Simple, low cost P2 board (1st one seems to work)

There seems to be a need for a very low cost P2 board, here's a thought on how to implement that.

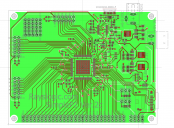

See the attached image of a potential layout...

It has the FTDI FT231X for serial programming, a flash chip, some linear regulators, two leds and not much else...

There are 3 of the Parallax Eval board style headers and then a long, header for 32 P2 pins (P24..P55).

The two rows are connected, like Propeller Platform did. There is also GND and +3.3V there at the end.

This might be good for connecting to a breadboard.

Very rough estimate of the cost is between $30 and $35 delivered in USA.

Any thoughts?

Update: Just built one. Still checking but seems to work so far.

Comments

Note: It's not fully routed yet and still needs some more caps at the headers...

I think the mere board size will not allow low cost ?

Was checking board cost using Seeed Studio Fusion... It's 2 layers, 102x78 mm. With ENIG (gold) finish, I get about $2 per board at qty. around 50.

Yeah, I have some thoughts but please, do take them lightly.

Personally, I think number 6 is the lowest risk and highest productivity option. Plus, we really, by experience, can establish which board is good for what purpose when people start doing things with them and experimenting. Cost should not determine the "must have" features but the other way around.

If we really are ready to carry out steps 1 to 5 then I am ready with my list, already grouped by must and nice to have options and a target price must not exceed that of a current Edge board delivered to anywhere in the world (must be less than the Edge plus shipping).

...

Linear regulators impose a thermal ceiling on operation, but maybe the large PCB area here can be used to your advantage ?

If you spread those regulators around the whole board, to give better thermal balancing, and move to a better-thermal-package & higher I limit, (but still low cost) maybe that can be 'good enough' ?

Maybe mounting the regulators on the rear side allows more unbroken copper cooling, and the whole board can then optionally mount on a aluminum plate for those who want to push things ?

Or, being more creative, could copper areas be allocated in a row, for something like a solderable clip S8131-46R, or S8121-46R and a PCB thermal spreader can slot into that,

or someone could simply solder edge-on to copper areas, if they expected to push things ?

@jmg This board is actually a reduced version of the ones described here:

https://forums.parallax.com/discussion/170725/my-first-p2-pcb-its-finally-done/p1

So, the power supply portion has already been tested. But, maybe not at full rated current.

But, it's just a bit warm in use, as I recall.

There are vias meant to take heat to the bottom layer.

Still, there may be room for improvement there.

That one looks to have 2 x SMPS on the 3v3 and 1v8 and just one linear regulator ?

I found some good thermal info in a ROHM data sheet , for TO-252 packages

This shows you can get reasonable power spreading, provided you throw enough copper at the problem

The SOT-223 package is too feeble for good thermal operation, and the x1117 parts have OUT on the TAB, which excludes good GND plane connect.

Looking around for TAB=GND regulators, with reasonable current overhead, I find these

AP7363-18D-13 1.8V 1.5A (3.7A typ peak) TO252 Stocked at DK and Mouser ~23c.1k

AP7363-33D-13 3.3V 1.5A (3.7A typ peak) TO252 Stock arriving at Mouser ~23c/1k

For the optional 6~9V pre regulator, things are a little murkier...

You can get a 7805 generic regulator for sub 20c, in TO-252, (TAB=GND) but the large 2V drop-out of that means 6V in will give 4V out. The 3v3 and 1v8 rails are ok with that, but it is not 5V anymore.

Better LM29150/MIC29150 series parts can come in TO-252 with TAB=GND and those are ~ 42c/1k from lcsc. Some of these parts claim to be -20V tolerant, which can solve reverse battery cases.

Or, there is LDL212PU50R - rated to 18V, with ISC > 1.5A typ 2A and with a claimed 10°C/W θJC on the 3x3 DFN6 package, and the PAD is GND there, and about 20c/1k

Not showing in that 3x3 package are 1v8 or 3v3 parts, but they do have 5v0

Just FYI: The KISS board design has a switching mode regulator for 1.8V and an LDO for 3.3V. It's tested and works with little heat and small board area. Schematic is available here. If you want to make your own layout I don't want to stop you. Jus go ahead. However, if there's only small changes that needs to be made to the KISS board layout so it would fit your needs I'd suggest adding those to the KISS board instead of re-inventing the wheel.

Hi Rayman,

yeah, it would be great, to have P2 available with an attractive price!

I assume, that you could put a single line of pins into the DIL holes, which are doubled, to plug it into a breadboard?

As a matter of fact, I already do use DIL-boards in this way, that one row is not used, because I often do not need too many pins.

So for me this is an acceptable compromise and way better than the edge connector!

It is very good, to have 5V input voltage, usb-serial-connector and the boot flash onboard to be able to start easily!

If possible, a reset switch or at least the solder connectors for it would be very helpful.

A power LED ist helpful!

A single LED at a port is nice. (Maybe a neopixel?)

It would be good, to have the +5V available on the DIL or at least at a solder point.

As I would like to have a file system, either boot from SD-card or a flash with >=4 Megabytes would be good.

If possible, a place to solder SPI-Ram would be nice.

If for low cost customers have to solder some parts anyway, they could attach some heat sink or even solder a through hole regulator, if this helps.

As far as I understand, low cost is enabled by:

1. Low individual service for low selling overhead.

2. Production with high volume methods.

3. Customer must solder through hole parts.

Sounds good.

From #1 "It has the FTDI FT231X for serial programming,"

...

