Bs2 Tank w/HM55B

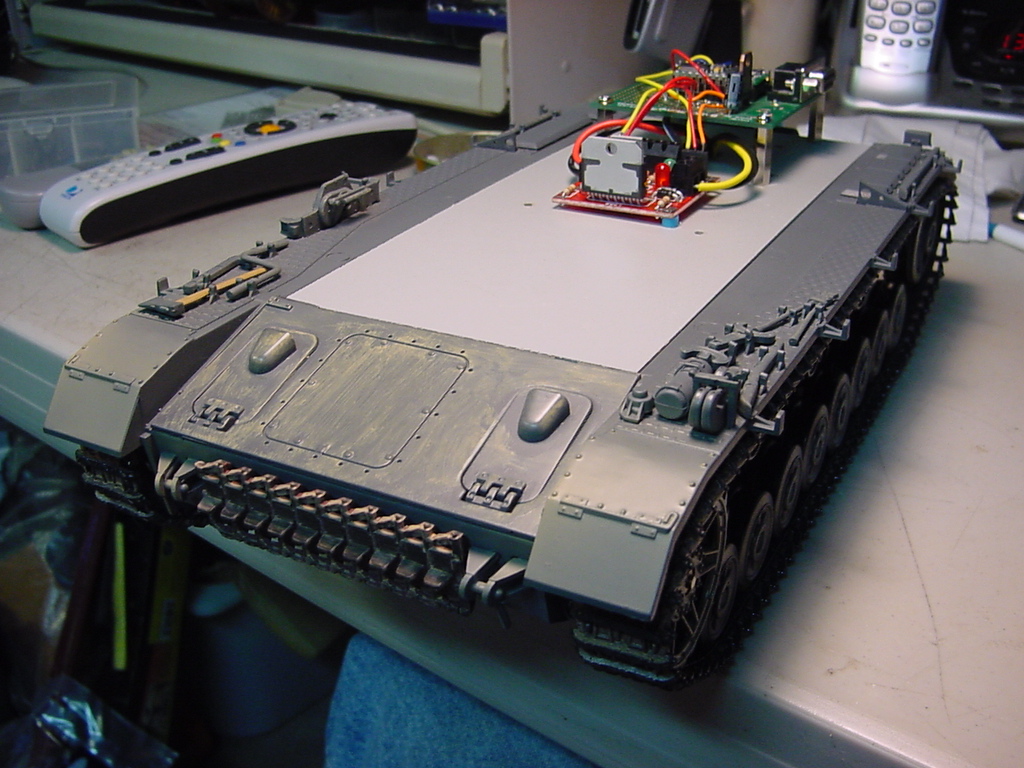

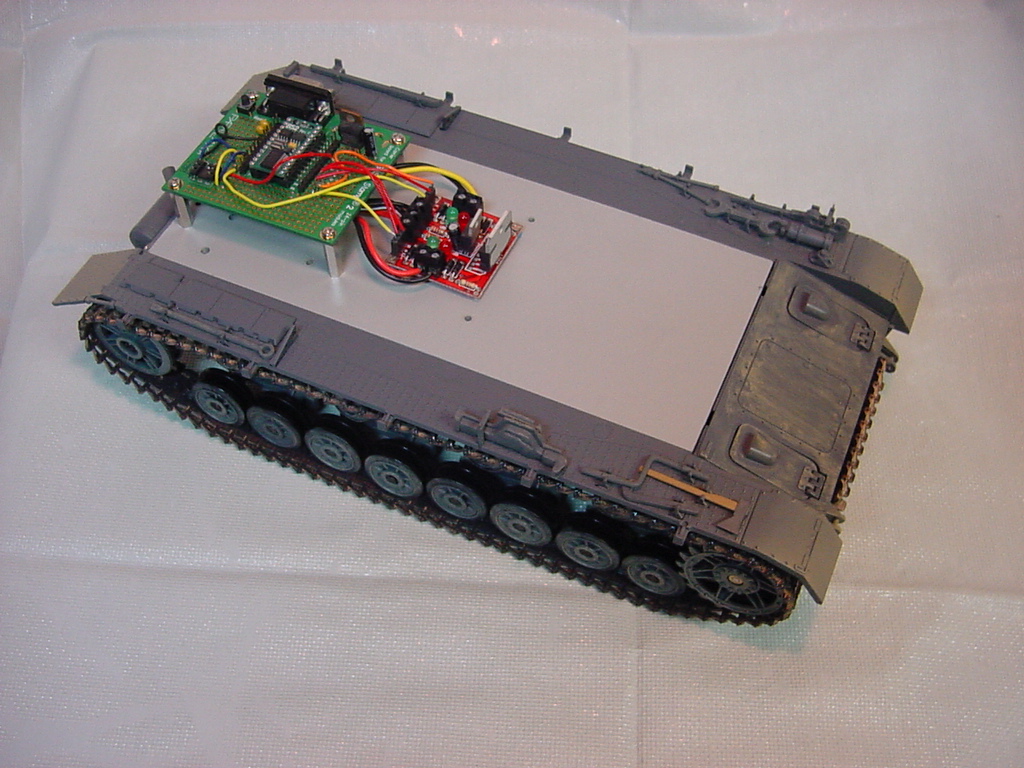

Hi Everyone, I have been away from the forum for awhile, but I'm back·and playing with the Bs2 again. Here are some pics of·my lastest project.

