ServoPAL and SoundPAL: A Tale of Two Products

Phil Pilgrim (PhiPi)

Posts: 23,514

Phil Pilgrim (PhiPi)

Posts: 23,514

The ServoPAL product announcement engendered an interesting discussion about what it takes to develop and market a product in this industry. I thought it might be instructive — or entertaining, at least — to recall the steps I undertook, in conjunction with Parallax, to bring the ServoPAL and SoundPAL to market. I have to preface this with the most effusive praise possible for Parallax. Ken Gracey, along with Parallax's engineering, tech support, manufacturing, purchasing, sales, marketing, and accounting folks are an amazing and supportive bunch of people to work with. Without such a team behind my efforts, none of this could ever have happened!

Since these two products were developed in parallel, I shall present their chronology together.

February and March, 2007: Laid out PCBs and developed firmware for a "Servo Buddy" and "Sound Buddy". The technical issues that had to be solved included:

1. Getting the servo pulse widths to match exactly the pulses input to the Servo Buddy and to output with the least amount of jitter possible.

2. Coming up with alarm timer scaling that not only covered a useful range but was easy to remember — at least for a BS2.

3. Picking a speaker and drive transistor for the Sound Buddy that not only kept the size tiny, but didn't sound tiny (or tinny).

4. Coming up with a drive scheme that allowed for maximum loudness without overdriving the speaker or overheating the transistor.

5. Discovering that a "sonic resonator" made from shrink tubing would help produce a louder, fuller sound. Getting this right involved a lot of cutting, listening, and cutting some more.

6. Coming up with a pinout scheme so the SoundPAL could be plugged into a servo header in any direction and still function.

By the end of March I had working prototypes and some initial documentation. Together, these constituted "devices", not "products". To turn them into products would require a lot more work. I hinted to Ken that a couple "surprises" would soon be headed his way.

April 17: Sent initial protos and docs to Parallax to evaluate as potential products.

April 24: Answered questions from Parallax tech support.

April 29: Got positive product reviews from Parallax tech support, with a few suggestions regarding demo program formatting (needed to adhere to Parallax's standard PBASIC template) and a demo program request (IR roaming using the Servo Buddy). Chris Savage really did some thorough testing on these units, particularly regarding the ServoPAL's pulsewidth accuracy. This was very satisfying to me, since it's something I expended a lot of effort on to get right.

May 1: Discussed with Ken changing the product names from "Buddy" to "PAL", in line with Parallax's PWM Pal. Also discussed what silkscreen legending should be put on such tiny boards.

May 9: Received final product approvals from Parallax to proceed with the manufacturing packages. This mostly entails writing a lot of documentation for their Chinese manufacturer, which must include a bill-of-materials (Excel file), Gerber files and layout drawings for the PCBs, detailed specs, and illustrated step-by-step assembly instructions. All of this has to follow a strict format to eliminate as many variables and possibilities for misunderstanding as possible. In addition, masked and screened protos along with any specialized fixtures and equipment required to manufacture and test the products are required.

May 17: Since both products use an AVR microcontroller, a question came up about whether the Chinese factory was equipped to program them. I was informed I'd have to provide the equipment to do that.

May 25: In response to a further question about pre- or in-circuit programming, I was told by Parallax's factory rep that in-circuit programming was preferred. (As it turned out later, it's a good thing this route was chosen.)

June 5: Got stock numbers from Parallax, which are needed to label everything in the manufacturing docs so nothing gets mixed up.

June14: By now, the masked and screened boards had arrived and I'd assembled the final protos. I had mistakenly printed the wire color designators upside-down on the ServoPAL silkscreen and debated whether to redo the boards. As it turns out, all I had to do was flip the entire board over, changing the outputs to inputs and vice-versa. I'd also finished the bill of materials for the ServoPAL but had some last-minute component changes to make on the SoundPAL. In order to get maximum sound volume, I had switched to some Schottky diodes with a lower forward voltage, resulting in a higher on-board Vdd. But now the speaker drive transistor was getting hot. A different MOSFET with a lower "on" resistance solved the problem. Driving with a lower duty cycle also helped, without diminishing the sound level.

