any difference on PCB?

i made a PCB for a project, which worked on the BOE.

it doesnt seem to work on the PCB board. when exporting

a project to a PCB, is there any other component i need

besides those that are on the BOE and a voltage regulator?

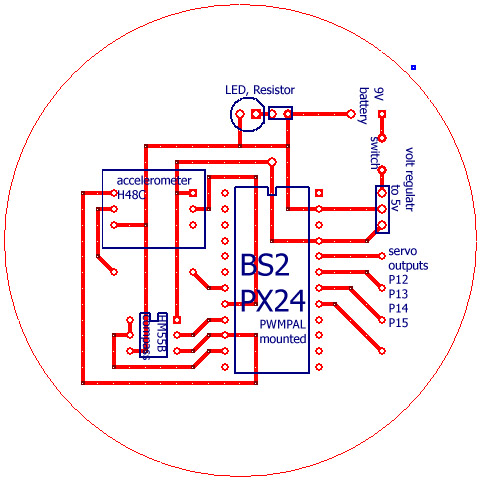

attached is my PCB diagram (the right way around, so its

easier to see)

the servos are powered by a RC receiver (with an attached

battery, ample power supply) and only the signal comes from

the PCB/BOE. common grounded

the voltage regulator regulates to 5v, and is around the

same voltage as the BOE. i didnt measure current, does the

amount of current entering a compass (HM55B), an accelerometer

(H48C) and a BS2PX24 make a difference?

i am missing something here and it's making me very irritated [noparse]:([/noparse]

it doesnt seem to work on the PCB board. when exporting

a project to a PCB, is there any other component i need

besides those that are on the BOE and a voltage regulator?

attached is my PCB diagram (the right way around, so its

easier to see)

the servos are powered by a RC receiver (with an attached

battery, ample power supply) and only the signal comes from

the PCB/BOE. common grounded

the voltage regulator regulates to 5v, and is around the

same voltage as the BOE. i didnt measure current, does the

amount of current entering a compass (HM55B), an accelerometer

(H48C) and a BS2PX24 make a difference?

i am missing something here and it's making me very irritated [noparse]:([/noparse]

Comments

Let me just repeat what I think you're saying for clarity. Here's the way I'm interpreting what you're saying:

First, you made your own carrier board (or PCB) for use on a BOE BOT. That seems to work well, and as you expected.

Then, you have duplicated that circuitry on a separate PCB for use elsewhere, and it is not working.

If that's true, or essentially true, in what way is the (new) separate PCB not working?

One change I'd make immediately, even if it's only on a test basis, is to replace the 9 volt battery with a power supply (of appropriate voltage) and see if the problems disappear.

Regards,

Bruce Bates

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

<!--StartFragment -->

i have a circuitry on the BOE's breadboard, i made an equivalent in PCB version.

on the BOE, i simply have wires on the breadboard connecting P2-P6 to their

required places, VDD, VSS wires and all.

i did not have a previous PCB used for the BOE (just BOE, not bot), i used the

breadboard on the BOE.

the PCB version of the circuitry does not work, because the servos being controlled

do not function as i want them to, they just go crazy. i'm having a hard time getting

to a oscilloscope so i can't see if the signal being sent is correct.

i also cannot see the debug because i do not have an LCD. if there is a way to stick

a wire to enable the board of education to show me the debug, that would be great.

I'm still not exactly sure what you're attempting, but it is a bit cleared now. You can use the DEBUG command to send information back to the PC for display during testing. The programming cable must be in place for this to work properly.

I suspect that changing from a 9 volt battery to an appropriate wall adapter may solve your problems, as mentioned before.

Regards,

Bruce Bates

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

<!--StartFragment -->

I can't tell what the power source for the servos is. If it is separate, make sure to tie the grounds together.

Opps, re-read your post. That's not it. ...nevermind.

HTH, Chris

Post Edited (CCraig) : 1/12/2007 4:15:46 PM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Chris Savage

Parallax Tech Support

crgwbr

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

NerdMaster

For

Life

You mention that the servos are powered by a radio receiver, and just the signal is coming from your board. Were you able to use this setup with the bread board?

