Drag bike shift and NOS control

This started as a project about 2 and a half years ago when I started drag racing motorcycles with a friend who has a bike shop. The original project started as how to make things more efficient, easier on the motorcycle and of course more constistant. Of the bikes we race the fastest when pushed to the edge has been 7.92 seconds at 181mph if I remember the mph correctly, it consistantly runs 8.05 to 8.15 seconds in the 170's so obviously safety is paramount. Now of course this is the disclaimer that has to come with posting a project like this. Racing, Air Shifters and of course Nitrous Oxide can be very dangerous even in a well maintaned and planned system. I highly recommend that only individuals with full understanding and experience work on or operate either of these systems and claim no liability for there use. With that said, on with the project.

A short explanation of the systems in question would probably make the whole thing more understandable at this point. First the Air shifter portion of the project. An air shifter is a pneumaticaly operated shifter almost excusively used in drag racing. When the rider presses a button at any throttle position the air shifter system activates a pneumatic cylinder that pulls the shift lever and kills the motorcycles ignition at the same time. During this the forward momentum of the bike unloads the transmission and allows it to change gears even at wide open throttle without the use of the clutch. A well sequenced systems adds virtually no wear or damage to the transmission. In short, it allows gear changes at wide open throttle without the use of a clutch which in turn results in 1-4 tenths of a second on average faster 1/4 mile times. The orignal air shifter modification was to add a pressure switch to the line feeding the cylinder and activate the ignition kill from it. This resulted in not losing time with a dead ignition while the shifter built pressure and started is motion since the ignition didnt kill until the shifter was in position to make a gear change, sequencing the shifter operation like this resulted in approx a tenth faster 1/4 mile by shortening ignition kill time as much as 30 milliseconds. 30 x 4 gear changes = 120 milliseconds or 1.2 tenths. These modifications lead me into building the ignition kill unit myself since the current retail units had a minimum time to kill the ignition that we were below on a well adjusted system. The original unit was analog using a 555 timer circuit extrmely high component count and good but not excellent reliability.

The next hurdle we encountered was with Nitrous Oxide systems. I'll keep this one short, beyond a certain amount of horsepower the general rule of thumb is that you have to dissasemble the transmission and make certain modifications to allow higher horsepower applications to make the gear change. (Having the shift drum cut at minimum). In the original systems that we were using there was a complex series of relays and another 555 timer circuit tying the nitrous oxide system and the shifter system together to cut the nitrous system an adjustable amount of time in milliseconds before the actual shift was made. This allowed us to make consistant gear changes at higher levels of horsepower without the need for transmission modifications.

All of this of course was a very complex system of relays and analog circuits that was tedious to assemble and just about as tedious to install and adjust. Here in this long story is where Parralax comes in. During the early spring of this year I discovered Parallax and the BS2 OEM board, at this point with a little analog circuitry understanding and little else. However I knew enough to realize that this could make things far easier, less complex and more reliable. I purchased a couple, spent several months tinkering and eventualy converted the air shifter over to operate from the BS2, the next step was to eliminate the relays and timer tying it to the nitrous system which was very simple at the level I was at by the time I'd gotten through most of the WAM kit.

The end result was that now I've developed and succesfuly tested an SX18 based system that uses an SX18, 3 fets, and some minor support components that does all of this extremely reliably, and consistantly. The final circuit is installed on a 2004 Kawasaki ZX10 that with very little modification has run as fast as [url=mailto:8.71@164]8.71@164[/url] mph on a totaly stock engine and transmission, and runs consistantly in the 8.70's. To most people this may not mean much but trust me, for what it is, its extremely fast.

The key features using Parallax components allowed me with the BS2 and later with the SX were, far lower cost $30 relative to $400. Simplicity, one unit rather than going with the standard 2 pieces, and with both controls being integrated it allowed me control of the NOS system relative to what the shifter was doing without interfacing the two together. Most important of all, consistancy, for my own use the BS2 and the SX have both been extremely reliable and consistant. The BS2 system that was created at the beginning of summer while less advanced is still running on another bike, slated to be replaced this winter.

My first and biggest thank you goes to Parallax for the products and support, and of course also to all the members of these forums. While I wasnt posting over the summer I was reading and many of the projects and discussions in these forums answered the questions I had and taught me what I needed to know to make the control portion of this project succesful. The next stages are to install it on the rest of the race bikes that we run from Daves shop (currently versions are running on two) and wait for spring. Needless to say, thanks goes out to Dave for having faith in the work I was doing, and to Eric for having enough faith turn down large drag bike teams while the system was being developed on his bike. Neither of who will probably ever read this but it had to be said anyway.