One problem with 'user assembly', is the savings are often an illusion.

Testing the board is now harder, and the packages need parts counted into them, one at a time. Then, you have extra support needed when the user 'stuffs things up'...

I can see merit in a user soldered heat spreader approach, where a SMD regulator is fitted, and then a plated PCB strip from the PCB panel, (or even a fan bracket), could be user fitted if they know they are going to push things.

On the KISS board I only run a very basic self-test which tests for shorts and stuck-at-low/high on the IO pins. Continuity of the board traces has already been testend by the flying probe test at the board house. So the board can be tested without the TH parts soldered.

Yes, but #11 was talking about manual user fit of voltage regulator parts.

@"Christof Eb." Adding a uSD with dedicated pins does give enough room to add a Propeller Platform style power header with GND, +3.3V, +5V, and VIN without changing the board size.

P56 and P57 are currently brought out to LEDs and 3-pin headers.

It's now routed...

Just a thought:

I seem to remember, that P2 can be hand-soldered, if there is a borehole in the middle of the ground pad?

Cooling must be ensured otherwise then.

There might be a possibility to do the routing in a way, that this bore could be done?

I don't know if this is worth to consider.

Is there a chance, that someone would offer populated boards in Europe?

If there is sufficient demand then I'd guess probably yes but it's up to @Rayman to decide.

The overseas shipping costs are steep these days. We all suffer because of this.

Boards on order. Wish I had remembered to label the reset button. But, I did attempt to label most everything else. Hopefully, comes out OK.

I've also posted the Eagle design files in the top post.

@"Christof Eb." The P2 part is known to work, and I don't want to mess with anything there. A hole might be nice though. I've used a hot air gun to rework a P2 chip that I placed in the wrong orientation once. It worked although needed some rework afterward.

@Maciek I was just looking an USPS international rates... Priority shipping is pretty expense, but regular looks to be half that at ~$14. Appears that you get delivery notification but no tracking...

Got one built and it seems to work. Still some things to test out though...

The regulators and P2 get a little warm at 300 MHz, but not too bad.

I can leave my thumb over the regulators although doing so makes them get hotter!

Had to rework the P2 with hot air gun as it wasn't perfectly aligned when it went in the oven.

These big chips don't seem to align themselves as nicely as the little ones.

Have to be more careful with P2 alignment...

I was quite surprised to find the P2 Edge for <£27 (excl VAT) from Digikey.

Just grabbed two of them plus the breadboard, a mini breakout and a few accessories. This will be for industrial use and "Parallax Made In the USA" is nice to have on there (for me)

@Mickster Glad to hear it's available at Digikey there now too. That seemed to be a major issue for Europe....

What is the total cost for a minimal setup?

Guess you need Edge+breakout+propplug right?

Hi Rayman!

Nice outcome! Your oven seems to be a dependable friend.

Exposed pad (larger than usual, in case of P2), LQFP-100-alignment can be improved a bit, by increasing the number of vias at the EP to a 9 x 9 grid. Via diameter can also be tweaked, though I'm not sure about the exact numbers used at your design.

In general, surface tension can both be a friend, or an enemy; as you iterate thru some revisions, the better balance will show up, for sure.

Excess wicking at the EP can counteract the composed self-alignment, resulting from the sum of each one of the hundred-pads individual-forces.

Poor dispersion of solder can also be a problem, as many voids can be formed underneath.

Only X-Ray (man ) examination can make you sure of the final results.

) examination can make you sure of the final results.

Yeah, this didn't format too well

149-P2-EC-ND

P2 EDGE MODULE

Available

Quantity Backorder

Quantity Unit

Price Extended

Price

2 0 28.77000 £57.54

149-64019-ND

P2 EDGE MINI BREAKOUT BOARD

Available

Quantity Backorder

Quantity Unit

Price Extended

Price

2 0 18.94000 £37.88

149-64008-ND

P2 TO CLICK ADAPTER

Available

Quantity Backorder

Quantity Unit

Price Extended

Price

2 0 3.34000 £6.68

149-64020-ND

P2 EDGE MODULE BREADBOARD

Available

Quantity Backorder

Quantity Unit

Price Extended

Price

1 0 49.96000 £49.96

149-64007-ND

P2 TO WX ADAPTER

Available

Quantity Backorder

Quantity Unit

Price Extended

Price

1 0 3.34000 £3.34

32201-ND

PLUG USB-SRL FOR PROPELLER CI

Available

Quantity Backorder

Quantity Unit

Price Extended

Price

2 0 13.03000 £26.06

149-805-00019-ND

CABLE, USB A TO DC 2.1MM JACK

Available

Quantity Backorder

Quantity Unit

Price Extended

Price

2 0 3.14000 £6.28

7 of 7 parts displayed.

You’ve purchased these products.

Now stay up to date with PCN notifications by creating a My Digi-Key account.

Order Summary

Items in Order: 7

Subtotal: £187.74

Shipping: £0.00

VAT £37.55

Total: £225.29

Back in 2018, @WBA Consulting did linked some useful resources, in one of his posts:

https://forums.parallax.com/discussion/comment/1441367/#Comment_1441367

P.S. Any unevenness on temperature distribution within the reflow oven can also be cause of "pivoting" (aka: tombstone, but the term seems a little exagerated, as to be used with large LQFPs), where some contiguous edges of the package (but not all) starts to adhere earlier than the others.

Can be rulled-out (or confirmed) as a cause, by rotating each board in a slightly different way, as the assembly of the batch proceeds.