ServoSpy: tuning without PC software

ManAtWork

Posts: 2,316

ManAtWork

Posts: 2,316

I just started another small hardware project with the P2. I have to tune the control loops of Chinese servo drives. The cheaper ones don't support autotuning and there is often no PC software provided. Or if it is it's only in Chinese language and the manuals are really poor.

But fortunatelly, for the P2 it's no big deal to simply tap the Step/Dir command signals and the encoder cable. The idea is to compare both position values and provide some sort of scope display of nominal vs. actual velocity and following error.

Step/Dir is simple, there's a smart pin mode for this (%01101 = P_REG_UP_DOWN). The absolute encoder signal is a bit more tricky but not really hard to hack. I found out that the magnetic 23-bit absolute encoders use the same protocol as some older optical encoders from Tamagawa Seiki I already knew. It's called "SmartAbs" and uses a 2.5MBd serial communication via an RS485 line.

CON

_xtlfreq = 25_000_000 ' KISS board Xtal

_clkfreq = 200_000_000 ' clock frequency

pinDp = 33 ' RS485 D+

pinDm = 32 ' RS485 D-

pinOut = 31 ' Test output

pinStep = 41 ' Step input

pinDir = 40 ' Dir input

VAR

byte rxCog

long stepCmd

OBJ

PUB main ()

wrpin (pinDir, P_SCHMITT_A)

pinstart (pinStep, P_REG_UP_DOWN + P_MINUS1_B + P_SCHMITT_A, 0, 0)

rxCog:= coginit (NEWCOG, @StartRx, @dataRq)

repeat

eofSig:= 1

repeat while eofSig>0

stepCmd:= rdpin (pinStep)

debug (UHEX_BYTE_ARRAY (@dataRq, 7), UHEX_LONG (encPos), UHEX_LONG (stepCmd))

waitms (100)

DAT

' SmartAbs Encoder Data transmitted over RS485 line @2.5MBd

' See Tamagawa Seiki docs for TS5700N8501 (17 bit or 23 bit)

dataRq byte 0 ' request byte

dataCf byte 0 ' control field

dataSf byte 0 ' status field

dataDf byte 0,0,0 ' position data

dataCrc byte 0 ' CRC field

eofSig byte 0 ' end of frame signal

encPos long 0

DAT

ORG

StartRx fltl #pinDp ' reset smart pin

wrpin ModeRx,#pinDp ' async serial RX

wxpin BaudRx,#pinDp ' 2.5MBd 8N1

drvl #pinDp

newFrame mov rxCnt,#7

mov ptrb,ptra

newByte mov time,Timeout ' timeout 50us

waitRx testp #pinDp wc

if_nc djnz time,#waitRx

if_nc jmp #newFrame ' if timeout -> start over

rdpin rx,#pinDp

shr rx,#24

rolbyte newPos,rx,#0

wrbyte rx,ptrb++ ' write byte to buffer

djnz rxCnt,#newByte

movbyts newPos,#%00011011

shl newPos,#9 ' 23 bits -> 32 bits left justified

sub newPos,oldPos

add oldPos,newPos

sar newPos,#9

add pos,newPos ' handle rollover/multi-turn

wrlong pos,ptra[2] ' write 32 bit position

wrbyte #0,ptra[7] ' write EOF flag

dropByte mov time,Timeout ' timeout 50us

waitGap testp #pinDp wc

if_nc djnz time,#waitGap

if_nc jmp #newFrame

rdpin rx,#pinDp ' ignore more bytes until inter-frame gap

jmp #dropByte

ModeRx long P_ASYNC_RX + P_MINUS1_B + P_COMPARE_AB

BaudRx long 80<<16 + 7 ' 2.5MBd 8N1

Timeout long 200*50/8 ' timeout 50us

oldPos long 0

pos long 0

rxCnt RES 1

rx RES 1

time RES 1

newPos RES 1

This little program can at least display the nominal and actual position. The next challange is to do proper scaling and offset correction. The servo uses some sort of so called "electronic gear" to scale 10,000 step pulses per revolution to 2^23 encoder counts.

Comments

@ManAtWork

I have been looking at the Chinese drives and might be about to pull the trigger on a couple; a 2KW and a 4.5KW.

I see that they are available with analogue input which is what I prefer and they have a simulated encoder output.

What I am aiming for is to simplify everything. A servo-drive, configured for "torque mode" (current command) requires minimal setup, literally a transconductance and commutating module.

I prefer to handle everything else on the P2 but I'm curious about why you are going with pulse & direction?

Craig

The step+dir signals have historical reasons. I had and still have a lot of customers who use stepper motors or want to use their own drives. Another reason is simplicity. I don't need (simulated incremental) encoder signals.

