Proposed robot

Hello guys

I need help please if you can, I am new to pbasic [noparse][[/noparse]but learning] through parallax manuals it will take me time as I am SLOW LEARNER.

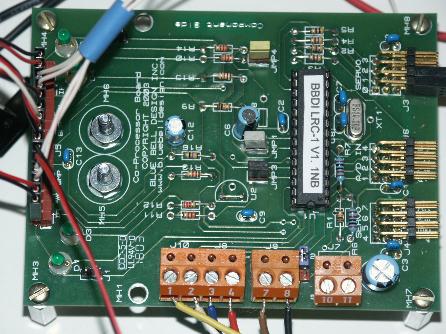

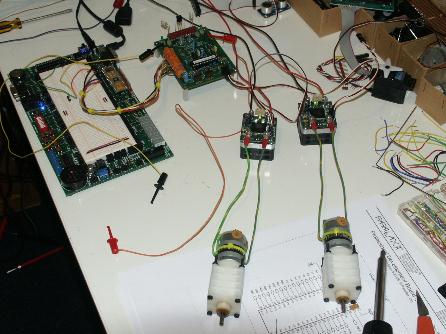

I have the Professional dev board/ 2 x HB 25 motor controllers and also a Bluebell design co-processor board connected to th dev board. Connected to the HB 25 are two como drill piledrive motors. The co-processor

board has two bump and one irpd sensor all of this works great and does what it is supposed to do. I am using the subsume_libby96.bsp code for this to function.

However I wish to add a ping ultrasonic sensor and a pir sensor module + a parallel lcd to read the ping distance and have two servos for pan/tilt UNFORTUNATLY I do not know where to place the code in the libby program or the code used to make these extra functions work.

I find it a lot easier if I have code already made so a project can work then if I need to alter this I can do a bit at a time and see what the results are, I find it easier to learn this way although you may not agree with this statement.

I am 53 and not a young person entering this field of robotics programming but find it very facinating. I have had over 30yrs in digital/analogue circuit building robots but they have all been hard wired and no software to run them.

Will post some pics later of my workshop and project. The co-processor has the facility for 8 servos and 4 A/D input lines.

+ the extra 28 I/O from the stamp. I am using 4 of the 32 I/O lines at present.

'{$STAMP BS2p}

' Subsume_Libby96.BSP - This shows the Subsumption engine in the Stamp 2p40.

' It uses the ramping servo controllers and sensors from the Co-Processor

'

[noparse][[/noparse] I/O Definitions ]

To_Co_Proc CON 10 ' pin for data to BBDI Co-Processor

Frm_Co_Proc CON 9 ' pin for data from BBDI Co-Processor

Timer_Exp VAR IN11 ' Timer Expired I/O pin from BBDI Co-Processor

BAUD CON 240 ' 2400 BAUD => BS2 = 396, BS2p = 1021 = CoProc V1.0

' 9600 BAUD => BS2 = 84, BS2p = 240

' CoProc V1.1 pin 21 pulled up = 2400 Baud

' CoProc V1.1 pin 21 grounded = 9600 Baud

LF CON 10 ' Line Feed

'

[noparse][[/noparse] Constants ]

bot_control CON $D5 ' this byte controls the Subsumption Architecture.

' it is programmable in Co-Processor

' bot_control is also defined below as its separate named bits for clarity here

' D = Ball Bearing = 1; Show Vision = 1; level 5 = 0; do_bumpers = 1;

' 5 = level 3 = 0; do_vision = 1; level 1 = 0; do_bot = 1

Ball_Bearing CON 1 ' Ball Bearing determines the relative directions

' vs servo pulse width. Libby has ball bearing

' servos so it is set to 1. This program will

' not show Ball Bearing usage.

Show_Vision CON 1 ' IF enabled shows the vision output on chan 6 and 7

level_5 CON 0 ' Level 5 is like Level 1 except highest priority

do_bumpers CON 1 ' bumpers are at level 4

level_3 CON 0 ' Level 3 is like Level 1 except higher priority

do_vision CON 1 ' enable vision from the IR Proximity Detector

level_1 CON 0 ' you write the direction and duration for level 1

' and it gets integrated into the Subsumption

' calculations.

' The lowest level is randomly wandering around.

' it is always enabled

do_bot CON 1 ' enables the subsumption engine.

