn't you have a RAM test app that ran when the other Cogs were running sprite stuff at rated game clock speed? That could potentially be useful to debug this issue.

yes. Will need to drop the customized NeoVGA into this.

Note that this doesn't just test PSRAM integrity, but is also really hard on the P2. If it doesn't run properly or locks up, that's a P2 core fault. Bad PSRAM only ever leads to red FAIL prints.

@rogloh said:

EDIT: ... I think an actual heatsink plate is going to be needed.

And now a whole other hand-warmer engineering exercise begins.

If a suitable part is modelled, we could potentially then create a 3d printed metal backshell in the same profile as the plastic (or squeezes just under the existing plastic) and contacts the P2 - this would give a large surface area to spread/radiate the heat. But whether stainless steel is as good enough a heat conductor vs Al or Cu not sure.

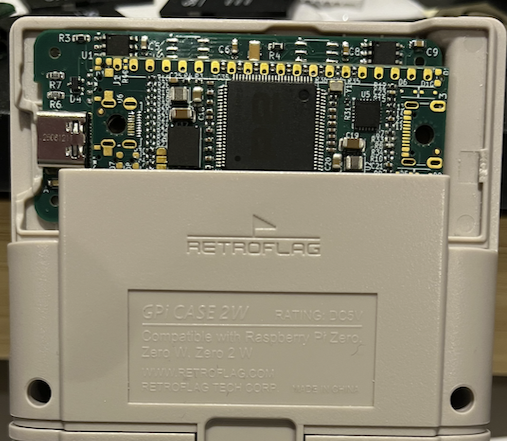

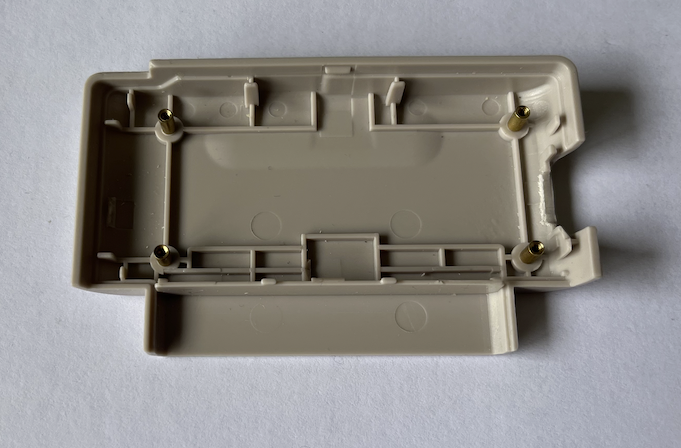

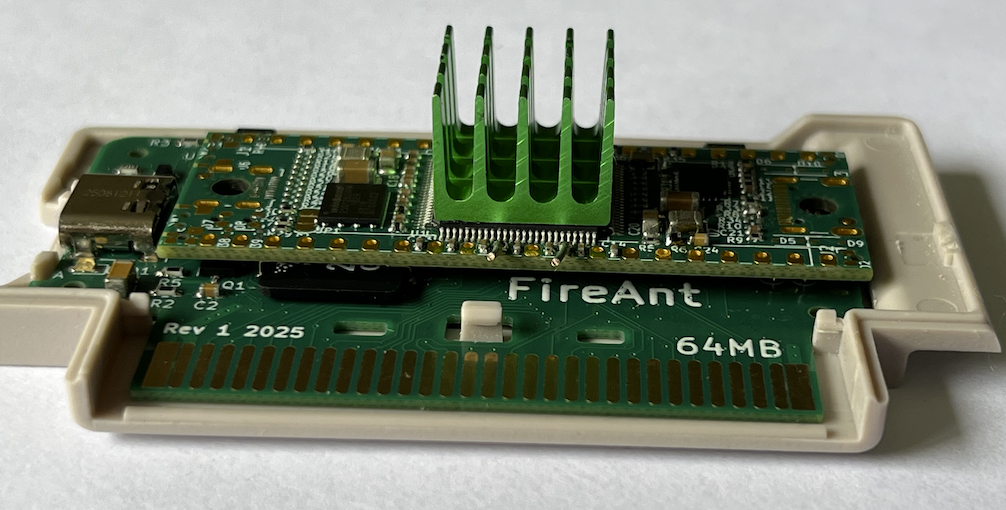

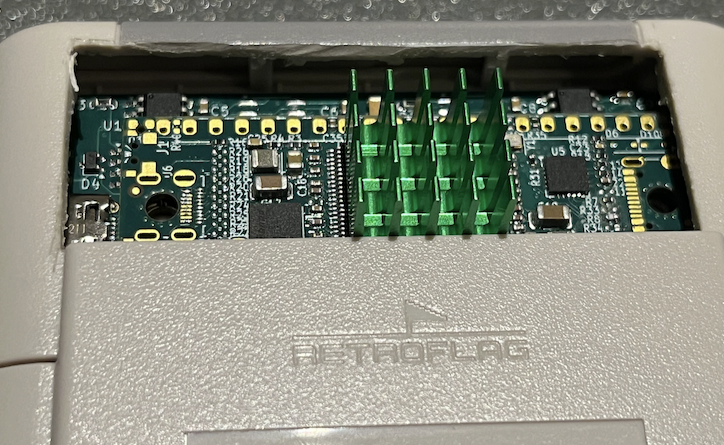

Existing cartridge shell looks like this inside. There's probably a 2-3 mm gap above the components on Lachlan's P2 board to the back surface, so enough room for a custom metal plate. It could also go though to the outside of the plastic at the back with fins in the worst case. But ideally it could retain the same external size for a cleaner look.

@Wuerfel_21 said:

You did try tweaking the sync/async settings, right?

Yeah, tried a few combos but was not exhaustive at every single nearby delay step - could retry again.

@rogloh said:

