Square tubing connectors needed for robot frame.

I like the design of the robot prototype in the modular wheel thread. However, I was not too pleased with the bracket screwed on the outside of the tube. I understand its a prototype, but I want something a little bit nicer, and preferably in the tube.

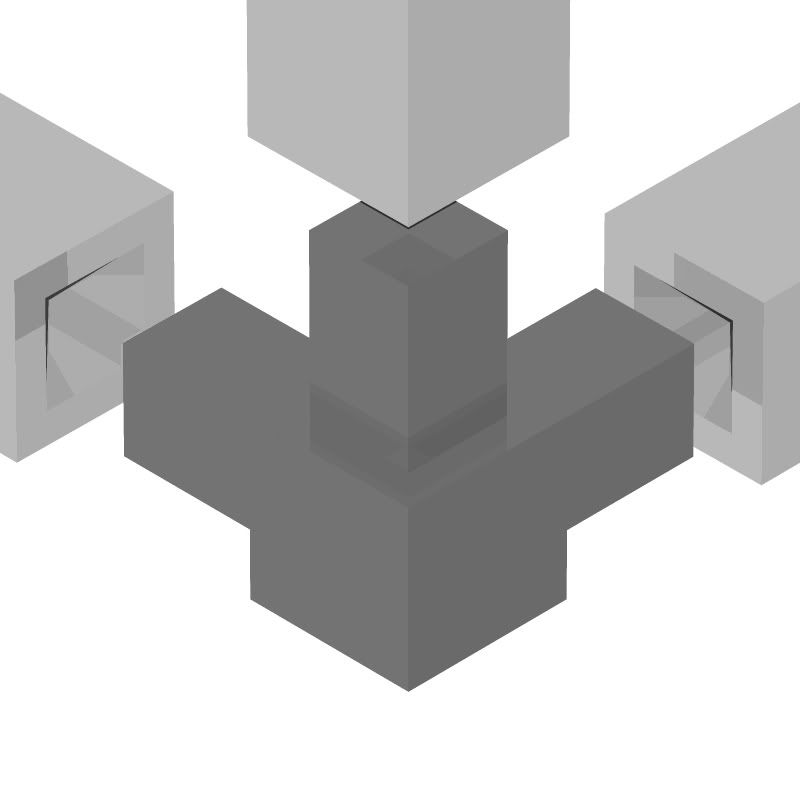

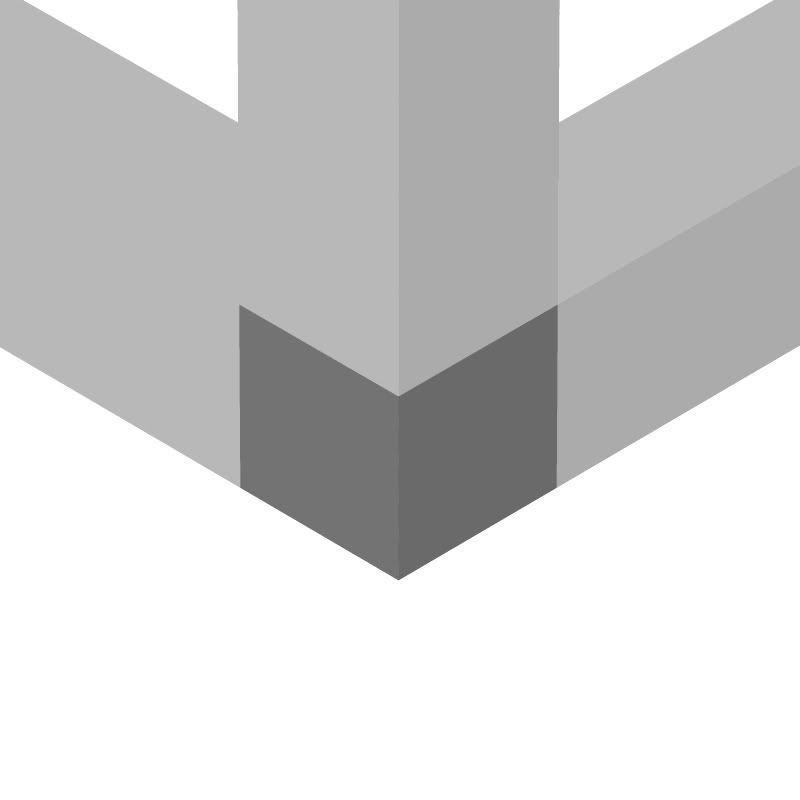

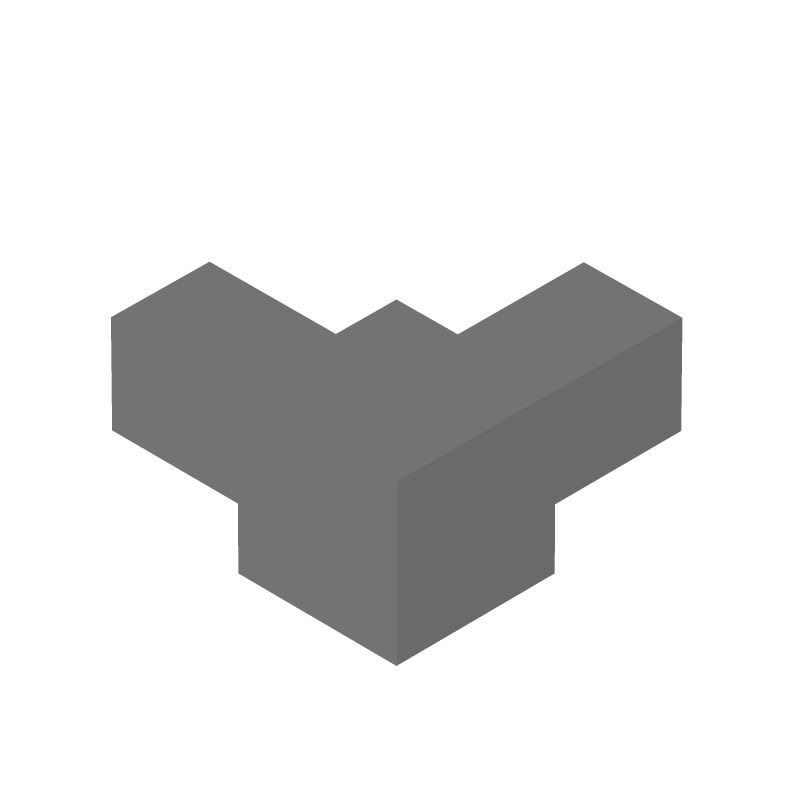

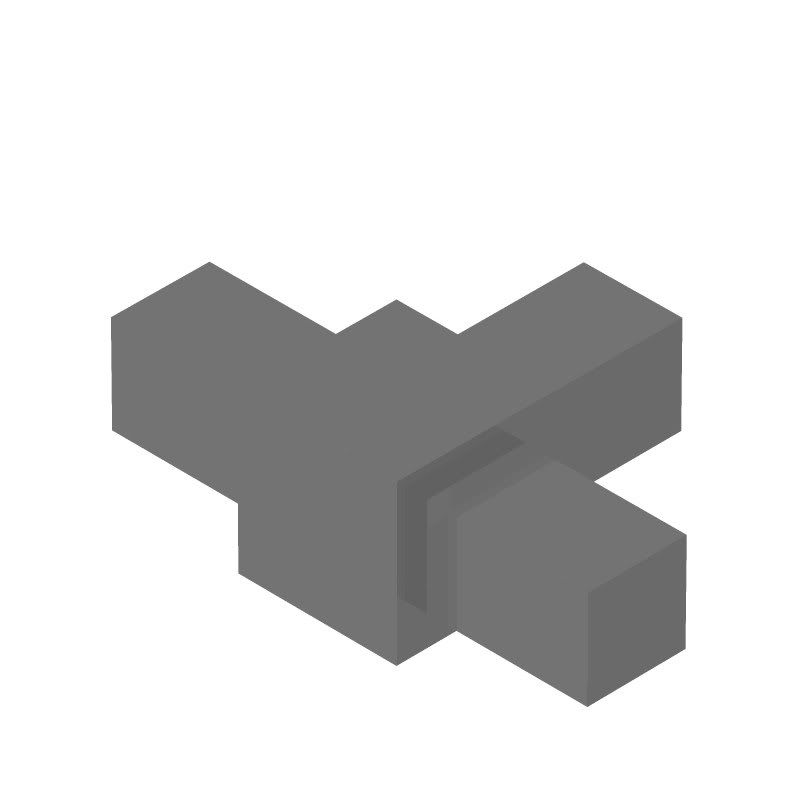

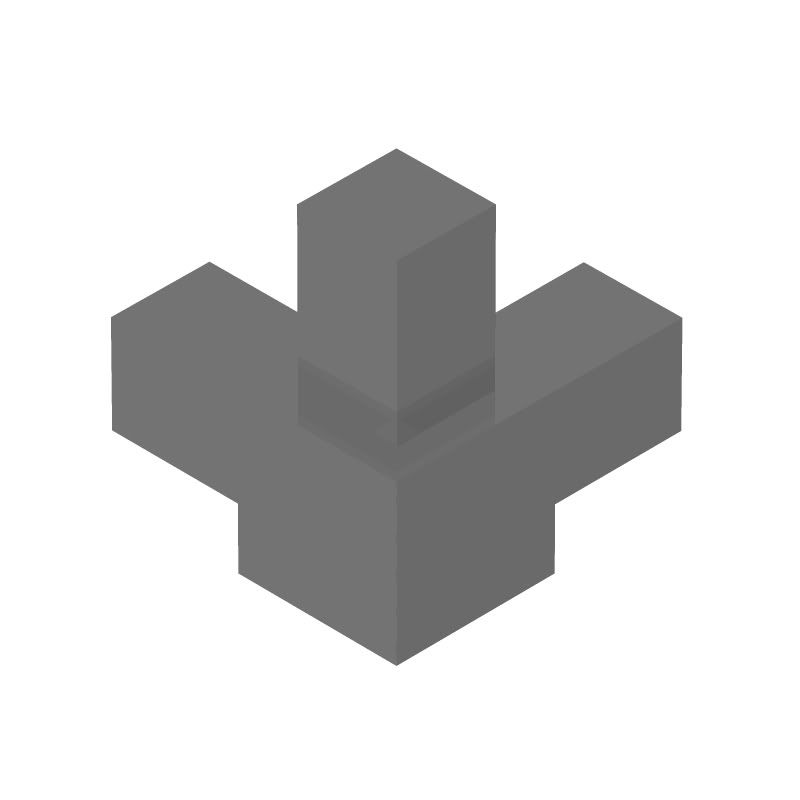

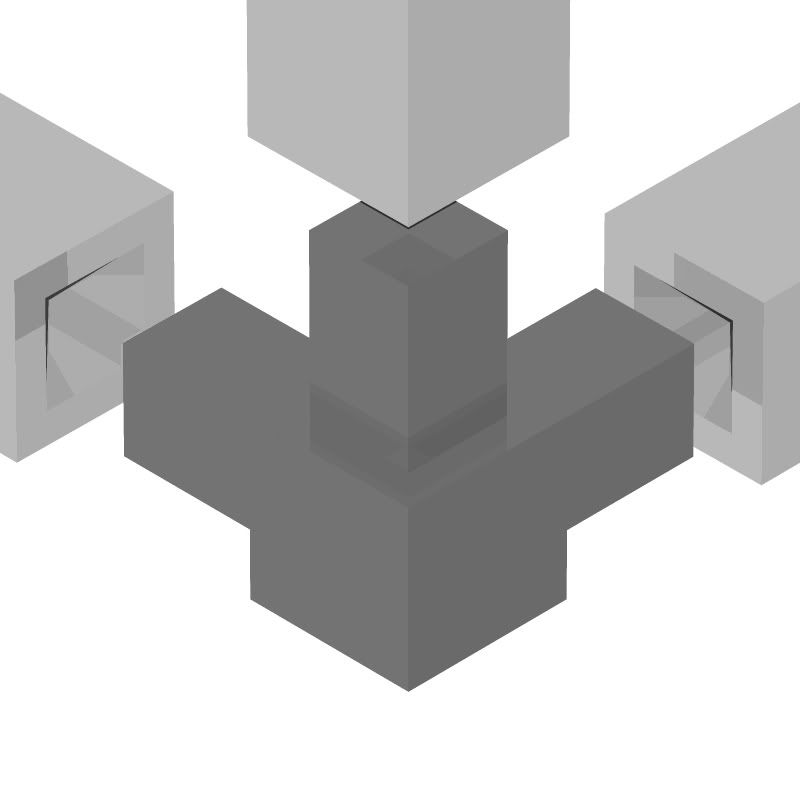

