Parallax customer feedback requested: project box / enclosure

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

Dear Customers,

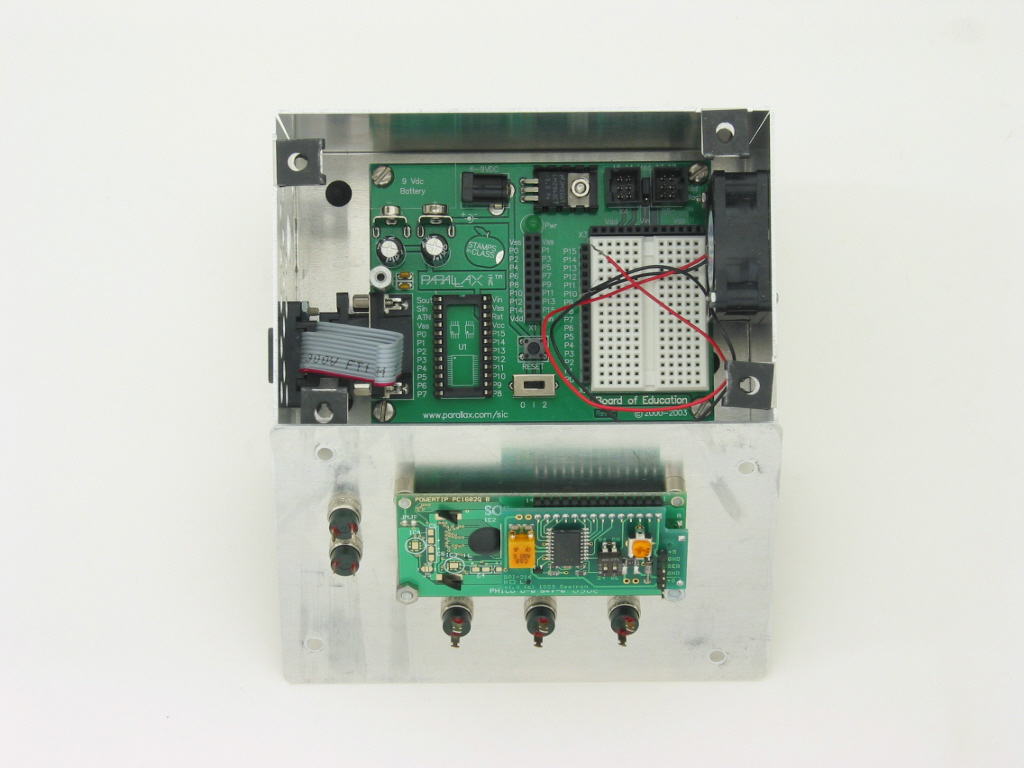

A while back we designed a project box enclosure. Around our office this project was received with minimal enthusiasm (of course·this concept·was my idea). Jon Williams says I take criticism like water flowing off of·a duck's back, so I followed through with my great idea and got a few prototypes. Now I am showing them to you to determine your interest, which will help us to decide whether or not to make a few hundred.

Our customers·frequently ask for project boxes, but they're never happy with what's available because·a solution·isn't NEMA, not water-resistant, it's too big, too small, etc. It seems that no box is ideal for·a project. But sometimes all it takes is a bit of time with a drill press and file to change somebody's mind and make the "not so perfect box" a more ideal solution to the problem. Especially when they're attempting to make an LCD cutout.

Here·are the details about the Parallax enclosure:

The design is very economical to manufacture - four edges folded up with tabs bent over. Edges are not sealed and the box is not water resistant. Material is AL 5052 .063".·The box·can be painted, anodized, powder coated, etc.

We wouldn't pretend to make a profit selling project boxes. They'd be sold·slightly above·our cost, which would be something between $8 and $20 depending on how·we package the solution. For example, we could offer the box, two lid options·and a small pack of strain-reliefs. This way you can only buy what you need. If we proceed I will add mounting holes for the SX Tech Board, since our SX/B·compiler is being widely utilized.

Pictures are below.

