P2 Controls Circular Knitting Machine for 2 Color Jacquard Pattern

Hi,

this is a fun project using a P2 Kiss Bord to control a modified "Addi Express Kingsize" circular knitting machine.

Normally the "Addi Express" is operated with a hand crank and only one yarn is used. This video shows, how a beanie hat can be made:

https://youtube.com/watch?v=NjIPEoDu-OI

The "Addi Express Kingsize" is suitable for relatively thick yarns for needles 3.5...8mm. It has 46 needles. 46 is not very ideal for repeating patterns, so you have to cheat a little bit....

Updates:

02.11.22

To improve reliability:

The possible pull back length for the threads was enlarged. In addition I program stops, when a thread has not been used lately and shall now be used.

To improve reliability of the stitch-counter, modulated light (40kHz) is now used together with a hacked infrared reflection sensor module. The original sensor did not work, when there was sun light shining onto the machine. For this application I even now use a 1k resistor between the receiver collector and 3.3V. https://forums.parallax.com/discussion/174955/p2-taqoz-2-8-dac-comparator-and-goertzel-touch-sense-and-reflex-sensor-with-modulated-light#latest

The modulated light sensor with "Goertzel Mode" uses an own cog in addition to Main-cog and Vga-cog.

All in all I was now able to make a beanie hat without a single issue.

As there was some interest in the software, I post it as is. It uses value type variables and local variables because for me they improve readability very much. Their code is included in AutoJ.fth. Explanation is here: https://forums.parallax.com/discussion/174531/taqoz-reloaded-2-8-better-readability-named-local-variables#latest

If there are questions, feel free to ask.

#

Original Text:

Modifications of the machine:

- The mechanic row counter was removed, because it interferes with smooth drive. You can dismantle this machine easily, because it is held together with screws.

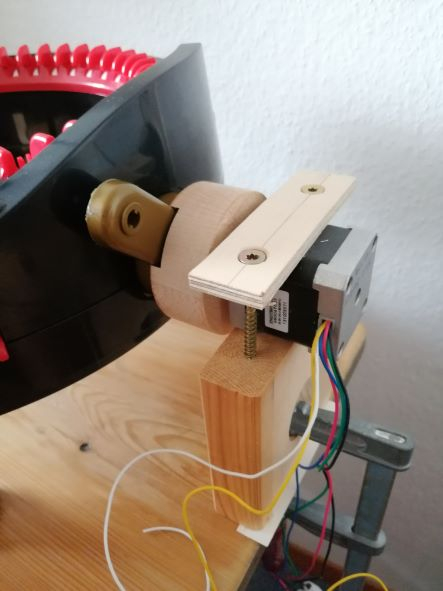

- Motor for main drive. I used a Polulu 1206A stepper motor with a A4988 stepper motor driver module. The motor is just strong enough with 12V supply. Actually the steps are not used for positioning. The motor is just used to control speed and start/stop. Using the steps is not so easy because the gear drive has an odd ratio. Something like 20/255.

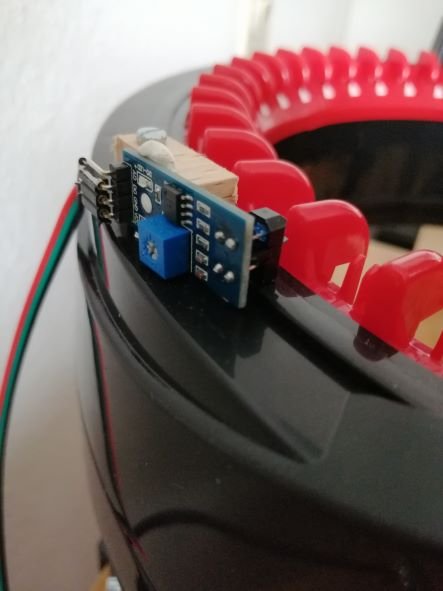

- To get the position of the needle-drum an infrared reflection sensor based on tcrt5000 and a LM393 comparator is used. It detects the teeth of the needle drum on the top of the machine. (Unfortunately this sensor fails, if the room is lit by direct sun light.)