'Values shown are initialization values

LEFT_STOP CON 127 'Left Stop - reprogrammable in Co-Processor

RIGHT_STOP CON 127 'Right Stop - reprogrammable in Co-Processor

LEFT_MIN CON 0 'Left Min - reprogrammable in Co-Processor

RIGHT_MIN CON 0 'Right Min - reprogrammable in Co-Processor

LEFT_MAX CON 255 'Left Max - reprogrammable in Co-Processor

RIGHT_MAX CON 255 'Right Max - reprogrammable in Co-Processor

' DIRECTION VALUES WRITTEN INTO THE DRIVE REGISTER BY THE VARIOUS BEHAVIORS

'Direction, bit3, bit2, bit1, bit0

'xxyy

'xx = 00 -> left motor stopped

'xx = 01 -> left motor forward

'xx = 10 -> left motor backward

'xx = 11 -> left motor forward

'yy = right motor

'normal list follows

fd CON %0101 'forward

rv CON %1010 'reverse

st CON %0000 'stop

tr CON %0100 'turn right

tl CON %0001 'turn left

rr CON %0110 'rotate right

rl CON %1001 'rotate left

bl CON %1000 'backup turning left

'

[noparse][[/noparse] Variables ]

SerDIn VAR Byte 'gets serial data back from Co-Proc

ServVal_0 VAR Byte 'to load servo 0 delays

ServVal_0_Old VAR Byte 'remember old servo 0 delays

ServVal_1 VAR Byte 'to load servo 1 delays

ServVal_1_Old VAR Byte 'remember old servo 1 delays

ramp_0 VAR Byte 'servo 0 ramp rate

ramp_1 VAR Byte 'servo 1 ramp rate

Drive VAR Byte 'each behavior subroutine writes direction here

wDir VAR Byte 'Wander Direction

wDur VAR Byte 'Wander Duration

IRPDDir VAR Byte 'IRPD Direction

IRPDDur VAR Byte 'IRPD Duration

bDir VAR Byte 'Bump Direction

bDur VAR Byte 'Bump Duration

L1_Dir VAR Byte 'Level 1 Direction

L1_Dur VAR Byte 'Level 1 Duration

L3_Dir VAR Byte 'Level 3 Direction

L3_Dur VAR Byte 'Level 3 Duration

L5_Dir VAR Byte 'Level 5 Direction

L5_Dur VAR Byte 'Level 5 Duration

i VAR Byte 'used by IRPD

seed VAR Word 'random number seed

ir_left VAR SerDIn.BIT5 '1 = IR sensed something on left side

ir_right VAR SerDIn.BIT6 '1 = IR sensed something on right side

bumper_Left VAR Bit '1 = IR sensed something on left side

bumper_Right VAR Bit '1 = IR sensed something on right side

first_bump VAR Bit 'tells first impact for immediate stop

bstate VAR Nib 'holds state of bumper FSM

'

[noparse][[/noparse] Initialization Code ]

ServVal_0 = LEFT_STOP + 1 ' need a value different from what

ServVal_0_Old = LEFT_STOP + 2 ' is to be sent

ServVal_1 = RIGHT_STOP + 1

ServVal_1_Old = RIGHT_STOP + 2

ramp_0 = 24 '6 counts/20ms

ramp_1 = 24 '6 counts/20ms

first_bump = 0

bumper_Left = 0

bumper_Right = 0

AUXIO '2p40 processor only!

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]116]

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]116] 'Reset Co-Processor

'Reset turns servos off

' and turns ramping off

' We would normally initialize for robot operation. That would start the IRPD

' (IR Proximity Detect). Here we don't want the Subsumption Engine to start.

' We just want to turn on the IRPD so we can look at what is happening.

' Notice that the IRPD LEDs can still light IF you set the bot_control.

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]214,23] 'write IR Freq Register

'default = 23; max sensitivity = 27; min = 20

'Writing a nonzero value enables the IRPD

'period = 15.6 + 0.4*counts (us) (23 = 24.8uS)

'Change the 23 to other values and see the effect

' on sensitivity.

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse](218)] 'command to write bot_control

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]$40] 'run the IRPD display LEDs but not the robot.

'without this command the display LEDs (ch 6 and 7)

' won't light.

' D = Ball Bearing = 0; Show Vision = 1; level 5 = 0; do_bumpers = 0;

' 5 = level 3 = 0; do_vision = 0; level 1 = 0; do_bot = 0

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]144,ramp_0] 'write ramp rate to servo 0

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]145,ramp_1] 'write ramp rate to servo 1

'Ramp rate of x will incr or decr

' pulsewidth by x/4 per 20 ms

' up to a max of x = 31

'write ramp command = 144 + ch#

'

[noparse][[/noparse] Main Code ]

Main: 'subsumption architecture

GOSUB Rd_Sensors ' check bumpers and vision values

' takes 9.6 ms (mostly because

' 2 bytes @ 2400 Baud = 8.33ms)

' (9600 Baud will reduce by over 6ms)

IF do_bot = 0 THEN no_subsum: ' subsumption engine enabled?