Didn't you have a RAM test app that ran when the other Cogs were running sprite stuff at rated game clock speed? That could potentially be useful to debug this issue.

yes. Will need to drop the customized NeoVGA into this.

Note that this doesn't just test PSRAM integrity, but is also really hard on the P2. If it doesn't run properly or locks up, that's a P2 core fault. Bad PSRAM only ever leads to red FAIL prints.

Ran MSlug with the back open for over 8mins before it locked up. Temp started out at ambient 19C and then rose to ~64C on the hottest part detected by my infrared thermometer when pointing towards the P2. I think this is probably a thermal issue. I might try blowing air on it while playing and see how it behaves and whether it lasts even longer before failing, if it even does fail with that. I could also try to add a heatsink from a RasPi kit or similar as another test.

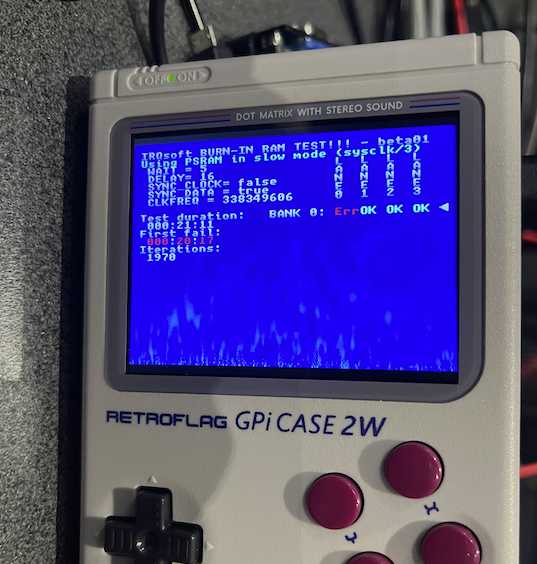

This test was run with the slow PSRAM clock enabled (sysclk/3) and a 16 clock delay according to these config.spin2 settings.

@rogloh said:

EDIT: ... I think an actual heatsink plate is going to be needed.

And now a whole other hand-warmer engineering exercise begins.

If a suitable part is modelled, we could potentially then create a 3d printed metal backshell in the same profile as the plastic (or squeezes just under the existing plastic) and contacts the P2 - this would give a large surface area to spread/radiate the heat. But whether stainless steel is as good enough a heat conductor vs Al or Cu not sure.

Aluminium is the way. Cheap, easy to work, lightest weight of the three, and does a good job as a heatsink. Anodise it for looks and wear resistance, then maybe add plastic handles or similar where it gets a lot of wear.