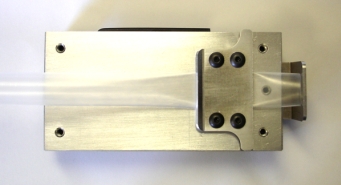

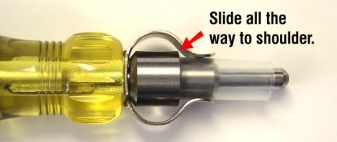

In order to form the "sonic resonators" some sort of jig to cut the shrink tubing to length was necessary, as well as a mandrel to shrink the tubing over. I was able to build the cutting jig myself but, lacking a lathe, had to get the local machine shop fabricate the mandrels. Two were necessary, so one could cool while the other was being reloaded. Here are some photos from the assembly docs:

····

····

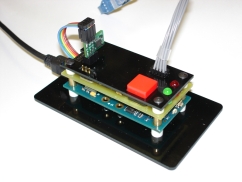

It was also time to design a program-and-test fixture that would work with both products. Programming is done via a Pomona test clip that snaps onto the installed micro. I laid out a PCB that plugs into a MoBoStamp-pe and that handles both the program and test functions. It has a large "start" button, along with green and red pass/fail LEDs. When the start button is pressed, it can detect where a board is plugged or clipped in (and which board it is), as well as whether it's backwards. From there, it "knows" which programming or test function to perform. The BASIC Stamp is great for apps like this! It would have taken weeks to come up with a test unit using just a micro. Here's a photo:

June 25: The manufacturing packages were done, and I sent them off to Parallax to forward to China.

August 24: The "first articles" (manufactured prototypes) arrive from China! This is an anxiously anticipated event, since you finally get to see how your instructions were interpreted and whether any parts were substituted for the ones you called out (which can be okay). Sure enough, I had spec'd some 0603 diodes on the ServoPAL for which direct replacements weren't available in China. Consequently, they had substituted some parts that were a little bigger and didn't fit the pads as well. On the SoundPAL they had subbed a different speaker. I was expecting this and had hoped they would find something equivalent to the one I used in my protos. They came very close, but it wasn't as loud. Moreover, it was taller, leaving less airspace in the sonic resonator, which dulled its effectiveness. So both first articles had to be redone with parts consigned from the States before they could pass.

September 17: I found a bug in my firmware that only manifested itself in the first articles from China. Fortunately, since we'd decided to program the parts onboard, all I had to do was email a new PBASIC program for the program/test unit. This is another reason the BASIC Stamp works so well for stuff like this! But this only underscored the risk associated with products that embody firmware and the amount of testing required to make sure it's right.

October 8: The second articles arrive. The SoundPAL still wasn't quite as loud as my proto, despite using all the same parts. I consulted with the speaker manufacturer, who informed me that this is normal, that I should expect variations in sound volume across various lots. But it's still plenty loud, so I signed off on it.

October 9, 10: I put the ServoPAL through its paces, concentrating on timing accuracy and pulse jitter. Parallax tech support sent me some data from the protos they had to compare with the second articles. Once all this data had been reviewed, I signed off on the ServoPAL as well. Once Parallax signed off on both units and gave the go-ahead to manufacture, it would just be a matter of waiting for the products to show up.

October 29: There were still a lot of i's to dot and t's to cross in the user docs. (They still carried the "Buddy" nomeclature and photos of the unmasked boards.) And I needed to come up with the IR roaming program that tech support had requested. In order to plan my time, I inquired about an ETA for the production units.

October 30: Was informed the products had already arrived at Parallax! Yikes! Still so much to do! So I spent a day cleaning up the docs and writing the IR roaming program. I pretty much detest writing, but doing the IR programming was fun, and I was very happy with the result.

November 1: Spoke with Ken to discuss costs, royalties, and retail pricing. The costs from China can sometimes be a surprise. As much as one hopes that things will be ridiculously cheap, that's not always the case. So other factors, like how an item fits into the pricing structure alongside similar items, have to be brought into the discussion. All things considered, though, it was relatively easy to come up with mutually-acceptable figures.

November 2: Showtime! The items that, seven months prior, were mere devices have finally earned their stripes as products and make their official debut on the Parallax website.

My work on these is pretty much done now and other products are in the works. But I know that the SoundPAL and ServoPAL are in good hands, given Parallax's legendary track record for marketing, sales, and support. As always, it's been a fun ride!

-Phil

Since these two products were developed in parallel, I shall present their chronology together.