Be careful, not all Chinese drives support them. I think, the dirt cheap ones from HLTNC and PFDE don't. Those from JMC and Lichuan do.

I don't know how many times in my life I have programmed some sort of bresenham interpolator or electronic gear. They all work very similar but according to murphy there is always at least one reason why I can't use one of the existing implementations. This time it needs to be 64 bits and signed. After the usual mistakes of taking the wrong register or forgetting to set the right flag it finally works.

This time it needs to be 64 bits and signed. After the usual mistakes of taking the wrong register or forgetting to set the right flag it finally works.

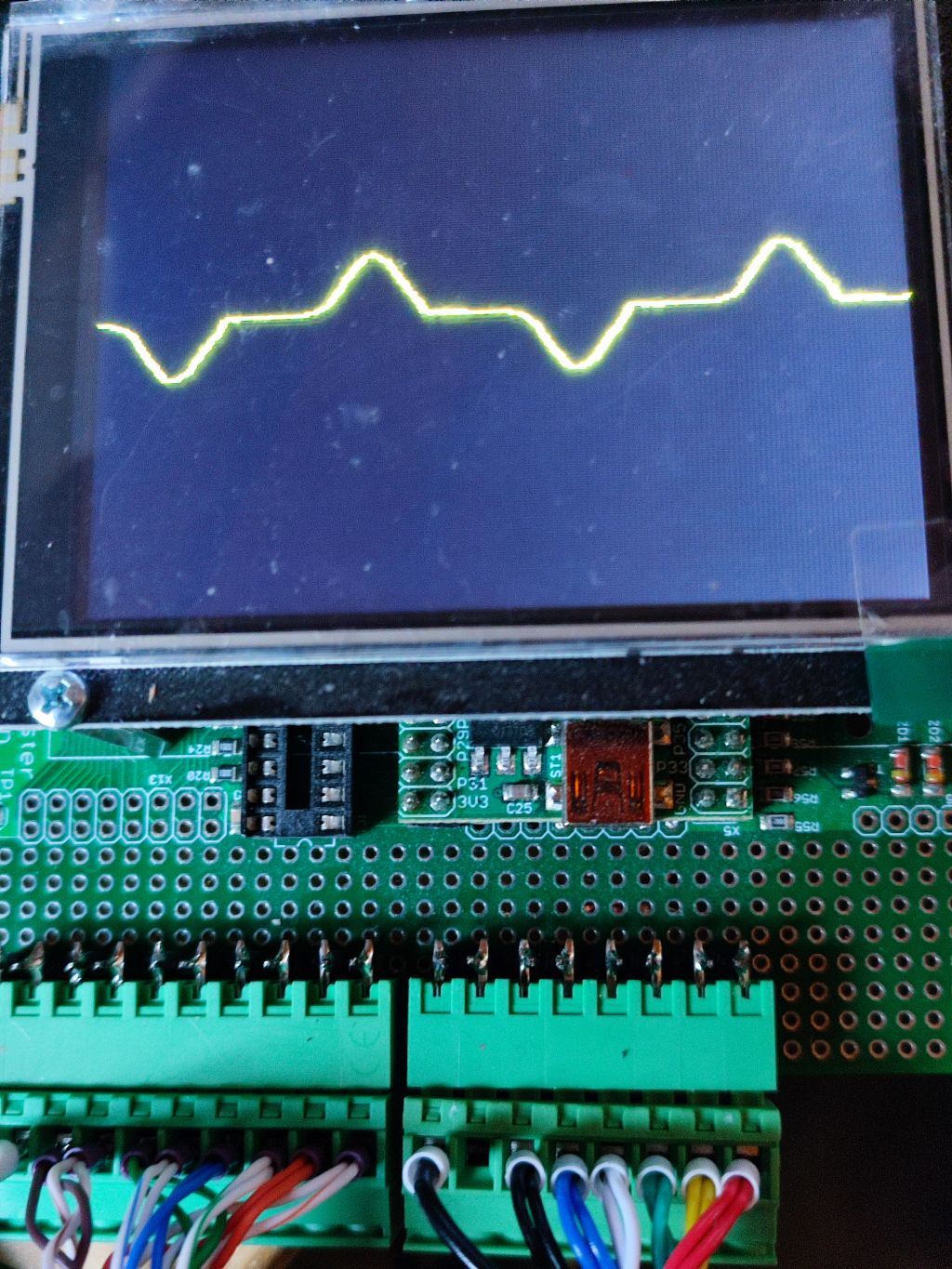

'' Servo Spy: Servo tuning by comparing nominal vs. actual position '' Monitor Step/Dir command and absolute encoder serial data communication ' bene 16-Aug-2025 first test ' bene 18-Aug-2025 + scope window CON _xtlfreq = 25_000_000 ' KISS board Xtal _clkfreq = 200_000_000 ' clock frequency pinDp = 33 ' RS485 D+ pinDm = 32 ' RS485 D- pinOut = 31 ' Test output pinStep = 41 ' Step input pinDir = 40 ' Dir input VAR byte rxCog long stepCmd long encOffs long lastPos OBJ PUB main () | np, ap, la, ln wrpin (pinDir, P_SCHMITT_A + P_INVERT_IN) pinstart (pinStep, P_REG_UP_DOWN + P_MINUS1_B + P_SCHMITT_A, 0, 0) rxCog:= coginit (NEWCOG, @StartRx, @dataRq) encOffs:= GetEncPos () la:= GetEncPos () ln:= 0 debug (`SCOPE Motion SIZE 500 330 SAMPLES 500) debug (`Motion 'NomVel' -1000 1_000 300 10 15 GREEN) debug (`Motion 'ActVel' -1000 1_000 300 10 15 YELLOW) debug (`Motion 'PosErr' -1000 1_000 300 10 15 RED) debug (`Motion TRIGGER 0 -5 5 350) repeat np:= stepCmd:= rdpin (pinStep) ap:= GetEncPos () 'debug (UHEX_BYTE_ARRAY (@dataRq, 7), UHEX_LONG (GetEncPos ()), UHEX_LONG (stepCmd)) debug (`Motion `(np-ln, ap-la, np-ap)) la:= ap ln:= np waitms (10) PRI GetEncPos (): p eofSig:= 1 repeat while eofSig>0 return