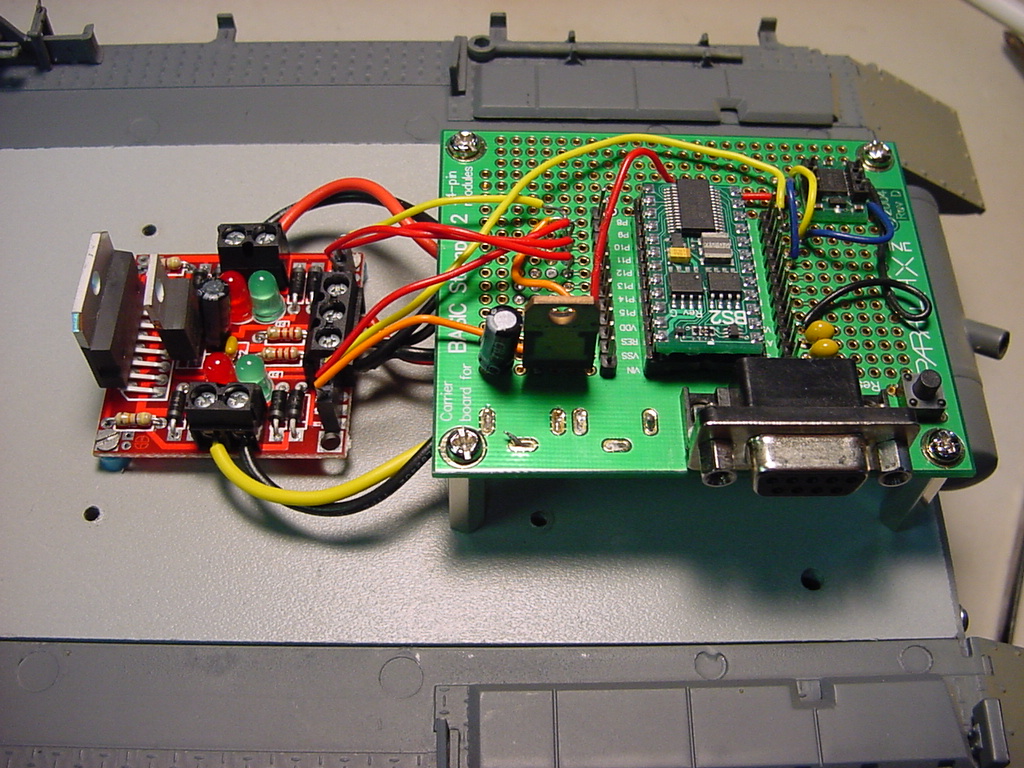

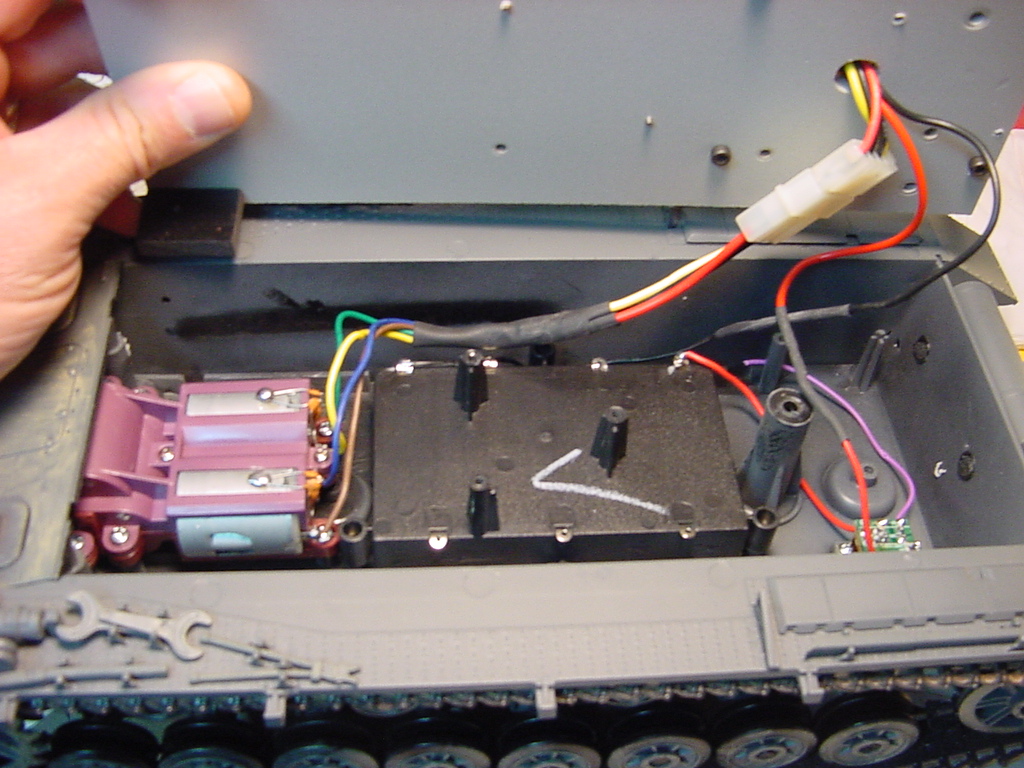

Notice the HM55B is as far as I can get it from the drive motors, I even raised the carrier board 1 inch. This gets it out of the range of the EMF of the DC motors. I wont tell how long it took me to figure out that there was emf interference and not my code (-:·· anyway it works very well now. The robot is programmed to seek magnetic north and move in that direction for a few feet and check for north again etc..

Tom

·

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Robot vision is the the future, and Vision will take us there.

http://www.youtube.com/watch?v=gbf0zaxWjvI

Post Edited (T0m) : 11/25/2007 11:55:54 PM GMT

Notice the HM55B is as far as I can get it from the drive motors, I even raised the carrier board 1 inch. This gets it out of the range of the EMF of the DC motors. I wont tell how long it took me to figure out that there was emf interference and not my code (-:·· anyway it works very well now. The robot is programmed to seek magnetic north and move in that direction for a few feet and check for north again etc..

Tom

·

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Robot vision is the the future, and Vision will take us there.

