Our newest Propeller accessory

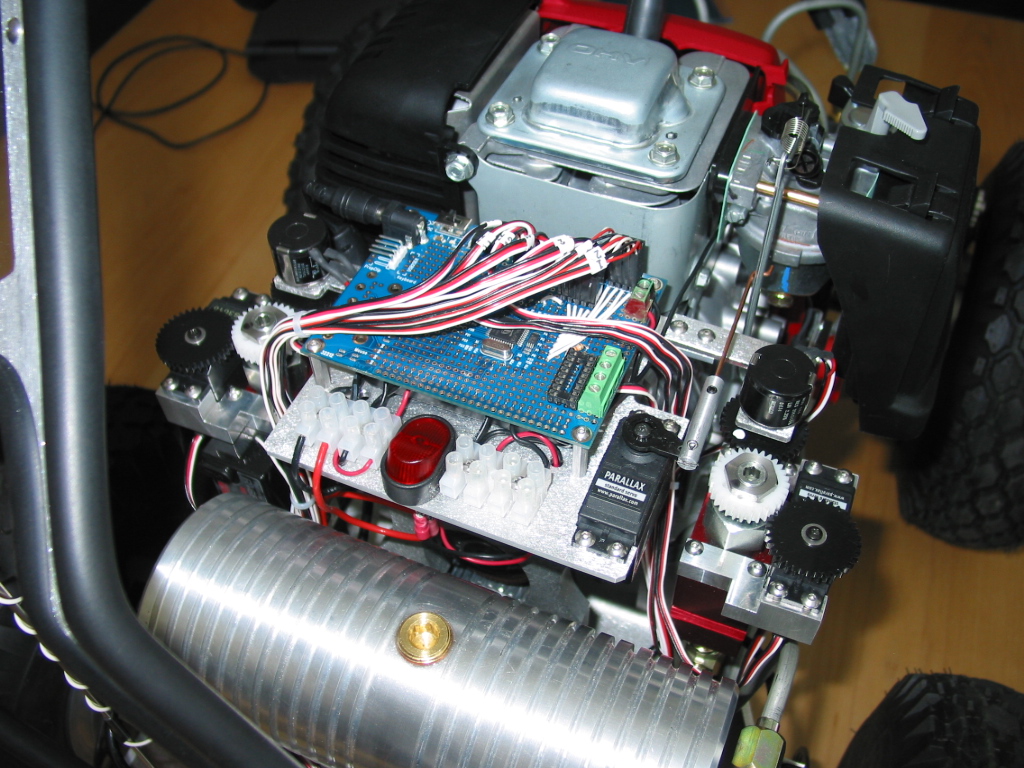

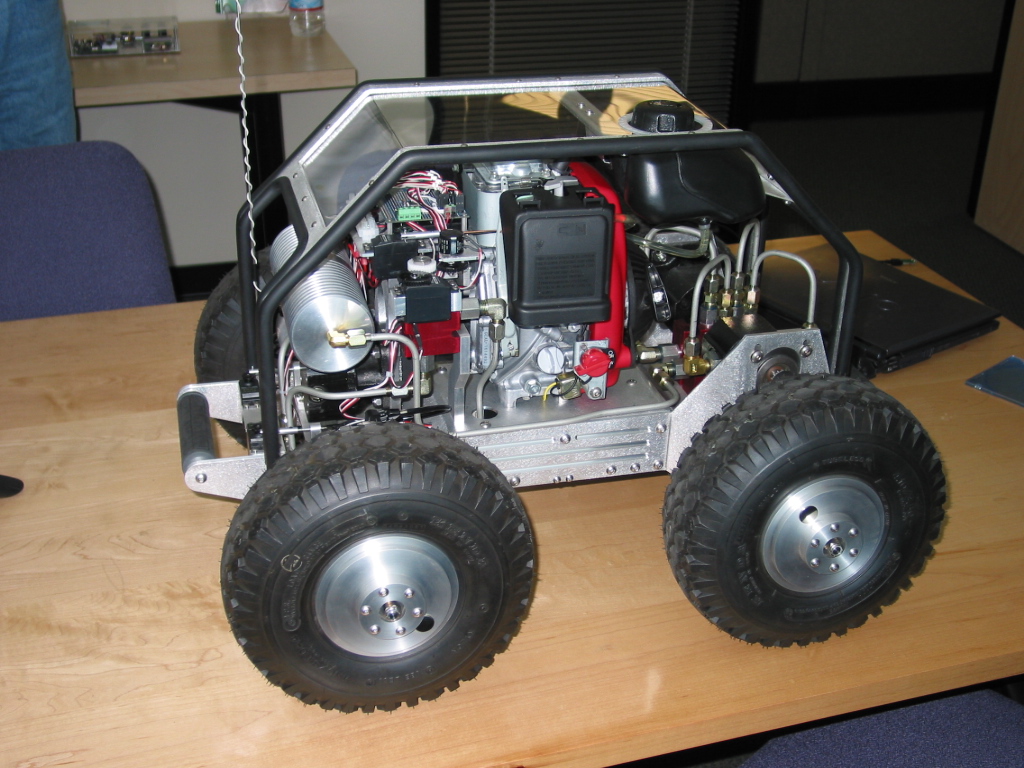

Thought I'd show a couple pics of our newest Propeller accessory currently in development, it's very own gas/hydraulic powered robot. A must for every Propellerhead! Just a couple minor changes and we should be starting a limited run production.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

Comments

WOW!

I'd guess a Prop Protoboard is just a $$mall % of that accessory!!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Harley Shanko

h.a.s. designn

But yes it will easily be our most expensive item we produce, and it will come with a custom Propeller board. The protoboard was used during development.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

My two cents,

Marty

As Tim the Toolman Taylor would say,"Ho, ho, ho-ho, Hoooooh!"

[noparse]:)[/noparse]

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

I hear, I forget

I see, I remember

I do and I understand

-Confucious

Looks great guys!!!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔ D Rat

Dave Ratcliff· N6YEE

Ratronic,

Sometime this year, in the $3K range, yes however I do not know if the RC transmitter/receiver will be included.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

Can I ask a stupid question? Why are you selling this? What market are you guys after? I have NO intensions of coming across sounding negative, please, it just seems like a wierd product from you guys, completely logical, but wierd. Is this a "poops-n-giggles" type of project, or have you guys been getting a lot of requests for something like this?

-Parsko

I speak as a representative of the Frequent Fryers Club:

We demand tracks[noparse]:)[/noparse]

Where did I put my LiDar object?

Rich

AND... for a few dollars more...can we have sockets?

Rich

Also, the hybrid gasoline powered alternator and electric drive is quite appealing if noise can be minimized.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Everything in the world is purchased by labour; and our passions are the only causes of labor." -- David·Hume (1711-76)········

P.S. I am assuming that when you say "gas" you are referring to gasoline?