' subsumption takes 5.8 ms to execute

'Below are the behaviors (in subroutines)

GOSUB wander 'do the random wander about subroutine (Level0)

' wander is lowest priority

GOSUB Level1 'do user subroutine

GOSUB IRPD 'do the IRPD subroutine (Level2)

GOSUB Level3 'do user subroutine (not shown)

GOSUB bumpck 'do the bumper subroutine (Level4)

GOSUB Level5 'do user subroutine (not shown)

' Level5 is highest priority

GOSUB action 'figure out servo values from results of

' previous subroutines

no_subsum:

PAUSE 5 'NEEDED TO KEEP LOOP AT ROUGHLY 20 MS FOR DURATION COUNTERS

' DECREMENT IN THE RIGHT AMOUNT OF TIME

' 9.6 ms + 5.8 ms = 15.4 ms -> need 5 more

' for 20.4 ms period

GOTO Main 'keep looping doing it

'

[noparse][[/noparse] Subroutines ]

Rd_Sensors: ' reading the sensors takes 9.6 ms,

' of that, 8.3 ms is the serial transfer

'structure of bot_status byte from the CoProcessor

'bstate1 VAR BIT 'Bumper Finite State Machine = LSB

'bstate2;

'BumperFlg_Leftbmp VAR BIT 'bumper hit

'BumperFlg_Rightbmp;

'first_bump VAR BIT 'bumper just hit - to stop NOW!

' N/A if robot mode isn't running

'see_on_left VAR BIT 'vision sees something on left

'see_on_right VAR BIT 'vision sees something on right

'bit7 VAR BIT 'NOT USED = MSB

' read_CoProc 'read the value from the CoProcessor

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]118] 'Send the byte command to read robot status

SERIN Frm_Co_Proc, BAUD, [noparse][[/noparse]SerDIn] 'Data comes back into SerDIn

'since ir_right is defined as SerDIn.BIT6 and

' ir_left is defined as SerDIn.BIT5,

' they are set by the definitions

IF (SerDIn & $08)=0 THEN chk_bmp_L

bumper_Right = 1 '1 = hit something on right side - bit is sticky

' it is reset in bumper FSM

chk_bmp_L:

IF (SerDIn & $04) = 0 THEN done_sense

bumper_Left = 1 '1 = hit something on left side bit is sticky

' it is reset in bumper FSM

done_sense:

RETURN 'completed

'

wander: ' The lowest level is randomly wandering around.

' it is always enabled

IF wDur > 0 THEN wDone0

RANDOM seed 'random direction

LOOKUP (seed & %111),[noparse][[/noparse]fd,tl,fd,fd,fd,tr,fd,fd],wDir

RANDOM seed 'random duration

wDur = (seed & %1111111) 'mask for 128 choices of duration

IF wDir = fd THEN add20

wDur = wDur & %111111 'mask turns down to 64 choices of duration

add20:

wDur = wDur + 20 'add 400ms for a minimum duration

wDone0:

wDur = wDur - 1 'decrement wander counter

drive = wDir 'get direction

RETURN 'completed

'

Level1: 'do user subroutine

' you write the direction and duration for level 1

' and it gets integrated into the Subsumption

' calculations.

IF level_1 = 0 THEN Done1 ' not enabled

IF L1_Dur = 0 THEN Done1 ' not active now - timed out

L1_Dur = L1_Dur - 1 ' decrement duration counter

drive = L1_Dir ' get direction

Done1:

RETURN ' completed

'

IRPD: 'do IRPD Vision subroutine

IF do_vision = 0 THEN IRPDdone ' not enabled

'decide on movement direction always

i = ir_left * 2 + ir_right '1=right, 2=left, 3=both

BRANCH i,[noparse][[/noparse]IRPDDec,IRPDleft,IRPDright,IRPDfront] 'if IR left -> go right

IRPDfront:

IRPDDir = rl 'rotate left away

' internal CoProcessor code rotates randomly either direction

IRPDDur = 16 'Duration + 1

drive = IRPDDir

RETURN

IRPDleft:

IRPDDir = tl

' IRPDDur = 10 'same # as IRPDright - so share

GOTO IRPDsdur

IRPDright:

IRPDDir = tr 'turn right

IRPDsdur:

IRPDDur = 10 'Duration + 1

' goto IRPDDec 'falls through

IRPDDec: 'decrement current one

IF IRPDDur = 0 THEN IRPDdone 'no IRPD move in progress

IRPDDur = IRPDDur - 1

IRPDDrv:

drive = IRPDDir

IRPDdone:

RETURN

'

Level3: 'do user subroutine

' Level 3 is like Level 1 except higher priority

IF level_3 = 0 THEN Done3 ' not enabled

IF L3_Dur = 0 THEN Done3 ' not active now - timed out

L3_Dur = L3_Dur - 1 ' decrement duration counter

drive = L3_Dir ' get direction

Done3:

RETURN ' completed

'

bumpck: 'do bumper subroutine (= Level4)

'Bumper reaction Finite State Machine (FSM)