February and March, 2007: Laid out PCBs and developed firmware for a "Servo Buddy" and "Sound Buddy". The technical issues that had to be solved included:

1. Getting the servo pulse widths to match exactly the pulses input to the Servo Buddy and to output with the least amount of jitter possible.

2. Coming up with alarm timer scaling that not only covered a useful range but was easy to remember — at least for a BS2.

3. Picking a speaker and drive transistor for the Sound Buddy that not only kept the size tiny, but didn't sound tiny (or tinny).

4. Coming up with a drive scheme that allowed for maximum loudness without overdriving the speaker or overheating the transistor.

5. Discovering that a "sonic resonator" made from shrink tubing would help produce a louder, fuller sound. Getting this right involved a lot of cutting, listening, and cutting some more.

6. Coming up with a pinout scheme so the SoundPAL could be plugged into a servo header in any direction and still function.

By the end of March I had working prototypes and some initial documentation. Together, these constituted "devices", not "products". To turn them into products would require a lot more work. I hinted to Ken that a couple "surprises" would soon be headed his way.

April 17: Sent initial protos and docs to Parallax to evaluate as potential products.

April 24: Answered questions from Parallax tech support.

April 29: Got positive product reviews from Parallax tech support, with a few suggestions regarding demo program formatting (needed to adhere to Parallax's standard PBASIC template) and a demo program request (IR roaming using the Servo Buddy). Chris Savage really did some thorough testing on these units, particularly regarding the ServoPAL's pulsewidth accuracy. This was very satisfying to me, since it's something I expended a lot of effort on to get right.

May 1: Discussed with Ken changing the product names from "Buddy" to "PAL", in line with Parallax's PWM Pal. Also discussed what silkscreen legending should be put on such tiny boards.

May 9: Received final product approvals from Parallax to proceed with the manufacturing packages. This mostly entails writing a lot of documentation for their Chinese manufacturer, which must include a bill-of-materials (Excel file), Gerber files and layout drawings for the PCBs, detailed specs, and illustrated step-by-step assembly instructions. All of this has to follow a strict format to eliminate as many variables and possibilities for misunderstanding as possible. In addition, masked and screened protos along with any specialized fixtures and equipment required to manufacture and test the products are required.

May 17: Since both products use an AVR microcontroller, a question came up about whether the Chinese factory was equipped to program them. I was informed I'd have to provide the equipment to do that.

May 25: In response to a further question about pre- or in-circuit programming, I was told by Parallax's factory rep that in-circuit programming was preferred. (As it turned out later, it's a good thing this route was chosen.)

June 5: Got stock numbers from Parallax, which are needed to label everything in the manufacturing docs so nothing gets mixed up.

June14: By now, the masked and screened boards had arrived and I'd assembled the final protos. I had mistakenly printed the wire color designators upside-down on the ServoPAL silkscreen and debated whether to redo the boards. As it turns out, all I had to do was flip the entire board over, changing the outputs to inputs and vice-versa. I'd also finished the bill of materials for the ServoPAL but had some last-minute component changes to make on the SoundPAL. In order to get maximum sound volume, I had switched to some Schottky diodes with a lower forward voltage, resulting in a higher on-board Vdd. But now the speaker drive transistor was getting hot. A different MOSFET with a lower "on" resistance solved the problem. Driving with a lower duty cycle also helped, without diminishing the sound level.

In order to form the "sonic resonators" some sort of jig to cut the shrink tubing to length was necessary, as well as a mandrel to shrink the tubing over. I was able to build the cutting jig myself but, lacking a lathe, had to get the local machine shop fabricate the mandrels. Two were necessary, so one could cool while the other was being reloaded. Here are some photos from the assembly docs:

It was also time to design a program-and-test fixture that would work with both products. Programming is done via a Pomona test clip that snaps onto the installed micro. I laid out a PCB that plugs into a MoBoStamp-pe and that handles both the program and test functions. It has a large "start" button, along with green and red pass/fail LEDs. When the start button is pressed, it can detect where a board is plugged or clipped in (and which board it is), as well as whether it's backwards. From there, it "knows" which programming or test function to perform. The BASIC Stamp is great for apps like this! It would have taken weeks to come up with a test unit using just a micro. Here's a photo:

June 25: The manufacturing packages were done, and I sent them off to Parallax to forward to China.