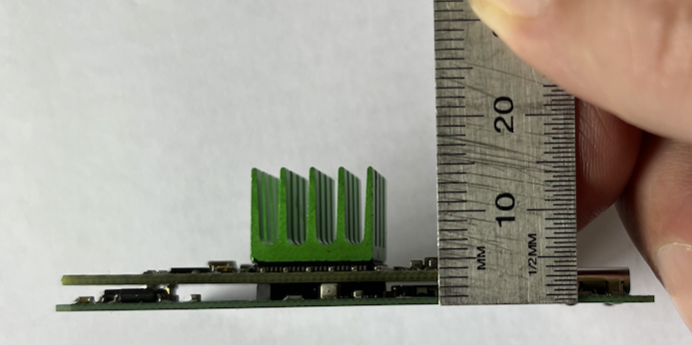

So I went and quickly purchased a 14x14 mm stick on heatsink and ran with that (back open) and I played for 30mins then I stopped without crashing. Heat reached about 58C on the back of the P2 according to my thermometer which is 5C less than the crash point, although this was with 19C ambient so room temp of 25C may still fail.

At least this shows a marked improvement and it would appear overheating is the prime issue to resolve. A custom heatsink case or insert would be nice to sort out and 3d print.

Nice work on a heatsink. Amazing what a difference it makes, hate to think how hot this P2 is internally.

Its easy enough to make up an AL plate, probably have 1.6, 2 or 3mm at work, and its so each to machine. We also have some bergquist thermal blanket somewhere

3D printing a stainless cover won't help, unfortunately. Stainless famously doesn't spread heat, you get real hot spots and yet next to no spread. AL or copper PCBs are an option though and provide the ability to be insulated where you need insulation (above the reg gaps etc)

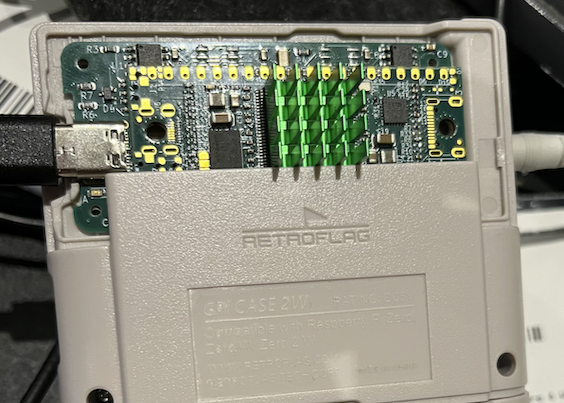

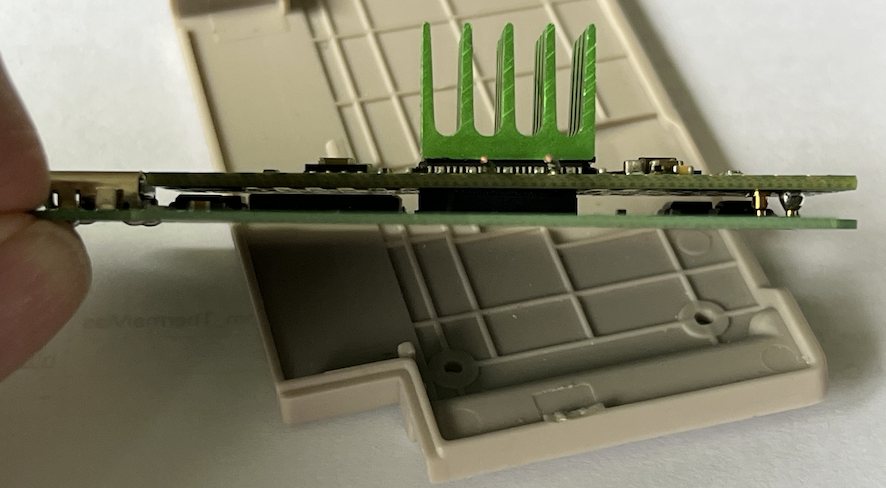

Yeah maybe stainless is not the best option. These pics show the space available after I put the cover on the back that I'd already cut up in the past for the proof of concept design with the P2 edge sticking out. It'd be good to make something fit even if the cover has to be cut to expose to outside airflow etc. Looks like about 3mm from the top surface of the upper P2 board to the underside of the plastic.

