High Altitude Photographic Balloon

I have been working on this project for over 9 months now and it is finally complete. The launch will be in August and is located either right next to NASA’s balloon launch facility in Palestine, Texas or Lake Whitney. The Palestine location has an airport where I have already received permission to launch. I am still talking to Texas State Park services about the secondary location. Lake Whitney has a small dirt landing field for small planes. I was really hoping to use NASA’s balloon launch facility and get that “cool factor” but it is not to be. Nevertheless, it will be a fun day. My wife is making sure she has plenty of batteries for her cameras and video equipment.

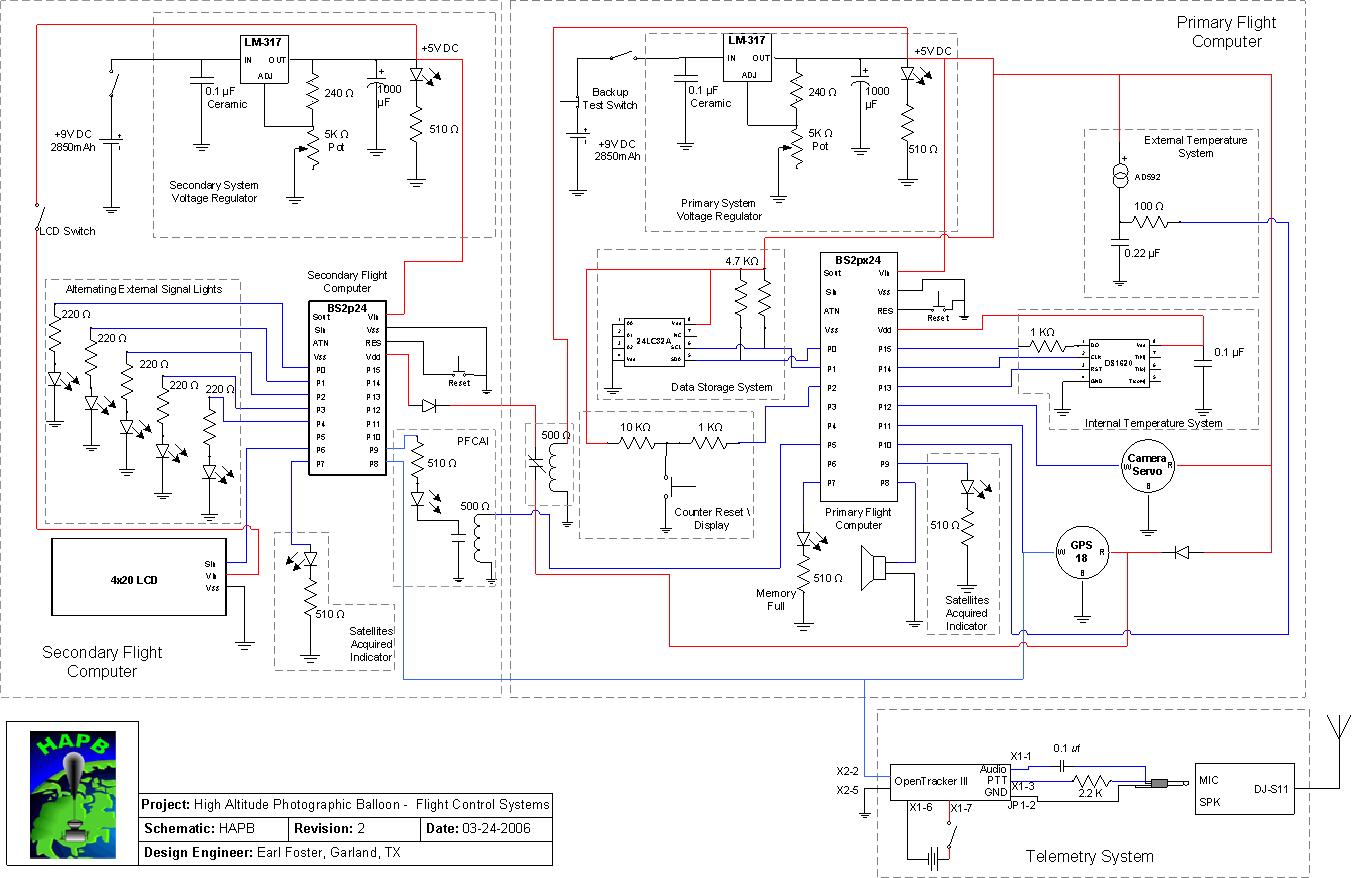

The Flight computer system consists of a Primary Flight System (PFS), a Secondary Flight Computer (SFC), and a telemetry system. Each system handles several functions with some overlap for reliability. See HAPB-FCS.JPG for schematic. I tried to upload the ExpressSCH file but I keep getting an error. I have been able to included the ExpressPCB layout file. Additional pictures of structural design are available at www.photoesque.com/HAPB. If you want the schematic just let me know and I will forward it to you.

