Been thinking about ways to use the two RJ-45 jacks with 4 P2 pins on each...

VGA is possible, but have to give up one color...

Was just thinking about grayscale HDMI. If one connects the RGB lines together, should work?

Impedance might be an issue though... Might need a buffer...

Populated bottom board for the tiny 4771 board.

Identifies with Prop tool, powered by USB-C connection, so that's good.

Didn't really have space for pinned version of FT231X, so it needs Prop Plug for programming.

But, there is an 8-pin port that connects to middle PCB.

A future version of middle board could have an FT231X. Flip-flopping on this design decision though...

This 4771 sized board basically has no space for I/O terminals, besides the USB-A and twin RJ-45 jacks.

Guess the network jack could also be used one day when there's a daughter board to drive it.

But, idea here is that if you need I/O could put this in the 4773 case and have 18 I/O terminals or the 4774 and have 36 I/O or the 4778 and have 56.

You'd probably need I2C expanders for that though.

Still, there are two Eval style ports on one side that could directly connect 16 P2 I/O pins to another board, sideways.

And, the other side has a bank of 8 I/O pins in a single row.

So, maybe this board is more flexible, but not as straightforward as the 4775 based board with built in I/O terminals...

One mistake is that the boards are a hair too long. They just fit, but with zero margin, so can't remove them without damaging the plastic tabs that hold it in place. Next revision will be 0.5mm shorter...

Working on an I2C I/O expander pcb that can connect to one of the RJ45 jacks for signals.

This should be enough for my application, but making it so they can be daisy chained if need more...

@Rayman said:

Gotta love it when a plan comes together!

Think it's done...