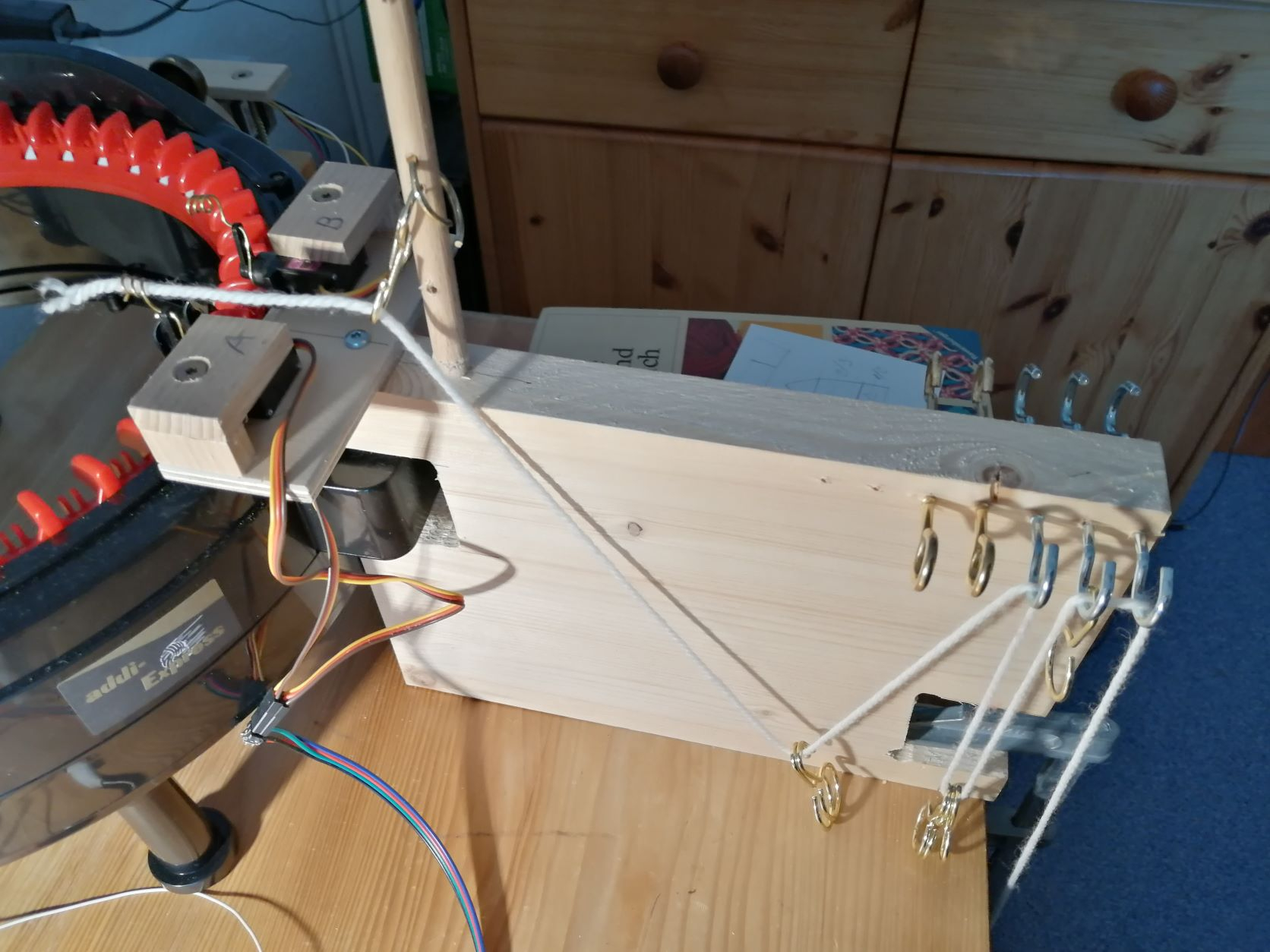

- To generate the Jacquard Pattern, two feeding systems for two yarns have to be used. This is achieved with two micro servo motors. The thread, which is not active at this moment, will run along at the inner side of the circle. So the original yarn "nozzle" is removed and two moving nozzles are installed.