August 24: The "first articles" (manufactured prototypes) arrive from China! This is an anxiously anticipated event, since you finally get to see how your instructions were interpreted and whether any parts were substituted for the ones you called out (which can be okay). Sure enough, I had spec'd some 0603 diodes on the ServoPAL for which direct replacements weren't available in China. Consequently, they had substituted some parts that were a little bigger and didn't fit the pads as well. On the SoundPAL they had subbed a different speaker. I was expecting this and had hoped they would find something equivalent to the one I used in my protos. They came very close, but it wasn't as loud. Moreover, it was taller, leaving less airspace in the sonic resonator, which dulled its effectiveness. So both first articles had to be redone with parts consigned from the States before they could pass.

September 17: I found a bug in my firmware that only manifested itself in the first articles from China. Fortunately, since we'd decided to program the parts onboard, all I had to do was email a new PBASIC program for the program/test unit. This is another reason the BASIC Stamp works so well for stuff like this! But this only underscored the risk associated with products that embody firmware and the amount of testing required to make sure it's right.

October 8: The second articles arrive. The SoundPAL still wasn't quite as loud as my proto, despite using all the same parts. I consulted with the speaker manufacturer, who informed me that this is normal, that I should expect variations in sound volume across various lots. But it's still plenty loud, so I signed off on it.

October 9, 10: I put the ServoPAL through its paces, concentrating on timing accuracy and pulse jitter. Parallax tech support sent me some data from the protos they had to compare with the second articles. Once all this data had been reviewed, I signed off on the ServoPAL as well. Once Parallax signed off on both units and gave the go-ahead to manufacture, it would just be a matter of waiting for the products to show up.

October 29: There were still a lot of i's to dot and t's to cross in the user docs. (They still carried the "Buddy" nomeclature and photos of the unmasked boards.) And I needed to come up with the IR roaming program that tech support had requested. In order to plan my time, I inquired about an ETA for the production units.

October 30: Was informed the products had already arrived at Parallax! Yikes! Still so much to do! So I spent a day cleaning up the docs and writing the IR roaming program. I pretty much detest writing, but doing the IR programming was fun, and I was very happy with the result.

November 1: Spoke with Ken to discuss costs, royalties, and retail pricing. The costs from China can sometimes be a surprise. As much as one hopes that things will be ridiculously cheap, that's not always the case. So other factors, like how an item fits into the pricing structure alongside similar items, have to be brought into the discussion. All things considered, though, it was relatively easy to come up with mutually-acceptable figures.

November 2: Showtime! The items that, seven months prior, were mere devices have finally earned their stripes as products and make their official debut on the Parallax website.

My work on these is pretty much done now and other products are in the works. But I know that the SoundPAL and ServoPAL are in good hands, given Parallax's legendary track record for marketing, sales, and support. As always, it's been a fun ride!

-Phil

Comments

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There's nothing like a new idea and a warm soldering iron.

~50 hours: Total time·spent between·tech support's testing and documentation review (Chris), the purchasing manager, projections from our marketing (Lauren), inventory transaction processing, coordinating samples to/from Phil and Parallax Hong Kong, and identifying substitute components. Depending on how you·value your costs, and it never seems like enough, this is at least $5,000.

~$200 in miscellaneous shipping charges, $1,000 in various·test·and setup charges

~Unknown number of hours from·Parallax Hong Kong·General Manager·(Aristides)

Nothing will make you more careful about making decisions·about new products than·standing in the foreground looking backwards. Considering starting·production·and integration·costs at least $10,000 one way or another, the experience makes you very considerate of·what you decide to do. We·alwayls have a return on investment in mind for smaller products like ServoPAL and SoundPAL, whereas return from larger designs (Propeller) can't be measured by applying any kind of formula.

Ultimately·it's just a guess, and the "right" answer only emerges years later.

And when we're working with an outside engineer, like Phil, it takes a lot of strength on their end to become one of us - because we force our mini-bureacracy on them so it looks like something we did and that our staff buys into the product. After they can match our system and needs they are an extension of our staff in·terms of productivity and effectiveness.

This is only my perspective, and based on the current time snapshot.·If you're looking at this·scenario as a case study for·making and selling your first small products it's not the best model for a new web business. Due to the fairly long return on investment of these products they could sink a two-man shop under startup manufacturing costs alone, not to mention that a marketing and sales·network is·needed to sell them. Without the distribution abilities Phil's direct-sales volumes may be 1/10th of Parallax's. This is more of a partnership where each party brings resources·where they exceed.