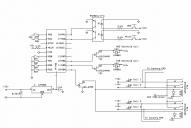

The schematic is attached and the SX/B source code will be posted tonight after Ive had a chance to go over the new code one more time. I dont care who builds it, uses it, I just dont want it manufactured, without going into details the nitrous oxide control is progressive and this project replaces about $400.00 worth of retail components and has several large advantages. Side note, portions of the schematic are for safety reasons, like the activation inputs also supplying solenoid power etc. Again, racing is dangerous and parts fail, this setup has worked well for me but I can take no responsibility for its use, modfication or failure.

Thanks again everyone

Ok, there's the code, sloppy and horrible but it works. As I get time I'll clean it up

Chris

Post Edited (ChrisP) : 6/30/2007 3:13:37 AM GMT

A short explanation of the systems in question would probably make the whole thing more understandable at this point. First the Air shifter portion of the project. An air shifter is a pneumaticaly operated shifter almost excusively used in drag racing. When the rider presses a button at any throttle position the air shifter system activates a pneumatic cylinder that pulls the shift lever and kills the motorcycles ignition at the same time. During this the forward momentum of the bike unloads the transmission and allows it to change gears even at wide open throttle without the use of the clutch. A well sequenced systems adds virtually no wear or damage to the transmission. In short, it allows gear changes at wide open throttle without the use of a clutch which in turn results in 1-4 tenths of a second on average faster 1/4 mile times. The orignal air shifter modification was to add a pressure switch to the line feeding the cylinder and activate the ignition kill from it. This resulted in not losing time with a dead ignition while the shifter built pressure and started is motion since the ignition didnt kill until the shifter was in position to make a gear change, sequencing the shifter operation like this resulted in approx a tenth faster 1/4 mile by shortening ignition kill time as much as 30 milliseconds. 30 x 4 gear changes = 120 milliseconds or 1.2 tenths. These modifications lead me into building the ignition kill unit myself since the current retail units had a minimum time to kill the ignition that we were below on a well adjusted system. The original unit was analog using a 555 timer circuit extrmely high component count and good but not excellent reliability.

The next hurdle we encountered was with Nitrous Oxide systems. I'll keep this one short, beyond a certain amount of horsepower the general rule of thumb is that you have to dissasemble the transmission and make certain modifications to allow higher horsepower applications to make the gear change. (Having the shift drum cut at minimum). In the original systems that we were using there was a complex series of relays and another 555 timer circuit tying the nitrous oxide system and the shifter system together to cut the nitrous system an adjustable amount of time in milliseconds before the actual shift was made. This allowed us to make consistant gear changes at higher levels of horsepower without the need for transmission modifications.

All of this of course was a very complex system of relays and analog circuits that was tedious to assemble and just about as tedious to install and adjust. Here in this long story is where Parralax comes in. During the early spring of this year I discovered Parallax and the BS2 OEM board, at this point with a little analog circuitry understanding and little else. However I knew enough to realize that this could make things far easier, less complex and more reliable. I purchased a couple, spent several months tinkering and eventualy converted the air shifter over to operate from the BS2, the next step was to eliminate the relays and timer tying it to the nitrous system which was very simple at the level I was at by the time I'd gotten through most of the WAM kit.

The end result was that now I've developed and succesfuly tested an SX18 based system that uses an SX18, 3 fets, and some minor support components that does all of this extremely reliably, and consistantly. The final circuit is installed on a 2004 Kawasaki ZX10 that with very little modification has run as fast as [url=mailto:8.71@164]8.71@164[/url] mph on a totaly stock engine and transmission, and runs consistantly in the 8.70's. To most people this may not mean much but trust me, for what it is, its extremely fast.

The key features using Parallax components allowed me with the BS2 and later with the SX were, far lower cost $30 relative to $400. Simplicity, one unit rather than going with the standard 2 pieces, and with both controls being integrated it allowed me control of the NOS system relative to what the shifter was doing without interfacing the two together. Most important of all, consistancy, for my own use the BS2 and the SX have both been extremely reliable and consistant. The BS2 system that was created at the beginning of summer while less advanced is still running on another bike, slated to be replaced this winter.

