Propeller Mini and 5 Volts

iseries

Posts: 1,529

iseries

Posts: 1,529

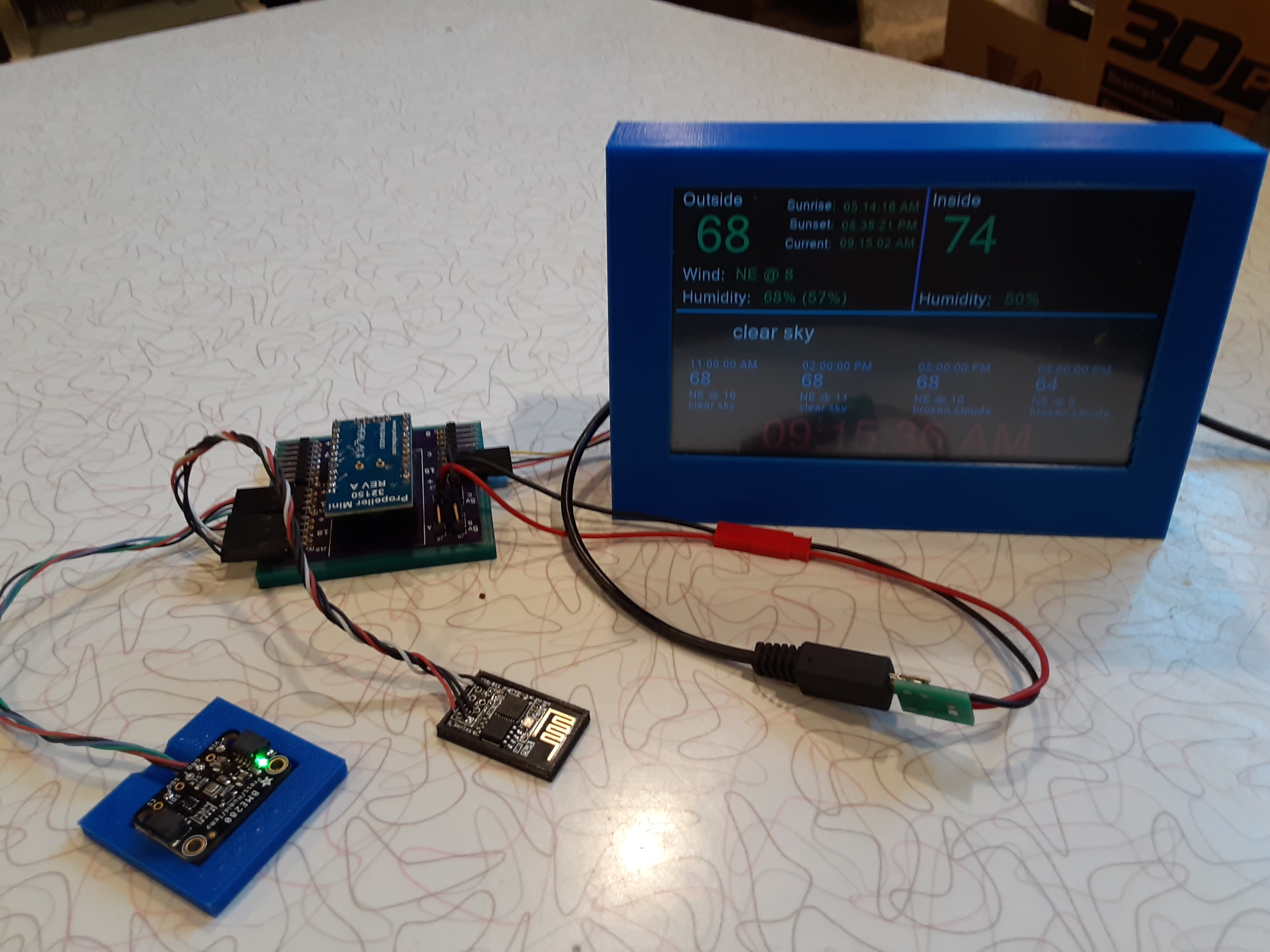

I recently put together a project where I have a Nextion 5 volt display that I am driving with the Propeller Mini board.

The problem I was having is that the Propeller Mini 5 volt power supply is too small to drive this display. This means I need a dedicated 5 volts just to power the display and other power supply larger than 7 volts to drive the Propeller Mini. This seemed ridiculous.

Now the other thing is that I have several 5 volts USB adapters laying around from various phones and devices that I no longer use. Why can't I just use one of those to power this project. Maybe I can get some value out of those old adapters.

So the ideal solution would be to replace the 5 volt LDO on the Propeller Mini with a USB plug. Then I could just plug in my USB adapter and power the display and the propeller.

Well it turns out that the Nextion display comes with a USB adapter that breaks out just the 5 volts. I then soldered on two wires to this adapter and also soldered the two wires to the 5 volts and ground pins on to the Propeller Mini. This bypasses the 5 volt LDO and gives me enough power to drive the display and the Propeller Mini.

Now I could as well have used the barrel jack cable they sell and added a barrel plug to my project but that would mean I have to purchase extra hardware to convert everything just to get to 5 volts.

Maybe Parallax need to sell a USB adapter board that breaks out the 5 volts so that if 5 volts is needed for a project that a option exists.

In any case I now have one less 5 volts adapter laying around collecting dust.

Mike

Comments

the mini 5Vdc supply is probably not very powerful because of the size. Yeah having 5 vdc available that easily accessible is nice. I also used the mini and had to provide a separate 5VDC power supply because it would not power multiple pixel leds sufficiently.

For prototyping I was thinking about making a bench power supply from a left over computer PSU. It would have 3.3, 5, 12, and some higher voltages and provide pretty high current. That would be great for initial building of a project.

For the final projects, I'm still learning about what works best. Seems I either had to build my own circuit, which as a non-electrical background is not easy. The forums recommended me to an ATX pico PSU, which I have found is small form factor, lots of amps, and easy to work with (minor taking apart). That is what I've been using for projects. It will power the mini and the secondary devices.

Hi

@iseries Nice clean looking fonts. Mind sharing how you generated them?

Dave

@tritonium ,

Believe it or not, Nextion has cleaned up there font conversion function so now they all look great. Many years ago when I got my first unit the font conversion function produced characters that were mono spaced and had large gaps between the letters. Many threads were opened on there site about this issue.

My original unit was a basic 4.3 inch model which was ok, but I later found that the 5 inch model was the same size with a larger screen and better graphics. Also the enhanced version has many feature that are worth the extra cost.

So if you are new to Nextion HMI displays, they have a graphics design program where you place your objects on the screen and all the texted is generated from the windows desktop fonts. You pick the font and size and it generates a font file that is downloaded along with the code for the display. All you need to do is send commands to the display to update the data.

This works great for the P1 that has limited memory as all the resources needed to render on the display are stored right on the display. You just send a command to display them.

Mike

Hi

No I wasn't familiar with Nextion displays. So they do all the work, and store the image data- a nice solution- although at a price I see! A solution I played with for a while was to use a car tft screen (for reversing cameras, dvd's etc) with a vga interface and a raspberry pi running a freebasic graphics program communicating with the prop 1 (or any other 8 bit microcontroller) over ascii async serial. It worked very well but was a lot of work to set up- everything had to be invented from scratch. Your solution will produce MUCH quicker results.

Dave