The PFC is a BS2px and is responsible for reading and recording Latitude, Longitude, Time, Altitude, Internal capsule temperature, external capsule temperature, and taking pictures. Additional responsibilities include managing memory storage, relay controls, and audible signals.

The program flow process is simple: Initialize computer system; Check for manual resets; Get GPS data; Parse string and extract pertinent information; Read internal and external temperature; Check memory allocation; Storage information if space available; Evaluate altitude; Determine if picture can be taken; Toggle relay; Start over again. The program has many debugs that I could remove but decided to leave them in so I could watch the process while connected to a PC. I tried to optimize sub procedures and variables based on my coding ability. I am sure a more experienced coder could do better but I am happy with the results. Code available in HAPB_PFC.bsp.

The SFC is a BS2p24 and is responsible for reading GPS data and displaying this information to an LCD. The LCD is powered during testing and pre-launch activities to verify GPS data acquisition. Additional responsibilities include activating external signal lights when the capsule is below 1000 meters. I used oversized high output LEDS that are setup in a rotating fashion. This way I could maximum the current output without exceeding the Stamps current thresholds. The SFC also provides visual indication that the PFC is working through the use the Primary Flight Computer Active Indicator (PFCAI) light. The PFCAI toggles on and off each time the PFC competes a full cycle of the flight program. Code available in HAPB_SFC.bsp.

The indicator and display systems are used during testing, pre-launch, and post-launch activities. Tracking the payload throughout the flight is done via the onboard telemetry system and the vehicle tracking system. All in-flight data and photographs will be stored within the payload until recovery of the capsule, hence the importance of the telemetry system.

The onboard telemetry system is responsible for sending the payloads position back to my PC via amateur radio operating at 144.39 MHz. This is a well establish automatic position reporting system (APRS) frequency used by HAM’s in the US. Getting the amateur radio license is really easy now since you don’t have to know Morse code anymore for a Technician class license.

The Garmin GPS-18 sends native NMEA sentencse directly to the APRS device. The OpenTracker (n1vg.net/opentracker/index.php) converts NMEA sentences to APRS format. The APRS sends the data as audio to the radio and triggers the push-to-talk (PTT) button. The device can transmit other data such as power supply voltage and temperature.

I will be using my laptop PC connected to a Kenwood D700 dual band radio with built in TNC. This allows me to track the balloon on one band while monitoring voice activity in the area on the another band. Used in conjunction with WinAPRS software (www.winaprs.org/) I will be able to track the payload in real time and isolate my radio signal from others. This will facilitate the recovery process. I will also use Balloon Track (www.eoss.org/wbaltrak/) the morning of the launch to predict the flight direction and flight duration of the balloon. I want to stay within a 60 mile radius recovery area. If the prediction software puts the payload outside that range then I reschedule the flight.

Each system has its own single power supply with the exception of the GPS unit. I decided to use the SFC power supply as backup for the GPS to extend its life. If the PFC power supply fails then a normally closed relay is deactivated and power is supplied by the SFC power supply. The APRS and radio have their own power supplies and can last for over 24 hours. Between the PFC and SFC the GPS can be powered for 24 hours. This will allow me time to broaden my search area if needed.

The housing assembly is divided into 4 sections consisting of an Instrumentation platform, an Avionics compartment, a Battery compartment, and a Telemetry compartment. To keep the weight down I chose Expanded PVC Plastic sheets that I obtained from Budget Robotics (www.budgetrobotics.com/).

The Instrumentation platform is where all my bells and whistle are located for easy access. It contains the toggle switches, LCD, and light indicators. In addition, it has my contact information in case someone else finds it before I do.

The Avionics compartment contains the PFC and SFC. I decided to use a single PCB – again - weight factor.