wow! you took that idea and ran with it. nice touch on the display

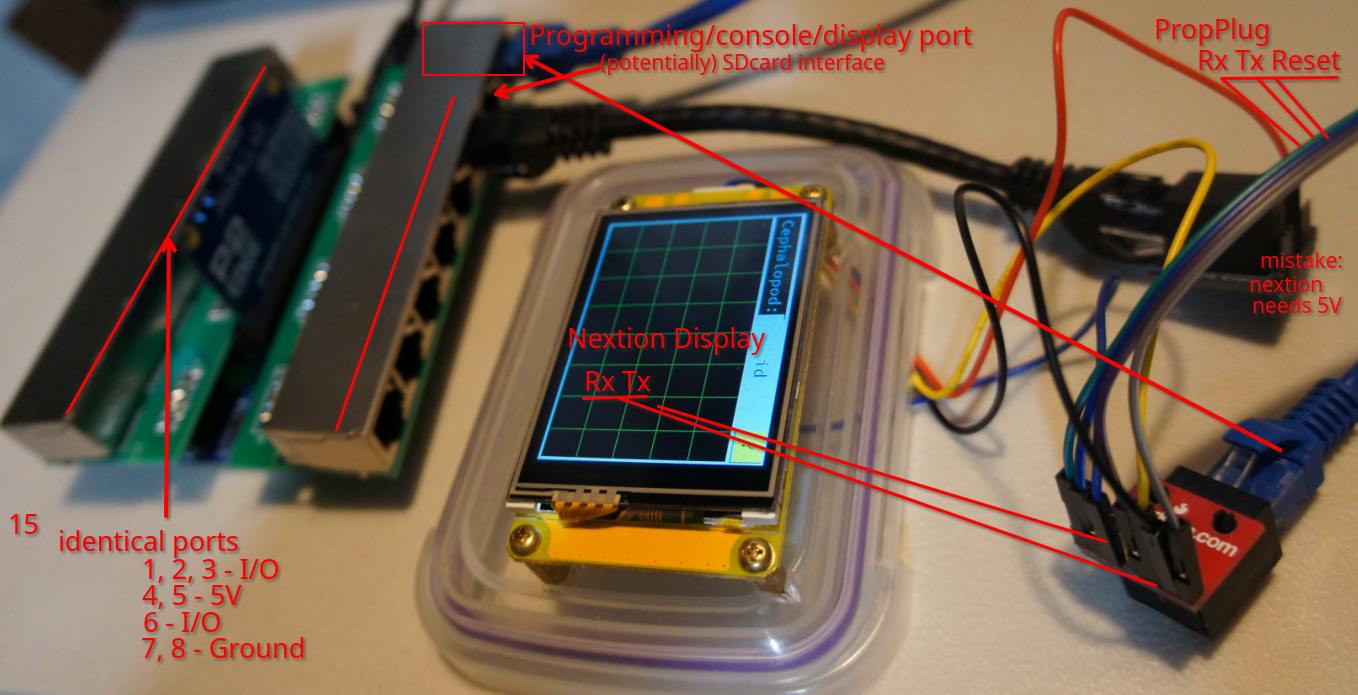

I'm only here now. using a serial rx/tx Nextion display usurping the two LED pins and wiring up the propplug rx/tx/reset on one of the ports and potentially SDcard on one, leaving the rest basically open.

@refaQtor That little RJ45 breakout is nice. Have to get that. Think I see a Ti symbol on it?

Been thinking about doing like @Mickster and programming the thing in BASIC (from Flexprop) so that other could more easily understand it.

That machine code stuff our Siemens thing is programmed in is a nightmare...

Still, thinking C might be the way to go as it is extremely well documented...

@Rayman said:

@refaQtor That little RJ45 breakout is nice. Have to get that. Think I see a Ti symbol on it?

that's Sparkfun red. but easy to find on amazon, along with cheap bunches of ethernet patch cables of various lengths. right now, just straight connections to TTL pins and lengths suitable for benchtop experiments

Liked the idea of two switches with leds and another led on the top board, just like for the DMB-4775.

But, this one is smaller, so switched to this tiny OLED.

Using the Edge/Eval style header allows for convenient testing outside the box...

I also find the idea of a P2 based PLC quite interesting and I already had some possible applications for it (see crane balancer, reflow oven controller, PCB tester...). But I fear making a flexible, modular and universal solution that really fits all possible cases like...

water tight case vs. DIN-rail cabinet

high speed IO vs. protected 24V signals

with/without display

extension connectors / accessory boards?

... is quite difficult. There's always at least one requirement that doesn't fit already existing boards. Only the classic P2Eval with accessory boards fits everything but that's not an option in a harsh environment with shock & vibration.

So at the moment I keep making custom PCBs for each different application.

Well, that's one nice thing about the DBM-4775... Comes in 3 boards. If you want, could just use my center board and use your own bottom for whatever I/O you need to do on the terminals.

And, can design your own top board or just not use one.

Planning on posting the Eagle files, so people can do whatever they want...

So at the moment I keep making custom PCBs for each different application.

There is no better way than this to address a specific need.

As much as I'd like to have an universal controller that fits all possible needs I may have, the reality proved that's not going to happen at an acceptable cost.

And it seems to me, that there is no better solution than this one in other trades as well.

My recent visit to a hardware store proved this point with as simple tool as a hammer. There were at least seven types (not sizes) of hammers for different purposes and it was quite easy to see why they differ in shapes, weights and materials used.

@ManAtWork said:

... is quite difficult. There's always at least one requirement that doesn't fit already existing boards. Only the classic P2Eval with accessory boards fits everything but that's not an option in a harsh environment with shock & vibration.

So at the moment I keep making custom PCBs for each different application.

well, yup...that's the conundrum. the complexity of making things simple... or, vice-versa.

just let's keep having fun along the way. P2 !

@Mickster said:

We want flexibility and we want finished products that don't scream "built by some dude in his shed".

A P2 hosted motherboard for the Tibbit Blocks would be nice. I don't like their own MCU offering.

interesting... my recent noodlings have been along these lines of modular I/O,, and the prices on their I/O seem reasonable. I had a different form-factor, but different processor on a compatible mainboard might have legs. haven''t looked into the claims/license they try to protect on the physical interface, or is it all open.