My first and biggest thank you goes to Parallax for the products and support, and of course also to all the members of these forums. While I wasnt posting over the summer I was reading and many of the projects and discussions in these forums answered the questions I had and taught me what I needed to know to make the control portion of this project succesful. The next stages are to install it on the rest of the race bikes that we run from Daves shop (currently versions are running on two) and wait for spring. Needless to say, thanks goes out to Dave for having faith in the work I was doing, and to Eric for having enough faith turn down large drag bike teams while the system was being developed on his bike. Neither of who will probably ever read this but it had to be said anyway.

The schematic is attached and the SX/B source code will be posted tonight after Ive had a chance to go over the new code one more time. I dont care who builds it, uses it, I just dont want it manufactured, without going into details the nitrous oxide control is progressive and this project replaces about $400.00 worth of retail components and has several large advantages. Side note, portions of the schematic are for safety reasons, like the activation inputs also supplying solenoid power etc. Again, racing is dangerous and parts fail, this setup has worked well for me but I can take no responsibility for its use, modfication or failure.

Thanks again everyone

Ok, there's the code, sloppy and horrible but it works. As I get time I'll clean it up

Chris

Post Edited (ChrisP) : 6/30/2007 3:13:37 AM GMT

Comments

Chris

Do you guys have a website with more pictures, video, etc? Thanks.

The bike shop that I race with is a small performance type shop, they dont keep a website. The bike pictured was just finished before the end of the season for racing here. It made the last 4 weeks of the season with the system functioning properly so there isnt a lot in the way of pictures and video. Several pic's and one out of focus video clip of it going 8.79 that I shot with my digital camera. The code in the original project is very sloppy, currently I'm learning better programming practices to do some cleanup. If you would tell me what your looking for I'd be happy to send it to you.

Chris

Remember...

Provas, GReece

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

-Rule your Destiny-

--Be Good. Be Bad. Be Provas--

Chris

·

A few things that are still being researched are the relationship to solenoid duty cycle and horsepower, which looks like it may be nonlinear or at least not a 1:1 ratio, and better ways to put horsepower down to the road.

So far testing is showing

1. 100% duty cycle may not be the best or most stable for large horsepower increases (there are program changes under testing for that to lock at 80-90% instead of 100) 80% appears to be a good number for now.

2. pulse rate has an effect on horsepower and how smooth the curve is. (currently testing at 15 and 20 hz)

3. linear horsepower isnt the best way to get a bike down the track at large horsepower increases. So were looking into a curve, and/or ramp rate change at 60-%70 duty cycle.

Results from first race Valdosta Georgia were promising, progressive/ramp and shift functions worked perfectly but at 60-90 horsepower increases a linear ramp proved to be nearly uncontrollable.

Conclusions:

1. Current testing indicates that it functions as originaly designed and works well at lower horsepower levels

2. Meets our goals of drasticaly cutting racing/performance costs while maintaining reliability.

3. Function/software design· requires changes to meet our goals of large overall performance increases

4. At higher horsepower levels a single linear ramp rate seems to result in either less performance than desired, or an almost uncontrolable pass down the track with no happy medium.

Current goals:

1. Quantify the ratio of nitrous solenoid duty cycle to horsepower increase.

2. Quanitfy the ratio of time:horsepower increase that is useable in a/our racing application

3. Possibly change program to achieve a dual ramp system where one ramp leades into the other for more precise control to gain the maximum value from larger increases in horsepower, or currently a more specialized ramp rate/curve for our application.

Current function:

1. Complete sequencing of air shifter

2. 20ms delay between shifter activation and engine kill to allow system pressure buildup and decrease engine off time.

3. Interaction between nitrous and shifter systems allowing automatic nitrous shut off during gear changes.

4. Precise engine kill time control

It looks like I was way ambitious in that 2 week estimate but its working well, and cleaned up quite a bit. Thanks to Geunther and PJ for the tip over in the SX forums about the ramp over time increase.

Post Edited (ChrisP) : 3/12/2006 5:13:29 PM GMT

A very professional approach to a DIY scheme!

Don't forget some videos of your race....that'd be cool to see!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·

Steve

"Inside each and every one of us is our one, true authentic swing. Something we was born with. Something that's ours and ours alone. Something that can't be learned... something that's got to be remembered."

And Steve is right... some videos won't hurt....

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

-Rule your Destiny-

--Be Good. Be Bad. Be Provas--

Nitrous solnoids are only designed to be turned on/off not pulsed like I think you are trying to do. Their are special Solnoids/Valves called "Dithering Valves" ( I hope i spelled that right) that can be plulsed at a higher frequency.

