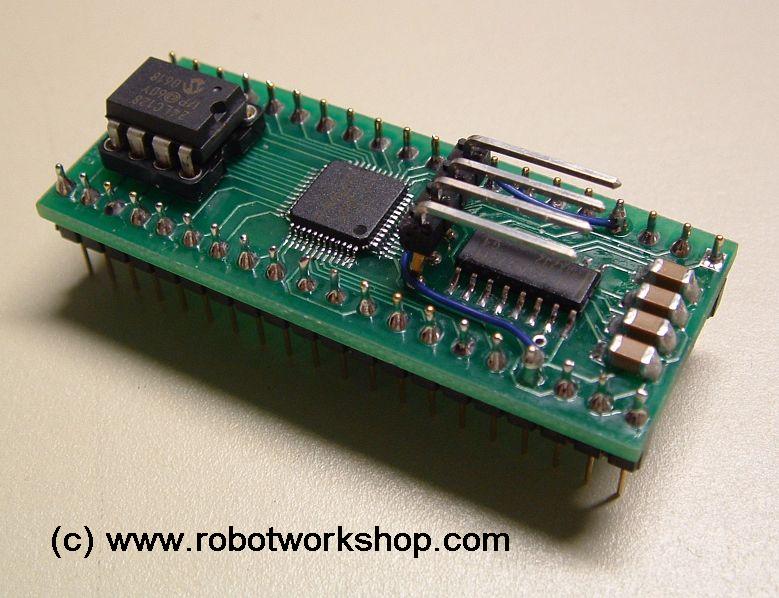

New SX48 module prototype.

RobotWorkshop

Posts: 2,307

RobotWorkshop

Posts: 2,307

Hello,

After a few twists in the learning curve i've been having pretty good luck

using the SX28 and SX48 chips. Since there wasn't a convient way to use

the SX48 on a breadboard or small robots I made one up that suited my

needs. It has an onboard MAX232, a spot for DIP EEPROM, and is made

from parts that can be assembled without getting all the fancy surface

mount tools. A fine tip iron, tweezers, and a bit of solder wick for the

CPU does the job nicely. It made a nice upgrade from the BS2p40 I had

installed before. Overall I am happy with the way it came out. It has

a socket for an external resonator. At this time there is not a socket for

an oscillator as I just couldn't fit it on the board and I really didn't need

it for what I am using the chip for.

Attached is a picture of my prototype. The two extra wires are a mod

for the programing adapter that will get into the next rev of the board.

If there is interest I could certainly see about a full kit for a module like

this. It would be a great way for someone to learn more about surface

mount parts. It is like an OEM kit for the SX.

Let me know what you think.

Best Regards,

Robert

After a few twists in the learning curve i've been having pretty good luck

using the SX28 and SX48 chips. Since there wasn't a convient way to use

the SX48 on a breadboard or small robots I made one up that suited my

needs. It has an onboard MAX232, a spot for DIP EEPROM, and is made

from parts that can be assembled without getting all the fancy surface

mount tools. A fine tip iron, tweezers, and a bit of solder wick for the

CPU does the job nicely. It made a nice upgrade from the BS2p40 I had

installed before. Overall I am happy with the way it came out. It has

a socket for an external resonator. At this time there is not a socket for

an oscillator as I just couldn't fit it on the board and I really didn't need

it for what I am using the chip for.

Attached is a picture of my prototype. The two extra wires are a mod

for the programing adapter that will get into the next rev of the board.

If there is interest I could certainly see about a full kit for a module like

this. It would be a great way for someone to learn more about surface

mount parts. It is like an OEM kit for the SX.

Let me know what you think.

Best Regards,

Robert

Comments

Nice job!

Another thread has someone asking for a SX48 con carne. I'd say you have already made it, and then some!

Is this going to be open-source ? Will you post schematic and/or layout ?

Bean.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Cheap used 4-digit LED display with driver IC·www.hc4led.com

Low power SD Data Logger www.sddatalogger.com

SX-Video Display Modules www.sxvm.com

Stuff I'm selling on ebay http://search.ebay.com/_W0QQsassZhittconsultingQQhtZ-1

"USA Today has come out with a new survey - apparently, three out of every four people make up 75% of the population." - David Letterman

Well done. I think that there is some interest. SMT has always scared me. This might be the thing that can cure me.

I hope that it comes about.