http://www.youtube.com/watch?v=gbf0zaxWjvI

Post Edited (T0m) : 11/25/2007 11:55:54 PM GMT

Comments

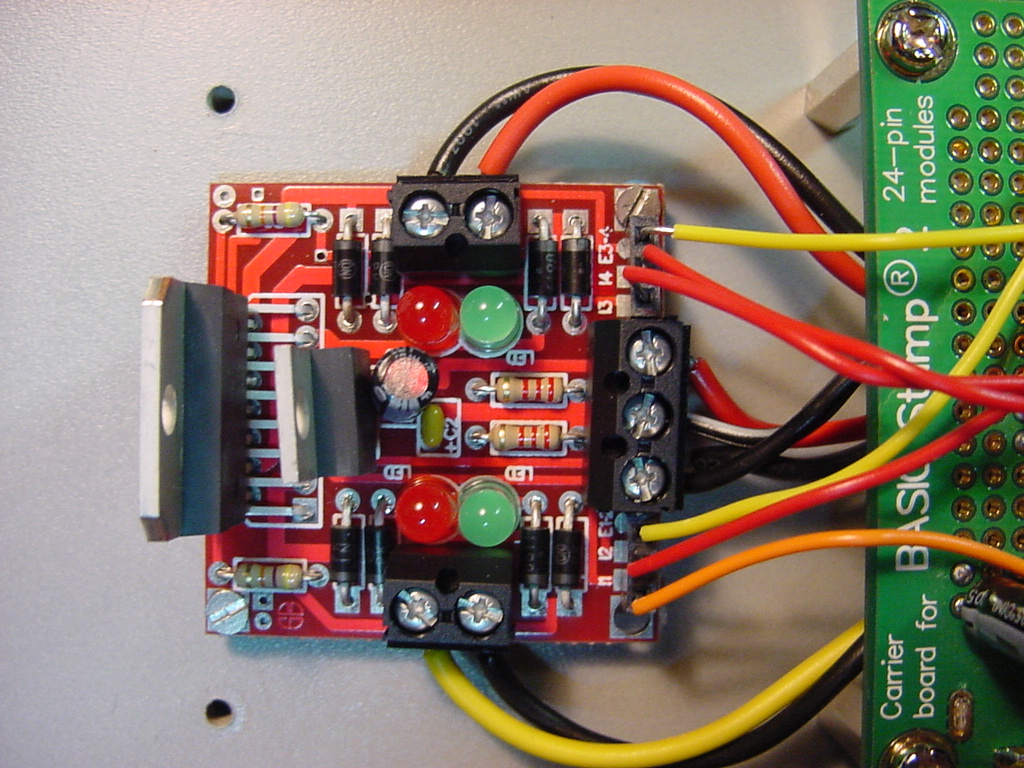

Tom. What is the motor driver you are useing ?

Will you post any code?

Rob7

The motor driver is a Solarbotics L298 kit. The code is a combination of cut and paste and luck. I am not much of a programmer. Here it is. The backward subroutine is not needed, but it is there for future use.

'{$STAMP BS2}

' {$PBASIC 2.5}

'Sample Code for the Parallax BS2 using the

'Solarbotics CMD Motor driver

'Contributions

'Parallax Inc.

'Solarbotics Ltd., 2006

'Dan Gates June 12 2006

'Thomas Amara Nov. 2007

'

Program Description

' This CMD Sample program is for testing your CMD motor driver with a Basic

' Stamp2 or compatable.

' First we declare the motor connection pins in the "Pin Allocation category

' and create a temp register for good measure.

' Then in MAIN we turn OFF both motor enable lines for about 1 second and

' Proceed to turn each motor on in the following sequence as if they were

' driving a robot:

' Forward, Backward, LEFT, and RIGHT each for a brief period of time (about

' two and a half seconds).

' A last we jump back to the beginning of the code and start over in a never

' ending loop.

'

'This program assumes that you connect the CMD to the following BS2 pins;

'Pin7 = E 1-2

'Pin8 = E 3-4

'Pin9 = L1

'Pin10= L2

'Pin11= L3

'Pin12= L4

' Be sure to connect at least 6v to the power input and connect the motors

' to the outputs.

'