Plan for USB Serial over FT231X and ethernet over Wiznet io modules is to have them on separate boards.

The DMB-4771 doesn't have room for either of these things on the main board, so they have to be on separate boards.

Also, people may not need USB serial as can just use prop plug connector.

Also, people may not need Wiznet. Or, want to do something else.

The serial and ethernet boards work, just need to change form factor so they can fit inside the DMB-4771 and DMB-4775 boxes...

Learned that doing i2c over a 10ft long RJ45 cable between the PLC and I2C expander board might not be a good idea...

Was having kind of random issues with PCA9673 not always replying with ACK when addressed and doing other bad things when the inputs to the expander where toggled...

The 10ft cable inside the box was way overkill anyway, just all had lying around.

Replaced with ~1.5 ft cable and seems all better now.

Thought that the problem might be that had forgotten to add bypass caps near the expander chip.

Soldered some in, but that didn't help.

But reminds me that I'm not entirely onboard with the PoE pinout for RJ-45 that has two grounds on a twisted pair, two 5V on another pair, and 2 pairs of P2 pins on the other pairs.

If each P2 pin was paired with either gnd or 5V, then could use PCA9600 in the best way.

Still, maybe PoE style pinout buys something that am just not seeing yet...

Ethernet 8P8C pinning is for 2V differential signalling to allow common mode rejection of noise. The PoE extension of that can use the same two pairs, the “spare” pairs only, or all four pairs to transmit DC power independently. As you are not using these signalling and supply schemes there’s no benefit in simply replicating the pin use.

The EIA/TIA-568 pinout of the 8P8C connector for Ethernet was inspired by telephony cabling standards (including RJ-11, RJ-12, and RJ-45 connections) to take advantage of existing cabling infrastructure to implement Ethernet more cheaply. It sounds like you are free to allocate the pins and pairs any way you like, although varying the physical connections would require you to make your own cables.

Pairing single-ended signals with a ground reference is good practice, but I’d still keep the power separate from the signals.

@Rayman said:

Learned that doing i2c over a 10ft long RJ45 cable between the PLC and I2C expander board might not be a good idea...

Was having kind of random issues with PCA9673 not always replying with ACK when addressed and doing other bad things when the inputs to the expander where toggled...

The 10ft cable inside the box was way overkill anyway, just all had lying around.

Replaced with ~1.5 ft cable and seems all better now.

Sounds like you did not need 10ft, but I recall we did long i2c years back (across a room type distances).

We used a 3 pin approach on host MCU : buffered CMOS slew limited on the SCL to control bounce, and use 2 pins for SDA.

One pin drives a simple NPN open collector and another pin reads SDA level. SDA resistor was the lowest the remote i2c slave could safely drive.

Can't recall the value, may have been 470 ohms ?

This did not have high load currents, so we managed on 4 core cable.

I chose that to actually move power down the conductors of a common and cheap cabling/connector components that had been historically, as I understand it, and primarily to move just signals. so, doubling up to move power, and since now there is PoE, it made sense for me. I never cared to do I2C or SPI over those external connections.

Comments

Been thinking about ways to use the two RJ-45 jacks with 4 P2 pins on each...

VGA is possible, but have to give up one color...

Was just thinking about grayscale HDMI. If one connects the RGB lines together, should work?

Impedance might be an issue though... Might need a buffer...

Populated bottom board for the tiny 4771 board.

Identifies with Prop tool, powered by USB-C connection, so that's good.

Didn't really have space for pinned version of FT231X, so it needs Prop Plug for programming.

But, there is an 8-pin port that connects to middle PCB.

A future version of middle board could have an FT231X. Flip-flopping on this design decision though...

This 4771 sized board basically has no space for I/O terminals, besides the USB-A and twin RJ-45 jacks.

Guess the network jack could also be used one day when there's a daughter board to drive it.

But, idea here is that if you need I/O could put this in the 4773 case and have 18 I/O terminals or the 4774 and have 36 I/O or the 4778 and have 56.