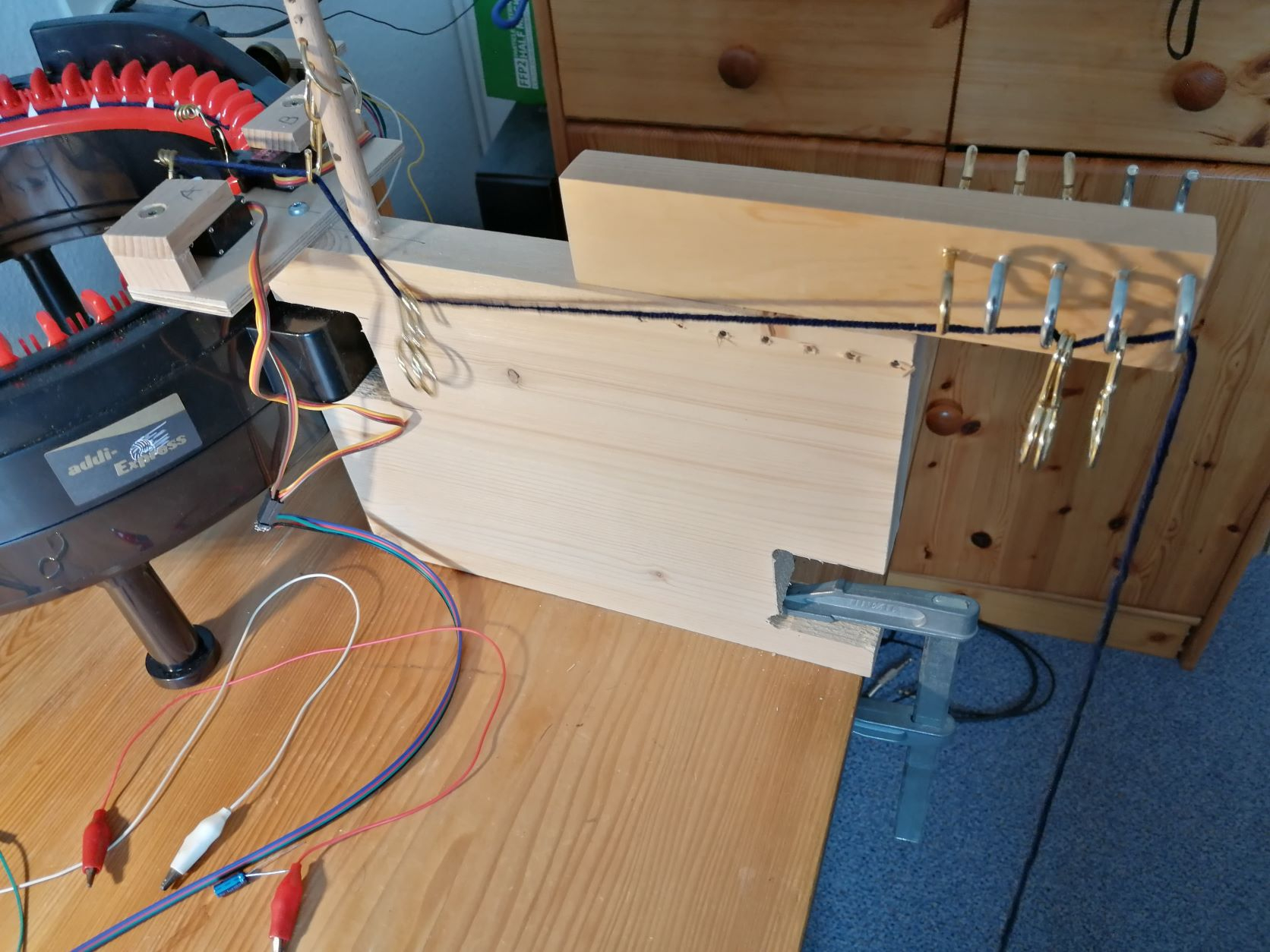

- The tension of the yarn is very important. It has to be kept constant. So a kind of yarn friction break is needed together with a means to pull back the thread. I was very happy, when I found the "RT6-12AL" type break. https://textilmaschinenzubehoer.de/produkte/fadenbremse/ It's function can be achieved relative simply. Pulling back is achieved with weight too.

The photo shows the thread tension control and on the left hand side the thread feeding. Both servo arms are upright in inactive position. The servo motors are clamped down. This enables fine adjustment of the position of the "yarn nozzle".

This shows the thread feeds. In this very moment the black yarn had just been used and it's arm is already moving upward. The pattern is hidden on the outside of the knitted hose. Instead you can see the inactive threads.

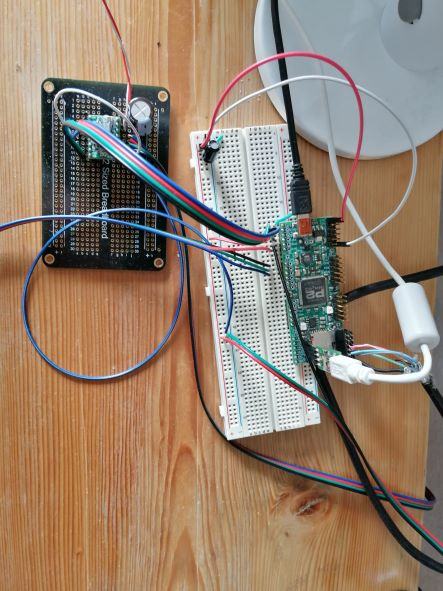

P2 Kiss board and a little board with the stepper controller module:

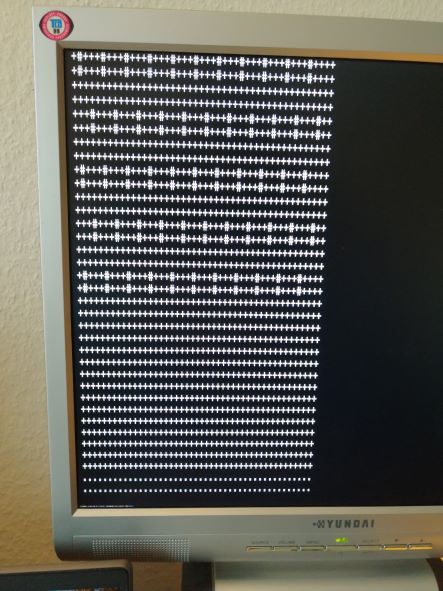

VGA Output is used to check the pattern:

Motor Mount and coupling:

Infrared Reflection Sensor Mount:

All the alterations to the machine have been done in a way that the original mechanical function can be completely restored.