Interesting that the heat sink does anything. When I had issues with the P2EDGE developing MisoYume, I needed to go for fan cooling to fix it. Maybe the heat sinks I got just suck and aren't very effective.

Fundamentally the P2 is designed to sink heat into the GND plane, so if that's not working, you should probably consider improving the thermal design of the PCB. I know the even smaller P2Stamp/Swap boards don't have this issue.

In general, as far as heat/power use by software goes, it's roughly: MegaYume < NeoYume < MisoYume < RAMtest

It'd be good to get the thermistor on P61 into the action, to get some data points while we're playing around with different thermal options.

I realised this morning that I have other AL boards that would have the exact same mounting hole pitch, and it would be easy to carve these up into a fairly precise spreader plate.

@Wuerfel_21 , I was able to build your RAMtest app (with Flexspin 7.5.0) and got some video data on screen though no audio output (was there meant to be audio too?). I'd copied my working patched NeoVGA.spin2 and my config.spin2 settings file from NeoYume. I also tried setting _CLKFREQ to 128000000 and _XTLFREQ to 64000000 as the initial default in case it was starting out with bad values assuming a 20MHz XTAL instead of my 64MHz clock - I presume that NeoVGA will update the clock to the real frequency later anyway. Not sure if there's anything else I'm supposed to do that you know to make the audio work if there is meant to be some - code seems to show OPNAcog being spawned with playVGM stuff.

Ran for a few mins

2nd try once warmed up - failure seen right away and then locked up to black screen a few mins in. This was with that green heatsink on too.

Yeah it does use PWM audio not DAC audio Not a big deal to not hear it.

Am planning to visit Lachlan's work again soon to try more customized heatsink options to see if it helps with heat transfer away from his P2 board at the high overclock speeds. It's good this test triggers failures so early as we can make use of it for benchmarking these options.

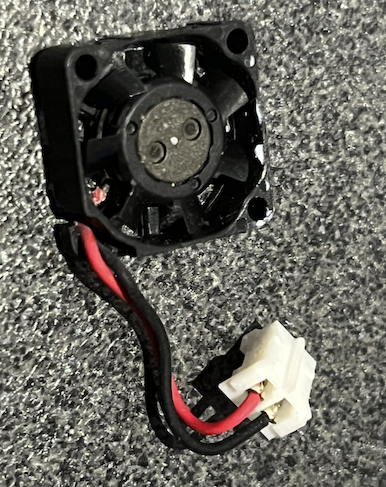

E.g. Something like this might help too - I reckon 4mm could just about be made flush with a drilled out case back for airflow and I could tap the source 5V power which is switched on/off by the main switch anyway. https://www.ebay.com.au/itm/304477919935

EDIT:LOL turns out I already have one from an old P1V tablet project's heatsink. Slightly bigger at 15x15x5mm

I visited @Tubular again last week and we did some thermal experiments with heatsinks and fans etc. With the green heatsink and small fan above, the RAM test survived fine for at least 15mins - we stopped the test there thinking it was okay. We also ran it without the fan but it did fail after just a few minutes. We then changed out the heatsink for a much larger black one (16x60x16.5mm, 8 degrees C/W) and I ran the RAM test today with that and it lasted about 12 mins before the first failure was observed. Temperature reached 47C on the heatsink in a 21C room temp. We are using thermal tape (the sort you use with SSDs in enclosures) to transfer heat to this heatsink from the P2. It's not an ideal clamping pressure (as I don't want to crush the insulated regulator components) but I do see that it does make some contact between the P2 and the heatsink.

Based on these results it seems to me that a fan is pretty much needed to create at least some airflow to help remove the heat, or a very large/impractical heatsink is going to be required. We may look into a custom plate for holding a small fan over the P2 at some point next. The P2 at this overclock and PSRAMs just generate too much heat for a small enclosure like this without active cooling.

For sake of completeness, one thing we should still try is a heatsink with the fins oriented the correct direction, along the lines of the green heatsink you started with.

