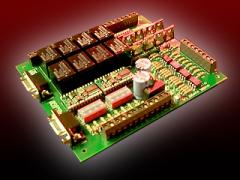

General Purpose Controller board

·· Here's the board that's the heart of most of my projects, including the truck dumper I described in a previous topic as well as the Wastewater Controller in the Customer Applications area of the Parallax site.

·· It evolved over quite a while and was protoyped ( in wire-wrap form ) on perf board a number of times. It wasn't possible to be all things to all people but we did cram in a lot of features useful in industrial projects:

········ Arbitrarily, we decided on a 8 in / 8 out split

············· - all inputs are switch selectable for digital or analog service

··············- digital inputs are all opto-isolated, active low

············· - when set for analog, the RCTIME caps are on the board

············· - all inputs and outputs have status LEDS

············· - has a switchmode power supply and an input full wave rectifier so·· any power source from 8 to 40 volts AC or DC will do. Built in solid state resettable fuse.

············· - every output has a MOSFET transistor and a relay available

············· - socket for LTC1298 A/D and a 1451 D/A. Control connections to Stamp are already on the board. An RS-485 chip can also use this socket.

············· - has a second stamp socket with two interconnections to the main socket for communicating between the two processors.

············· - board was purposely not shrunk down in size so the traces are reasonable sizes and can be easily cut and modified in the field.

·····

Its called an EnT, which actually was a contraction of the names of the two people invoved in its development -·· Ernie 'n Tom.

···· Pic and drawing is attached.

·· It evolved over quite a while and was protoyped ( in wire-wrap form ) on perf board a number of times. It wasn't possible to be all things to all people but we did cram in a lot of features useful in industrial projects:

········ Arbitrarily, we decided on a 8 in / 8 out split

············· - all inputs are switch selectable for digital or analog service

··············- digital inputs are all opto-isolated, active low

············· - when set for analog, the RCTIME caps are on the board

············· - all inputs and outputs have status LEDS

············· - has a switchmode power supply and an input full wave rectifier so·· any power source from 8 to 40 volts AC or DC will do. Built in solid state resettable fuse.

············· - every output has a MOSFET transistor and a relay available

············· - socket for LTC1298 A/D and a 1451 D/A. Control connections to Stamp are already on the board. An RS-485 chip can also use this socket.

············· - has a second stamp socket with two interconnections to the main socket for communicating between the two processors.

············· - board was purposely not shrunk down in size so the traces are reasonable sizes and can be easily cut and modified in the field.

·····

Its called an EnT, which actually was a contraction of the names of the two people invoved in its development -·· Ernie 'n Tom.

···· Pic and drawing is attached.

pdf

221K

Comments

Do you have better images?

Dave

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Dave Andreae

Tech Support

dandreae@parallax.com

Http://www.parallax.com

·

· Other details:

····· More or less 6.5" x 7", Stamp sockets have wire-wrap pins extended right through the board for easy wiring of "off-board" accessories.

···· If anyone has specific questions, just let me know.

· Tom Sisk

·

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"We Are Not Human Beings Having·A Spiritual Experience,

··············... We Are··Spiritual Beings Having·A·Human Experience"

Because of its flexibility, the board described here still costs about $250 Canadian in small quantities. But, the projects I use it in sell for $2500 and up so its not a huge factor in the overall cost.

If you were building a board for one specific application and watched your components costs, you could probably get within your budget by buying 20 - 50 boards at a time. For instance, using triac's to drive your AC solenoids could save some cash.

One thing to keep in mind, someone, somewhere will always be able to undercut your price. Unless you're doing the project as a hobby or as a learning experience, make performance your distinguishing feature, not price.

A really neat way to control costs is to use a smart relay board. The one I'm testing right now is by Vellemann and sold through Q-kits. You just use the Stamp to send a serial command and one or more relays close or open as required. Very low cost compared to designing your own.

Cheers,

Tom Sisk

And you're right....very nice and easy to use....pity they're rated so low....but I'll make do!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·

Steve

"Inside each and every one of us is our one, true authentic swing. Something we was born with. Something that's ours and ours alone. Something that can't be learned... something that's got to be remembered."

This is a reply to Noodless. (and the group)

I make a Stamp Based board that has up to 16 Solid State I/O modules on it. You can make it any I/O pattern you want. All I's..All O's or any mixture in between. I use Grayhill Mini SSIO (Solid State I/O) modules.

I have attached a picture of one that has been running a 120 kw Plasma Torch for about 4 years in Phoenix.

I am beta testing the new version of the board now prior to making them available commercially. I will be willing to provide you with one, minus the SSIO modules. The only cost is feedback on how it works. All my testing has been on my own CNC projects so far. Some fresh feedback would help.

The AC Output modules (70M-OAC) are rated for 3 Amps Maximum and 24 to 140 Volts AC. You can get them from Digikey.

The numbers are:

AC Output 24-140 VAC···· Grayhill# 70M-OAC· Digikey# GH7022-ND

AC Input 24-140 VAC······ Grayhill# 70M-IAC·· Digikey# GH7026-ND

Let me know if you have any questions.

Also I hope this in not out of line as far as posting to the group?

Thanks,

Alan Bradford

Plasma Technologies

www.plasmatechnologies.com

Nice looking setup.

Any idea on cost?

Tom Sisk

Sorry for the delay answering.

I am still trying to get the costs fixed. As it is a low volume board now it will be in the $200 range. As volume picks up the price should go down.