Basically you are trying to build a traction control system, and it will need to know the relationship between the tire speed and ground speed. And the only way to do that is a wheel speed sensor and some way to measure ground speed. (Their are ultrasonic ground· speed sensor out there but i neve priced them) Since you are building a system from scrach consider puting some data logging capabilities on it. The additional information will help you tune the bike better.

MY race pak system has.

Data logging.

4 thermocouple inputs for·EGT.

input shaft and output shaft sensors for clutch slipage.

RPM control for shifting and NOS activation.

Ignition kill.

Oil Pressure and water temp.

P.S. Any form of traction control is illegal in any form of class racing.

·

Doc Evil, We've been racing the Pro Star for several years now so I'm fully aware that traction control is illegal, however I'm not trying to control traction I'm controling the amount of power output to keep it manageable on a 1/4 mile pass.

As far as not pulsing nitrous solenoids.... Well you may want to talk to NOS (Nitrous Oxide Systems), Schnitz racing, NX (Next Generation Nitrous systems), Edlebrock, and most of the racers running serious nitrous power. However as far as solenoid performance, NOS is at the bottom of the list, an NX works much better in progressive systems, and the new NX is supposed to be far superior to anything else out there. Its actually the fuel solenoids that give you more problems.

None of that was meant as a rant, I truly appreciate your attempt to enlighten me on nitrous use but it sounds like your not that familiar with high horsepower street bike setups. Your data systems sounds awsome.

Chris

P.S. We've already sprayed a busa into the low 8's high 7's a couple of years ago. This is an attempt to do something new and different without spending a fortune. The busa owner had the 3k to drop in a nitrous system with off the shelf parts.

·

Chris

Post Edited (ChrisP) : 3/14/2007 5:17:32 AM GMT

They were simply to momentarily unload the transmission

Once the tranny was 'unloaded' momentarily,

then the solenoid 'kicked' the tranny into the next gear!

I think this project is AWESOME! - my experiences with 'analog' version were:

Resistors changed values throughout the day...

Capacitors changed with extreme heat....

You always had a bunch of resistors sitting around - to 'tune' the bike for that track...

Parts 'jiggled' loose sometimes (resistors were inserted into special 'sockets'...

Digital - now that seems like the way to go! - the old systems were an RC circuit....

specs on caps and resistors were loose, heat, vibration - too many variables....

Now honestly, I have no idea how/what he is doing with the NO2, but you'd have to shut this

down momentarily (not dither it!) just before ignition 'kill' - then shift....

Marvelous idea....and there's nothing traction control about it,

simply shut the ignition off for a fraction of a second,

shift,

go like hell again!

Last Kawasaki I saw with this type of setup had to have wheelie bars!

the man that drove it was CRAZY! (good crazy) and his girlfriend was his mechanic!

Hot Bike!

John

Wow, you really dug deep to find this post. Its been too long since I've posted anything remotely useful, but work gets in the way and other projects etc. The NOS thing is just a way to make it a little more controllable, instead of on and off, it comes on at 5% of its total jetting and over a switch selectable time period ramps to 100% of the total jetting. As Dr Evil noticed, in a round about way its a way to get more horsepower sooner, and still maintain traction, and keeping the thing pointed down track.

Your absolutely right on the shifter, you simply kill the ignition, let the transmission unload, then pop the next gear. Timing isnt really as critical as you would think, motorcycle transmissions are very tolerant of this treatment, but a well setup shifter will definately ease wear.

The major points to this system were.

Cost, its far cheaper than anything commercially available and fairly simple to build.

The shift is sequenced differently than your average commerial setup allowing shorter shift times.

The shifter and nitrous interact, yes the nitrous is cut completely during shift, it only dithers as it initially comes on. Bikes with nitrous and shifters generally dont, they just shift through, dead ignition is a dead ignition. You usually get a pretty interesting bang through the exhaust though when the ignition comes back in.

Chris

Are you still using / developing this project?

I am interested this project. I've started taking my FJ1200 to a local dragstrip and am looking for a DIY solution to an ignition kill and a shift light. Can you recommend any resources to "get up to speed" on this project? I've done limited electronics work in the past (simple O2 meter) and very limited programming (mostly some OLD college classes).

Thanks,

Chris W

I've found the downloads for the SX-Key/Blitz Development System Manual and am reading that now.· I've downloaded the Beginning Asembly Language for the SX Microcontrollers.· Any other recommendations?