But yes I suspect a tiny fan is going to be the best option going forward

I feel like mounting a heatsink on the top of the chip (going through the plastic package) does next to nothing. It did nothing when I had issues with my EC-32MB running/developing MisoYume (allegedly Rev. B units handle it better). That was basically going into the margin of instability just a little bit over what I was doing, so a little improved cooling should have fixed it. It really wants to dump heat downwards into the GND pad.

Sure, it 'wants do' dump heat towards the GND pad, but this is now a cul de sac of heat buildup, so secondary/less preferred paths now need do the heavy lifting of getting the heat out.

I'm pretty sure we're going to end up with a small fan, but its kind of borderline in that it can run for minutes, so getting it to run for some more minutes seems worth a try

Needs a connector reorientation to flip the Prop2 PCB over. So then the heat spreading underside of the Prop2 PCB becomes attachable to a bigger heat sink. Namely a machined aluminium case.

@evanh said:

Needs a connector reorientation to flip the Prop2 PCB over. So then the heat spreading underside of the Prop2 PCB becomes attachable to a bigger heat sink. Namely a machined aluminium case.

LOL. Yep major overhaul. In such a setup I'd make a single board with the P2 facing downwards on my FireAnt board, and have a larger area internally above it on the other side where the ground pad is to setup a bracket/fan/heatsink whatever.

After talking with Tubular today I ran the RAM test with the heatsink sideways so air would rise up along it and convect away more heat, and sure enough it lasted a fair bit longer with first RAM test failure at over 20mins. Same room temp 21C. Failure temp of heatsink around 47C max reported with my infrared thermometer - same as before as well. So any rear heatsink would be best with vertical fin alignment for optimal handheld use. Makes sense.

Comments

For reference this is the circuit I used for the SD on this board - it follows the same pin order as initially given in the SD card thread, although I didn't add the SD power LED to the 8th pin in this case as it is hidden inside the cartridge but I did include the general purpose LED on the 7th pin (also useful for debugging when standalone - eg. to find the xtal osc problem I had). Because I didn't have the power LED I just included a 1k8 to ground from the SD power supply to discharge the caps faster when the FET is turned off.

The V_USB and SENSE signals are not part of the SD stuff, they just happened to make use of a spare 22k resistor I had nearby for sensing 5V on the USB-C cable that can be optionally plugged-in.

Popcorn ready

Nice.

Discharge resistor isn't needed. The power LED stops conducting very early in discharge curve. The driver software pulls all the DAT and CMD pins low to drain caps. It takes about 37 28 milliseconds via the five 22 kR resistor paths.

PS: The level is monitored on the CLK pin so if it takes longer then no issue.

EDIT: Threshold is below 37 on 8-bit compDAC.

Actually, if you turn on -D SD_DEBUG it'll report how quickly the power-down happened.

Our external power feed resistor has now been cut and it runs the SD card test from inside the GPi case on it's internal Lipo powered 5V supply, with USB-C plugged directly into the cartridge. No more external supply shorting risk.

Now I just need to context switch back to messing with all the prior NeoYume settings etc - am a bit rusty for all that as it was several weeks ago now and I've been in HW mode since.

Just ran it again. But I see it did report some CMD10 errors before things ultimately worked, are they important?

( Entering terminal mode. Press Ctrl-] or Ctrl-Z to exit. )

clkfreq = 128000000 clkmode = 0x10001fb

SD card driver (4-bit SD mode) v1.12

sdsd_open: using pins: 53 52 48 55 54

Card detected ... power cycle of SD card

power-down threshold = 37 pin state = 1

power-down slope = 29633 us pin state = 0

SD clock-divider set to sysclock/320 (400 kHz)

Card idle OK

OCR register 80ff8000 - SDSC Card

Data Transfer Mode entered - Published RCA 1ff30000

CID register backed up

4-bit data interface engaged

Speed Class = C4 UHS Grade = U0

Video Class = V0 App Class = A0

Cache = 0 Queue = 0

TRIM = 0 FULE = 0

Card User Capacity = 1920 MB (1.88 GB)

High-Speed access mode engaged

SD clock-divider set to sysclock/4 (32.0 MHz)

. CMD10 error!

. CMD10 error!

