Crystal loading capacitors

This is a split off the KISS Board Eval thread, but is definitely its own topic.

@ManAtWork said:

@Circuitsoft said:

I have had plenty of designs using 10ppm crystals get 150ppm out because the loading capacitors aren't quite right. This really becomes an issue when you have a ground plane (which is a very good idea) because the loading caps then parallel/add to the ground-plane caps, so the frequency can wind up very wrong.I don't have much choice there because the loading caps are internal to the P2.

What are the internal loading caps when you select 15pf? The correct loading caps for a crystal often vary somewhat depending on what else is on the board, trace thickness, distance to ground plane, etc. Crystals being 150ppm off because of loading caps that don't account for board geometry is a problem on another product I'm working on now.

If somebody decides to use a smartpin counter, along with some software, as an RTC for example, and they choose a high-precision crystal for it, how would they go about tuning caps for the end board design within DVT?

Comments

I don't have the ready answers to your questions and know nothing about your project but if I needed a precision timing on board, fairly cheap and hustle free and I knew it from the start of the project, and I only planned to have one signal source for that, I'd go for the TCXO.

Many factors to consider here like scale for example or hours spent on designing and testing the product and, of course tolerances of the components used.

If every cent counts and the scale is huge then maybe you really need your questions answered. Otherwise I'd go for the TCXO.

You need to do the fine stuff experimentally, here are measurements I made on P2 Eval

That sounds extreme, but just possible. See the above measurements, where I can get 144ppm high, by selecting pin + layout cap only. ie a long way off from target CL.

As above, vary the P2 settings to get three points on the ppm/pF curve. This is what a representative curve looks like, so you can measure to fit that curve to P2 + Specific Crystal + PCB design.

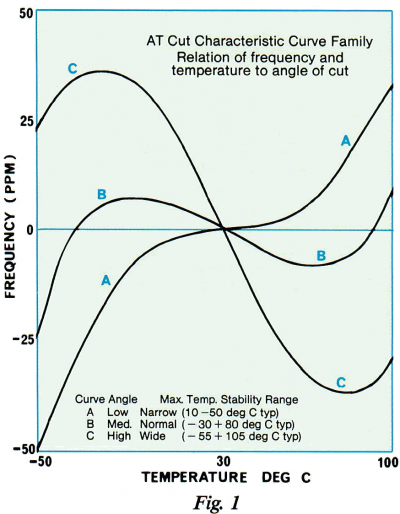

also keep in mind the temperature curve of a xtal is significant, and varies with the target temperature range. Wide range Xtals have a higher slope at 25°C.

In the above test, just self warming of an operating P2 on the board, moved 15~20ppm

Then you have aging to consider. The Epson Xtal in Eval, is a quite good ±1ppm/year, most low cost xtals are ±2~5 ppm/year

If you wanted to get a better spec RTC using a standard XTAL, in order to compensate for the predictable frequency-temp curves, you might want to choose a Xtal with a NTC included in the package.

One example is

https://datasheet.lcsc.com/lcsc/1912111437_NDK-EXS00A-CS08274_C280824.pdf

that's 26MHz 9pF 2520 100+ US$0.0854 ±10ppm -25°C~85°C 28 ±10% ppm/pF 1ppm/year

Thermistor 100k ±1% B = 4250K ±1%

it claims it can be curve fitted to ±0.5 ppm

Frequency perturbation - ±0.5 ppm *Measurement condition: Peak-to-peak deviation from the frequency versus temperature curve fit 3th order. Minimum of 1 frequency reading every 2°C over operating temperature range.

The P2 would need to measure the thermistor periodically and correct using that. It could generate a 1pps signal on a smart pin, that could be checked against a GPS 1pps, to confirm your corrections.

You could do 1 or 2 point calibration on each unit, to remove the reflow+offset effects.

The ±10ppm -25°C~85°C given above, looks like a 4° Crystal cut, on this curve set

Looks like the tcxo stuff is for When the temperature in the room varies a lot. Don’t think we have that issue. Also, not sure precision in clock is so important for me. Good subject to bring up though …

I was watching one of the BBC wildlife docos where they tack on a short making-of at the end. They were in -50 temperatures and the drone wouldn't start without an initial warming first.

Of course it wasn't long before the drone operator was having trouble feeling the controls.

I have a cheap Bluetooth adapter in my car that won't start in the cold, and once it warms up, it needs a power cycle before it'll work.