Okay, the duck awaits your comments!

Ken Gracey

Parallax, Inc.

A while back we designed a project box enclosure. Around our office this project was received with minimal enthusiasm (of course·this concept·was my idea). Jon Williams says I take criticism like water flowing off of·a duck's back, so I followed through with my great idea and got a few prototypes. Now I am showing them to you to determine your interest, which will help us to decide whether or not to make a few hundred.

Our customers·frequently ask for project boxes, but they're never happy with what's available because·a solution·isn't NEMA, not water-resistant, it's too big, too small, etc. It seems that no box is ideal for·a project. But sometimes all it takes is a bit of time with a drill press and file to change somebody's mind and make the "not so perfect box" a more ideal solution to the problem. Especially when they're attempting to make an LCD cutout.

Here·are the details about the Parallax enclosure:

- Mounting holes fit all of our 3" x 4" Parallax boards

- Additional accessories (AppMods) and other circuits fit within the box

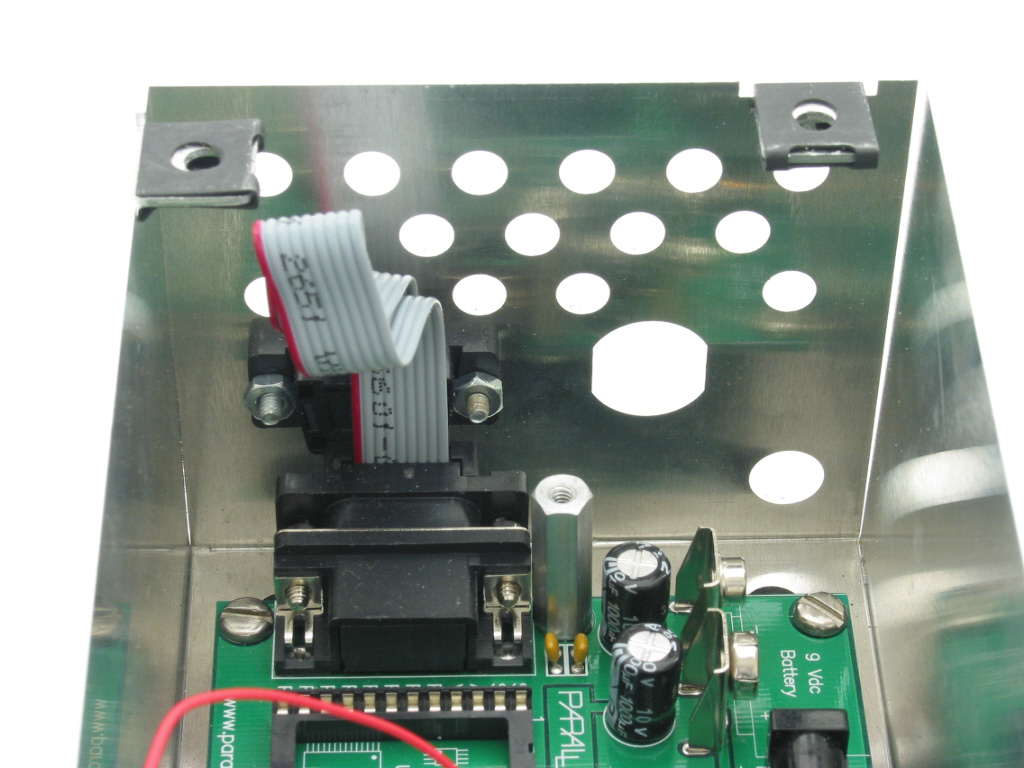

- Uses strain relief connectors for access to power, RJ11/RJ45, and a DB-9 extension from the side of the box to the Parallax board

- Two top options available: 1) plain; 2) LCD cutout with five·1/4" button holes····

- Metal insert screw-tabs for securing the lid to the box

The design is very economical to manufacture - four edges folded up with tabs bent over. Edges are not sealed and the box is not water resistant. Material is AL 5052 .063".·The box·can be painted, anodized, powder coated, etc.