Chris

Actually surface mount chips are not that bad once you start getting use to them! I too had an aversion to using them initially since I thought they would be hard to work with if I didn't own all the fancy surface mount soldering equipment. With careful selection of surface mount parts and order of assembly it is possible to build these with the tools many people already have on their workbench! One thing that makes a huge difference is having a high quality board with mask as the base to build upon since the pads are so fine for the CPU. The SX48 chip is the first and hardest one to mount on the board. I'll get it in position and then just warm one pin with a tinned soldering iron. Before soldering any others I check the alignment with a magnifier. If it isn't lined up just warm that one pin and adjust it. Once perfect i'll tack down another pin on the other side of the chip and check again. If all looks well i'll solder each side and let it cool before doing the next. Then, go over each side with solder wick and let cool before doing the next. The MAX232 goes on next and can be done the same way but I usually find that I don't need the wick on that one. The remaining parts are easy! I've documented a lot of this since which has come from other kits i've made in the past. Schematics would be included with the docs. A kit is a definite option (assuming there is enough to cover a run of boards) but i'd rather have the focus on the kit portion as a way for people to learn to work with surface mount parts.

It certainly helps to have an OEM type kit that is known to work to at least get you started on surface mount devices and also makes a great way to validate that you can actually use these Parallax chips. I've got a similar layout for the BS2p40 OEM chip which i've used in a couple of my projects with fantastic results. It too has a MAX232 for more of a true serial interface and if the EEPROM ever wears out I can just pop it out and plug in a new one! That came out perfect. I had started with that and then modified it for the SX48 so I could get the benifit from those chips as well. When I started I would have picked up an OEM kit had one been available but learned alot along the way so it was worth it. That's how I discovered that a real BS2p40 module would work if the TX and RX lines are reversed which threw me off track for a bit.

Best Regards,

Robert

Robert

Your module is very nice, but it has more capability than I need.

At present I use the Parallax SX48/52 Proto Board for some applications, but I would like to have the ability to

replace just the SX48 if there is a problem.

Here is a general description of what I am looking for. Perhaps other folks may have similar needs.

SPECIFICATIONS:

Similar to discontinued Parallax SX52 con CARNE module

Selling price: $39 max, assembled and tested

Board should contain:

1. SX48 microcontroller

2. 4 pin programming header, to interface with SX Key or Blitz

3. 3 pin socket for resonator

4. 4 pin socket for resonator caps or resistor

5. 2 rows of 0.019"dia pins on 0.1" spacing

6. 21-24 pins on each side

7. SX48 pins to be fanned out:

a. All I/O ports, 36 total

b. Vdd, Vss

c. RTCC, MCLR

d. Osc1, Osc2

8. All pins silkscreened with names

9. No other on-board chips are desired

Thanks.

DaveG

what do you think about a plain "straight-through" adapter for the SX48 with no additional components but the SX48, and four filter caps for the supply voltage on a two-layer board with ground planes on both sides (not shown in the attached picture).

This is only a draft - I don't have the board yet; but may need to have it manufactured for one of my projects in larger quantities. I was also thinking about a 48-pin DIL-shaped carrier but this one would require more real-estate on the mother board than the square format which is about 1.5" each side.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

G

G

I would buy a few assembled modules if the price is comparable to the SX48 proto board. Your design looks great! The EEPROM and RS232 support are features that I would use, and the size of the module would fit with some projects I have in mind.

Guenther, have you considered a 10x10 grid format instead of the 14x14? This would reduce the area quite a bit. I thought about this a few months ago, and came up with the idea shown in the attached image. I made the image by doing a cut and paste from a picture of the SX48 proto board. Note, this is just a concept drawing, and it is not intended to be an actual layout.

Sparks, I think your area calculations are off a little bit. Guenther's design uses a 14x14 grid, so he is only allowing an extra 0.1 inch along the edge. The SX48 chip is 9 mm in size, which is about 0.35 inches. I don't think you could fit this on a 0.4 inch wide DIL. Robert's module seems to have a 0.6 inch spacing. If you add 0.1 inch around the edges you will get 0.7 * 2.5 = 1.75 square inches, which is slightly less than your estimate.

If a 10x10 grid is used, then the area should be 1.1 * 1.1 = 1.21 square inches.