I have been using this design for over 5 years now and have not had any failures. This attests to the ruggedness of the stamp modules. 4 Years ago I accidently pumped 300 volts into my Torch Height Control board's 0-5 volt sense input. The board failed catastrophically, the A/D converter·went into orbit, the LCD Screen emitted lots of sparks before it caught fire, and the LCD controller just melted to the board. I took the Stamp2 out of its socket, put it in another board, and it is still running to this day, making tractor trailer milk tanks in Wisconsin.

Image 56 is the Torch Height Control Box sitting under the CNC. (This is prior to discovering Frontpanelexpress.com).·Image 58 is the replacement board, after the first one took the 300 volt hit, with the original Stamp2 Chip installed. The 8 pin chip to the left of the Stamp is the A/D converter that was just 8 smokin' pins. The Stamp lived through it. This picture was taken right after the board was replaced and before the wiring harness was dressed up again.

I have found that in lots of industrial machinery a·conventional PLC is overkill.· If you have 120 AC·and 24 volt AC/DC control voltages, like found in many Industrial Widgets, it is not cost effective to go the PLC route. When you add all the different I/O modules to take care a few of each voltage then you have an expensive control for a simple function.

One I/O point can be converted·read a pot at the cost of ome SSIO module.

I should have the silk screen boards in, in a week or two.

I also have a Stamp1 based board, as well as a Stamp1 & Stamp2 board that will connect to an external Opto 22 plug in I/O module board. Ill keep you posted on them also.

Ill post a picture of·them then.

Thanks,

Alan Bradford

Plasma Technologies

www.plasmatechnologies.com

We use something similar (quick look) in some of our smaller weather radars.

Robust buggers for sure! Lots of smarts and protection....bit of a chore tuning them though!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·

Steve

"Inside each and every one of us is our one, true authentic swing. Something we was born with. Something that's ours and ours alone. Something that can't be learned... something that's got to be remembered."

The controllers are DC PWM Brushed Servo Amplifiers. I use them in my lower end machine rebuilds. They are inexpensive, rugged and easy to tune. Just need a small screwdriver and 2 min.

They can handle 80 Volts DC at 12 amps cont, and 25 Amp peaks.

American Motion Controls makes them. www.a-m-c.com. I use the 25A8.

The big black box above the Stamp Box in Pic 56 is the CNC and it does all the work controlling the motors.

I have incloded 2 more pictures of a job in process (It was finished 3 years ago), the wiring is not complete yet.

The first picture #1280 is a 3 Axis Servo Drive and power supply. It is a 1500 Watt system. 3 500 Watt Drive motors were onthis machine. It weighs 3000 pounds and can move 300 inches per minute.

The second picture #1283 is another Stamp board that handles the limit switches and E-Stop Circuit.

Thank You,

Alan Bradford

Plasma Technologies

www.plasmatechnologies.com

I think our SErvo amps were american motor ones too!

Cool stuff!

(I think the guys working on the CNC machine on this board are drooling over your 300"/min speed)

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·

Steve

"Inside each and every one of us is our one, true authentic swing. Something we was born with. Something that's ours and ours alone. Something that can't be learned... something that's got to be remembered."

The fuse holders are Weidmueller. I had some of them left over from my first wiring job using DIN rail connectors. The rest is from Automation Direct. It works just as good, and is about 1/3 the price.

This machine is an X-Y Plasma/Oxy-Fuel Cutter. It is 30 feet long and 12 feet wide. It has a PC Based CNC controller. The Stamp is just for interfacing.

Thank You,

Alan Bradford

Plasma Technologies

www.plasmatechnologies.com

Sorry i have not posted a reply sooner, But I was injured on the job and am now out of work ( I still don't know how thats legal but after this BS i don't really want my job back, any one in SE PA need a PLC programmer/ industrial electrician ) so I've gotten the chance to catch up with my projects. I would be delighted to Test one of your boards I would be able to have my client pay for shipping as we will most likely test install it at his buisness. my eMail addy is rjdaggett@gmail.com. I can send you the address to ship to via email. how ever the smart relay board sounds real good, do the outputs latch? I like that I could prob use a PC or a etherNET to serial module to interface as well so the software could be located on the PC many of our customers want PC control and network connectivity. TTL serial ? well I'll look it up thanks for all the info. I hope to get alot done before I shocked ...err I mean started installing control systems again.

p.s. gMail accounts anyone? drop me a line Ive got like a hundred invites and their new voice IM service rocks.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"We Are Not Human Beings Having·A Spiritual Experience,

··············... We Are··Spiritual Beings Having·A·Human Experience"

The Beta StamPLC controller boards came in at last. When I return to the shop I will get 2 of them stuffed and tested.·I hope to get this done by the end of·next week.

I will send one to Jon and/or Chris at Parallax and one to Noodles for a Beta test.

I need to know what type of I/O SSR's to install on them.

Contact me and we can work it out.

Thanks,

Alan Bradford

Plasma Technologies

www.plasmatechnologies.com

PS: Does anyone know how to turn off the annoying double spacing?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Sid Weaver

Do you have a Stamp Tester yet?

http://hometown.aol.com/newzed/index.html

·

Cool...It works..

Look Ma, no wasted spaces....

Thanks,

Alan Bradford

welcome.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Sid Weaver

Do you have a Stamp Tester yet?

http://hometown.aol.com/newzed/index.html

·