SMT oven attempt

I am discovering that with a slight learning curve, smt is actually easier to do. I am working on a method to laser some material for the stencil overlay. The stencil gets put over the board, squeegied with alloyed paste, then place the parts and bake.

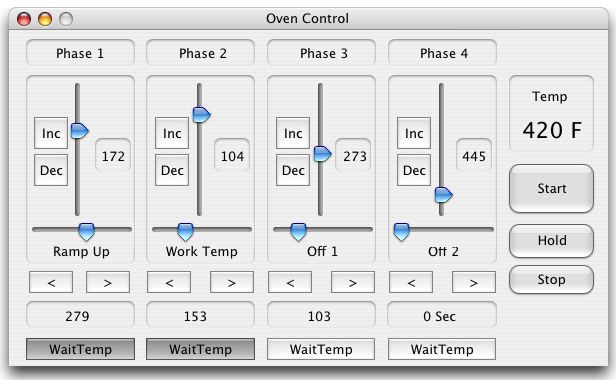

The oven needs to follow some general profiles to get things consistant. Here is an app I am working up that can be OS X or PC, it sends out the temp values as a string via USB2ser. Your favorite microm converts the string to a pwm rate( or just on off) that turns on the heating element on the convection oven. THere are two metheds to use:

The oven needs to follow some general profiles to get things consistant. Here is an app I am working up that can be OS X or PC, it sends out the temp values as a string via USB2ser. Your favorite microm converts the string to a pwm rate( or just on off) that turns on the heating element on the convection oven. THere are two metheds to use:

Comments

however you'll have to program a one-wire interface. There are othe chips out there that can read the millivolt range output by the thermocouple. I believe Circuit Celler as an article on it.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

I think there was a recent article in Circuit Cellar about using a toaster oven too.

Here's a spark fun artcle on using an electric frying pan!

http://www.sparkfun.com/tutorial/ReflowToaster/reflow-hotplate.htm

This was a design contest winner: http://www.circuitcellar.com/Renesas/winners/3323.htm

Rick B

But note I said try....I haven't yet.

James L

I thought the DS2760 would only go to 127 C........

But it may be my misunderstanding.

James L

K-type (Chromel / Alumel) Range: 32 F to 1873 F (0 to 1023 C)

J-type (Iron / Constantan) Range: 32 F to 1873 F (0 to 1023 C)

T-type (Copper / Constantan) Range: 32 F to 752 F (0 to 400 C)

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

I think this actually does read the higher temps, called Seebeck voltages.

Post Edited (originator99) : 11/13/2006 8:21:23 AM GMT

I am controlling an oven via USB2serial adapter straight to the SSR, no interface, just the + input on the SSR from the RTS line.

Next is to tackle the DS2760 I just got in today(Parallax kit). There is a chip that interfaces 1wire to serial that may work to minimize hardware and do all the work in the computer. The 1wire to serial chip is linked also for those interested. If any one has done this type interface before I'd love to find out how difficult it could be to access the DS2760 from the computer to get the temp.

pdfserv.maxim-ic.com/en/ds/DS2480B.pdf

studiotoyz.com/TempProfile.zip

studiotoyz.com/TempProfileOSX.zip

Post Edited (originator99) : 11/16/2006 9:36:25 AM GMT

I like your interface so far.....looks great.. Did you write that yourself?

James L

Post Edited (originator99) : 11/16/2006 7:40:29 PM GMT

Keep up the good work.

Also ....can I ask what "oven" you are using. There are so many out there.

James L

But I do have a problem. I have one board that can not be put into an oven. It has a package on it that will melt. I think I will have to "skillet" that board.

I would like to look at some of your electrical parts(photos) to get an idea on how you did it.

James L

Hmmm....souds interesting.....but I've never used the SX chip.

James L

My other boards that I'm designing can go into an oven. I just have that one design...that will have to have "special" care.

I just ordered two boards...and going to order components for them tomorrow. I haven't even started on an oven yet. I do have a skillet. I have read a lot about people doing their smt boards this way. These are prototypes....so if I mess them up....it's no· big deal.

I'm going to start designing my oven this weekend. Should be fun. I'll have to look at Beans info in the forum.

James L

www.studiotoyz.com/tempprofilepc.zip

www.studiotoyz.com/tempprofileosx.zip

Post Edited (originator99) : 11/21/2006 9:34:35 AM GMT