Dave

I spent quite a bit of time last night cleaning up the layout for the board and working on the silkscreen. Since the space is tight the 'R' in the port names was dropped. They now just go B0, B1, B2, etc..., thru E6, E7. So far it looks good and with a little more work an initial run can be made. At the moment I would be focusing on a kit version but won't rule out an assembled one down the road. I really feel strongly that at least the kit should be available since it may get people started with surface mount parts and help teach methods of assembling them.

In regards to the voltage regulator, yes, it is located neatly underneath the module along with the socketed resonator and other parts. That's why the top has a clean look (except for the two wires which have been incorporated on the board)

There is still work to do but so far I like the way it is turning out.

Best Regards,

Robert

Robert

Well for my two cent's.

I would use the "good" 40 pin for the assembly, with a regular or better socket for the memory chip.

It was designed for prototyping and it would be nice to be able to plug/unplug it from protyping carriers..

Bob

It has not been manufactured yet.

Minimal space between tracks is 8 mils.

Track width is 10 mils.

The board is slightly larger than a 24pin DIL.

regards peter

I like the look of your board, and am looking for something exactly like that both for a project I'm working on and because I want to gain some SMT fab experience. Please keep us posted as you progress and if/when it might be available.

yes, you are definitely right, the DIL arrangement actually requires less real estate on the "motherboard" than the square arrangement. I had better made the calcualtions you did, before posting

Nevertheless, what I meant was that a DIL48-sized board does possibly not have enough real estate to allow routing of all SX48 pins to the corresponding pins of a DIL48-sized PCB. I found that it can be done when you turn the SX48 by 45° (like Peter did).

The attached picture shows my design. Please note that I did not assign the SX48 pins 1:1 to the DIL pins. This is because I wanted to keep the traces for OSC1 and OSC2 as short as possible. Except of the SX48 and the two filter caps, there are no other components on this board because it is my idea to make an "SX48 DIL plug'n play' version allowing to access all I/O pins without any restrictions.

Whenever the traces connected to a high-speed device like the SX48 become longer (i.e. antennas), my "EMI alarm light" goes on. This is the main reason why I gave up the 1:1 pin assignment idea to allow for shorter traces for OCS1 and OSC2. I have also added two filter caps between the Vdd and Vss signals, and added a Vss plane almost all over the bottom side, and a Vdd plane covering as much space as possible on the top side. These two planes make an additional low-impedance capacitor between Vdd and Vss helping to reduce EMI.

Although I could have reduced the DIP package's pin-count by only providing just one pin for Vdd and Vss each, I have decided to keep the original number of four pins for Vdd and Vss each. This adds some freedom for selecting the power pins on the DIL48 socket. Nevertheless, for lowest impedance and EMI reduction, I suggest connecting them all to the supply potentials on the motherboard.

The minimum lead width is 10 mils, and the minimum spacing is 8 mils. So, this is not a typical design for a "home-brew" PCB but a professional PCB manufacturer can do it. The board size is approx. 2.4" x 0.7".

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

Günther

Keep updating the forum please [noparse]:)[/noparse]

Personally, I'm about to pick up a few of the sx48 proto boards to use as fast peripherals for my propellers for some projects; the sx28's i picked up off ebay does not have enough I/O's [noparse]:([/noparse]

Bill

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

www.mikronauts.com - a new blog about microcontrollers

yes, I agree your, Peter's, and mine design are similar but still different enough

For one of my products that currently uses an SX28, sitting in a socket, it might become necessary to switch to an SX48 due to more features, my customer is asking for. As the current design is all plated-through, and my customer wants to keep it this way, with the possibility to replace the controller without soldering, I would need an "SX48 DP". This means that I would then have my board produced in larger quantities, and have the SX48 professionally assembled on the boards. In this case, there is a good chance that I can offer these boards to the SX community at a reasonable price.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

G

I've just about finshed cleaning up the layout for the SX48 OEM module kit. The last bit of work is all about the silkscreen ledgends for the top/bottom of the board. Things are getting a bit tight since i'm trying to make sure all the pins and components are labeled and trying to orient them so they do not interfere with any solder pads or vias.

A few of the part numbers will end up being hidden underneath the part after it is installed. This shouldn't be a big deal since most are needed mainly for kit assembly and will be in the docs. Most of the pin labels have been shortened to 2 characters like:

RB0 --> B 0

...