The Battery compartment holds 3 sets of batteries. Each set consist of (6) 1.5 volt AA’s batteries and power the PFC, SFC, and APRS. I already have plans to reduce the power requirements for my next balloon project since this compartment contains almost half the total weight.

The telemetry compartment holds the APRS unit and my modified DL-11 hand held radio. The radio is fairly weak with its 0.3 watt power output and the stock antenna. I replaced the antenna with a 2-meter dipole made from coax cable. This will dramatically increase my transmission range.

The capsule consists of the housing assembly and film camera contained in a Styrofoam box. The box is wrapped in a silver space blanket to provide additional warmth and will provide better visibility during the search. I also added an emergency radar reflector for additional visibility. The total weight of the payload is 4.9lbs, which is well under the 6 lb FAA limit for a single payload unmanned balloon.

I will be posting more photos at www.photoesque.com/HAPB as they become available and we let the forum know when I have flight images available.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

The Flight computer system consists of a Primary Flight System (PFS), a Secondary Flight Computer (SFC), and a telemetry system. Each system handles several functions with some overlap for reliability. See HAPB-FCS.JPG for schematic. I tried to upload the ExpressSCH file but I keep getting an error. I have been able to included the ExpressPCB layout file. Additional pictures of structural design are available at www.photoesque.com/HAPB. If you want the schematic just let me know and I will forward it to you.

The PFC is a BS2px and is responsible for reading and recording Latitude, Longitude, Time, Altitude, Internal capsule temperature, external capsule temperature, and taking pictures. Additional responsibilities include managing memory storage, relay controls, and audible signals.

The program flow process is simple: Initialize computer system; Check for manual resets; Get GPS data; Parse string and extract pertinent information; Read internal and external temperature; Check memory allocation; Storage information if space available; Evaluate altitude; Determine if picture can be taken; Toggle relay; Start over again. The program has many debugs that I could remove but decided to leave them in so I could watch the process while connected to a PC. I tried to optimize sub procedures and variables based on my coding ability. I am sure a more experienced coder could do better but I am happy with the results. Code available in HAPB_PFC.bsp.

The SFC is a BS2p24 and is responsible for reading GPS data and displaying this information to an LCD. The LCD is powered during testing and pre-launch activities to verify GPS data acquisition. Additional responsibilities include activating external signal lights when the capsule is below 1000 meters. I used oversized high output LEDS that are setup in a rotating fashion. This way I could maximum the current output without exceeding the Stamps current thresholds. The SFC also provides visual indication that the PFC is working through the use the Primary Flight Computer Active Indicator (PFCAI) light. The PFCAI toggles on and off each time the PFC competes a full cycle of the flight program. Code available in HAPB_SFC.bsp.

The indicator and display systems are used during testing, pre-launch, and post-launch activities. Tracking the payload throughout the flight is done via the onboard telemetry system and the vehicle tracking system. All in-flight data and photographs will be stored within the payload until recovery of the capsule, hence the importance of the telemetry system.

The onboard telemetry system is responsible for sending the payloads position back to my PC via amateur radio operating at 144.39 MHz. This is a well establish automatic position reporting system (APRS) frequency used by HAM’s in the US. Getting the amateur radio license is really easy now since you don’t have to know Morse code anymore for a Technician class license.

The Garmin GPS-18 sends native NMEA sentencse directly to the APRS device. The OpenTracker (n1vg.net/opentracker/index.php) converts NMEA sentences to APRS format. The APRS sends the data as audio to the radio and triggers the push-to-talk (PTT) button. The device can transmit other data such as power supply voltage and temperature.

I will be using my laptop PC connected to a Kenwood D700 dual band radio with built in TNC. This allows me to track the balloon on one band while monitoring voice activity in the area on the another band. Used in conjunction with WinAPRS software (www.winaprs.org/) I will be able to track the payload in real time and isolate my radio signal from others. This will facilitate the recovery process. I will also use Balloon Track (www.eoss.org/wbaltrak/) the morning of the launch to predict the flight direction and flight duration of the balloon. I want to stay within a 60 mile radius recovery area. If the prediction software puts the payload outside that range then I reschedule the flight.

Each system has its own single power supply with the exception of the GPS unit. I decided to use the SFC power supply as backup for the GPS to extend its life. If the PFC power supply fails then a normally closed relay is deactivated and power is supplied by the SFC power supply. The APRS and radio have their own power supplies and can last for over 24 hours. Between the PFC and SFC the GPS can be powered for 24 hours. This will allow me time to broaden my search area if needed.