' State 0 = idle, just checking IF bumper is hit

' State 1 = currently backing up from hit

' State 2 = rotating away

IF do_bumpers = 0 THEN bDone4 ' not enabled

IF SerDIn.BIT2 = 1 THEN bmpnow 'Being bumped on left now! Restart state machine

IF SerDIn.BIT3 = 1 THEN bmpnow 'Being bumped on right now! Restart state machine

IF bDur > 0 THEN bmpact 'not done current state yet, continue bump

' action set by going into current state

'current state finished, set next state

BRANCH bstate,[noparse][[/noparse]bDone4,end_st1] 'jump to states 0-1, state 2 immed. follows

IF i < 3 THEN breset 'if both IR sensors aren't lit, done spinning

keepspin:

bDur = 20 'something is still in front, need to keep spinning

GOTO bdrive

breset: 'end state 2, now reset

bstate = 0 'state machine to idle

RETURN

end_st1: 'end state 1, now

IF bumper_Left = 0 THEN rtbmp

bDir = rr 'rotate right away from left bump

GOTO bmpdur

rtbmp:

bDir = rl 'rotate left away from right bump

'internal CoProcessor code is random direction if both bumpers hit

bmpdur:

bDur = 25 'internal CoProcessor code is random from 0.2 to 0.5 seconds

first_bump = 0 'reset sticky bits

bumper_Left = 0

bumper_Right = 0

bstate = 2 'next state

GOTO bdrive

bmpnow: 'being bumped now!

IF first_bump = 1 THEN still_bmp 'still being bumped?

first_bump = 1 'capture first bump only

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]152,LEFT_STOP] 'write position to servo 0 - immediate stop!

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]153,RIGHT_STOP] 'write position to servo 1 - immediate stop!

' trick - will over-ride ramping to stop but

' start ramping to the new value from there.

still_bmp:

bDir = rv 'set backup while bumped and

bDur = 18 'for a while (+1) after not being bumped

' internal CoProcessor code duration is shorter (10) if

' only one bumper side is hit

bstate = 1 'start state machine

bmpact: 'bump mode active

bDur = bDur - 1 'decrement bump timer

bdrive:

drive = bDir 'set drive direction to bump

bDone4: 'no bump and state machine not running - done level 4

RETURN ' completed

'

Level5: 'do user subroutine

' Level 5 is like Level 1 except highest priority

IF level_5 = 0 THEN Done5 ' not enabled

IF L5_Dur = 0 THEN Done1 ' not active now - timed out

L5_Dur = L5_Dur - 1 ' decrement duration counter

drive = L5_Dir ' get direction

Done5:

RETURN ' completed

'

action: 'moves servo motors

'uses ramping servo controller for simplicity

'servo 0 = Left, Servo 1 = Right

' Ball Bearing assumed to be 1 (for Libby)

' Ball Bearing being 0 reverses MINs and MAXes

' see Subsume_BoeBot1.BS2

IF drive.BIT2 = 1 THEN lftfwd 'jump if want to move left motor forward

IF drive.BIT3 = 1 THEN lftbak 'jump if want to move left motor backward

ServVal_0 = LEFT_STOP

GOTO lft_pulse

lftbak:

ServVal_0 = LEFT_MAX 'MIN is backward when BB = 0

GOTO lft_pulse

lftfwd:

ServVal_0 = LEFT_MIN 'MAX is forward when BB = 0

lft_pulse:

IF (ServVal_0 = ServVal_0_Old) THEN chkright

'Only need to send servo data

' IF different from last time.

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]136,ServVal_0] 'Set Servo 0 = Left side

ServVal_0_Old = ServVal_0 'remember value sent

chkright:

IF drive.BIT0 = 1 THEN rtfwd 'see comments for left side above

IF drive.BIT1 = 1 THEN rtbak 'MIN MAX are reversed to reverse

' servo direction on other side

ServVal_1 = RIGHT_STOP

GOTO rt_pulse

rtbak:

ServVal_1 = RIGHT_MIN

GOTO rt_pulse

rtfwd:

ServVal_1 = RIGHT_MAX

rt_pulse:

IF (ServVal_1 = ServVal_1_Old) THEN DoneServ

'Only need to send servo data

' IF different from last time.

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]137,ServVal_1] 'Set Servo 1 = Right side

ServVal_1_Old = ServVal_1 'remember value sent

DoneServ:

RETURN

END

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never give up when things go wrong.

Post Edited (StampNut2) : 6/13/2006 5:58:37 AM GMT

I need help please if you can, I am new to pbasic [noparse][[/noparse]but learning] through parallax manuals it will take me time as I am SLOW LEARNER.

I have the Professional dev board/ 2 x HB 25 motor controllers and also a Bluebell design co-processor board connected to th dev board. Connected to the HB 25 are two como drill piledrive motors. The co-processor

board has two bump and one irpd sensor all of this works great and does what it is supposed to do. I am using the subsume_libby96.bsp code for this to function.

However I wish to add a ping ultrasonic sensor and a pir sensor module + a parallel lcd to read the ping distance and have two servos for pan/tilt UNFORTUNATLY I do not know where to place the code in the libby program or the code used to make these extra functions work.