We wouldn't pretend to make a profit selling project boxes. They'd be sold·slightly above·our cost, which would be something between $8 and $20 depending on how·we package the solution. For example, we could offer the box, two lid options·and a small pack of strain-reliefs. This way you can only buy what you need. If we proceed I will add mounting holes for the SX Tech Board, since our SX/B·compiler is being widely utilized.

Pictures are below.

Okay, the duck awaits your comments!

Ken Gracey

Parallax, Inc.

Comments

Bob

Unless it's an optical illusion, it doesn't look like you'd be able to slip a 9 volt battery in Project Box Number 5. I certainly hope I'm wrong since the boxes look real nicely layed out, and quite custom-made.

Regards,

Bruce Bates

You can use a 9v battery connector that has two leads and plug them into Vin and Vss.· There is plenty of room for the battery to fit on the side of the BOE.

Dave

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Dave Andreae

Tech Support

dandreae@parallax.com

www.parallax.com

·

Chris

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Sid Weaver

NEW! 4 MB EEPROM

http://hometown.aol.com/newzed/page4.html

·

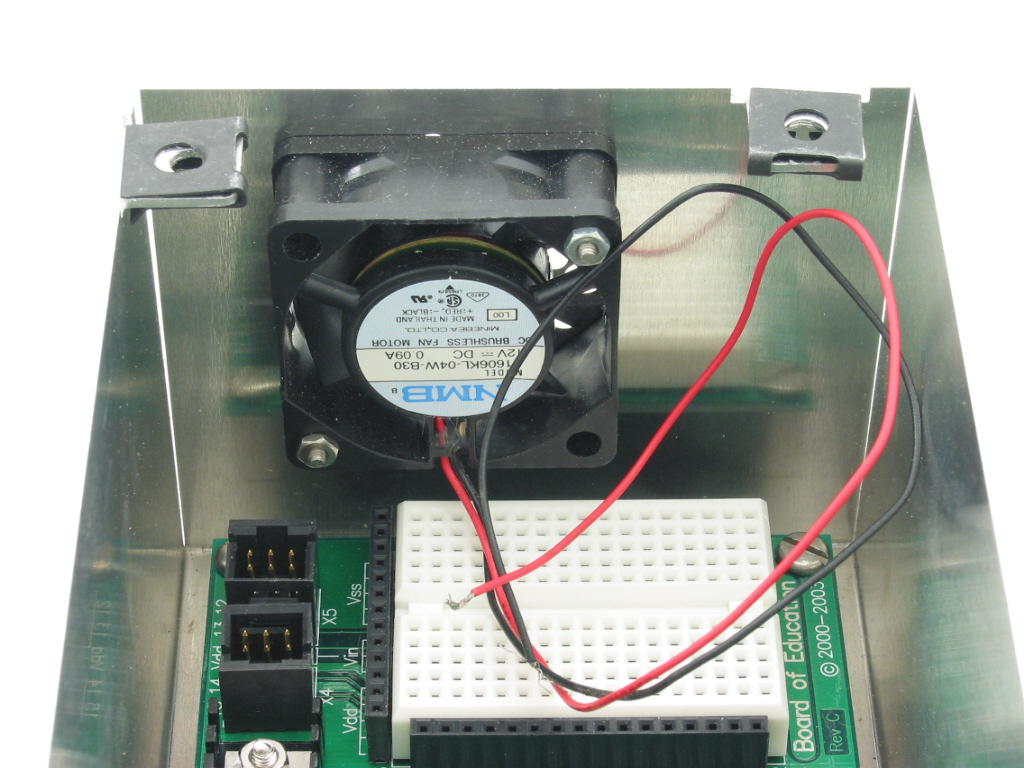

Is the fan optional ?

Bean.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"SX-Video Display Module" Available Now.

www.sxvm.com

"A problem well defined, is a problem·half solved."

·

"...and a DB-9 extension from the side of the box to the Parallax board"

How about USB?

Floyd

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Ben Damon

And may God Bless America!