The housing assembly is divided into 4 sections consisting of an Instrumentation platform, an Avionics compartment, a Battery compartment, and a Telemetry compartment. To keep the weight down I chose Expanded PVC Plastic sheets that I obtained from Budget Robotics (www.budgetrobotics.com/).

The Instrumentation platform is where all my bells and whistle are located for easy access. It contains the toggle switches, LCD, and light indicators. In addition, it has my contact information in case someone else finds it before I do.

The Avionics compartment contains the PFC and SFC. I decided to use a single PCB – again - weight factor.

The Battery compartment holds 3 sets of batteries. Each set consist of (6) 1.5 volt AA’s batteries and power the PFC, SFC, and APRS. I already have plans to reduce the power requirements for my next balloon project since this compartment contains almost half the total weight.

The telemetry compartment holds the APRS unit and my modified DL-11 hand held radio. The radio is fairly weak with its 0.3 watt power output and the stock antenna. I replaced the antenna with a 2-meter dipole made from coax cable. This will dramatically increase my transmission range.

The capsule consists of the housing assembly and film camera contained in a Styrofoam box. The box is wrapped in a silver space blanket to provide additional warmth and will provide better visibility during the search. I also added an emergency radar reflector for additional visibility. The total weight of the payload is 4.9lbs, which is well under the 6 lb FAA limit for a single payload unmanned balloon.

I will be posting more photos at www.photoesque.com/HAPB as they become available and we let the forum know when I have flight images available.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

Comments

Will be interesting to see launch video and the after pictures!

Very cool!!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·

Steve

"Inside each and every one of us is our one, true authentic swing. Something we was born with. Something that's ours and ours alone. Something that can't be learned... something that's got to be remembered."

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

how do you navigate that site?

I've tried the "CTRL+click a shape in the drawing to view details." but that didn't do anything for me!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·

Steve

"Inside each and every one of us is our one, true authentic swing. Something we was born with. Something that's ours and ours alone. Something that can't be learned... something that's got to be remembered."

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

I am working with a team on a similar project, albiet on a much smaller scale. However, looking at your schematic I see many similarities in design - the dual power supply, dual BS2p24's . We are using the second BS2p to work with our GPS to perform separate duties from the rest of the package as you are ( the GPS guides a servo to provide control of a parachute).

Very nice to see a similar idea implemented so well, gives me hope that everything will work out well for our team!

Thank you for sharing, and I look forward to following your project to completion.

Edit: Or more like I should say launch and recovery!

Alohas,

Robert

Post Edited (Robert@HCC) : 7/27/2006 10:46:52 PM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

Careful with the BS2p and high altitude. It's rated to 0C, and it's likely to get colder than 0C on decent. This is because your payload is being repressurized with air that can be as cold as -60C. I used the industrial BS2 (rated to -40C) on mine. If your oscillator stops, your SOL. You might get lucky, but it's a gamble.

Dave

Typical Density of air: 1.23kg/m^3 = .00123g/cubic cm

Let's say your enclosure is a 25cm cube (10" per side), so you have about 16,000cc's of volume. Let's assume it's mostly air. That means you have about 20 grams of air (at sea level).

The specific heat of air is "about" 1 J/g/K. So to heat up your enclosure 60 degrees (at sea level), you'd need over a kilojoule of energy. This is do-able, but you'd need alot more than voltage regulator.

At altitude, the air density is less, and increases throughout the decent. So this calculation is by far a "worst case" scenario. However, the problem isn't the total energy required, but the power needed. You need to have a heater capable of producing several watts of heat to warm the air fast enough, as it's decending rapidly and frigid air is coming in fast.

Hope that helps,

Dave

First off I would like to say wow. I am really impressed with this project. It is just a shame that NASA wouldn’t allow you to lunch at their site. I have a few general questions and one technical question for you for now. I know I will have more down the road. So how long do you plan on the balloon staying up for? How high do you plan on it going? How far do you plan on the balloon traveling? When you complete this project what do you plan on taking from it and putting towards your next one? From the technical aspect of this, I would say that you been working with electronics for a while? How did you approach this project? Did you have your PCB fabricated for you or did you etch it and what not on your own? Thank you for your time and look forward to your input on my projects. Good luck on lunch day.

