www.batchpcb.com

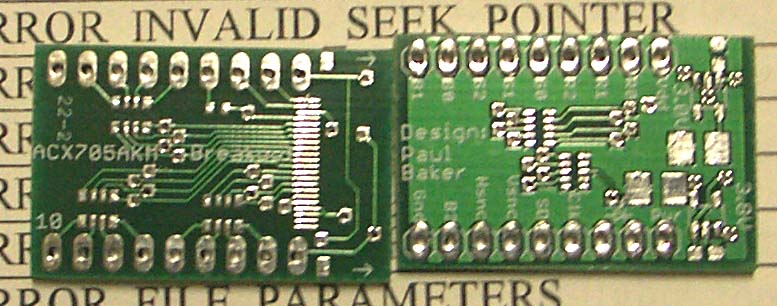

Sparkfun's PCB service is back up and doing weekly runs. I got a design in thier first week online, and the results are pretty good. I've included a photo of the front and back of the board for forum members to look at, the edge solder pads are standard 0.1" spacing to give you an idea of the scale of the board. A couple·things I've noticed is that the silk screen layer is not automatically masked out on the solder pads, so it will print right over a pad, the amusing thing is that one of the boards printed right over the pads while the other was moved out of the way, all from the same gerber file. The other thing is that the shear is not perfect, one of the boards extends beyond the shear border by about 0.5mm in one corner. All in all not bad for a prototype board service charging a $10 processing fee + $2.50 /in2. Also the processing fee is per order, so you can submit multiple designs and/or copies for just the additional $2.50 /in2 fee.

www.batchpcb.com

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·1+1=10

www.batchpcb.com

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·1+1=10

Comments

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·1+1=10

What's the SMT pitch on your board - looks pretty small. What's the board going to be when it's assembled?

The board is a breakout board for the Sony color LCD from Electronic Goldmine, the board provides the 3.0V and 3.8 V required and 5V->3V resistor dividers for all the signal lines.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·1+1=10