Bergamot, can you describe what size you're looking for? Usually, the challenge is that properly designed wheels need to be coupled with a specific shaft or axle size for robotics. In my view, the wheel (or a hub, at a minimum) needs to be designed to match the motor if it is to be directly mounted. Are you looking for something around 7"?

I'd like us to offer some larger wheels, but here is the challenge:

- one size won't fit everybody's needs

- they usually need to be coupled with a motor of appropriate size so the hub/wheel arrangement is resolved

- they're expensive, probably machined, because of the low volume (Harbor Freight wheels are stamped with giant presses)

How much could you pay for a wheel and motor assembly?

Ken Gracey

Parallax, Inc.

This robot uses the gasoline engine to cycle hydraulic fluid, and with valves and hydraulic motors transfers that energy to the wheels. This thing has some serious torque and can climb some pretty steep inclines and can go places an electric motor robot cant go.

Practically every structural element was machined, including the wheel assembly. The tires are for high end standing scooters.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

Post Edited (Paul Baker (Parallax)) : 5/9/2007 4:40:25 PM GMT

1. Blink LED. Check.

2. Drive robot through living room wall. Check.

3. Explain to wife the new house ventilation.

I am much too *frightened* to get one of these. Ten miles per hour, and

it probably weighs fifty pounds; that's a lot of kinetic energy. A propeller

"crash" takes on a totally new meaning.

Wow, This is cool. and being a hydraulics dude this is right up my alley.

Couple questions though,

What hydraulic motors are you using? and it appears you are using a chain/belt drive to transfer to the wheels. Any gear reduction or do the motors not spin that fast? (we use a 15:1 planetary for the gear reduction but have fast spinning motors.) Maybe a gear change is all you need to increase to the desired 10MPH vs. running the engine at a higher speed (may help the overall life of the engine to run at the slower speed, we max our Cummins QSB 6clyn to 2100RPM)

If you have customers that are wanting to tap into the hydraulics does the pump your using allow for the extra GPM needed without slowing the motors down or is that just up to the customer to resolve?