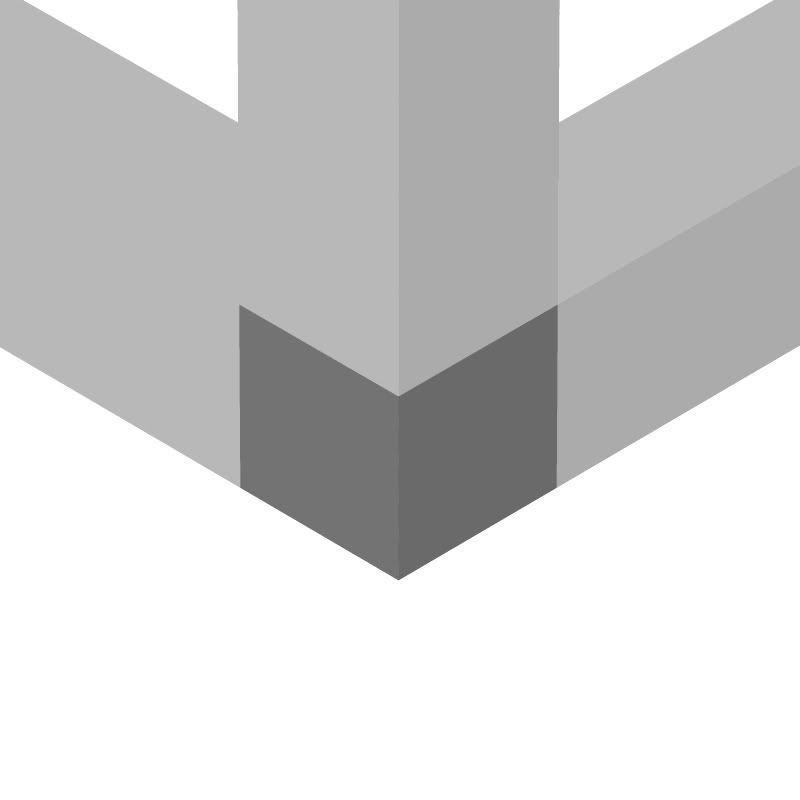

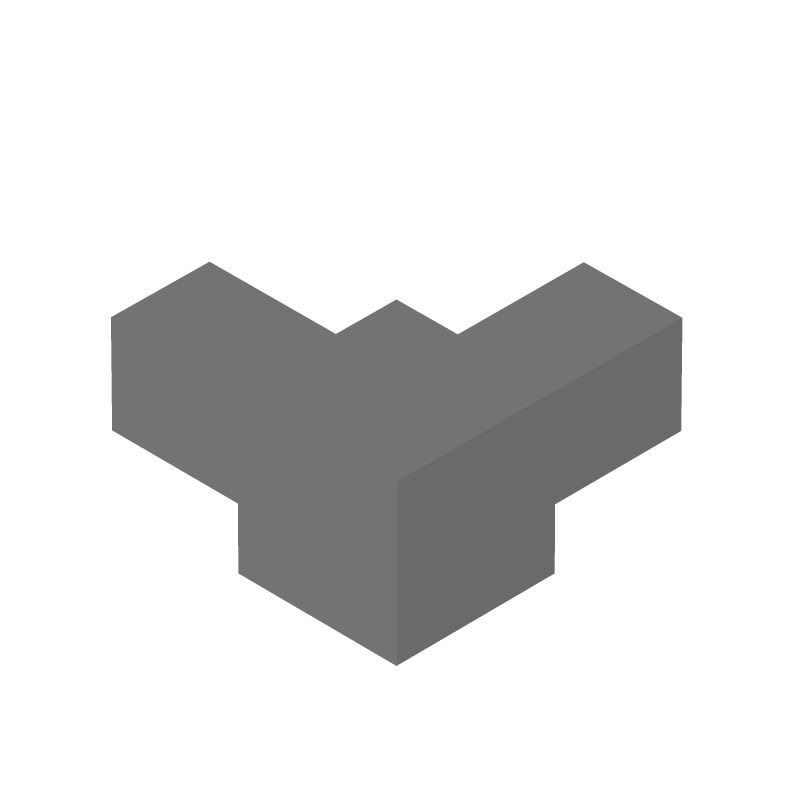

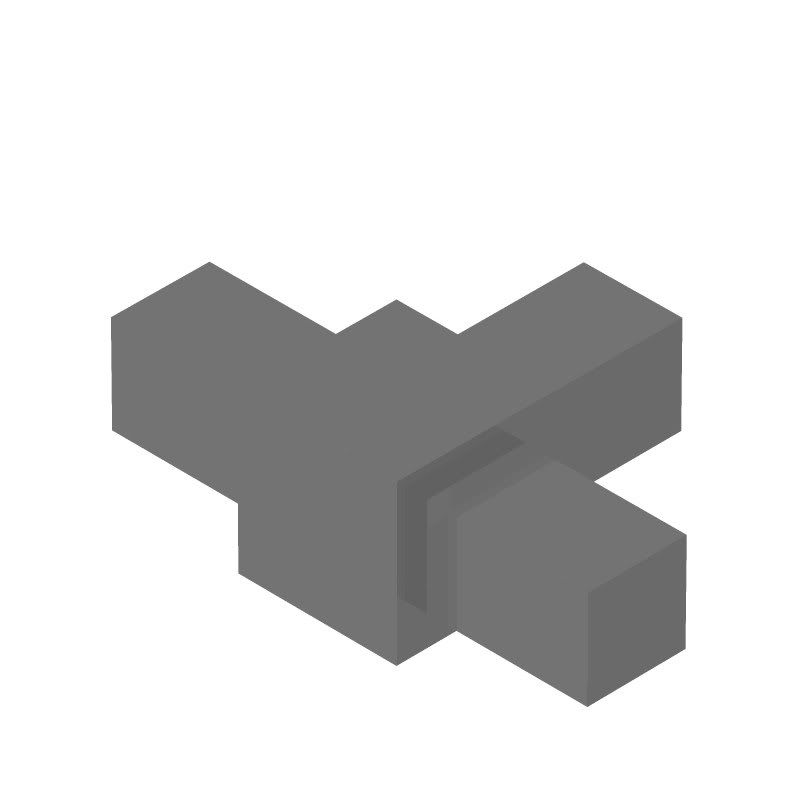

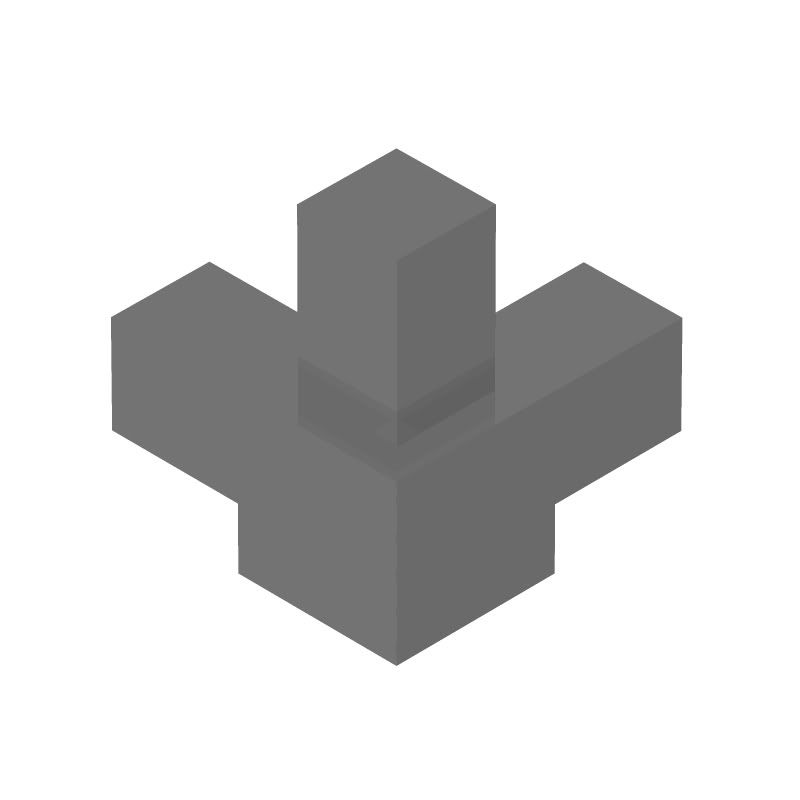

I came up with these, but I am not able to machine them:

These could easily be done with 1" PVC plate. The only hard one would be the 90° tee (last pic), but it could be made out of two separate pieces and glued together. The connectors would need to take into account the wall thickness of the tubing, and this would force the use of one wall thickness. I don't see this being an issue though. The 3D models shown above assume a .188" wall tube.