I find it a lot easier if I have code already made so a project can work then if I need to alter this I can do a bit at a time and see what the results are, I find it easier to learn this way although you may not agree with this statement.

I am 53 and not a young person entering this field of robotics programming but find it very facinating. I have had over 30yrs in digital/analogue circuit building robots but they have all been hard wired and no software to run them.

Will post some pics later of my workshop and project. The co-processor has the facility for 8 servos and 4 A/D input lines.

+ the extra 28 I/O from the stamp. I am using 4 of the 32 I/O lines at present.

'{$STAMP BS2p}

' Subsume_Libby96.BSP - This shows the Subsumption engine in the Stamp 2p40.

' It uses the ramping servo controllers and sensors from the Co-Processor

'

[noparse][[/noparse] I/O Definitions ]

To_Co_Proc CON 10 ' pin for data to BBDI Co-Processor

Frm_Co_Proc CON 9 ' pin for data from BBDI Co-Processor

Timer_Exp VAR IN11 ' Timer Expired I/O pin from BBDI Co-Processor

BAUD CON 240 ' 2400 BAUD => BS2 = 396, BS2p = 1021 = CoProc V1.0

' 9600 BAUD => BS2 = 84, BS2p = 240

' CoProc V1.1 pin 21 pulled up = 2400 Baud

' CoProc V1.1 pin 21 grounded = 9600 Baud

LF CON 10 ' Line Feed

'

[noparse][[/noparse] Constants ]

bot_control CON $D5 ' this byte controls the Subsumption Architecture.

' it is programmable in Co-Processor

' bot_control is also defined below as its separate named bits for clarity here

' D = Ball Bearing = 1; Show Vision = 1; level 5 = 0; do_bumpers = 1;

' 5 = level 3 = 0; do_vision = 1; level 1 = 0; do_bot = 1

Ball_Bearing CON 1 ' Ball Bearing determines the relative directions

' vs servo pulse width. Libby has ball bearing

' servos so it is set to 1. This program will

' not show Ball Bearing usage.

Show_Vision CON 1 ' IF enabled shows the vision output on chan 6 and 7

level_5 CON 0 ' Level 5 is like Level 1 except highest priority

do_bumpers CON 1 ' bumpers are at level 4

level_3 CON 0 ' Level 3 is like Level 1 except higher priority

do_vision CON 1 ' enable vision from the IR Proximity Detector

level_1 CON 0 ' you write the direction and duration for level 1

' and it gets integrated into the Subsumption

' calculations.

' The lowest level is randomly wandering around.

' it is always enabled

do_bot CON 1 ' enables the subsumption engine.

'Values shown are initialization values

LEFT_STOP CON 127 'Left Stop - reprogrammable in Co-Processor

RIGHT_STOP CON 127 'Right Stop - reprogrammable in Co-Processor

LEFT_MIN CON 0 'Left Min - reprogrammable in Co-Processor

RIGHT_MIN CON 0 'Right Min - reprogrammable in Co-Processor

LEFT_MAX CON 255 'Left Max - reprogrammable in Co-Processor

RIGHT_MAX CON 255 'Right Max - reprogrammable in Co-Processor

' DIRECTION VALUES WRITTEN INTO THE DRIVE REGISTER BY THE VARIOUS BEHAVIORS

'Direction, bit3, bit2, bit1, bit0

'xxyy

'xx = 00 -> left motor stopped

'xx = 01 -> left motor forward

'xx = 10 -> left motor backward

'xx = 11 -> left motor forward

'yy = right motor

'normal list follows

fd CON %0101 'forward

rv CON %1010 'reverse

st CON %0000 'stop

tr CON %0100 'turn right

tl CON %0001 'turn left

rr CON %0110 'rotate right

rl CON %1001 'rotate left

bl CON %1000 'backup turning left

'

[noparse][[/noparse] Variables ]

SerDIn VAR Byte 'gets serial data back from Co-Proc

ServVal_0 VAR Byte 'to load servo 0 delays

ServVal_0_Old VAR Byte 'remember old servo 0 delays

ServVal_1 VAR Byte 'to load servo 1 delays

ServVal_1_Old VAR Byte 'remember old servo 1 delays

ramp_0 VAR Byte 'servo 0 ramp rate

ramp_1 VAR Byte 'servo 1 ramp rate

Drive VAR Byte 'each behavior subroutine writes direction here

wDir VAR Byte 'Wander Direction

wDur VAR Byte 'Wander Duration

IRPDDir VAR Byte 'IRPD Direction

IRPDDur VAR Byte 'IRPD Duration

bDir VAR Byte 'Bump Direction

bDur VAR Byte 'Bump Duration

L1_Dir VAR Byte 'Level 1 Direction

L1_Dur VAR Byte 'Level 1 Duration

L3_Dir VAR Byte 'Level 3 Direction

L3_Dur VAR Byte 'Level 3 Duration

L5_Dir VAR Byte 'Level 5 Direction

L5_Dur VAR Byte 'Level 5 Duration

i VAR Byte 'used by IRPD

seed VAR Word 'random number seed

ir_left VAR SerDIn.BIT5 '1 = IR sensed something on left side

ir_right VAR SerDIn.BIT6 '1 = IR sensed something on right side

bumper_Left VAR Bit '1 = IR sensed something on left side

bumper_Right VAR Bit '1 = IR sensed something on right side

first_bump VAR Bit 'tells first impact for immediate stop

bstate VAR Nib 'holds state of bumper FSM

'

