Hexcrawler Assembly Issue

Hi all!

First off let me tell everyone what I great time I've been having with all my "loot"! (See my earlier thread here in the Sandbox if you missed it).

I have spent the better part of today putting my hexcrawler together. I've been taking my time and enjoying it. It's starting to get late and I ran into an issue I'm not sure how to handle, so I thought I'd stop for the night and post a question about it.

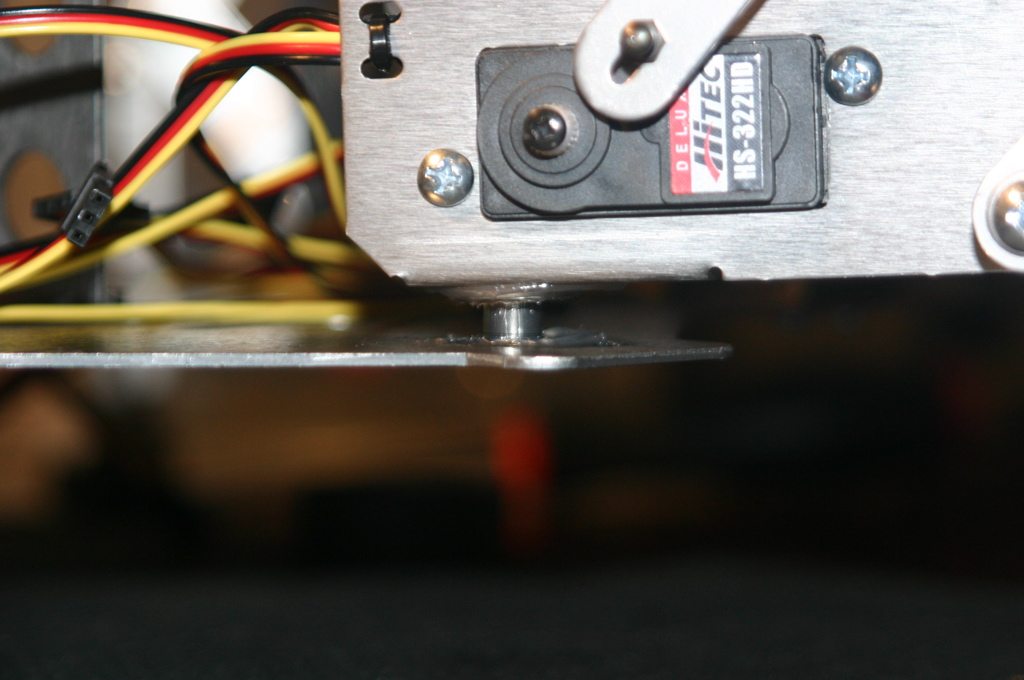

The pivot point on the bottom deck plate and the PEG on the leg-servo assemblies don't come "together". There is a small gap that and the peg doesn't stay in the hole. This seems to put a lot of pressure on the top servo mounting point on the upper deck. This is true for all 6 leg assemblies. I have re-read the instuctions and studied all the images in the book. Every thing "appears" right.

Below is an image of what I am talking about.

It looks like to me I may need to "massage" the upper and lower decks a little downward and upward respectively to make it fit better. Before go to bending on the thing - how about some suggestions... or point out where I may be goofing up!

Thanks in advance!

Doc

First off let me tell everyone what I great time I've been having with all my "loot"! (See my earlier thread here in the Sandbox if you missed it).

I have spent the better part of today putting my hexcrawler together. I've been taking my time and enjoying it. It's starting to get late and I ran into an issue I'm not sure how to handle, so I thought I'd stop for the night and post a question about it.

The pivot point on the bottom deck plate and the PEG on the leg-servo assemblies don't come "together". There is a small gap that and the peg doesn't stay in the hole. This seems to put a lot of pressure on the top servo mounting point on the upper deck. This is true for all 6 leg assemblies. I have re-read the instuctions and studied all the images in the book. Every thing "appears" right.

Below is an image of what I am talking about.

It looks like to me I may need to "massage" the upper and lower decks a little downward and upward respectively to make it fit better. Before go to bending on the thing - how about some suggestions... or point out where I may be goofing up!

Thanks in advance!

Doc

Comments

Is there some "slop" in the joint, meaning that the leg can slide up and down within the pem joint? Is there so much slop that the leg can pop out of the body plates? If not, how about if we throw a couple of nylon spacers in there which would (a) reduce friction by being plastic and (b) take the slop outta there?

If that works, I could poke around Parallax and see what we have in the way of spacers.

In the meantime, I think we should summon "Alex" who designed the HexCrawler. I'm on it. . .

- Ken

Thanks for the prompt response.

All 6 PEM joints are "luxated" if I may use a medical term. The peg isn't even in the hole on any of the legs. It is that way if it is right-side up or dead-bug. Thanks for any help.

Doc

PS:

and this is off topic, but what's with the anti-spam limits.... seems like way longer than 20 seconds between posts....

This doesn't seem right - as if the sheetmetal is pretty far out of tolerance. We're still waiting for Alex to show up here and tell us what to do. . .

As for the spam limitation being 20 seconds - not sure what's up with that but I'm not about to find out. My IT Guy is riding his Harley somewhere in Southern California on a much needed break.

Ken

I couldn't sleep so I've been studying it a bit further. By taking each leg-servo assembly out and flexing the "wings" on the top and bottom panels inward somewhat (not bending mind you) I was able to get all 6 leg assemblies to seat just fine. I wonder if I had just one or two that were not seated and that was making the others stay out as well.

Anyway, I have it working fine now. I suppose I just needed to take a break from it for a bit.

Thanks for the help.

--About the IT guy taking a break: You don't have to tell me! I do this to break away from the Grind of owning a veterinary hospital. It really helps me to do something different on my time off. (When I get time off!)

Thanks again,

Doc

Then the problem would be solved for now. It's possible that one of them wasn't seated, like you said. This would cause the others to bend the bottom deck edges downward.

You've had a real Parallax day today, between Elements of Digital Logic and the HexCrawler. Neat! You'll be fixin' them dogs better than ever this week since you've had some hobby time.

- Ken

One more thing to check.

Make sure that the horizontal servo is mounted on top of the servo holder tabs (picture) not below.

Mike Gebhard

CrustCrawler

·· One more final note from me...I couldn't tell from your picture whether the large steel washers were there on the PEM Studs?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Chris Savage

Parallax Tech Support

csavage@parallax.com

Just kidding. Glad you got it working.

I could have sworn the picture was below the tab. I checked and you are right! I put the servo below instead of on top. That accounts for the discrepency in the distance to the PEM.

Chris-

The washers are in place.

RoboROOKIE -

I did a little "redneck engineering" - and no, I didn't use duct tape. But I did gently flex the wings of the deck plates towards each other and it seated nicely after that.

It seems to be ok now, but I wonder if I should go ahead and move those top servo's to the top of the tab? It probably would do better; ya' think?

Thanks everyone!

Doc

ON EDIT: I uploaded an IMAGE of after I "worked on it". I plan to move the servos to the top where they go. It appears that will make for better articulation by a degree or two.

Post Edited (doggiedoc) : 9/19/2005 8:56:35 PM GMT