Pin Allocations

'Motor control

Enable_Right CON 7 'Enable high, disable low

Enable_Left CON 8 'Enable high, disable low

'

Direction Truth Table

'L1 & L3 | L2 & L4 | M1,M2,M3,M4 Outputs

'

|

|

L1_Direction CON 9 ' HIGH | HIGH | Outputs = High (Motor Break)

L2_Direction CON 10 ' LOW | LOW | Outputs = LOW (Motor Coast)

L3_Direction CON 11 ' HIGH | LOW | Current flows POS.(Direction 1)

L4_Direction CON 12 ' LOW | HIGH | Current flows Neg.(Direction 2)

DinDout PIN 6 ' P6 transceives to/from Din/Dout

Clk PIN 5 ' P5 sends pulses to HM55B's Clk

En PIN 4 ' P4 controls HM55B's /EN(ABLE)

Reset CON %0000 ' Reset command for HM55B

Measure CON %1000 ' Start measurement command

Report CON %1100 ' Get status/axis values command

Ready CON %1100 ' 11 -> Done, 00 -> no errors

NegMask CON %1111100000000000 ' For 11-bit negative to 16-bits

x VAR Word ' x-axis data

y VAR Word ' y-axis data

status VAR Nib ' Status flags

angle VAR Word ' Store angle measurement

'

Temp VAR Word 'Temp register for manipulating bits

'

Start of main program

MAIN:

DO

GOSUB Compass_Get_Axes ' Get x, and y values

angle = x ATN -y ' Convert x and y to brads

angle = angle */ 360 ' Convert brads to degrees

PAUSE 150 ' Debug delay for slower PCs

DEBUG HOME, DEC angle, " degrees", CLREOL

IF angle >355 AND angle <360 THEN GOSUB forward

IF angle >0 AND angle <5 THEN GOSUB Forward

IF angle >1 AND angle <180 THEN GOSUB left

IF angle >179 AND angle <358 THEN GOSUB right

LOOP 'Go back and start again

'

Subroutines

FORWARD:

