SX28 Multi-Board

Hello SX28'ers,

for the SX28 ACT, I have designed a general-purpose PCB with positions for the most commonly used components around the SX28. Here are the major features:

You can find the complete documentation for the SX28 Multi-Board at g-daubach.com/docs/sx28multiboard.pdf.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

Günther

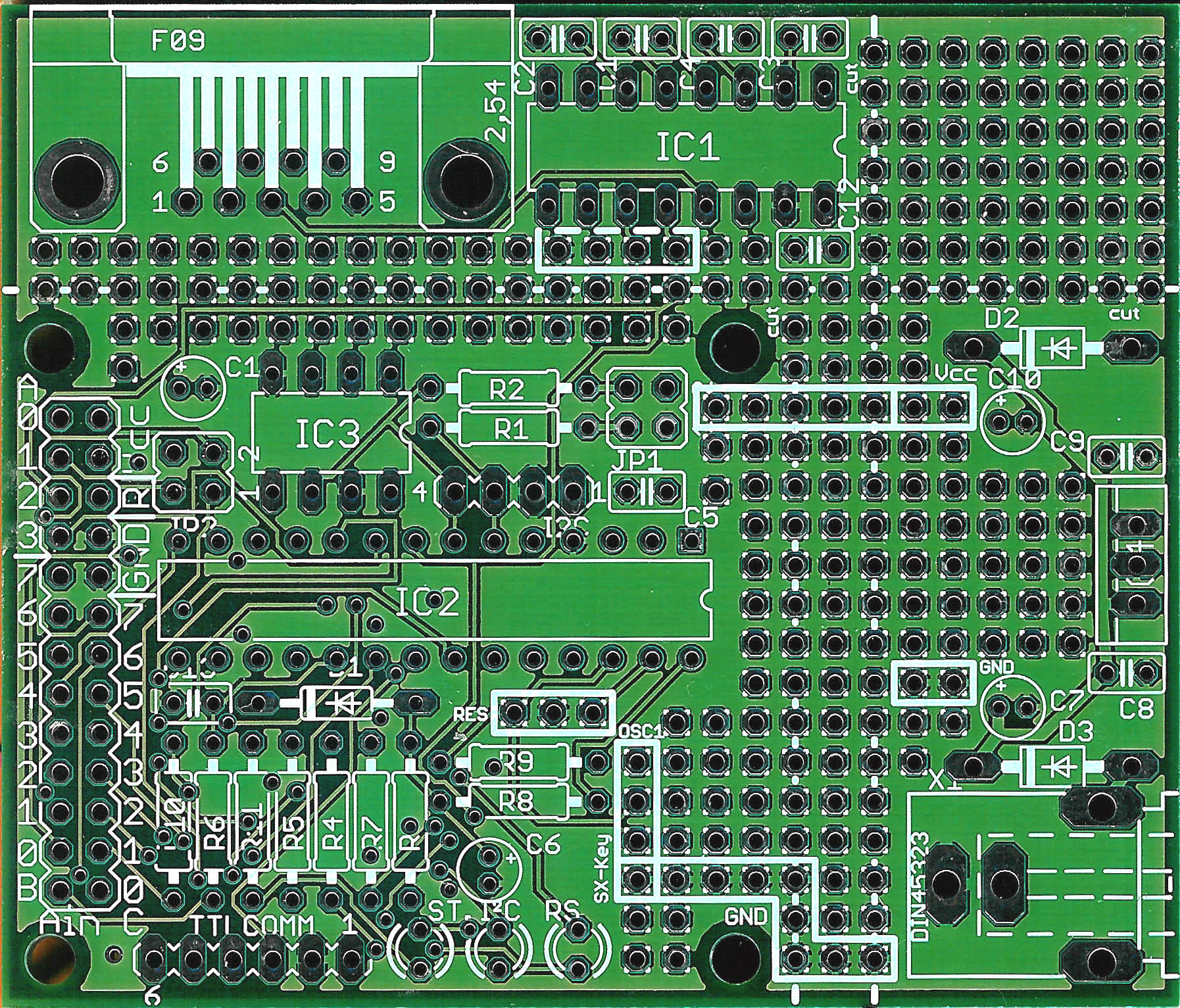

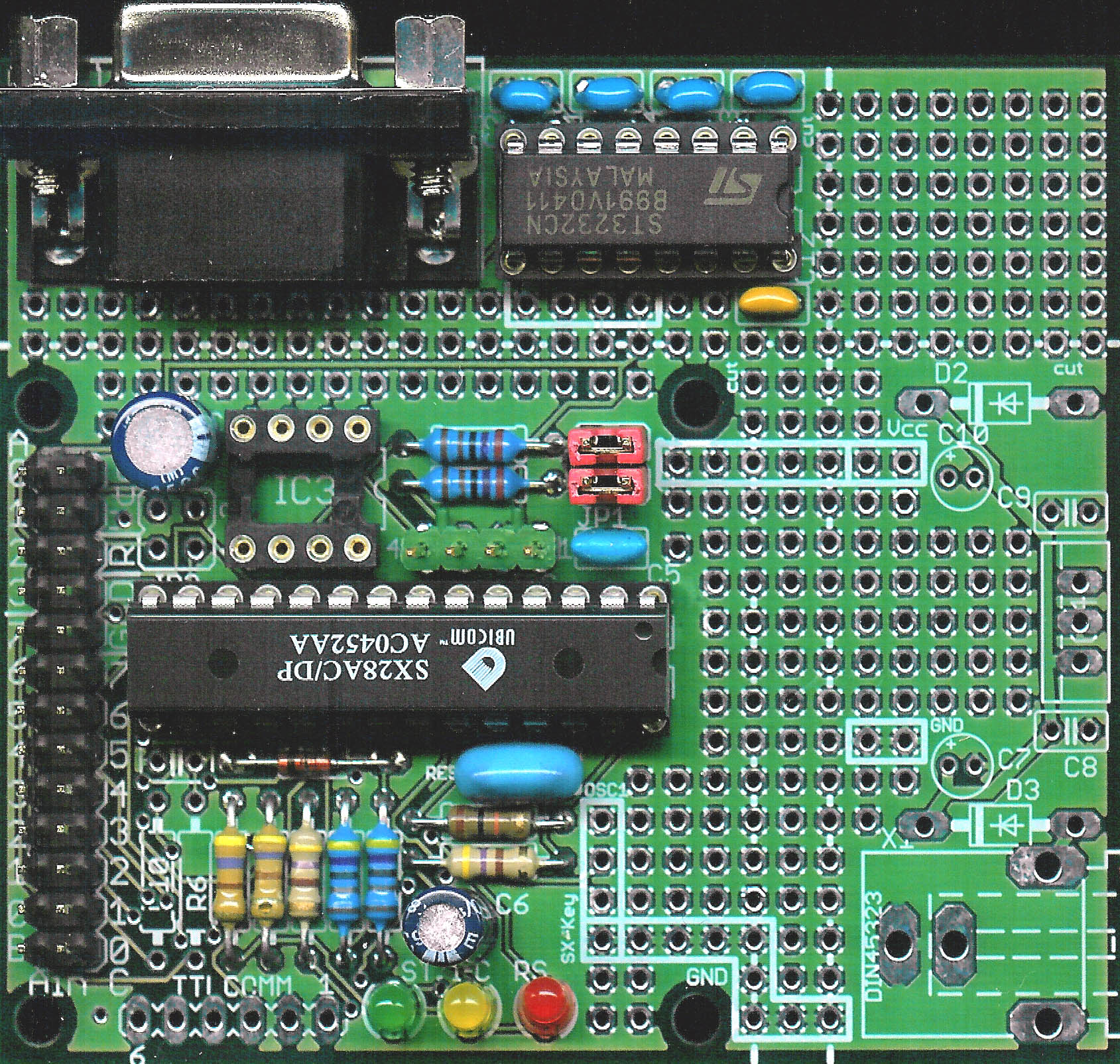

for the SX28 ACT, I have designed a general-purpose PCB with positions for the most commonly used components around the SX28. Here are the major features:

- Size: 2.95x2.5" (75x63.5mm).

- Four-layer PCB with two inner supply layers for enhanced EMI protection.

- All components are non-SMT, so the board can be hand-soldered.

- Socket pads for an SX28 ACT together with a ceramic resonator and an optional reset circuit.

- All SX28 port pins are available via a 26-pin-header.

- The board is divided in three sections, the "Main" section, the "RS-232" section, and the "Voltage Regulator" section. Both, or one of the last two sections may be cut off, when board size is a concern, leaving a "Mini-Main" section of 2x1.8" (50.5x46mm). Cut-off sections can be used as stand-alone modules.

