It's working!! BoE/Stamp controls braking on RC sailplane winch simulator

It's been a while since my previous post about using a BoE and Stamp to

control the braking on a winch for launching RC sailplanes. http://forums.parallax.com/forums/default.aspx?f=5&m=96533&g=96698#m96698

I've been hard at it, and the work has paid off. It's only working on the

simulator so far, but I'm very confident I can make the step up to full-scale

winch with no major problems.

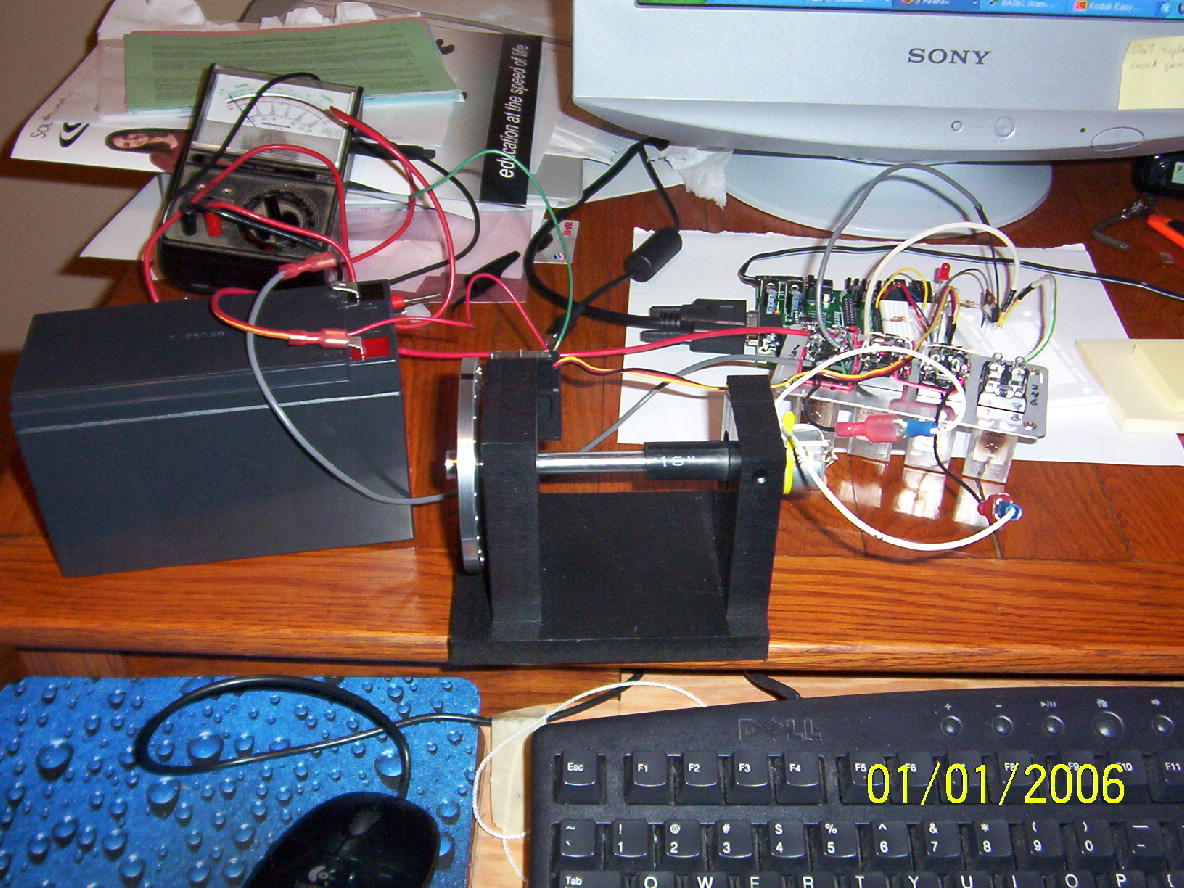

The simulator I built to test the program is ridiculously simple. Just a little

DC motor from a junked RC car driving an aluminum wheel. The size of the

wheel puts the target for the sensor at the same radius it will be on the full-size

winch drum.

The simulator motor is switched on just before the Stamp is powered up

or reset. The speed curve of the simulator motor is much the same as the winch

drum after the launch when there's a lot of tension on the line. It starts out

with rapid acceleration at low speed, then less and less acceleration as the

speed increases.

I can vary the timing between starting the simulator and powering up the

Stamp to cover the range of speed and acceleration the Stamp sees during the

test runs. There were lots of failures early on, but the final version of

the program hasn't missed a beat in over fifty runs.

The bank of relays behind the simulator is the control system for the motor.

Two of the relays are used to reverse the current to the motor when the

"brake" is applied. The third relay is set up as a latching relay to

prevent the motor from running in the forward direction when the brake is

released. The other relay isn't used.

The LED on the BoE is the brake light. Just had to have one. Actually, it's

so I could tell if the Stamp was working if the simulator control system didn't

respond like it was supposed to. It would have made it easier to troubleshoot,

but I didn't need it.

