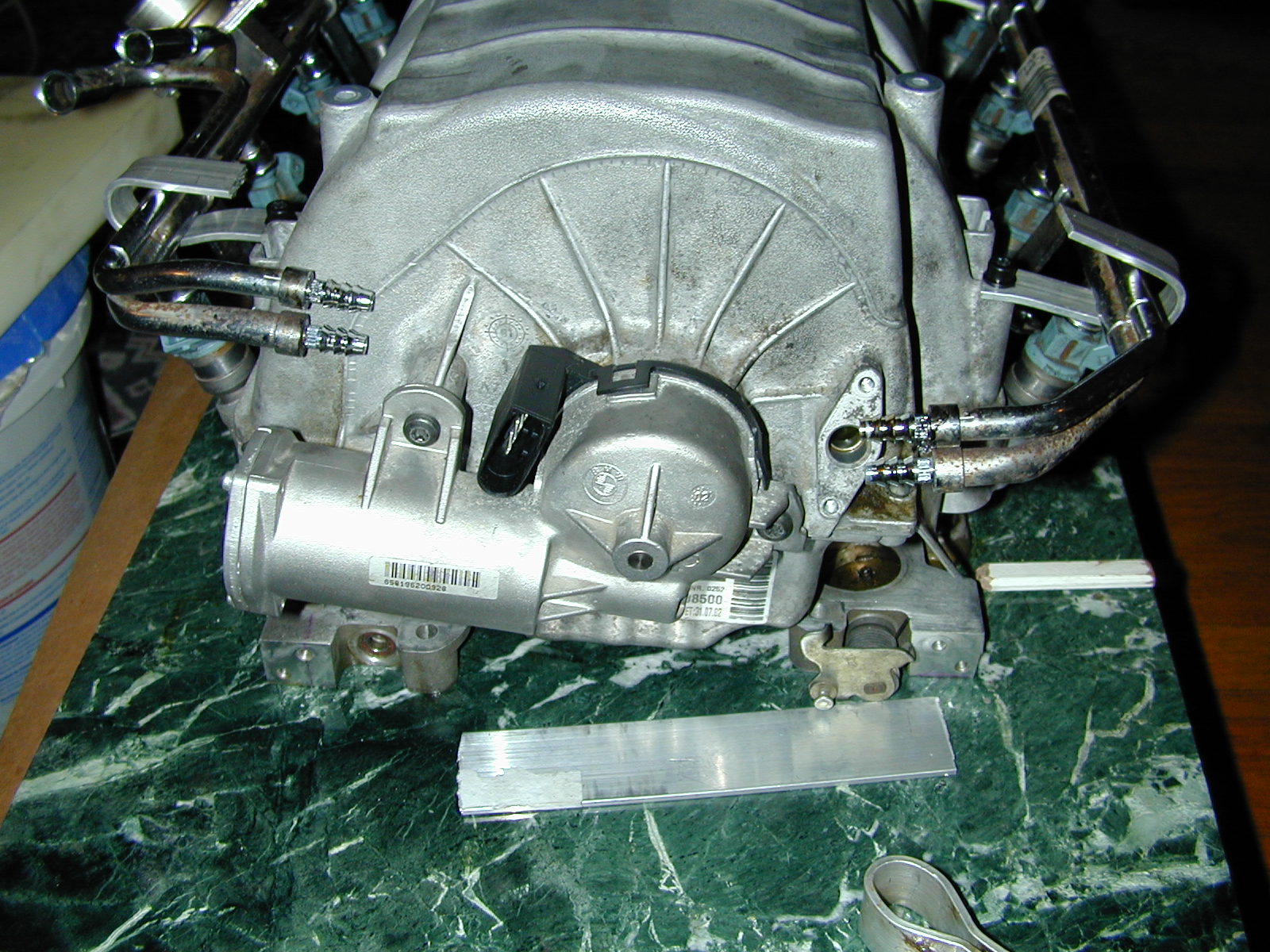

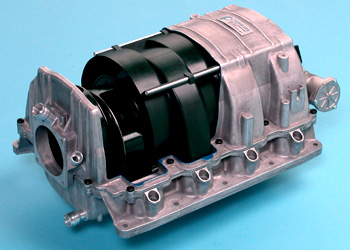

2002 bmw servo controlled intake manifold

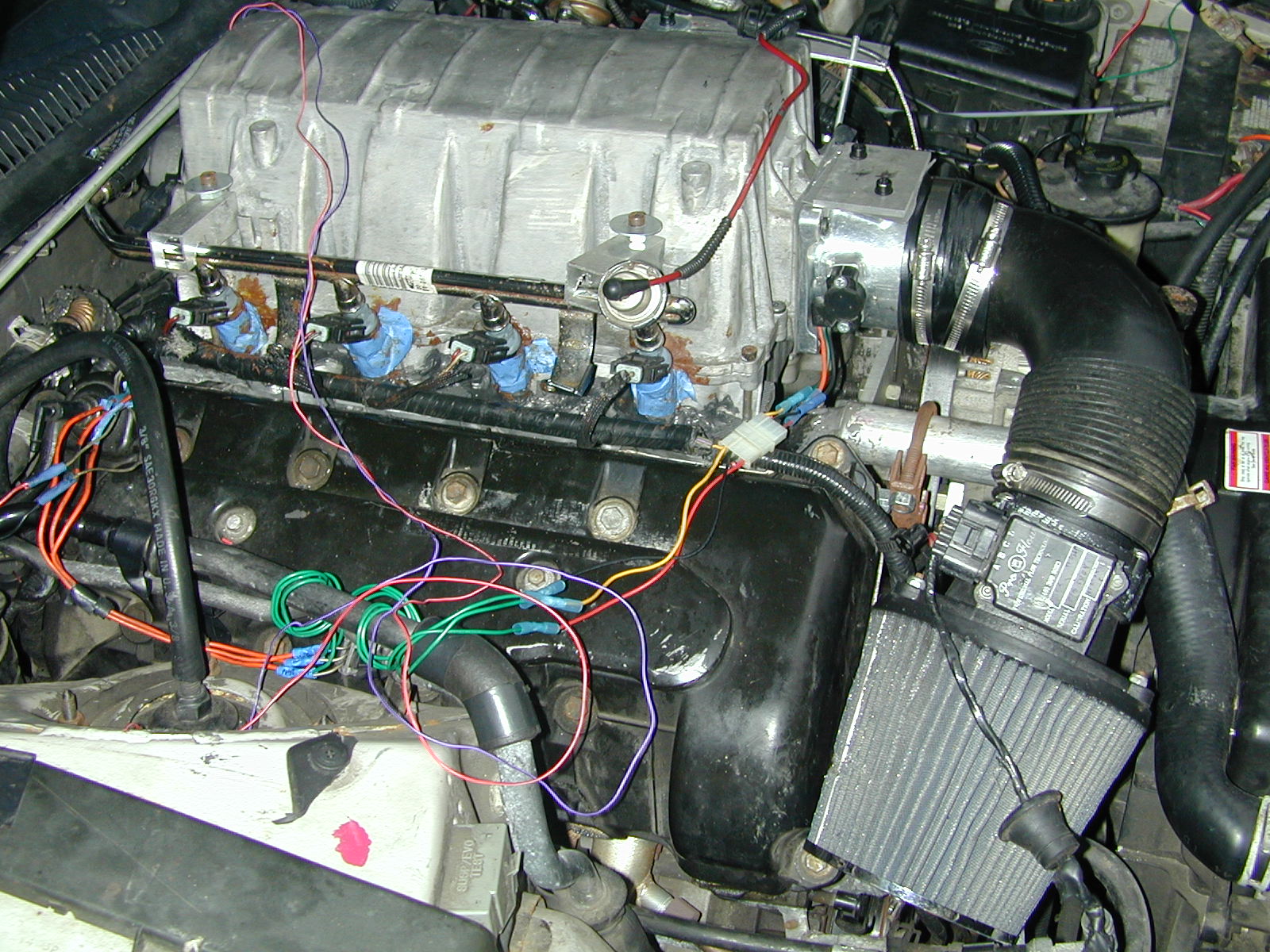

Bmw has devoleped·the worlds first fully variable intake manifold. The intake runners can traverse 230 degrees 13 inches of travel in less than 1 second. A set runner length will have a single point that based on wave reflections will aid in cylinder filling. With the variable length the·wave tuning can be used at all rpms. ·I bought a used intake 4 months ago and have it on a 4.6 liter ford 32 valve motor. I am controlling the motor that has a + and - marked with a 6 volt lantern battery its slower and easier to move it. Im sure it uses 12 volts for the proper speed required. Theres 5 pins 1 - 1 +·that go to motor then theres 3 more pins. I have sent a 5 volt signal into the pot? and I am using a volt meter for position. The readings are .80 -4.69. I can determine length of runner via voltage. I now need to control the servo. I need to be able to take a tach signal there are 2 hallmeters? one is for crankshaft position 1 is for camshaft position. I could try to piggyback off of one of those? I could buy a hallmeter. I could get a signal from a plug wire. I am looking for a controller. Input from motor rpm converted to servo-runner positions. 12 volt to motor. The motor is about 3 inches long and 1.5 diameter. I think it needs a good ammount of amps to do its job. Any suggestions?