Also, Controlling the motors? I think I see what appears to be a 2 SERVO DRIVEN? line bodies. (we electrically control our transmission's swash plate and use electric controlled valves to shift the wheel motors) Is this due to the 12/24V needed to control the coils of a conventional hydraulic cartriage? I must say if your using servos to do the controlling of the hydraulic motors, that is pretty Cool!

What is the other round Black device that is geared to the white line body gear? Position sensor?

and just because you may be curious as to what we build (fully hydraulic drive and steer) I'll post a pic.

This is totally cool. Keep up the good work guys! your inspiring all of us.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

HOLY *@Microsoft%@! (sorry for the cuss, I've been trying to clean up my language)

Live, Love, Learn!

My web: www.geocities.com/jet_aj

My Car Audio site: www.jdubaudio.com

The gear ratio will be adjusted to achieve the greater speed. Control of the fluid is achieved by solenoid actuated valves, as I explained in a previous post the servo valves are being replaced by solenoid valves. That geared black body you asked about is an external 10-turn pot, the internal feedback pot was replaced because we needed to measure a 10 turn revolution of the servo since it is a 10 turn valve. But using the brakes and a on/off valve achieves better performance than the 10 turn valves (which took a·couple seconds to fully actuate from one extreme to another), so they are being replaced.

Any hydraulic modifications is up to the customer to work through. We discussed the idea of a dual chamber pump with a contol valve so it would act as a 2·way transmission, but decided against it since it would require an entire overhaul of the cart.

Your truck is a monster, I bet it was alot of fun to build.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

Post Edited (Paul Baker (Parallax)) : 5/9/2007 9:35:06 PM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

We have built those trucks in various arrangements for several years now. That one is a cross mount (the engine sits sideways behind the cab)... They are designed for the Coal Mines, we have nearly 100 in service over the US that I can think of off the top of my head. Anywhere from 78" wide to 90" wide and from 48" high to 78" high... Air suspension and hydraulic drive train. Pretty fun to build indeed! It's like programming the Propeller or BS2, each truck/project has its difficulty but is very rewarding in the end. But now I'm getting off topic so I'll quit...

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

HOLY *@Microsoft%@! (sorry for the cuss, I've been trying to clean up my language)

Live, Love, Learn!

My web: www.geocities.com/jet_aj

My Car Audio site: www.jdubaudio.com

Isn't gasoline powered hydraulic more expensive than gasoline to electric hybrid?

I am guessing that the hydraulic offers either substantially more power or less noise involved. It certainly adds another layer of control. Is there a substantial benefit?

Can't wheels be on appropriately sized axles [noparse][[/noparse]sized for payload] rather than motor shafts with power transferred via gears, chain, or belt drive?

I know that everyone wants to save $$$ by direct drive, but motors generally like to run smoothly at higher RPMs than robotic wheels require. It is about inertia.

Also, having a chain or gear drive between motor and wheel may allow you to get a very low center of gravity.

Wouldn't alternator to electric motor be more fuel efficient?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Everything in the world is purchased by labour; and our passions are the only causes of labor." -- David·Hume (1711-76)········

Post Edited (Kramer) : 5/11/2007 1:48:53 PM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

How soon before a track drive is available. I would not want to invest all that money and not be able to climb over small obstacles. The wheel base will have to be adjusted also with a track drive or it will turn up-side-down as it climbs over obstacles. Right now it almost has the shape of a small sphere.

Jim.

No plans for tracks at the moment, so from the time a tracked solution is envisioned it would require at least a year of prototype and production. This robot climbs a square curb, by the way. It's got all the torque needed to go straight up steep hillsides. You may change your mind when you see the videos, maybe not.

Ken Gracey

Any news?

I really like things that work... and Parallax stuff works. I was wondering what the plans are for this peripheral? I would assume that a kit form might be available... and I was wondering whether the individual components might also show up as Parallax parts.

In particular, I am interested in the solenoids.

Rich

<Edit> Please see Ken's post below for availibility </Edit>

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

Post Edited (Paul Baker (Parallax)) : 7/30/2007 6:51:48 PM GMT

We will prepare documentation and some electronics in the meantime, and the early units will be available for sale as soon as we meet some minimum internal documentation/support goals.

Ken Gracey

Parallax, Inc.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

E3 = Thought

http://folding.stanford.edu/·- Donating some CPU/GPU downtime just might lead to a cure for cancer! My team stats.