Post Edited (Chris_W) : 11/14/2007 7:26:45 PM GMT

Sorry for not replying sooner.

Yes I am, its in its 4th board revision at the moment and I just received a new batch of prototypes with a layout mistake of course.... The SX is a very friendly processor to program in SX/B thanks to Parallax and all the people that made fast basic a reality so I'd definately recommend using it and building your own shift controller. As soon as the current one is tested I'll be posting the full details here on this thread. Schematics, board layout, bill of materials and program.

Current version, no NOS control although it could be used that way with some clever program changes, the kill delay time is brought out to the second set of dip switches instead of being hard coded into the program, the second input is now used for an optional auto shift input using a Dyna shift minder. and a 20mhz resonator is added to get increased accuracy, as well as real filtering in the power supply courtesy of these forums if I remember it right...

If you dont mind i would like to include a two step ignition kill into the program to use with the efi controllers i use i dont use NOS so i could take that part out and add what i need if you dont mind i dont want to just take something and call it my own without permission.

Thank you for asking but of course, hopefuly it helps someone else here and there with something they are working on.

If you want to test it out run rb.o to a 10k pulldown and hook two leds up one to RC.2 and the other to RC.6 put a 5v signal to the RB.0 and it should flip the leds from one to the other i have tested this so far on the board to 11,500 RPM (2 pulses per rev at half rate so actual is 5750 rpm).

Basically the firing order is per 720deg rotation is ( This is with a coil on plug setup with one output hooked to 1-4 and the other to 2-3)

If you cycle through the rotations this is what it looks like

1-3-4-2 _ 1-3-4-2 Now with the two step activated it should look like this> 0-3-0-2_1-0-4-0_0-3-0-2_1-0-4-0 <this way might work the best i dont know

Depending on how you have the coils hooked up you can change it

This is with 1-2 and 3-4 hooked together

1-3-4-2_1-3-4-2 Activated 0-3-4-0_1-0-0-2_0-3-4-0_1-0-0-2

Now all this is untested on the bike but hopefully it all works. I dont have any schematics yet i still need to draw that up but im hoping for the best.LOL

Post Edited (turbo) : 12/8/2007 3:46:43 AM GMT

Personaly, I would probably suggest looking into a solid state method of pulling the coils down for a 2 step, timing is fairly important and most relays capable are in the 3-9 millisecond closure range, also add a cap in there somewhere or the relays releasing the ground is actually going to fire the coils when they let go.......

Do you retard your ignition at all with the nitrous? Separate system?

I've got a mostly stock FJ1200 that I've been taking to a local 1/8 mile strip for fun (lot better than speeding tickets!).· It has a Dyna 2000 with the orange "kill wire".· I successfully made a simple shift kill and used an NPN transistor (TIP31) to ground the orange wire.· Unfortunately the tranny wouldn't tolerate the high-rpm shift from 1-2 with just an electric kill.· The 2-3 shift and higher were good, but the 1-2 wasn't since I haven't had the transmission·undercut·yet.· Then I got a good deal on a lightly used·airshifter.· I had trouble getting the transistors (used D44H11 this time)·to operate the shift solenoid and the shift light I made.· So I had to revert to the stock MPS box for the shifter for last weekend (last·test-n-tune·of the season).·

I'm still very interested in developing this project.· I've got to learn a bit more on integrating the·control of the external parts.· I'm lost right now with when, where, and sizes for resistors and capacitors to use to protect the chips.·

Thanks for sharing the info and your time here.

Chris W.

The bike in question above was a stock motored ZX10 at the time, running VP C16 race fuel, and no timing retard. It dyno'd 225 at the rear wheel with this combination, on a 12.3:1 average air fuel ratio. For us it was a reliable combination.

On the aforementioned setup we made 2 passes running plain old turbo blue with a spark plug inspection on each pass for detonation, times definately fell off, but no detectable detonation so we were very comfortable running it with C16.

Short answer, it all depends on the setup. Higher horsepower systems running pump gas, yes, very high horsepower systems running race fuel, yes. Always do final setup on a reliable dyno and watch your air fuel.

Rear wheel horsepower numbers on that setup were

All motor, ideal fuel map

165-168

All motor, nitrous fuel map

135-139

Nitrous, nitrous map

225-227

As for the shift controler/ignition kill itself.. At this point its actually a very developed product, the 5th generation simplified with production quality boards is about to go into testing as I write this. Just finished half a dozen of the advanced units listed in the project, and just recevied the boards for the simplified boxes.