Post Edited (mark8) : 10/29/2006 11:51:52 PM GMT

Post Edited (mark8) : 10/29/2006 11:51:52 PM GMT

Comments

I know this doesn't answer your question but it might give you some more to think about.

I would like to know more about your progress.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Dale Bartel

Portland Or

Post Edited (mark8) : 11/2/2006 1:53:45 PM GMT

Post Edited (mark8) : 11/3/2006 3:46:49 AM GMT

As for hardware, Parallax has several microcotrollers that could probabaly handle the servo & engine sensing. Parallax esentially sels three lines of microcontroller products - the Stamps (Basic & Javelin), the SX micros, and the Propeller. Each model in the various lines have their design pros & cons, but there should be something that can do what you are looking for. You just need to compare features to find the right fit for your technical needs and design/programming capabilities.

As for building the unit, I would break it down into stages:

1) Control the servo positioning independently of engine sensing

2) Sense engine RPMs independently of controlling the servo

3) Combine the engine sensing & servo controlling programs for final results

If you want to see a project that somebody has been working on that involves engine sensing, take a look here:

http://forums.parallax.com/showthread.php?p=609533

Of the books that I have one is fairly old and is based on organ pipe theory, it has plans for a mechanical valve to masure the pressure in the manifold for a given crank angle, 2 are from the SAE site. "The Design and Simulation of 4 stroke Engines" uses 3d CFD to track pressure and flow from atmosphere to atmosphere, and "Modern Manifold Design" talks about Helm Holtz Resonators.

I think you will find that the runner length will need to change depending on temp, altitude, and engine load for any given cam, valve, and port configuration.

To get the optimum runner length measuring the presure at the ports in relation to crank angle will be the way to go.

The same pulsing that is going on in the intake is going on in the exhaust as well and will affect the intake.

From a programming standpoint I would bet a table look up would be needed as I doubt that you will be able to do and equation that will work.

What will the car be used for? Will it have an air cleaner? What are you useing for fuel and spark control?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Dale Bartel

Portland Or

Post Edited (mark8) : 11/4/2006 2:04:11 PM GMT

What will help you get the right length will be a way to measure the pressure at the port as a function of crank angle.

To avoid driveability problems your transitions from one RPM to another will need to be well thought out.

What engine management computer are you using?

If you have any questions you can msg me at tech_mech_db@yahoo.com

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Dale Bartel

Portland Or