- Optional serial I²C EEPROM.

- Optional components for one bitstream continuous calibration ADC, or for a PWM-controlled DAC output.

- Separate pin-headers for an external I²C bus, and for TTL-level serial communication, e.g. for Parallax BASIC Stamp modules.

- Up to three on-board indicator LEDs.

- Breadboarding areas with solder pads for additional components.

- Two jumper blocks for activating pull-up resistors on the I²C bus, and to configure the handshake lines for the serial TTL port.

You can find the complete documentation for the SX28 Multi-Board at g-daubach.com/docs/sx28multiboard.pdf.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

Günther

Comments

I have one of these in my office right now. If I weren't heading out on a trip today I'd be running Guenther's sample code and seeing how it works. It's a nice design and truly functional.

Guenther and I are trying to figure out how to make the SX MultiBoard available, since that is something you will ask. As much as I'd like to sell it, I think it is best for the community buy them directly from Guenther's eBay web pages. Parallax would simply add unnecessary cost to the customer if we got in between him and you. We would hardly add any value in terms of support since Guenther is so active on the SX forums and he writes so much of the SX documentation anyway. The German (and entire EU) manufacturing costs are now higher than ours in the U.S. This is because the $/Euro exchange rate is so poor (and heavily in their favor to buy American goods).

Ken Gracey

Parallax, Inc.

thanks a lot for your support and your realistic description of the distribution situation. Manufacturing costs are one side of the coin but shipping costs for single units from Germany to the American continent would be way to high, ending up in an un-acceptable price for the customers.

Fortunately (or maybe unfortunately), my daughter now lives in South Carolina (unfortunately because she's so far away from us). I can send her a bulk of boards and she will take care of the local distribution. This should bring down the shipping costs per uint to a reasonable amount.

BTW: Right now, I have used the SX Multi-Board to prototype an interesting SX application some of you have been asking for in the past. Sorry, I can't tell you more about that right now. The final version of this application will come with its own dedicated PCB. But by using an SX Multi-Board with the "usual" components placed on the provided board locations plus some extra parts in the beadboarding area, I could remarkably cut down the time to get it completed, compared to a full breadboard design.

Another BTW: If anybody is interested in the RS-232/I²C adapter, please contact James Newton james@sxlist.com - he is going to have several versions of the adapter on stock soon (from assmbed and tested units down to just the controller+resonator parts kit).

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

Günther

although my board would be fine for newcomers - especially when delivered in kit form with the most common components, the better first choice for a beginner would be a prototype board with a solder-less breadboard area. This allows adding and removing components for various experiements. The SXTech board is a fine beginner's choice, like a "Volkswagen", where the Professional Development Board is definitely the "Mercedes" among the prototype boards because it comes with such a variety of useful peripheral components available on-board, together with plenty of solder-less breadboard space.

After having prototyped and successfully tested an SX application on a prototype board, for the hobby developer it would be nice, and for the professional developer it is a must to convert this application from a solder-less pototype design with its relatively loose wires into a stable construction, under both - mechanical and electical aspects. "Mechanical" means no plugged-in interconnections but solid soldered connections, being able to stand mechanical stress like shocks or vibrations. "Electircal" means optimized, i.e. shorter interconnections better filtering of supply voltages to reduce EMI problems.

The best solution for such an "after-prototype" version certainly would be a PCB designed especially for this application. A pretty expensive solution. Even when you initially order 10 or 20 PCBs for the "after-prototype" version, or for the first production series, this is still expensive enough. Often enough, when the first units are used in the field, it turns out that there are some changes in the board design are necessary. So, for the next run of the PCB production, you will have to pay once again for the basic costs, like film plotting, setting up the drill program, etc.

Having this in mind, I designed the SX28 Multi Board. My idea was to design a board that can be used as host for various SX applications, offering space for the components, most frequently used together with an SX.

In the meantime, I have used this board to build various SX-based applications:

The RS-232/I²C Adapter

Master PWM Controller for concrete saws

Dual Pulse-stretcher for decoding motor tacho pulses

Parallel- to serial and code converter for absolute position sensors (parallel Gray Code to serial binary)

Variable PWM generator

Service hour counter with serial EEPROM

Interface for a temperature/humidity sensor (SHT11)

plus some more applications, that I'll keep a secret for now

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Greetings from Germany,

Günther

Post Edited (Guenther Daubach) : 11/20/2005 11:41:31 PM GMT