[noparse][[/noparse] Initialization Code ]

ServVal_0 = LEFT_STOP + 1 ' need a value different from what

ServVal_0_Old = LEFT_STOP + 2 ' is to be sent

ServVal_1 = RIGHT_STOP + 1

ServVal_1_Old = RIGHT_STOP + 2

ramp_0 = 24 '6 counts/20ms

ramp_1 = 24 '6 counts/20ms

first_bump = 0

bumper_Left = 0

bumper_Right = 0

AUXIO '2p40 processor only!

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]116]

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]116] 'Reset Co-Processor

'Reset turns servos off

' and turns ramping off

' We would normally initialize for robot operation. That would start the IRPD

' (IR Proximity Detect). Here we don't want the Subsumption Engine to start.

' We just want to turn on the IRPD so we can look at what is happening.

' Notice that the IRPD LEDs can still light IF you set the bot_control.

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]214,23] 'write IR Freq Register

'default = 23; max sensitivity = 27; min = 20

'Writing a nonzero value enables the IRPD

'period = 15.6 + 0.4*counts (us) (23 = 24.8uS)

'Change the 23 to other values and see the effect

' on sensitivity.

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse](218)] 'command to write bot_control

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]$40] 'run the IRPD display LEDs but not the robot.

'without this command the display LEDs (ch 6 and 7)

' won't light.

' D = Ball Bearing = 0; Show Vision = 1; level 5 = 0; do_bumpers = 0;

' 5 = level 3 = 0; do_vision = 0; level 1 = 0; do_bot = 0

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]144,ramp_0] 'write ramp rate to servo 0

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]145,ramp_1] 'write ramp rate to servo 1

'Ramp rate of x will incr or decr

' pulsewidth by x/4 per 20 ms

' up to a max of x = 31

'write ramp command = 144 + ch#

'

[noparse][[/noparse] Main Code ]

Main: 'subsumption architecture

GOSUB Rd_Sensors ' check bumpers and vision values

' takes 9.6 ms (mostly because

' 2 bytes @ 2400 Baud = 8.33ms)

' (9600 Baud will reduce by over 6ms)

IF do_bot = 0 THEN no_subsum: ' subsumption engine enabled?

' subsumption takes 5.8 ms to execute

'Below are the behaviors (in subroutines)

GOSUB wander 'do the random wander about subroutine (Level0)

' wander is lowest priority

GOSUB Level1 'do user subroutine

GOSUB IRPD 'do the IRPD subroutine (Level2)

GOSUB Level3 'do user subroutine (not shown)

GOSUB bumpck 'do the bumper subroutine (Level4)

GOSUB Level5 'do user subroutine (not shown)

' Level5 is highest priority

GOSUB action 'figure out servo values from results of

' previous subroutines

no_subsum:

PAUSE 5 'NEEDED TO KEEP LOOP AT ROUGHLY 20 MS FOR DURATION COUNTERS

' DECREMENT IN THE RIGHT AMOUNT OF TIME

' 9.6 ms + 5.8 ms = 15.4 ms -> need 5 more

' for 20.4 ms period

GOTO Main 'keep looping doing it

'

[noparse][[/noparse] Subroutines ]

Rd_Sensors: ' reading the sensors takes 9.6 ms,

' of that, 8.3 ms is the serial transfer

'structure of bot_status byte from the CoProcessor

'bstate1 VAR BIT 'Bumper Finite State Machine = LSB

'bstate2;

'BumperFlg_Leftbmp VAR BIT 'bumper hit

'BumperFlg_Rightbmp;

'first_bump VAR BIT 'bumper just hit - to stop NOW!

' N/A if robot mode isn't running

'see_on_left VAR BIT 'vision sees something on left

'see_on_right VAR BIT 'vision sees something on right

'bit7 VAR BIT 'NOT USED = MSB

' read_CoProc 'read the value from the CoProcessor

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]118] 'Send the byte command to read robot status

SERIN Frm_Co_Proc, BAUD, [noparse][[/noparse]SerDIn] 'Data comes back into SerDIn

'since ir_right is defined as SerDIn.BIT6 and

' ir_left is defined as SerDIn.BIT5,

' they are set by the definitions

IF (SerDIn & $08)=0 THEN chk_bmp_L

bumper_Right = 1 '1 = hit something on right side - bit is sticky

' it is reset in bumper FSM

chk_bmp_L:

IF (SerDIn & $04) = 0 THEN done_sense

bumper_Left = 1 '1 = hit something on left side bit is sticky

' it is reset in bumper FSM

done_sense:

RETURN 'completed

'

wander: ' The lowest level is randomly wandering around.

' it is always enabled

IF wDur > 0 THEN wDone0

RANDOM seed 'random direction

LOOKUP (seed & %111),[noparse][[/noparse]fd,tl,fd,fd,fd,tr,fd,fd],wDir

RANDOM seed 'random duration

wDur = (seed & %1111111) 'mask for 128 choices of duration

IF wDir = fd THEN add20

wDur = wDur & %111111 'mask turns down to 64 choices of duration

add20:

wDur = wDur + 20 'add 400ms for a minimum duration

wDone0:

wDur = wDur - 1 'decrement wander counter

drive = wDir 'get direction

RETURN 'completed

'

Level1: 'do user subroutine

' you write the direction and duration for level 1

' and it gets integrated into the Subsumption

' calculations.

IF level_1 = 0 THEN Done1 ' not enabled

IF L1_Dur = 0 THEN Done1 ' not active now - timed out

L1_Dur = L1_Dur - 1 ' decrement duration counter

drive = L1_Dir ' get direction

Done1:

RETURN ' completed

'

IRPD: 'do IRPD Vision subroutine

IF do_vision = 0 THEN IRPDdone ' not enabled

'decide on movement direction always

i = ir_left * 2 + ir_right '1=right, 2=left, 3=both

BRANCH i,[noparse][[/noparse]IRPDDec,IRPDleft,IRPDright,IRPDfront] 'if IR left -> go right

IRPDfront:

IRPDDir = rl 'rotate left away

' internal CoProcessor code rotates randomly either direction

IRPDDur = 16 'Duration + 1

drive = IRPDDir

RETURN

IRPDleft:

IRPDDir = tl

' IRPDDur = 10 'same # as IRPDright - so share

GOTO IRPDsdur

IRPDright:

IRPDDir = tr 'turn right

IRPDsdur:

IRPDDur = 10 'Duration + 1

' goto IRPDDec 'falls through

IRPDDec: 'decrement current one

IF IRPDDur = 0 THEN IRPDdone 'no IRPD move in progress

IRPDDur = IRPDDur - 1

IRPDDrv:

drive = IRPDDir

IRPDdone:

RETURN

'

Level3: 'do user subroutine

' Level 3 is like Level 1 except higher priority

IF level_3 = 0 THEN Done3 ' not enabled

IF L3_Dur = 0 THEN Done3 ' not active now - timed out

L3_Dur = L3_Dur - 1 ' decrement duration counter

drive = L3_Dir ' get direction

Done3:

RETURN ' completed

'

bumpck: 'do bumper subroutine (= Level4)

'Bumper reaction Finite State Machine (FSM)

' State 0 = idle, just checking IF bumper is hit

' State 1 = currently backing up from hit

' State 2 = rotating away

IF do_bumpers = 0 THEN bDone4 ' not enabled

IF SerDIn.BIT2 = 1 THEN bmpnow 'Being bumped on left now! Restart state machine

IF SerDIn.BIT3 = 1 THEN bmpnow 'Being bumped on right now! Restart state machine

IF bDur > 0 THEN bmpact 'not done current state yet, continue bump

' action set by going into current state

'current state finished, set next state

BRANCH bstate,[noparse][[/noparse]bDone4,end_st1] 'jump to states 0-1, state 2 immed. follows

IF i < 3 THEN breset 'if both IR sensors aren't lit, done spinning

keepspin:

bDur = 20 'something is still in front, need to keep spinning

GOTO bdrive

breset: 'end state 2, now reset

bstate = 0 'state machine to idle

RETURN

end_st1: 'end state 1, now

IF bumper_Left = 0 THEN rtbmp

bDir = rr 'rotate right away from left bump

GOTO bmpdur

rtbmp:

bDir = rl 'rotate left away from right bump

'internal CoProcessor code is random direction if both bumpers hit

bmpdur:

bDur = 25 'internal CoProcessor code is random from 0.2 to 0.5 seconds

first_bump = 0 'reset sticky bits

bumper_Left = 0

bumper_Right = 0

bstate = 2 'next state

GOTO bdrive

bmpnow: 'being bumped now!

IF first_bump = 1 THEN still_bmp 'still being bumped?

first_bump = 1 'capture first bump only

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]152,LEFT_STOP] 'write position to servo 0 - immediate stop!

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]153,RIGHT_STOP] 'write position to servo 1 - immediate stop!