How did you break out the signal wire for the servos? Are they possibly getting a signal from both the radio and the STAMP?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

John R.

8 + 8 = 10

the servos are powered by the receiver, i removed the white (signal) wire and brought it around to my PCB board. so its not likely that there is conflict.

the mentioned setup works on my breadboard (with the STAMP on the BOE's IC holder), so im wondering if there is any extra component on the BOE that allows my stamp to perform as it does. on top of that, if i simply get the STAMP to PWMPAL to output a PWM=50% of the servo (1.5ms i think), pause 20ms, it works fine (fixed servo positions). Chris, does this mean that there is no problem with the browning out? (what is browning out?)

however my program does some servo corrections according to the tilt and direction of the robot itself. (Bruce) i am attempting a robot stability thing, such that i always want it level (at least Gforces in X and Y as ~zero) and to always face a certain heading (maybe north)

i have no access to a wall adapter, is there any other option i can use? and what is the reasoning for using a wall adapter? insufficient current? thanks.

Post Edited (jawnlooi) : 1/13/2007 3:17:00 AM GMT

An appropriate sized (voltage and available current) "wall wart" or wall adapter takes all kinds of variables associated with batteries out of the picture.

Can you mechanically disconnect the servos from your robot, and if you do, how do things work? If they work "disconnected", but you get the erratic behavior when they are mechanically connected, it would seem to indicate either bad mechanical alignment/excessive friction, or and underpowered system.

Back to the fact that this was working with the BOE, and if indeed, the only change was moving from the BOE to your PCB, then there are a few things that you could/should check. First, look at the schematic for the BOE. It is avaialble at www.parallax.com/dl/docs/prod/boards/BOERevC.pdf. There are things on that board that you may not need (like the USB/serial connections), but you should definitely follow the power traces and make sure your board compares. The other "obvious" thing to look at is that your board truely reflects how you had the BOE wired up. A simple switch like what side of a resistor the STAMP pin is on could make all the difference.

Making a circuit board, even a trivial one, is not always a straight forward task. Don't get too discouraged, and keep plugging away.

A next step, after checking the above might be to fire up the BOE, and take voltage measurements where ever you can, and then fire up the PCB, and take measurements at the same spots. The voltages should be close. If you find one way off, that would be an area to start looking.

Good luck, and let us know what you find!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

John R.

8 + 8 = 10

would browning out still occur if i put a multimeter and get a good reading? (5v) but i only checked at the VR exit and common ground, i assumed voltage stays the same on parallel circuits (but you're asking me to check the voltage drop right? i should do that)

does current have anything to do with it? i havent measured the current in the circuitry though, but i have a resistor and LED to indicate when the board is in use, if current has anything to do with it then i suspect it would be my LED/resistor that eats up the current.

is there an alternate solution to a wall adapter? ie a whoopass battery or something. Singapore isnt too big on electronics so we dont have radioshack and all that jazz.

and i'm not very good at this electronic stuff, so what does a capacitor running from VDD to VSS do? doesnt a capacitor just charge up and discharge when needed? if so then won't it just discharge into VSS? (i think ill read up about capacitors and delete this when i understand) [noparse][[/noparse]edit: aight, i love howstuffworks, anyone can direct me where to place a capacitor on my circuit? would it be wise to remove the resister and LED and replace it with a capacitor at that position?]

Post Edited (jawnlooi) : 1/13/2007 1:41:12 PM GMT

If the entire system works on the bread board, but not on your circuit board, we need to focus on what's different.

Have you carefully compared the schematic from the BOE to your board? Pay special attention to the power supply portions (follow the schematic from the battery to the STAMP VCC and VSS pints). Also double/tripple check that you really have all of your circuit matching EXACTLY as you had things set up on the bread board. If you can go back and forth between the two setups, taking voltage readings at various points and comparing them may help track down your problem.