RE7 --> E 7

VSS --> VS

VOUT --> VO

VIN --> IN V ( Can change to VI )

/RES --> /R near the reset pin

There are a couple ways I can go with the remaining three pins. At the moment they are going to the MAX232 chip and I have them labeled as:

Pin 1 - S O (for SOUT)

Pin 2 - S IN (for SIN)

Pin 3 - A TN (Goes to MAX232) a 4.7K resistor can be installed on the bottom as a normal pull up on the reset line, or can be installed on the top to enable the ATN line to reset the CPU. When the resistor is on the bottom this driver is available and Pin 3 could then be used as a RS232 serial input by adding a jumper on the module. I want it to be flexible.

The RTCC pin from the CPU goes out to a single VIA (labeled RTC on the silkscreen) giving the builder the option of connecting it however they wish. If you'd like to ground it simply make a solder bridge right at the CPU to the pin next to it.

The optional resonator can go in a socket underneath the module. It is labeled Y1

And last of all is the four pin socket for the SX-KEY. It is labeled X1 and I labeled the pin on each end. VSS on one side and OSC1 on the other. I wanted to make sure that was clear to prevent someone from accidently plugging it in backwards.

At the moment the only portion I am on the fence about are the labels SOUT and SIN and if I should change them to the appropriate RA pins. I prefer to leave them as they are since it makes it obvious which way the MAX232 driver is setup and then note the pins in the docs.

I know the final result probably won't please everyone but I want to use what makes the most sense for most and go with it.....

Best Regards,

Robert

Robert

At the moment i've been using everything at 5v but it should be easy to build it either way.

Robert

as far as I have seen, the only voltage-critical part in your design is the MAX RS-232 level shifter. If you would use a MAX3232 device, the board should work at any supply from 3.3. to 5 Volts, or did I miss something ? In addition, the MAX3232 has the advantage that 100 nF pump-charge capacitors can be used instead of the 1 µF el-caps. Although the MAX3232 usually costs a bit more than the MAX232, I think the extra costs are well-spent to make your kit more "generic".

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

Günther

well, I overlooked the on-board voltage regulator, so this is what actually makes the difference between a 3.3V and 5V Version.

I think the SX is tolerant to 5 V on inputs when running at 3.3V. The Propeller is designed for 3.3 V so it comes with clamping diodes at its inputs, rated slightly above 3.3 V. When you apply a higher voltage, a relatively high current will flow through these diodes to Vdd. This is why series resistors in the Propeller input lines are necessary to limit this current. The SX, on the other hand, is designed for 5 V (and less) supply. Therefore, the clamping diodes are rated above 5 V. So 5 V at an input should be OK when the SX is running at 3.3 V.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

G

to be honset, I'm not really a BASIC Stamp expert but I can't see a reason why the OEM Stamp chips should not run from a 3.3V supply, as long as you use 3.3V-tolerant components around the chip. To my knowledge, the serial EEPROMs usually used for program memory are rated down to 3.3V. I have tried an SX28 together with a 24LC64 EEPROM, and a MAX3232 on my RS-232/I²C-Adapter, all powered at 3.3V without problems.

Concerning pin 37, there may be other forum members, more experienced with the Stamps, might give you a better advise but I think you should leave it connected as is.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

Günther

For a couple of customers we have produced 3.3-V BASIC Stamp chipsets using the SX28AC/SS. In fact, the MoBoStamppe runs at this voltage as well. The BASIC Stamp world tends to favor 5V and the requests for 3.3V are really not so common. My feeling is that 3.3V should only be supported on your module if it doesn't introduce substantial costs or extensive design modifications by the user. I bet that a few people will want to run it at 3.3V, but the vast majority would be happy with 5V. Sometimes you need to look at the cost/benefit ratio; just because you'll get a handful of requests doesn't necessarily mean you'll get additional sales that justify the expense (if there is one - I haven't read the thread in detail).

Ken Gracey

Parallax Inc.

I don't think i'd ever get this done if I try to make everyone happy

As of this morning I think I pretty much have the final board wrapped up and like the way it looks. I'm going to let it sit a day then go back over the board for a final check before sending them off. I think this will be really cool and a useful little kit!

Robert

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

---

James Newton, Host of SXList.com

james at sxlist,com 1-619-652-0593 fax:1-208-279-8767

SX FAQ / Code / Tutorials / Documentation:

http://www.sxlist.com Pick faster!

Count me in for the SX module kit -- it looks great. It's time for me to dive into SMT! Are you going to make it available here or at RobotWorkshop.com (or both). Do you have any fix on possible pricing?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

When the going gets weird, the weird turn pro. -- HST