Which surface mount package is easier to hand solder?

Hi,

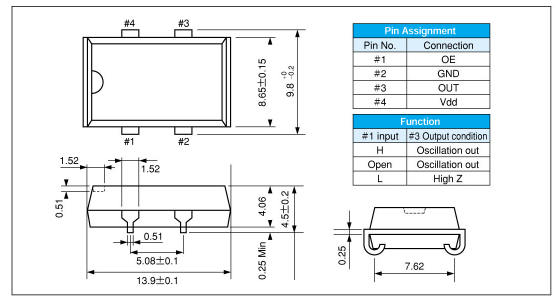

I have a circuit I'm designing and it looks like I may need to use a surface mount device on it. I'll be making a PCB and hand soldering the components. I have a choice between two styles of SMD packages, and (since I've never hand soldered SMD) I don't know which is the better choice for ease of soldering. I have attached pictures of both. Can anyone with experience recommend one or the other?

I have a circuit I'm designing and it looks like I may need to use a surface mount device on it. I'll be making a PCB and hand soldering the components. I have a choice between two styles of SMD packages, and (since I've never hand soldered SMD) I don't know which is the better choice for ease of soldering. I have attached pictures of both. Can anyone with experience recommend one or the other?

-

Thanks,

PeterM

Comments

-Phil

Is this intended for surface mount devices or is it an adapted device?

If I were to use a solder iron, I would go with the J mounts. Though I have no experience with such, I just feel more confident if I can visually inspect the connections.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"If you want more fiber, eat the package.· Not enough?· Eat the manual."········

The solder iron will work, but you'll have to hold the part in place, and have to deal with placing your solder, etc. If you invest the money to get the paste, you'll be glad to learn how the process works, plus be able to solder any smt part without a second thought.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Think Inside the box first and if that doesn't work..

Re-arrange what's inside the box then...

Think outside the BOX!

Thanks, PeterM