Would this be within the capabilities of anyone here with a CNC router/mill? Would Parallax be interested in this for a robot frame system to go along with their motors?

I came up with these, but I am not able to machine them:

These could easily be done with 1" PVC plate. The only hard one would be the 90° tee (last pic), but it could be made out of two separate pieces and glued together. The connectors would need to take into account the wall thickness of the tubing, and this would force the use of one wall thickness. I don't see this being an issue though. The 3D models shown above assume a .188" wall tube.

Would this be within the capabilities of anyone here with a CNC router/mill? Would Parallax be interested in this for a robot frame system to go along with their motors?

Comments

www.brunnerent.com

But do a Google search on aluminum framing-systems, and you'll find a ton of 'em. The extruded T-slot systems are the most adaptible, since they allow you to position parts and cross members anywhere along their length, without having to cut the extrusion to make a joint. Some of them produce quite nice-looking structures.

-Phil

Thanks for the help though.

http://gatorjaw.com/

http://www.8020.net/ (check out the Quickframe)

If welding gets too expensive, round tubing that is bent into U shapes will reduce the welded joints.

I like square tubing better, but economics is always the trade off in design.

And aluminum is 50% of the weight of steel.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Everything in the world is purchased by labour; and our passions are the only causes of labor." -- David·Hume (1711-76)········