. CMD10 error!

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

. CMD10 error!

rxlag=8 selected Lowest=4 Highest=11

CID decode: ManID=02 OEMID=TM Name=SD02G

Ver=3.2 Serial=a8ab6696 Date=2008-4

SD Card Init Successful

/sd1 handle = 105f0 ... mounted

Delete 100 files ... Duration 1197 ms, 83.5 files/s

File size = 512 bytes

Create 100 files ... Duration 3964 ms, 25.2 files/s

Verify 100 files ... Duration 357 ms, 280.1 files/s

Clean-up ... errno = 0: OK

Thanks. Those errors are complete normal, it's the calibration routine making use of the regular command/response functions to find the good/bad boundaries of rxlag setting.

@Wuerfel_21 I have ported your emulators to my updated HW and ran into some issue after loading screen. Screen changes and freezes and looks like this once MSLug gets loaded. I tried with 4 bit SD initially then backed off to original SPI mode but effect is the same. Using PSRAM timing same as edge but also tweaked up and down a few clocks without help.

It did load up once the very first time and let me get into the initial in-game MSlug menu and played sound fx etc but locked up just before it would have started actual gameplay when I wanted to start it.

Wondering if PSRAM settings might cause this, or actual overheating...?

Didn't you have a RAM test app that ran when the other Cogs were running sprite stuff at rated game clock speed? That could potentially be useful to debug this issue.

EDIT: wow the boards are HOT. Just took them out of the case to see how warm. Would be worth adding a thermocouple into the housing if I can fit it in while game is running. Even though my board is transferring some P2 heat too, I think an actual heatsink plate is going to be needed. Might also explain why it seemed to work the first time but not afterwards (once it had warmed up a lot). Also when I ran the memory test again now when things were warm I got worse values vs prior run.

Might also explain why it seemed to work the first time but not afterwards (once it had warmed up a lot). Also when I ran the memory test again now when things were warm I got worse values vs prior run.

I can actually run it with the cartridge opened so it can be probed.

You did try tweaking the sync/async settings, right?

Hard to decisively distinguish. But looks to me moreso like PSRAM fail rather than P2 core fail.

That the screen changes when trying to boot is normal, on startup the menu fix graphics are kicked out in favor of the game's fix graphics.

yes. Will need to drop the customized NeoVGA into this.

Note that this doesn't just test PSRAM integrity, but is also really hard on the P2. If it doesn't run properly or locks up, that's a P2 core fault. Bad PSRAM only ever leads to red FAIL prints.

And now a whole other hand-warmer engineering exercise begins.

If a suitable part is modelled, we could potentially then create a 3d printed metal backshell in the same profile as the plastic (or squeezes just under the existing plastic) and contacts the P2 - this would give a large surface area to spread/radiate the heat. But whether stainless steel is as good enough a heat conductor vs Al or Cu not sure.

Existing cartridge shell looks like this inside. There's probably a 2-3 mm gap above the components on Lachlan's P2 board to the back surface, so enough room for a custom metal plate. It could also go though to the outside of the plastic at the back with fins in the worst case. But ideally it could retain the same external size for a cleaner look.

Yeah, tried a few combos but was not exhaustive at every single nearby delay step - could retry again.

Thanks for this, I'll try it today.

Ran MSlug with the back open for over 8mins before it locked up. Temp started out at ambient 19C and then rose to ~64C on the hottest part detected by my infrared thermometer when pointing towards the P2. I think this is probably a thermal issue. I might try blowing air on it while playing and see how it behaves and whether it lasts even longer before failing, if it even does fail with that. I could also try to add a heatsink from a RasPi kit or similar as another test.

This test was run with the slow PSRAM clock enabled (sysclk/3) and a 16 clock delay according to these config.spin2 settings.

Aluminium is the way. Cheap, easy to work, lightest weight of the three, and does a good job as a heatsink. Anodise it for looks and wear resistance, then maybe add plastic handles or similar where it gets a lot of wear.

So I went and quickly purchased a 14x14 mm stick on heatsink and ran with that (back open) and I played for 30mins then I stopped without crashing. Heat reached about 58C on the back of the P2 according to my thermometer which is 5C less than the crash point, although this was with 19C ambient so room temp of 25C may still fail.