The Hall-effect sensor with the moving magnet didn't work very well. The

values were scattered too much. I put an electromagnet (a small relay coil)

behind the sensor to act as a bias, and I put a steel setscrew on the

simulator wheel as the target. Using an electromagnet prevents "cogging"

between the magnet and target when the system isn't on.

The program uses "PULSIN" to measure the duration of the pulse from the

sensor on each revolution, and a "moving average" math routine to average

the speed measured on four revolutions.

The first part of the program determines if the drum is slowing or

accelerating. If it's slowing, the Stamp exits without doing anything. It

only takes about a dozen revolutions to do this.

If it's accelerating, the Stamp compares the moving averages until the slope

of the speed curve falls below an adjustable setpoint value. Then it counts

an adjustable number of revolutions before switching the motor on to stop

the drum. These two adjustable setpoints will make it easy to fine-tune the

program for the full-size winch

The Stamp continues to measure the speed of the drum as it slows.

When the duration of the pulse exceeds 1000 or a timeout occurs, the Stamp

switches the motor off, and exits. The drum is either stopped or turning

very slowly when the motor is switched off.

It's really exciting to see the BoE, Stamp, and simulator working like I

want it to. I can't wait to try it out on the full-size winch I'm already building.

Roger

control the braking on a winch for launching RC sailplanes. http://forums.parallax.com/forums/default.aspx?f=5&m=96533&g=96698#m96698

I've been hard at it, and the work has paid off. It's only working on the

simulator so far, but I'm very confident I can make the step up to full-scale

winch with no major problems.

The simulator I built to test the program is ridiculously simple. Just a little

DC motor from a junked RC car driving an aluminum wheel. The size of the

wheel puts the target for the sensor at the same radius it will be on the full-size

winch drum.

The simulator motor is switched on just before the Stamp is powered up

or reset. The speed curve of the simulator motor is much the same as the winch

drum after the launch when there's a lot of tension on the line. It starts out

with rapid acceleration at low speed, then less and less acceleration as the

speed increases.

I can vary the timing between starting the simulator and powering up the

Stamp to cover the range of speed and acceleration the Stamp sees during the

test runs. There were lots of failures early on, but the final version of

the program hasn't missed a beat in over fifty runs.

The bank of relays behind the simulator is the control system for the motor.

Two of the relays are used to reverse the current to the motor when the

"brake" is applied. The third relay is set up as a latching relay to

prevent the motor from running in the forward direction when the brake is

released. The other relay isn't used.

The LED on the BoE is the brake light. Just had to have one. Actually, it's

so I could tell if the Stamp was working if the simulator control system didn't

respond like it was supposed to. It would have made it easier to troubleshoot,

but I didn't need it.

The Hall-effect sensor with the moving magnet didn't work very well. The

values were scattered too much. I put an electromagnet (a small relay coil)

behind the sensor to act as a bias, and I put a steel setscrew on the

simulator wheel as the target. Using an electromagnet prevents "cogging"

between the magnet and target when the system isn't on.

The program uses "PULSIN" to measure the duration of the pulse from the

sensor on each revolution, and a "moving average" math routine to average

the speed measured on four revolutions.

The first part of the program determines if the drum is slowing or

accelerating. If it's slowing, the Stamp exits without doing anything. It

only takes about a dozen revolutions to do this.

If it's accelerating, the Stamp compares the moving averages until the slope

of the speed curve falls below an adjustable setpoint value. Then it counts

an adjustable number of revolutions before switching the motor on to stop

the drum. These two adjustable setpoints will make it easy to fine-tune the

program for the full-size winch

The Stamp continues to measure the speed of the drum as it slows.

When the duration of the pulse exceeds 1000 or a timeout occurs, the Stamp

switches the motor off, and exits. The drum is either stopped or turning

very slowly when the motor is switched off.

It's really exciting to see the BoE, Stamp, and simulator working like I

want it to. I can't wait to try it out on the full-size winch I'm already building.

Roger

Comments

Kudos on getting your winch project so far along, so quickly. Thanks for keeping us all informed with your progress. Merely seeing someone else, new to the world of Stamps, will give many the impetus to further their own thinking and efforts to develop bigger and more sophisticated projects on their own. We can all use a bit of vicarious motivation from time to time, just to keep us headed in a more productive and expansive direction. Yours was by no means an elementary project, especially for a first time Stamper!

Imagine trying to develop this automated version with something OTHER than the PBASIC Stamp. The utter simplicity, and reliability of the Stamp platforms make them a real pleasure to use, during all phases of project development. The cooperation, information, and support of this Stamp Forum can be a huge asset as well, as you have well seen.

When you get done with the entire project, and it's all in working order the way you want it to be, you might want to consider putting together some more formal documentation, possibly with some video footage, to submit to Parallax for inclusion on their Customer Applications page here:

http://www.parallax.com/html_pages/resources/custapps/main.asp

I'm reasonably sure they'd be happy to add your efforts to the growing list of successful major projects. Again, keep up the good work, and good luck as you reach your completion goal. Long live Stampers and Stamping!

Regards,

Bruce Bates