The capacitors will help "even things out" on the power supply side. When there is plenty of voltage, they will charge up. When the voltage drops, they will discharge in an attempt to keep the voltage constant. That's why they are sometimes referred to as "filter capacitors". They will "filter out" some of the drops and spikes in the voltage. (Simplified, but I hope it helps you understand.) Another way to think about this is to think of the capacitor as a small rechargeable battery. When the voltage is adequate, it charges to a steady state. If the voltage "spikes", it takes on extra charge, trying to keep the voltage across its pins constant. When the spike is over, it stays at the "steady state". Now when the voltage drops momentarily, the capacitor will release some of its charge, trying to keep the voltage across its pins constant. Basically, that's what a capacitor tries to do, keep the voltage across its pins from changing.

As far as the battery vs. wall adapter goes, if indeed, the setup on the bread board works, then we need to focus on what's different with your PCB. Besides all the connections, we also need to check out if you have good conductive paths. This is one of the things that taking various voltage readings could help track down. You may have all the traces going to the right places, but if you have a "bad trace" where some of the copper was etched away, or there is a scratch or other flaw through the trace, that could be a problem too.

If you could draw and post schematics or pictures, that might help too.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

John R.

8 + 8 = 10

i will place a capacitor on the PCB board and see if it works. referring to the PCB layout in the first post, would it be wise to replace the LED and resistor with a capacitor (in that position)? looking at the schematic, the only difference i see that might matter is the two 1000uF caps. by the way, i wired the power source of my PCB (from the PCB) to the BOE and it worked fine too, does this mean that the capacitors arent an issue? (oh, another difference is the resistor and LED, which might be eating up alot of current)

the circuitry is fine, no scratched copper. i do thinning as a precaution against that and corrosion. its an aviation practice i picked up, thinning of PCB traces are mandatory in the airline industry (feel safer now? :P)

theres a circuit diagram on the top, which i labelled so its almost as good as a schematic (i think). thanks for your interest, im learning alot from this thread.

Again, if this works on the BOE, check and compare every connection to see that it matches. Check all the VSS and VDD connections on each chip, and make sure they all (each chip) sees a steady 5 volts between their VSS and VDD pins.

I don't have pinouts handy for the other devices, so I can't say if you have any other problems with the circuit board.

I don't see any provision for connecting a PC or other debug device (LCD, etc.) so it would be hard to check for the recycling caused by brown outs.

Other then checking and comparing, along with voltage measurements, I don't know if there is anything more we can help with.

There is not going to be any short cut to solving this. You'll need to take a very methodical, step by step, connection by connection approach to checking and comparing with what you had on the BOE.

You should get the capacitors installed as discussed above. I suspect that you have other issues, but you should still have the capacitors in place.

Also, while tinning will help the PCB, I would still check all the traces. You're having problems, and should not make ANY assumptions.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

John R.

8 + 8 = 10

with the new resistor location, would having a capacitor at that place help?

i can only work on the device on monday (its in a locker at school), so i can only return the voltage readings across the devices on monday.

can i get the debug readouts if i wire 3 wires from the PCB to the BOE's SIN SOUT ATN?

It's time for you to take some initiative. See the above posts on where to put capacitors (two of them). Even if they are not your problem, they should be there.

Trace your other circuits. It's obvious that the picture you posted is not what you've got, so any further conjecture on our part is a waist of both your and our time.

Read this thread, and when you have the device in front of you, start going through all the suggestions. Until you have the device in front of you, anything else is pur conjecture.

Your idea for debug may work, assuming that those connections will get you to the BOEs USB or Serial adapter.

Keep in mind the following: Something is different from the breadboard setup you had, and the PCB you have. DON'T ***-U-ME ANYTHING! Check EVERYTHING out, and then get back to us.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

John R.

8 + 8 = 10

the PCB layout is the same, except for the resistor orientation, which i corrected a few posts earlier.

it works fine now, i removed the resistor/LED and tested it. the resistor LED was probably taking up too

much of the current.

i could respond without the device because i had the breadboard version of it with me, though not the

actual PCB, but i had done the voltage measurements before i posted on this forum, sorry if i caused

any undue stress.