A fist "product" is this :

As the beanie has got two layers, the inactive threads are hidden between these layers. The third color is achieved by manual substitution of one of the 2 threads.

The code is written in Taqoz Forth for P2. Actually the control is just using one cog at this moment, because the process is so slow, that you can poll the sensor. PWM for the two servo motors is generated via smart pin pwm. VGA output is used to check the pattern and to show progress.

If someone is interested in this project, I could share my Taqoz Forth code as is.

Comments, ideas,... ?

Christof

Comments

@"Christof Eb." - I love your project. I love it very much.

Not because of the "product", but because it combines totally different disciplines to create something very real and usable.

Here we have knitting, then knitting machine modifications, some woodwork, mounting techniques, electronic hardware and software and above everything else, an idea that was actually brought to the existance.

Bravo !

My most succesful projects usually end somewhere "in between" and most of the times I just toy with the idea before deciding not to pursue it .

.

Thank you, Maciek!

Yes, this brings together quite different worlds and I am learning a lot of interesting things here.

For example I did buy the wool at a shop, which is at the very place, where 1822 the Woolfirm was founded. The old buildings (with the tower) are still there, while there is no more production in Germany. At this location there is a river which gives power and a railway was built early. https://admin.shop.mezcrafts.com/media/88/d9/2e/1646400313/1240x600_Historie_1b.jpg

Then in the 1980ies there was a great time for knitting machines. rette-strickmaschine.ch/download.htm

Quite a lot of history and the versatility of the technique is broad: https://lucas-elha.de/catalogue/pdfs/R-Katalog.pdf

Another dimension is, that knitting is a "rather feminine world", which is sometimes rather strange for me.... It is quite nice, that I have the subject to discuss and share with my mother. I do value the knowledge and skills of her and her generation!

At the start of the project I wanted to make the mechanics of a knitting machine. You can buy spare needles for knitting machines. But I did drop this, because this part of the project alone would need a lot of time and the risk of a failed project is not low. The machine has to be rather reliable, because if it drops stitches, you have a lot of trouble. (I am learning how to mend them....)

I do know this "ending in between" very well. I think, it is often most interesting just to learn and explore a subject alone. My best motivation to bring a project to reality is to achieve something, that is "nice" for others too.

At the very moment I am a little bit surprised myself, that the machine works well enough to produce a Jacquard hat at all. But there is certainly room for improvement for the sensor, the pull back device and to add yarn tension sensors. So this is "in between" too....

Have fun, Christof

---snip---

YES! please post!

Say? I hate to be blasting mynocks here, but isn't that style machine normally controlled by a punched card, about the size of stock also used for player pianos? Take a look. The name invented the process for making difficult weaves like tweeds around the late 19C, the same idea found itself being used for the 1880 Census, the tabulators were designed by a chap named Hollerith. And we know where his punched cards were also used next.

Mascot away.

Oh @"Buck Rogers",

don't be mean.

I looked at those videos and mechanizing this knitting tool is a amazing step.

Not sure on how to do Patterns, except colorizing white thread while knitting?

fun Project, well done @"Christof Eb."

Mike

Great....now I go to my YouTube and 50,000 woolly-hat-making vids come up...it used to be MCUs and Formula-One

Craig

Thx for the warning Just kidding of course, woolly-hats are nice, as are MCUs, F1, ...

Just kidding of course, woolly-hats are nice, as are MCUs, F1, ...

Hi Dave,

it took some time to post the code. Please find it in the 1st post together with some improvements.

Do you think about doing such a machine?

Christof

What a cool idea, a robotically knitted hat as a gift.

I must admit, I am a bit enamored with your P2 Kiss board. Where could I pick one of those up? XD

~JD

https://forums.parallax.com/discussion/172391/kiss-eval-board-ready-to-ship-taking-orders/p1

Christof

Thank you. I am in the US, and it looks like Publison is handling the shipping of those boards, is that correct? I didn't see a way to order one from the post.

Hi @JD

Publison had not been well and has not been active at these forums since last year. I would suggest to ask at the KISS thread Christof mentioned about US availability.

Oh no! @Publison, I hope you get better and return to the forums soon!

Sorry for the interruption.

Cool project, @"Christof Eb."!

A little video of the moving machine:

https://youtube.com/shorts/NBm7fYkf97M

That is neat @"Christof Eb."

Nice work!