You'd probably need I2C expanders for that though.

Still, there are two Eval style ports on one side that could directly connect 16 P2 I/O pins to another board, sideways.

And, the other side has a bank of 8 I/O pins in a single row.

So, maybe this board is more flexible, but not as straightforward as the 4775 based board with built in I/O terminals...

One mistake is that the boards are a hair too long. They just fit, but with zero margin, so can't remove them without damaging the plastic tabs that hold it in place. Next revision will be 0.5mm shorter...

Working on an I2C I/O expander pcb that can connect to one of the RJ45 jacks for signals.

This should be enough for my application, but making it so they can be daisy chained if need more...

Third time's a charm!

Finally got LCD for the top board of 4775 wired correctly...

Gotta love it when a plan comes together!

Think it's done...

wow! you took that idea and ran with it. nice touch on the display

I'm only here now. using a serial rx/tx Nextion display usurping the two LED pins and wiring up the propplug rx/tx/reset on one of the ports and potentially SDcard on one, leaving the rest basically open.

@refaQtor That little RJ45 breakout is nice. Have to get that. Think I see a Ti symbol on it?

Been thinking about doing like @Mickster and programming the thing in BASIC (from Flexprop) so that other could more easily understand it.

That machine code stuff our Siemens thing is programmed in is a nightmare...

Still, thinking C might be the way to go as it is extremely well documented...

@refaQtor Am appreciating more and more your idea of using RJ45 jacks to connect P2 pins to other things.

I looked in to vibration testing, a couple of years ago but the Neutrik PDF was too big to upload so;

Link to my DropBox

that's Sparkfun red. but easy to find on amazon, along with cheap bunches of ethernet patch cables of various lengths. right now, just straight connections to TTL pins and lengths suitable for benchtop experiments

Was just thinking that for RJ45 pinout might be better to pair p2 pin with either find or 5v to avoid crosstalk on long runs.

On the other hand, not really thinking about long runs at the moment…

Here's a revised top PCB for the DMB-4771 case.

Liked the idea of two switches with leds and another led on the top board, just like for the DMB-4775.

But, this one is smaller, so switched to this tiny OLED.

Using the Edge/Eval style header allows for convenient testing outside the box...

I also find the idea of a P2 based PLC quite interesting and I already had some possible applications for it (see crane balancer, reflow oven controller, PCB tester...). But I fear making a flexible, modular and universal solution that really fits all possible cases like...

... is quite difficult. There's always at least one requirement that doesn't fit already existing boards. Only the classic P2Eval with accessory boards fits everything but that's not an option in a harsh environment with shock & vibration.

So at the moment I keep making custom PCBs for each different application.

Well, that's one nice thing about the DBM-4775... Comes in 3 boards. If you want, could just use my center board and use your own bottom for whatever I/O you need to do on the terminals.

And, can design your own top board or just not use one.

Planning on posting the Eagle files, so people can do whatever they want...

There is no better way than this to address a specific need.

As much as I'd like to have an universal controller that fits all possible needs I may have, the reality proved that's not going to happen at an acceptable cost.

And it seems to me, that there is no better solution than this one in other trades as well.

My recent visit to a hardware store proved this point with as simple tool as a hammer. There were at least seven types (not sizes) of hammers for different purposes and it was quite easy to see why they differ in shapes, weights and materials used.

well, yup...that's the conundrum. the complexity of making things simple... or, vice-versa.

just let's keep having fun along the way. P2 !

I have brought this up in the past but "the crowd went mild"

We want flexibility and we want finished products that don't scream "built by some dude in his shed".

A P2 hosted motherboard for the Tibbit Blocks would be nice. I don't like their own MCU offering.

A main P2 board similar to this

Enclosures come with packaging

interesting... my recent noodlings have been along these lines of modular I/O,, and the prices on their I/O seem reasonable. I had a different form-factor, but different processor on a compatible mainboard might have legs. haven''t looked into the claims/license they try to protect on the physical interface, or is it all open.

will have to look more at those.

good find.