·· These are really well designed for people who want to make small projects and not have to mill every little hole and cut-out.· Plus they simply look cool!· Anymore questions?·

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Chris Savage

Parallax Tech Support

csavage@parallax.com

Maybe I missed it, but what are the dimensions ?

Bean.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"SX-Video Display Module" Available Now.

www.sxvm.com

"A problem well defined, is a problem·half solved."

·

·· You can sort of get an idea by looking at the BOE mounted inside for comparison, but I will measure it tomorrow at Parallax and post the dimensions here.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Chris Savage

Parallax Tech Support

csavage@parallax.com

The reason for the lack of enthusiasm around the office is probably because its a box!· Its not anything real cool like a new stamp or new sensor.· I'll be honest with its a very nice project enclosure and I would buy a few myself... You got to put your cool new sensor and stamp into something to make it rugged and professional looking right?!

good job Ken!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

DTQ

Any chance of a hermetically sealed one?! Maybe even a submersible one?

Maybe have "add-on kits" to modify a 'generic' box (similar to the one posted).

Someguys operated outdoors and some at depth in water.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·

Steve

http://ca.geocities.com/steve.brady@rogers.com/index.html

"Inside each and every one of us is our one, true authentic swing. Something we was born with. Something that's ours and ours alone. Something that can't be learned... something that's got to be remembered."

I foresee lots of little aluminum "bricks" popping up everywhere, as soon as you finalize your design and start selling it. Having a naked BOE in a project just screams "amateur", no matter how clever the coding.

A couple of suggestions (you knew that was coming, right?)

1. Have a couple of heights -- one for just a BOE with a few circuits in the prototyping area. A nice 3" x 4" x 1.5" high (or 2" high) 'flat pack' enclosure would look nicer than the full 'brick' you've shown. But the full 'brick' would allow a few app-mods to be stacked, so would also have application.

2. It would be nice to have a prototyping version of the BOE board -- one without the plastic 'bread-board', but with a 'sea-of-holes'. Perhaps the 'sea of holes' could have the same connectivity as the bread-board.· In fact, a new breadboard with the same dimensions but with minimal circuitry (BS2 socket, DB-9, 5.5/2.1 power, couple of caps, LM2940-5 regulator, a row of I/O breakout pads, power LED with resistor) would allow a larger 'sea-of-holes' prototyping area.

3. The only scale element in the picture is the BOE -- you might include a quarter in the picture so newbies get a better idea. I suspect the box is 'cuter' than its apparent dimensions make it seem.

Post Edited (allanlane5) : 4/12/2005 1:31:12 PM GMT

Here's an example:

http://www.robotics.com/robomenu/tether.html

Camel= horse designed by commitee.

Please keep those good ideas coming

Glen

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Chris Savage

Parallax Tech Support

csavage@parallax.com

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Truly Understand the Fundamentals and the Path will be so much easier...

I like Power LEDs next to connectors-

The boxes look great, I would like to see the fan as an option also.

How about anodized colors? [noparse];)[/noparse]

I would buy some.

Ryan

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

***************************· Any Ideas?· ****************************************

using a keyboard and a PAK 6 to geneerate decimal characters sent via serout to a second stamp on the underwater robot, it receives and interprets the keystroke from the pak 6 and sends a command to a pak 5 motor control chip to send pwm at the appropriate duty cycle and for the correct motor.· There are 3 trolling motors and the motor controllers are Diverse Electronic MC-7's.·

One of the motors has clear magnetism, the other two do not, whats that all about?· I can get one motor to work, the other two appear to be being "braked" as the armature resists turning.· The motor controllers do have breaking but I am not turning it on.·· The 3 motors have the expected red and black power wires but also have a yellow and blue wire, any ideas on their purpose?

This project was interrupted some years ago, but I·am ready to go again.

********************************······· ******************************************

Just a suggestion.

Sid

BTW I typically like to use the cast aluminum boxes.· They are very easy to machine and they·provide a good head start to a nice finished look.

Daniel

kelvin