encPos - encOffs DAT ' SmartAbs Encoder Data transmitted over RS485 line @2.5MBd ' See Tamagawa Seiki docs for TS5700N8501 (17 bit or 23 bit) dataRq byte 0 ' request byte dataCf byte 0 ' control field dataSf byte 0 ' status field dataDf byte 0,0,0 ' position data dataCrc byte 0 ' CRC field eofSig byte 0 ' end of frame signal encPos long 0 DAT ORG StartRx fltl #pinDp ' reset smart pin wrpin ModeRx,#pinDp ' async serial RX wxpin BaudRx,#pinDp ' 2.5MBd 8N1 drvl #pinDp newFrame mov rxCnt,#7 mov ptrb,ptra newByte mov time,Timeout ' timeout 50us waitRx testp #pinDp wc if_nc djnz time,#waitRx if_nc jmp #newFrame ' if timeout -> start over rdpin rx,#pinDp shr rx,#24 rolbyte newPos,rx,#0 wrbyte rx,ptrb++ ' write byte to buffer djnz rxCnt,#newByte movbyts newPos,#%00011011 shl newPos,#9 ' 23 bits -> 32 bits left justified sub newPos,oldPos add oldPos,newPos ' handle rollover/multi-turn sar newPos,#9 ' right justified 23 bits abs x,newPos wc qmul x,GearMul testb rem,#31 xorc modz _C wz ' Z = signs of rem and newPos differ abs rem getqx x getqy y if_nz add x,rem wc if_nz addsx y,#0 wc if_z sub x,rem wc ' add/sub remainder if_z subsx y,#0 wc if_c add x,GearDiv ' if YX<0 then YX+=GearMul.. if_c mov y,#0 setq y qdiv x,GearDiv getqx x getqy rem if_c sub x,#1 ' ...and result-=1 abs y,newPos wc negc rem ' set sign of remainder sumc pos,x wrlong pos,ptra[2] ' write 32 bit position wrbyte #0,ptra[7] ' write EOF flag dropByte mov time,Timeout ' timeout 50us waitGap testp #pinDp wc if_nc djnz time,#waitGap if_nc jmp #newFrame rdpin rx,#pinDp ' ignore more bytes until inter-frame gap jmp #dropByte ModeRx long P_ASYNC_RX + P_MINUS1_B + P_COMPARE_AB BaudRx long 80<<16 + 7 ' 2.5MBd 8N1 Timeout long 200*50/8 ' timeout 50us GearMul long 625 ' 10_000 / 2^23 GearDiv long 524288 oldPos long 0 pos long 0 rem long 0 rxCnt RES 1 rx RES 1 time RES 1 newPos RES 1 x RES 1 y RES 1The servo repeatedly moves forth and back by 10mm with this little NC program.