Finally got around to putting together this new PCB for DMB-4771.

Seems to be OK so far...

Plan for USB Serial over FT231X and ethernet over Wiznet io modules is to have them on separate boards.

The DMB-4771 doesn't have room for either of these things on the main board, so they have to be on separate boards.

Also, people may not need USB serial as can just use prop plug connector.

Also, people may not need Wiznet. Or, want to do something else.

The serial and ethernet boards work, just need to change form factor so they can fit inside the DMB-4771 and DMB-4775 boxes...

Learned that doing i2c over a 10ft long RJ45 cable between the PLC and I2C expander board might not be a good idea...

Was having kind of random issues with PCA9673 not always replying with ACK when addressed and doing other bad things when the inputs to the expander where toggled...

The 10ft cable inside the box was way overkill anyway, just all had lying around.

Replaced with ~1.5 ft cable and seems all better now.

Thought that the problem might be that had forgotten to add bypass caps near the expander chip.

Soldered some in, but that didn't help.

I've seen long-distance I2C projects in Elektor magazine so I asked ChatGPT about buffers. It recommended:

Thanks @JonnyMac that's interesting.

But reminds me that I'm not entirely onboard with the PoE pinout for RJ-45 that has two grounds on a twisted pair, two 5V on another pair, and 2 pairs of P2 pins on the other pairs.

If each P2 pin was paired with either gnd or 5V, then could use PCA9600 in the best way.

Still, maybe PoE style pinout buys something that am just not seeing yet...

@refaQtor Do you see a disadvantage to changing the RJ-45 pinout to the one described in previous post?

Ethernet 8P8C pinning is for 2V differential signalling to allow common mode rejection of noise. The PoE extension of that can use the same two pairs, the “spare” pairs only, or all four pairs to transmit DC power independently. As you are not using these signalling and supply schemes there’s no benefit in simply replicating the pin use.

The EIA/TIA-568 pinout of the 8P8C connector for Ethernet was inspired by telephony cabling standards (including RJ-11, RJ-12, and RJ-45 connections) to take advantage of existing cabling infrastructure to implement Ethernet more cheaply. It sounds like you are free to allocate the pins and pairs any way you like, although varying the physical connections would require you to make your own cables.

Pairing single-ended signals with a ground reference is good practice, but I’d still keep the power separate from the signals.

Thanks @AJL

Maybe wrong but thinking that a well bypassed 5v line is just as good as ground for a p2 signal pin to be paired with.

Thinking that what one should avoid is a twisted pair with two different high freq signals…

With a p2 pin paired with ground or 5v there is capacitance to worry about but not crosstalk…

Sounds like you did not need 10ft, but I recall we did long i2c years back (across a room type distances).

We used a 3 pin approach on host MCU : buffered CMOS slew limited on the SCL to control bounce, and use 2 pins for SDA.

One pin drives a simple NPN open collector and another pin reads SDA level. SDA resistor was the lowest the remote i2c slave could safely drive.

Can't recall the value, may have been 470 ohms ?

This did not have high load currents, so we managed on 4 core cable.

Knock yourself out. (that's an odd expression, now that I write it down)... whatever you do, just make the pinout plain to users. I've been encountering many variations in serial pinouts over RJ45/RJ11/DB9/DB25 and keep a drawer of connector/converters to redirect pins between ends.

https://www.amazon.com/ANMBEST-Ethernet-Adapter-Modular-Converter/dp/B0CX8CLXHZ/ref=sr_1_4?sr=8-4

I chose that to actually move power down the conductors of a common and cheap cabling/connector components that had been historically, as I understand it, and primarily to move just signals. so, doubling up to move power, and since now there is PoE, it made sense for me. I never cared to do I2C or SPI over those external connections.

@refaQtor Thanks. Took a look at what this would look like... Want to make sure using a crossover cable wouldn't connect +5 VDC to a P2 pin...