' trick - will over-ride ramping to stop but

' start ramping to the new value from there.

still_bmp:

bDir = rv 'set backup while bumped and

bDur = 18 'for a while (+1) after not being bumped

' internal CoProcessor code duration is shorter (10) if

' only one bumper side is hit

bstate = 1 'start state machine

bmpact: 'bump mode active

bDur = bDur - 1 'decrement bump timer

bdrive:

drive = bDir 'set drive direction to bump

bDone4: 'no bump and state machine not running - done level 4

RETURN ' completed

'

Level5: 'do user subroutine

' Level 5 is like Level 1 except highest priority

IF level_5 = 0 THEN Done5 ' not enabled

IF L5_Dur = 0 THEN Done1 ' not active now - timed out

L5_Dur = L5_Dur - 1 ' decrement duration counter

drive = L5_Dir ' get direction

Done5:

RETURN ' completed

'

action: 'moves servo motors

'uses ramping servo controller for simplicity

'servo 0 = Left, Servo 1 = Right

' Ball Bearing assumed to be 1 (for Libby)

' Ball Bearing being 0 reverses MINs and MAXes

' see Subsume_BoeBot1.BS2

IF drive.BIT2 = 1 THEN lftfwd 'jump if want to move left motor forward

IF drive.BIT3 = 1 THEN lftbak 'jump if want to move left motor backward

ServVal_0 = LEFT_STOP

GOTO lft_pulse

lftbak:

ServVal_0 = LEFT_MAX 'MIN is backward when BB = 0

GOTO lft_pulse

lftfwd:

ServVal_0 = LEFT_MIN 'MAX is forward when BB = 0

lft_pulse:

IF (ServVal_0 = ServVal_0_Old) THEN chkright

'Only need to send servo data

' IF different from last time.

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]136,ServVal_0] 'Set Servo 0 = Left side

ServVal_0_Old = ServVal_0 'remember value sent

chkright:

IF drive.BIT0 = 1 THEN rtfwd 'see comments for left side above

IF drive.BIT1 = 1 THEN rtbak 'MIN MAX are reversed to reverse

' servo direction on other side

ServVal_1 = RIGHT_STOP

GOTO rt_pulse

rtbak:

ServVal_1 = RIGHT_MIN

GOTO rt_pulse

rtfwd:

ServVal_1 = RIGHT_MAX

rt_pulse:

IF (ServVal_1 = ServVal_1_Old) THEN DoneServ

'Only need to send servo data

' IF different from last time.

SEROUT To_Co_Proc, BAUD, [noparse][[/noparse]137,ServVal_1] 'Set Servo 1 = Right side

ServVal_1_Old = ServVal_1 'remember value sent

DoneServ:

RETURN

END

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never give up when things go wrong.

Post Edited (StampNut2) : 6/13/2006 5:58:37 AM GMT

Comments

That being said, I would guess that if the PING and PIR are being used for obstacle-avoidence,

their code would be inserted in the same place as the code for the IR sensors.

Basically, since obstacle-avoidence has the highest priority,

they should be placed last (at the bottom) in the code.

(The lowest priority code would be placed closer to the top of the code - that way,

any code that follows it will "subsume" the earlier code.)

Parallax has some code examples for the PING and the PIR:

PING code:

www.parallax.com/dl/src/bs/BSExCode.zip

www.parallax.com/dl/src/prod/RoamingWithPING-V1.0.bs2

PING Documentation:

www.parallax.com/dl/docs/prod/acc/28015-PING-v1.3.pdf

PIR code:

www.parallax.com/dl/src/prod/PIR-Demo-Code-V1.0.zip

PIR Documentation:

www.parallax.com/dl/docs/prod/audiovis/PIRSensor-V1.1.pdf

HTH

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never give up when things go wrong.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

It's Only A Stupid Question If You Have Not Googled It First!!

The motor system that I am using is two Parallax HB25's and connected to these are two como drill 2 amp piledrive motors, these have stackable gearbox's and a voltage range from 3v-15v in 3v increments.

Thanks

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never give up when things go wrong.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

It's Only A Stupid Question If You Have Not Googled It First!!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never give up when things go wrong.

In a nutshell, subsumption architecture was created by Rodney Brooks, the man who built that robot named COG that has been on the Discovery channel a while back. It's a very simple form of A.I., simple meaning its not a full blown 2million lines of code simple. It's still a challenge to read and understand, at least it was for me.

For more information, go here and print it out for bathroom material:

http://www.bluebelldesign.com/FSM_explain.htm

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Mike

·

The code in the pic chip has been programmed for eight servos and four A/D inputs all it needs is the correct pbasic code for the bs2p 40.

Thanks for your interest.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never give up when things go wrong.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

There once was a lady named Bright

who traveled much faster than light

She departed one day in a relative way

and Returned on the Previous Night

Cheers,

Wannabe Ub3r Geek

World of Warcraft

Star Trek official website

Google (Man's best friend...)

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never give up when things go wrong.