At least this shows a marked improvement and it would appear overheating is the prime issue to resolve. A custom heatsink case or insert would be nice to sort out and 3d print.

Roger.

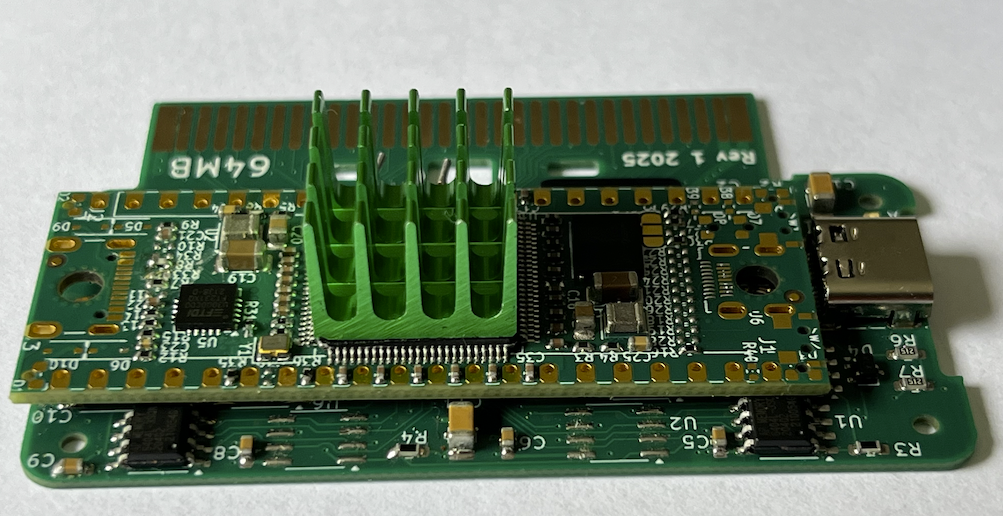

Few other pics...there's just a 2mm gap between the FireAnt board and Lachlan's P2 board.

Nice work on a heatsink. Amazing what a difference it makes, hate to think how hot this P2 is internally.

Its easy enough to make up an AL plate, probably have 1.6, 2 or 3mm at work, and its so each to machine. We also have some bergquist thermal blanket somewhere

3D printing a stainless cover won't help, unfortunately. Stainless famously doesn't spread heat, you get real hot spots and yet next to no spread. AL or copper PCBs are an option though and provide the ability to be insulated where you need insulation (above the reg gaps etc)

Yeah maybe stainless is not the best option. These pics show the space available after I put the cover on the back that I'd already cut up in the past for the proof of concept design with the P2 edge sticking out. It'd be good to make something fit even if the cover has to be cut to expose to outside airflow etc. Looks like about 3mm from the top surface of the upper P2 board to the underside of the plastic.

Interesting that the heat sink does anything. When I had issues with the P2EDGE developing MisoYume, I needed to go for fan cooling to fix it. Maybe the heat sinks I got just suck and aren't very effective.

Fundamentally the P2 is designed to sink heat into the GND plane, so if that's not working, you should probably consider improving the thermal design of the PCB. I know the even smaller P2Stamp/Swap boards don't have this issue.

In general, as far as heat/power use by software goes, it's roughly: MegaYume < NeoYume < MisoYume < RAMtest

Yeah I still want to try out that RAMTest as I didn't get to it today - perhaps tomorrow. It'd be good to see when that fails.

This was the heatsink I used

https://www.altronics.com.au/p/h0603a-mini-heatsink-plcc-14x14x11mm/

But they did not provide thermal characteristics like degrees/Watt etc. Lame. Probably also means it's minimal anyway.

It'd be good to get the thermistor on P61 into the action, to get some data points while we're playing around with different thermal options.

I realised this morning that I have other AL boards that would have the exact same mounting hole pitch, and it would be easy to carve these up into a fairly precise spreader plate.