If your doing this for the fun and challenge, my hats off to you and I'm more than happy to give you any pointers that I can. If its just to get a shifter together and play at the track, then send me a pm and I'll ship you a basic unit to test and play with for the heck of it.

Tips for the system your working on now though. I got away from transistors early on when I discovered logic level fets <IRLZ44 in particular>. Lots of power capacity, and designed specificaly to work with a logic level gate drive. Fantastic for a simple circuit and for driving the shift solenoid <humphrey #310-12VDC for the same one you see in everyones kit $28 new> beautifuly. I've used this fet with and without a gate resistor with equaly good results, eventualy I'll learn the importance of it. If you use it, just remember about a 4.7k or 10k resistor from the gate to ground to prevent an irritating solenoid fire on power up.

Logic level fets are great, internal kickback diode, no calculation of gain for current draw, just connect the stamp/sx output to the gate through a gate resistor (4.7K again), ground to source, and whatever your switching to drain. They easily switch nitrous solenoids, much less a shifter.

Chip protection, 100uh choke <radio shack part> in the power lead, a forward biased 1n4004 or 4007 between the choke and the voltage regulator, and then just the standard filtering caps listed in the data sheet for whatever regulator you use. Also, on a bike <read wicked nasty mean ugly electrical noise> it doesnt hurt to reverse biase an 18V zener across the incoming power leads to short transients generated in the electrical system outside your controler. Also dont forget your .1uf decoupling cap as close to the processor as you can get it, if your using a stamp is already has this I believe.

Thanks for the info on the logic level fets.· I will have to give those a try - they sound like an ideal solution.·

This project is sort of both to me - a project to learn on as well as filling the "need" for a shifter and the other electronics.· I'm hoping my elctronics skills will grow fast enough to keep up with my "needs"!·

Unfortunately, the last paragraph is over my head.· Time for me to look up chokes and keep learning...

My bike is an old 89 FJ1200.· I've had it nearly 7 years now - lots of changes - R1 forks, FZ1 swing arm, old PM Chicane rims and brakes, FZR1000 shock linkage, etc.· Recently took it to a test and tune and have had a lot of fun with it.· The transmissions are a weak point on these bikes - I intended the shift kill to help keep it alive.··The bike just wouldn't shift clutchless from 1-2 without an airshifter though.· I broke down and bought a lightly used airshifter and MPS kill box so I wouldn't hurt the tranmission.· I still intend to keep working on a Stamp kill box though and incorporate a shift light and possibly auto shifting (especially if I start bracket racing).·

Are your latest boards still programable by the user?· Are there any I/O pins still open for use?

Thanks again, Chris W.

·

Glad to hear that your having fun since thats what its all about!! Doesnt matter how fast you go, as long as its fun, when its not fun anymore its time to find a new hobby. An incoming diode and a couple of capacitors are commonly used to filter the power comming into an electronic device. If you look up the data sheet on an LM7805 the example circuit shows the standard filter caps used with it, a .1uf capacitor is usually used across the + and - power lines as close to the processor as you can get for further filtering.

On some of the bikes I've tested on, nitrous and shifter solenoids have generated voltage spikes in the electrical system as high as 70 volts for a few milliseconds time. <This is the reason for the choke in conjuction with everything else> The current boards that I'm waiting to test are a very simplified ignition kill for a regular shifter, and one with a few extra parts that controls the whole shift sequence. To answer your question about reprogramming, anyone that takes a notion to have at it is welcome, the oscillator pins on the SX are available to connect to for programming.

This leads into the next point, this circuit uses the SX chip which unlike the stamp takes a few more peripheral parts, and requires either an SX Key, or SX Blitz to program. Personally I recommend the Key because of the debugging features. I've attached a pic of the current ignition kill only board so you can get an idea of what I'm talking about. The bike sounds awsome, sounds like you have a lot of time and attention invested, my personal ride is an 02 FZ1 that I play with at the track. High 9.90's on a best day run, bracket race it no nitrous and dial 10.50 on the rare occasion that I get to compete anymore instead of just play. Its still my favorite bike to ride and at any point in time I have access to at least a couple of mid to high 8 second busa's to take down the track if I get the urge. For me though, its more fun to ride my own bike and just have fun.

As I said before, and it can't be said enough. If it wasnt for these forums and the awsome support from Parallax for their products I would never have learned enough for these simple circuits. Many thanks to everyone in the forums for their help and support.

Got to go.

dMann Dave