Servo speed weirdness

Hey everyone,

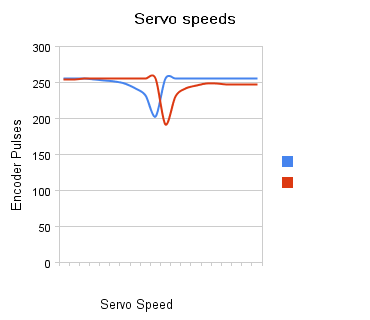

I wrote a little program to check what the difference was between the speeds of my servos at different pulse lengths. The results were quite interesting and a little disturbing, to be honest. My servos seem to be quite off. I created a small graph with these values:

You can see a two dips around the 750 value. Is this due to the servos not being centered properly? When they're at 750, they're totally motionless. Could it be a little "play" in the servo calibrations?

Gr,

Mightor

This is the raw data (also attached in xls file)

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

| What the world needs is more geniuses with humility, there are so few of us left.

Post Edited (Mightor) : 7/14/2007 8:06:23 PM GMT

I wrote a little program to check what the difference was between the speeds of my servos at different pulse lengths. The results were quite interesting and a little disturbing, to be honest. My servos seem to be quite off. I created a small graph with these values:

You can see a two dips around the 750 value. Is this due to the servos not being centered properly? When they're at 750, they're totally motionless. Could it be a little "play" in the servo calibrations?

Gr,

Mightor

This is the raw data (also attached in xls file)

650,255,254 660,255,254 670,255,255 680,254,255 690,253,255 700,251,255 710,248,255 720,241,255 730,232,255 740,203,255 760,255,192 770,255,230 780,255,242 790,255,246 800,255,249 810,255,248 820,255,247 830,255,247 840,255,247 850,255,247

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

| What the world needs is more geniuses with humility, there are so few of us left.

Post Edited (Mightor) : 7/14/2007 8:06:23 PM GMT

Comments

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Stephen

What pulses did you use?

For some reason the graph doesn't seem right...

EDIT: I noticed that you skipped pulse 750. any idea why?

I used PULSOUT values varying from 650 to 850. I skipped 750 because that wouldn't have resulted in any EPs at all and I would've been waiting until the cows came home for the program to be finished counting the 255 EPs.

There are 16 EPs in each rotation. They're related to the number of spokes in my Boe-Bot's wheels. I am using these: http://www.parallax.com/detail.asp?product_id=28107 .

The program counts until either the left or left encoder has counted 255 EPs then it prints out the number of EPs each side has seen for that particular PULSOUT value. That is why you always see a 255 value in either one or two columns in my data. If there are two values of 255 for a given servo pulse length that means both servos were running at the same speed. If there are fewer than 255 in one columns, it means that servo was slower than the other.

Mike,

As for accuracy, I am now playing with an auto-calibration tool for the servos where I take a speed I want the right servo to rotate at and find a matching left servo speed to go with it. I am still using the encoders for this. I only really need 4 speeds for the bot to go at; backwards slow and fast and forwards slow and fast. Turning is easy with the compass module and accurate enough for my purposes.

If nothing else, this is a fun little project to do. I guess if I really needed accuracy, I should use a stepper motor [noparse]:)[/noparse]

Gr,

Mightor

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

| What the world needs is more geniuses with humility, there are so few of us left.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Stephen

Gr,

Mightor

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

| What the world needs is more geniuses with humility, there are so few of us left.