Which rotational sensor...

...would be best for my project?

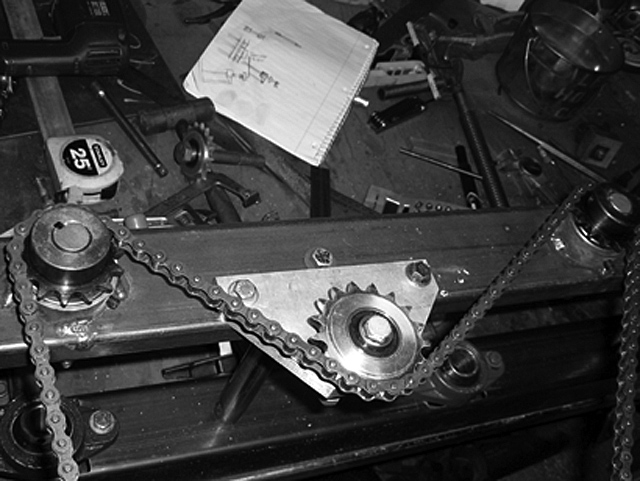

I need to make a BS2 aware of direction and RPM (this will be a very slow rotation, 30-40 RPM). I can use either a shaft, sprocket, idler sprocket, or flange bearing to get the info from, so I have options there.

My machine will most likely be pretty jerky & lumbering, so something delicate that needs to maintain a precise distance from sensor might not be ideal. "Forgiving" would be a good feature here.

So, photoelectric, infrared, hall effect; which would be suited best?

Thanks

Paul

I need to make a BS2 aware of direction and RPM (this will be a very slow rotation, 30-40 RPM). I can use either a shaft, sprocket, idler sprocket, or flange bearing to get the info from, so I have options there.

My machine will most likely be pretty jerky & lumbering, so something delicate that needs to maintain a precise distance from sensor might not be ideal. "Forgiving" would be a good feature here.

So, photoelectric, infrared, hall effect; which would be suited best?

Thanks

Paul

Comments

Not necessarily "firm" on the BS2, I just have a BOE so it's easy to test with what I've got. Sounds like the BS2 will be fairly useful here, I'll check out the quadrature encoder.

Would the Propeller be a better choice here?

Thanks

Paul

This won't be sold. I just wanted to build & develop a large walking machine; learning the programming is a recent development.

I will check out the Propeller...

Thanks a lot-

Paul