@Wuerfel_21 , I was able to build your RAMtest app (with Flexspin 7.5.0) and got some video data on screen though no audio output (was there meant to be audio too?). I'd copied my working patched NeoVGA.spin2 and my config.spin2 settings file from NeoYume. I also tried setting _CLKFREQ to 128000000 and _XTLFREQ to 64000000 as the initial default in case it was starting out with bad values assuming a 20MHz XTAL instead of my 64MHz clock - I presume that NeoVGA will update the clock to the real frequency later anyway. Not sure if there's anything else I'm supposed to do that you know to make the audio work if there is meant to be some - code seems to show OPNAcog being spawned with playVGM stuff.

Ran for a few mins

2nd try once warmed up - failure seen right away and then locked up to black screen a few mins in. This was with that green heatsink on too.

There ought to be audio, but remember that this board/case has super quirky/off-spec audio, doesn't it? It's not that important, anyways.

Yeah it does use PWM audio not DAC audio Not a big deal to not hear it.

Am planning to visit Lachlan's work again soon to try more customized heatsink options to see if it helps with heat transfer away from his P2 board at the high overclock speeds. It's good this test triggers failures so early as we can make use of it for benchmarking these options.

E.g. Something like this might help too - I reckon 4mm could just about be made flush with a drilled out case back for airflow and I could tap the source 5V power which is switched on/off by the main switch anyway.

https://www.ebay.com.au/itm/304477919935

EDIT:LOL turns out I already have one from an old P1V tablet project's heatsink. Slightly bigger at 15x15x5mm

UPDATE:

Found an even smaller one at just 3mm thick and up to 3.5V operation. Wow. I do wonder if it would have any effect at all.

https://www.digikey.com.au/en/products/detail/sunon-fans/UF3F3-700-TC/9805486

I visited @Tubular again last week and we did some thermal experiments with heatsinks and fans etc. With the green heatsink and small fan above, the RAM test survived fine for at least 15mins - we stopped the test there thinking it was okay. We also ran it without the fan but it did fail after just a few minutes. We then changed out the heatsink for a much larger black one (16x60x16.5mm, 8 degrees C/W) and I ran the RAM test today with that and it lasted about 12 mins before the first failure was observed. Temperature reached 47C on the heatsink in a 21C room temp. We are using thermal tape (the sort you use with SSDs in enclosures) to transfer heat to this heatsink from the P2. It's not an ideal clamping pressure (as I don't want to crush the insulated regulator components) but I do see that it does make some contact between the P2 and the heatsink.

Based on these results it seems to me that a fan is pretty much needed to create at least some airflow to help remove the heat, or a very large/impractical heatsink is going to be required. We may look into a custom plate for holding a small fan over the P2 at some point next. The P2 at this overclock and PSRAMs just generate too much heat for a small enclosure like this without active cooling.

For sake of completeness, one thing we should still try is a heatsink with the fins oriented the correct direction, along the lines of the green heatsink you started with.

But yes I suspect a tiny fan is going to be the best option going forward

I feel like mounting a heatsink on the top of the chip (going through the plastic package) does next to nothing. It did nothing when I had issues with my EC-32MB running/developing MisoYume (allegedly Rev. B units handle it better). That was basically going into the margin of instability just a little bit over what I was doing, so a little improved cooling should have fixed it. It really wants to dump heat downwards into the GND pad.

Sure, it 'wants do' dump heat towards the GND pad, but this is now a cul de sac of heat buildup, so secondary/less preferred paths now need do the heavy lifting of getting the heat out.

I'm pretty sure we're going to end up with a small fan, but its kind of borderline in that it can run for minutes, so getting it to run for some more minutes seems worth a try

Needs a connector reorientation to flip the Prop2 PCB over. So then the heat spreading underside of the Prop2 PCB becomes attachable to a bigger heat sink. Namely a machined aluminium case.

LOL. Yep major overhaul. In such a setup I'd make a single board with the P2 facing downwards on my FireAnt board, and have a larger area internally above it on the other side where the ground pad is to setup a bracket/fan/heatsink whatever.

After talking with Tubular today I ran the RAM test with the heatsink sideways so air would rise up along it and convect away more heat, and sure enough it lasted a fair bit longer with first RAM test failure at over 20mins. Same room temp 21C. Failure temp of heatsink around 47C max reported with my infrared thermometer - same as before as well. So any rear heatsink would be best with vertical fin alignment for optimal handheld use. Makes sense.