There's one guy who has a lot of sense about growing small companies and products: Joe Martin. He's put it all in his free book: http://www.sherline.com/business.htm. I frequently read excerpts from Joe's book, though it's always enthusiasm that plays the most important role from my perspective.

Ken Gracey

Parallax, Inc.

·

If you want to keep your per-piece cost down, you have to have large batches built. Nobody wants to set up a pick-and-place machine just to do a few hundred units. And you'll pay through the nose for any assembly that has to be done by hand, at least in this country. Also, most assembly houses will give you a choice of turn-key (they buy the parts) or consignment (you buy the parts) assembly. By buying the parts yourself, you'll save about half, but you might need to buy certain components in reels of 3000, since cut tape doesn't work on assembly machines.

Then there's the spoilage. American assemblers won't bother sweeping the floor and retaping consigned parts that fall off the machine or get sacrificed to form a tape leader. You can easily lose 5% of all the parts you buy this way. (Well, you might get them back — in a bag mixed together with all the other spoiled parts. That's what happened to me once.) This not only costs money but really screws up your bookkeeping, especially when you think there are enough parts to do a run and your assembler tells you to buy more.

Finally, there's the time all this takes. Ordering parts and managing an inventory is a huge time drain. And if you'd rather be spending that time designing new stuff, it's the kind of clerical drudgery that can suck the life out of you.

While a small business could sustain the overhead required to assemble and stock one or two products, trying to do that with an entire product line would be crippling, both financially and timewise. That's one thing (among many) that makes having a larger manufacturing and marketing partner such an attractive arrangement.

-Phil

Very interesting post - thanks for sharing. I am sure many of us wonder about the amount of effort input into putting a product onto the market.

Cheers,

James

Wow, that is alot of work and time. Thank you for sharing.

I have a deal with the person who does my assembly. He does the assembly for my products and I write the code for his products. So far it is working out great.

Bean.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

www.hittconsulting.com

·

Great job guys!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

<FONT>Steve

What's the best thing to do in a lightning storm? "take a one iron out the bag and hold it straight up above your head, even God cant hit a one iron!"

Lee Travino after the second time being hit by lightning!

Phil,

What do you do professionally that allows you so much time to tinker with these devices?

Ken,

What is the best way for someone with an idea or device to approach Parallax to discuss the possibility of a partnership?

Thank you very much for the information posted. I have often wondered about such things!

- Sparks

Professionally, designing electronics and programming microcontrollers is what I do. Well, that and designing fishing lure molds for a local tackle company.

-Phil

Depends on the proposal. Usually follows one of these forms:

(a) Parallax and inventor collaborate on the idea before it even gets started, and we both decide on our responsibilities and proceed to develop and manufacture the product.

(b) Developer may submit a complete working sample, with documentation and pricing, as it would be sold to our customers.

And there are many variations on this approach. It all depends. I think we've used every model that exists, plus some that don't!

Ken Gracey

Parallax, Inc.

I have had my own stints of 'We'll get it right any day now.', but the most memoriable was when I worked for a· mylar balloon manufacturer that sold nation-wide.

The company found that they could sell hellium ballons nation-wide through a well-known supermarket chain if only they could deliver product with·a refill value for the helium instead of the usual one-time method of sealing. The buyer didn't want to throw out unsold, deflated balloons [noparse][[/noparse]supermarkets are very sensitive to inventory shelf life issues].

About a year later, after developing a valve, developing and modifying the production line to install it, and getting it to market - it hit one snag that killed the deal. While the balloons floated just fine in San Francisco, they sat at floor level in Denver!· The tiny valve added too much weight for higher altitude locations - so hundreds of thousands of dollars were wasted.

Mr. Goodyear - who perfected stabilizing rubber -·of Goodyear Rubber fame never cashed in on his product, so someone else named the sucessful rubber company after him to commemorate a life-time of efforts and belief in the value of the idea.

Just having a good idea isn't enough. Now you know where 90% prespiration and 10% inspiration ratio was discovered.· It really helps to love your work for these kinds of efforts.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

PLEASE CONSIDER the following:

Do you want a quickly operational black box solution or the knowledge included therein?······

Post Edited (Kramer) : 11/9/2007 5:04:48 PM GMT