0.6" DIP compatible P2 without overhang - is it possible?

Peter Jakacki

Posts: 10,193

Peter Jakacki

Posts: 10,193

Just to break this off other threads and leave it for open discussion and ideas I started a new thread.

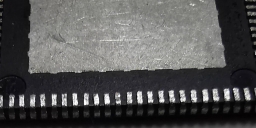

Here is an idea that could work where we reform the P2 leads although this would really need a jig but can be done manually with flat nosed smooth pliers and a hard even surface such as a ceramic working tile. The idea is to straighten the P2 leads and then bend the leads straight down hard against the body and then to bend the rest of it down under the package, a bit like a PLCC. I'm not advocating this for mass production but it can be done. Here is a picture of the reformed P2 chip (an old Rev A) that is sitting on top of a 24-pin DIP socket for comparison. The PCB should ideally be 4 layer to allow routing and the P2 could have regulators and crystal etc. Might be worth a try. Leads aren't meant to be rebent as they are quite fragile but I'm doing this for the fun of it.

This is a rough and ready test I just did.

btw, I don't see the need for a DIP version myself but knowing what can be done to fit the P2 into tight spaces could prove useful.

Here is an idea that could work where we reform the P2 leads although this would really need a jig but can be done manually with flat nosed smooth pliers and a hard even surface such as a ceramic working tile. The idea is to straighten the P2 leads and then bend the leads straight down hard against the body and then to bend the rest of it down under the package, a bit like a PLCC. I'm not advocating this for mass production but it can be done. Here is a picture of the reformed P2 chip (an old Rev A) that is sitting on top of a 24-pin DIP socket for comparison. The PCB should ideally be 4 layer to allow routing and the P2 could have regulators and crystal etc. Might be worth a try. Leads aren't meant to be rebent as they are quite fragile but I'm doing this for the fun of it.

This is a rough and ready test I just did.

btw, I don't see the need for a DIP version myself but knowing what can be done to fit the P2 into tight spaces could prove useful.

Comments

That's way worse than my DIP24 or DIP20 P1.

Beware of those heat mongers chasing you for the lack of proper pcb heatsinking.

So Dave, you are right, a DIP version is possible

I'd like 100 of the DIP24 versions. But since a DIP24 is only half a P1, I only want to pay half the price of a P1 chip that it will replace

How about half the price of a P1 for half the I/O but 16 times that for 512KB instead of 32KB RAM? So a P1 cost about $7 so that makes the P2DIP24 around $56

How does that look for creating an air-gap to the large GND pad ? Would enough paste there be able to fill the air-cap OK?

@ErNa - don't worry, I am making up boards all this week. These other things are only musings for now.

Great idea! P2 could replace a 40-pin DIP CPU/VDP/ULA/etc.

the real question is where have you been buying your P1's if they're half the price ? You must be buying truckloads of them at once. I'm in EU and the ~$7price in singles gets taxed by 23% in my case, plus the usual shipping, which is not cheap either.

He pays the full price but he cuts them in half with a hack saw. It's true, I've seen the results!

Yeah, but the other half acts exclusively as free to use, but aligned, pins

We have 10% GST here and in a proper business you can claim back when exporting. Selling here you have to charge 10% on the sale and claim back the 10% on costs.