Regards,

Matt

The tethered test was conducted at 200 feet with the electronics installed to ensure proper operation of the telemetry system, primary and secondary controllers, and camera operations. I adjusted the altitude algorithm so it would take pictures every 25 feet +/-3%. The computer systems worked without any programs. It also was a good exercise in pre-launch activities. Much easier then I imagined. Two people can launch a balloon with very little effort. Recovery might be a different story but we are confident that we will manage.

I removed the electronics for the drop test. Figured if the chute and capsule couldn’t survive a 100-foot drop I didn’t want to ruin the payload. We installed an equivalent amount of weight inside the capsule and pulled the release pin. Capsule landed square without any damage. This was another big confidence builder for this weekend

I will be posting launch and recovery photos on the web next week along with a small video of the activities.

Will keep you posted.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

I just updated http://www.photoesque.com/HAPB·with videos of the testing.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

Post Edited (Earl) : 8/24/2006 1:16:29 AM GMT

I put an APRS tracking link on the bottom of my webpage if anyone is interested in tracking. The launch is scheduled for 7 am Saturday morning.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

Actually Lithiums are much better at low temps. Alkalines basically stop around -18C, while lithiums are good down to about -40C or more. Lithiums also can also support a much higher current drain than alkalines can.

At far as temperature went I had the exact opposite problem. The handwarmers worked too well. At one point during the launch the inside capsule temperature exceeded 130 degrees and never fell below 80 degrees which caused moisture to form. Moisture damaged a couple of resistors and caps causing the onboard data to be questionable, however, it indicated that HAPB-1 went to an altitude of 98,500 feet.

www.photoesque.com/HAPB

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

Just a tip on the website for the movies....maybe put the file size beside the links. Some big sized movies there!

Look forward to seeing the data (and the next flight).

cheers

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·

Steve

"Inside each and every one of us is our one, true authentic swing. Something we was born with. Something that's ours and ours alone. Something that can't be learned... something that's got to be remembered."

Are you using electrolytic caps? Space born systems generally avoid electrolytic caps for low-pressure applications, as the electrolyte inside can boil off (outgas). Short duration exposure usually doesn't cause problems, but it's possible. Tantalum caps are preferred in the aerospace industry, and are more resistent to moisture damage as well.

Also, condensation generally occurs on surfaces that are COLDER than the surrounding air. Condensation doesn't generally occur on "warm" surfaces. (think of all the places you've seen condensation before... where any of them warm?) On decent, parts of the payload that aren't heated (both inside and outside) will get cold. Then, when it gets to the warmer parts of the atmosphere, condensation on these cold surfaces will occur.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

Can we get an update on HAPB-2 please? Thanks.

Matt

The new PCB is almost complete and the construction of the new capsule is well underway.· I had to stop construction to go to the advanced space academy in Huntsville, AL, which was really cool by the way.· NASA has some pretty neat stuff planned, its a shame it took them 30 years to go back to the moon, even if we did learn a few things along the way.

The new launch date is sometime this month if testing goods well.· I will post the new date when it is comfirmed.· You can·also go the·http://www.parallax.com/html_pages/resources/custapps/app_hapb.asp·to keep up-to-date with my HAPB projects.

Thanks for the interest

Earl

·

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Don't ask yourself what the world needs - ask yourself what makes you come alive, and then go do it." - Harold Thruman Whitman

Post Edited (Earl) : 10/8/2006 10:13:04 PM GMT

Work is so quiet lately (but not as different as when Mike moved). Let me know when HAPB-IIa or MMVII or whatever goes is going up!

See you online!

Paul

I live at Lake Whitney, let me know if you are coming down here to launch. I want to see.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

God Bless,

Jason

Here's an idea that scraps the use of handwarmers:· I recommend wrapping it in layers of fiberglass insulation, and adding a thermostat circuit to the unit. Have the thermostat unit control PWM power to some low-value resistors distributed·around the periphery of the·unit,·against the inner "wall" of the fiberglass layers. Furthermore, use a temperature setpoint for the thermostat that is as low as possible (maybe just 5·Centigrade above the lowest safe temperature).

With good insulation and the lowest practical Temperature setpoint, it should require very little power. Personally I always use Lithium batteries for flight applications, for their superb energy density (equal to TNT in fact!) and low-temp performance advantage over alkalines when dipping below 0 C. On the other hand, the batteries could be inside the insulation along with the other electronics, so they need not "see" -40 at extreme altitudes.