HIGH Enable_Right

HIGH Enable_Left

LOW L1_Direction

HIGH L2_Direction

LOW L3_Direction

HIGH L4_Direction

PAUSE 200

LOW Enable_Right

LOW Enable_Left

RETURN

BACKWARD:

HIGH Enable_Right

HIGH Enable_Left

LOW L1_Direction

HIGH L2_Direction

LOW L3_Direction

HIGH L4_Direction

PAUSE 40

LOW Enable_Right

LOW Enable_Left

RETURN

LEFT:

HIGH Enable_Right

HIGH Enable_Left

LOW L1_Direction

HIGH L2_Direction

HIGH L3_Direction

LOW L4_Direction

PAUSE 8

LOW Enable_Right

LOW Enable_Left

RETURN

RIGHT:

HIGH Enable_Right

HIGH Enable_Left

HIGH L1_Direction

LOW L2_Direction

LOW L3_Direction

HIGH L4_Direction

PAUSE 8

LOW Enable_Right

LOW Enable_Left

RETURN

Compass_Get_Axes: ' Compass module subroutine

HIGH En: LOW En ' Send reset command to HM55B

SHIFTOUT DinDout,clk,MSBFIRST,[noparse][[/noparse]Reset\4]

HIGH En: LOW En ' HM55B start measurement command

SHIFTOUT DinDout,clk,MSBFIRST,[noparse][[/noparse]Measure\4]

status = 0 ' Clear previous status flags

DO ' Status flag checking loop

HIGH En: LOW En ' Measurement status command

SHIFTOUT DinDout,clk,MSBFIRST,[noparse][[/noparse]Report\4]

SHIFTIN DinDout,clk,MSBPOST,[noparse][[/noparse]Status\4] ' Get Status

LOOP UNTIL status = Ready ' Exit loop when status is ready

SHIFTIN DinDout,clk,MSBPOST,[noparse][[/noparse]x\11,y\11] ' Get x & y axis values

HIGH En ' Disable module

IF (y.BIT10 = 1) THEN y = y | NegMask ' Store 11-bits as signed word

IF (x.BIT10 = 1) THEN x = x | NegMask ' Repeat for other axis

RETURN

'STOP ' Use STOP To Prevent State Change

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Robot vision is the the future, and Vision will take us there.

http://www.youtube.com/watch?v=gbf0zaxWjvI

Post Edited (T0m) : 11/26/2007 12:10:52 AM GMT

Thank's for the info

Rob7

If you work on this code, I would love to have the motors ramp up to speed rather then just turn on and off. Just a thought.

Thanks

Tom

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Robot vision is the the future, and Vision will take us there.

http://www.youtube.com/watch?v=gbf0zaxWjvI

I put the HM55B on my christmas list this year.

"You would like to have your bot to slowly ramp from a stop to full speed then ramp down to stop.

Compass_Get_Axes then ramp back up to full speed then ramp down to stop.

Continue in a loop" ?

Rob7

Thanks

Tom

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Robot vision is the the future, and Vision will take us there.

http://www.youtube.com/watch?v=gbf0zaxWjvI

Enjoyed the images of your tank, and I thought I would show you my attempts to

create something similar.

I have attahed 7 images that show how I started and where I am now.

I am using an·H-bridge control board from Jim Forkin's(Geocities) web site, which is exceptionally well designed and performs faultlessly.

My tank is·30 inches long and one foor wide. I has a cannon that fires pellets. The turret, of course rotates.

I have great plans for it. Now I am in the process of increasing my I/O ports to accomodate for 8 IR sensors(2 on each side). I intend to

use a color sensor·(I have a TCS230 from Parallax) and I intend to use it to detect a red color. Once it does, to aim and fire a pelet!!!!

Ambitious project but the little time that I have I spend it in writing some programs for it.

I would love to exchange ideas withn you.

John

Tom

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Robot vision is the the future, and Vision will take us there.

http://www.youtube.com/watch?v=gbf0zaxWjvI

look at the DIRS command you can really simplify your movement commands leaving room for more programing.

Added: can you post a link for the H-bridge site, I can't find it.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"A complex design is the sign of an inferior designer." - Jamie Hyneman, Myth Buster

DGSwaner

Post Edited (Dgswaner) : 11/27/2007 4:22:14 AM GMT

Here is the link http://www.solarbotics.com/products/k_cmd/resources/

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Robot vision is the the future, and Vision will take us there.

http://www.youtube.com/watch?v=gbf0zaxWjvI