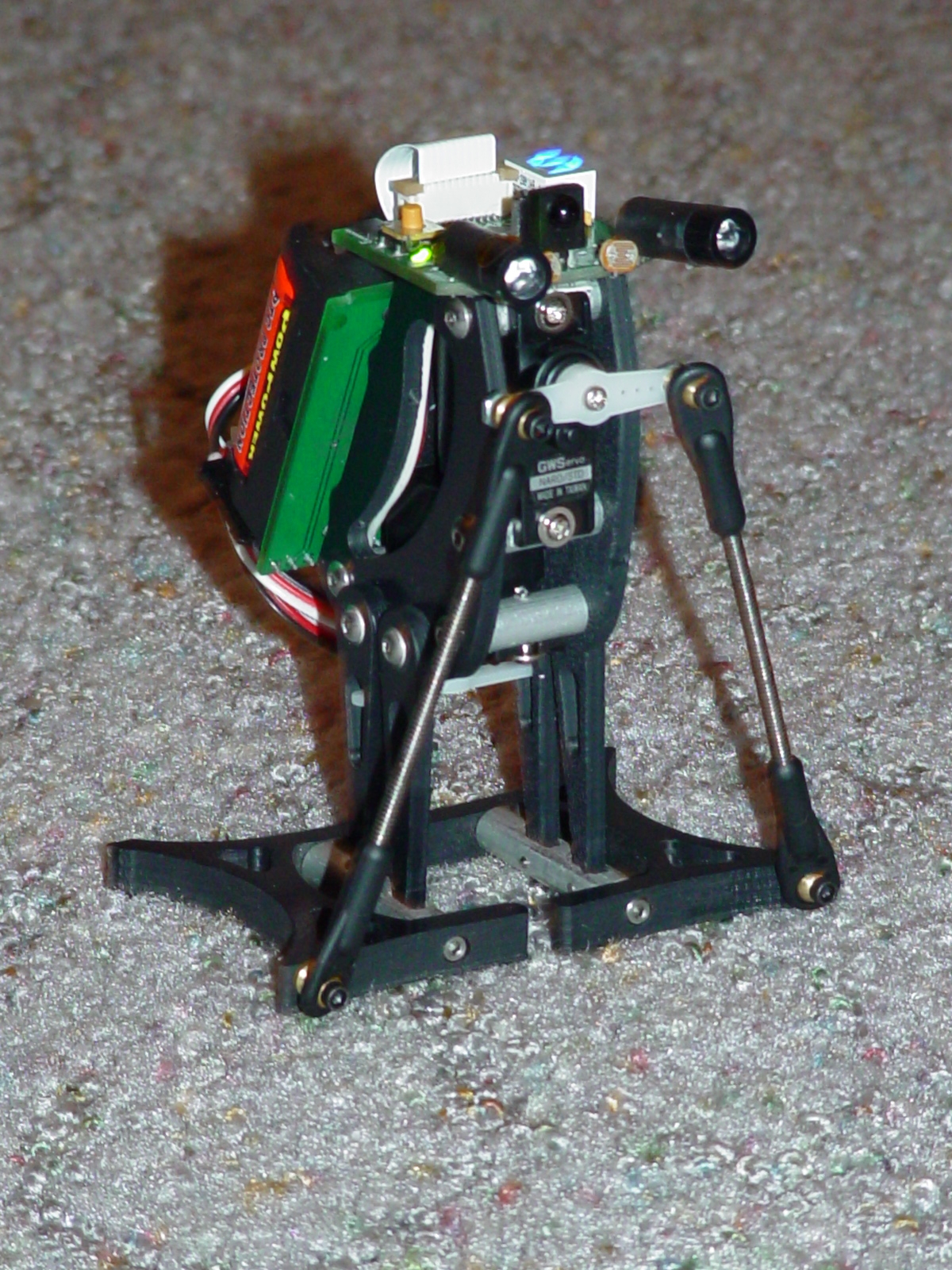

Penguin Pic and Video

Getting closer every day to getting this complete!

Still working on some details and the program but it is at least moving under its own power.

See the video below:

http://home.mchsi.com/~siliconsurfer1/Penguin1.mpg

A big thanks to Ken for all he has done.

Still working on some details and the program but it is at least moving under its own power.

See the video below:

http://home.mchsi.com/~siliconsurfer1/Penguin1.mpg

A big thanks to Ken for all he has done.

Comments

Very cool! Now you've got me curious about the stride linkage. Unless you've made a broaching tool for the spline, I'm curious as heck as how you got the stride servo connected to the linkage. You must have drilled through the servo spline and pinned it - not sure. There are a couple of ways to attach that part to the servo spline.

I'm also curious how you dealt with the slop in the leg/body/axle connections, or if this was a problem. It all adds up, but some level of loose connections is required for a fluid moving Penguin.

I've attached the infrared code, too.

Looks like you're 90% of the way there!

Ken Gracey

Parallax, Inc.

The stride linkage is just the standard white servo arm that came with the servo. It is the same one that the tilt servo is using. Since the servo arm is tapered, it is sloppy at the center position and binds at the end travel of the step. It will work for now.

The leg / body connection is still a problem. Creating a bolt with a shoulder for the leg to ride on is beyond the scope of my capabilities in a 4-40 size. With the spare parts I milled, I am working on a solution using small ball bearings. For now, I drilled and threaded the leg for 4-40 then stripped the threads and ran the screw with a dremel giving it a nice fit.·After every program cycle I need to tighten the leg bolts but for·the first day out, it·was a start anyway!

The last 10% will be the program and correcting the above issues but it was fun giving it a test run today!

Thanks for the code!

Eric