The tuning is terrible (default factory settings) and the following error is more than 0.5mm (1000 steps = 1mm). But with this little tool I hopefully can improve it in a convenient way, soon. While the NC program runs in the background I can simply move the feed override slider to adjust the speed, set parameters over the MODBUS and watch the results in realtime.

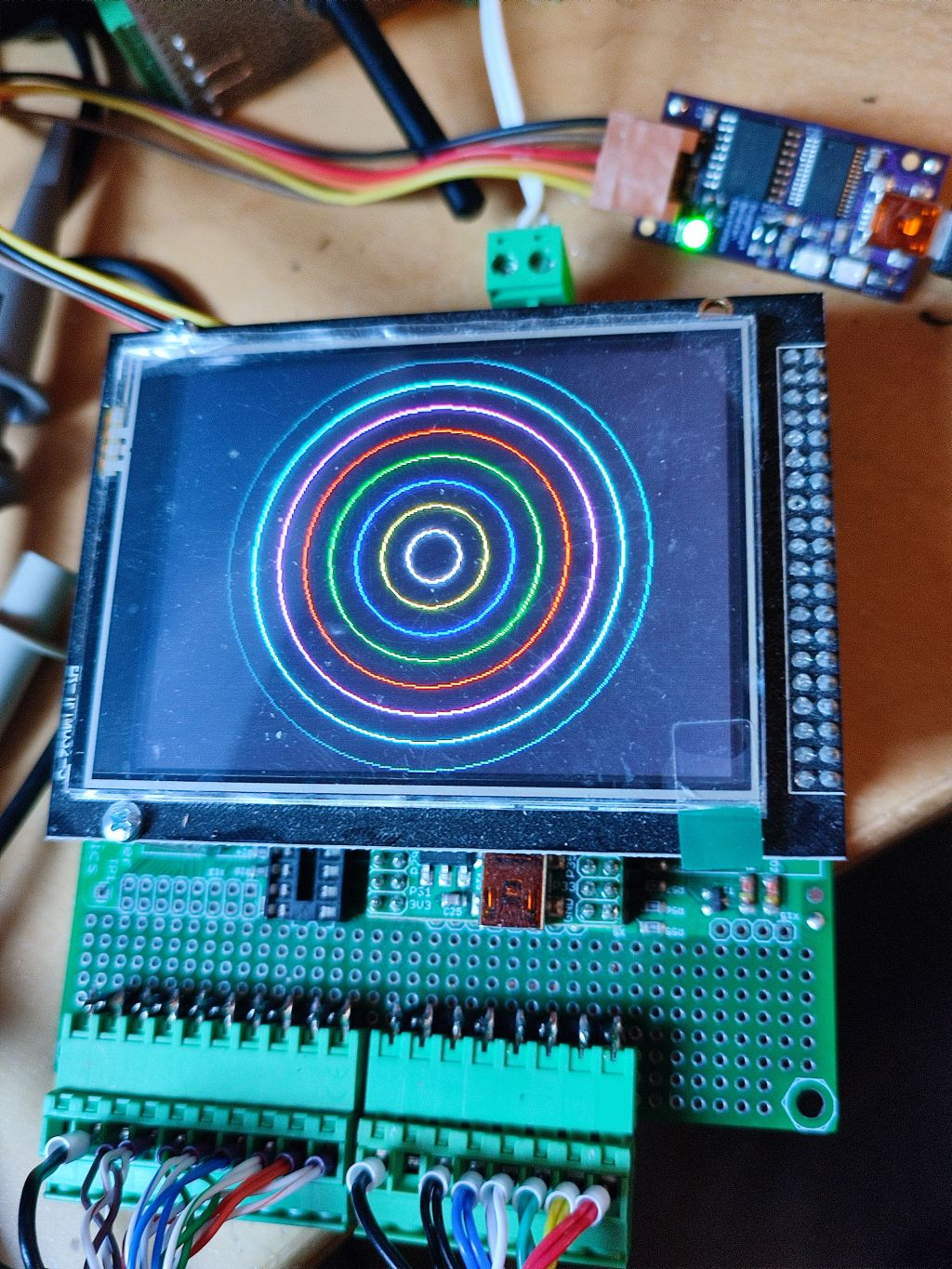

Of course, for the promise in the title "without PC software" to be true the scope traces have to be dispayed on the P2 board instead of the PC screen.

The plan is to use this little board with a KISS module and an LCS screen.

It works! But drawing the lines with the standard IL9341 LCD driver is way too slow. I need to draw to a RAM buffer, first, and then copy the bitmap data to the screen at once.

But drawing the lines with the standard IL9341 LCD driver is way too slow. I need to draw to a RAM buffer, first, and then copy the bitmap data to the screen at once.

I send via Bluetooth to an Android device: