50mil pitch plated through and ENIG matrix board

Peter Jakacki

Posts: 10,193

Peter Jakacki

Posts: 10,193

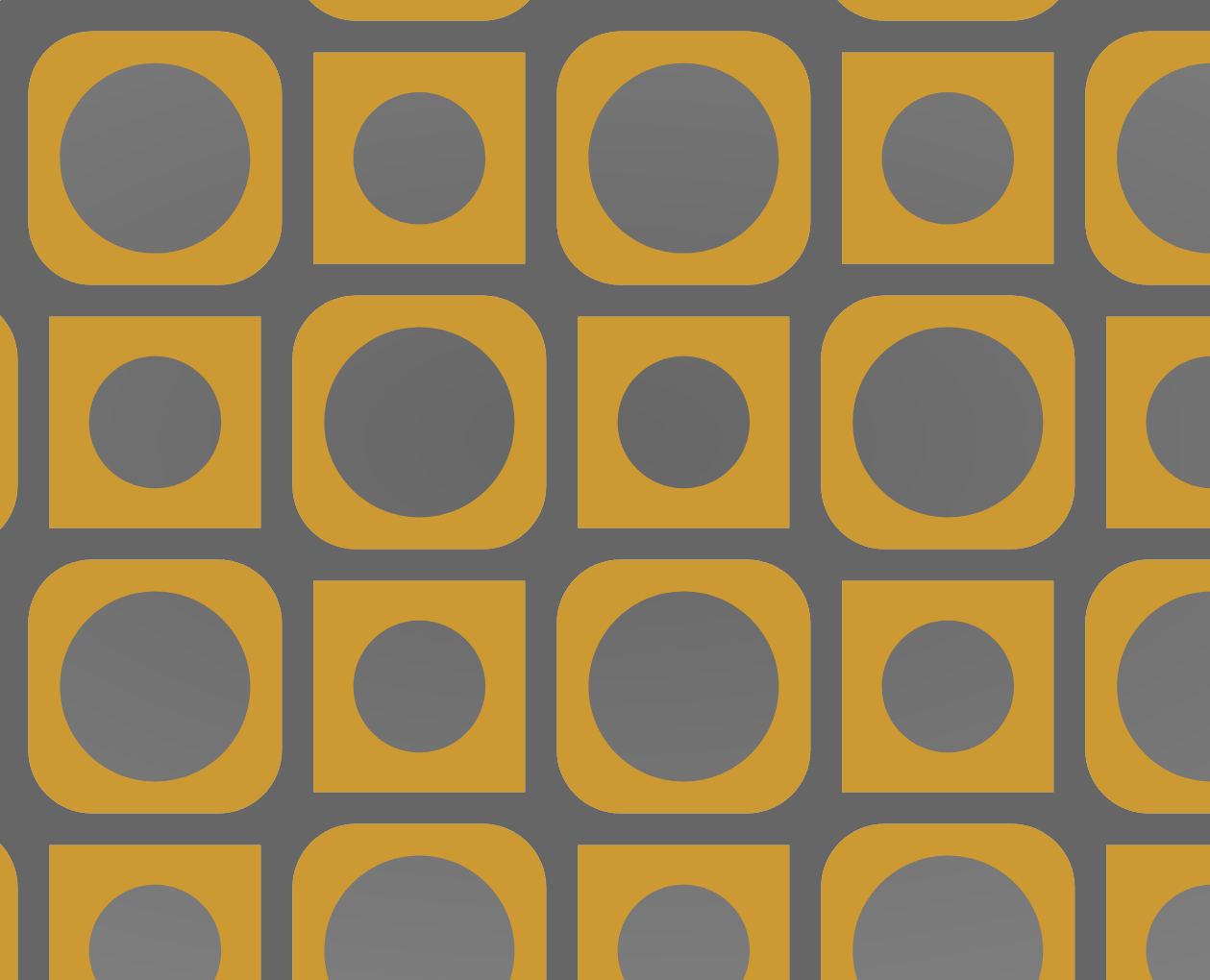

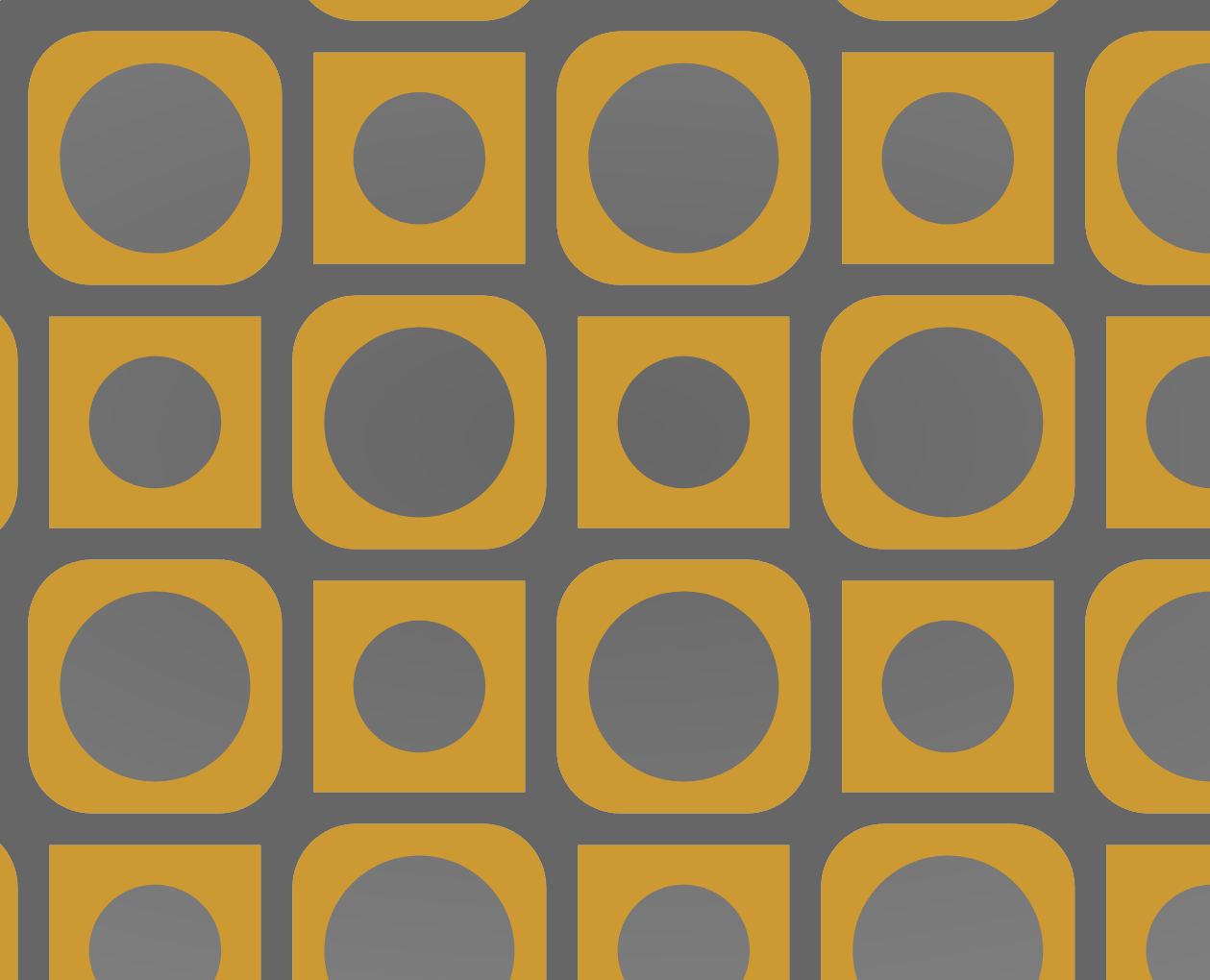

Here's a close-up shot of my 50mil prototyping matrix board. There is enough clearance between pads and I alternate a 25mil hole pad with a 35 mil hole pad so that I can still use 100mil header pins etc, but also 50mil as well as SOIC and other SMD parts on the board. They charge a little extra since there are 3,996 holes on each 3.75" x 2.75" panel and they are also ENIGed too. I will get 50 of these at least but possibly hundreds since they are so much better quality and cheaper than other stuff.

There is no wasted space on these boards, even in the corners since who needs to have fixed mounting holes when you may not even use them, or use rubber feet, or slots or just plain plug them into the P2LAB. For those of you who may wonder what ENIG is, it is basically the gold flash finish which is much easier to solder to and normally better for SMD work. The pads are plated through so they are plenty strong and 50mil connectors won't jiggle around since every second hole is 25mil. You will find that there are connectors that will be easier to fit simply because of the pitch without needing to drill extra holes and hacking the board.

I don't bother with power rails or any of that so called convenient stuff as it is inconvenient most of the time. It is just as easy to strip back some wire-wrap wire and tack it into place along the way so you can run it where you need. Alternatively I have used stick-on copper tape but normally that is totally unnecessary.

btw, I had to work this on Kicad since my Protel messes up the plotting of octagonal pads, so I exported to PCAD ASCII, imported into Kicad and saved it, then did a global search and replace on the 35mil hole pads in a text editor, then reloaded this back into Kicad.

There is no wasted space on these boards, even in the corners since who needs to have fixed mounting holes when you may not even use them, or use rubber feet, or slots or just plain plug them into the P2LAB. For those of you who may wonder what ENIG is, it is basically the gold flash finish which is much easier to solder to and normally better for SMD work. The pads are plated through so they are plenty strong and 50mil connectors won't jiggle around since every second hole is 25mil. You will find that there are connectors that will be easier to fit simply because of the pitch without needing to drill extra holes and hacking the board.

I don't bother with power rails or any of that so called convenient stuff as it is inconvenient most of the time. It is just as easy to strip back some wire-wrap wire and tack it into place along the way so you can run it where you need. Alternatively I have used stick-on copper tape but normally that is totally unnecessary.

btw, I had to work this on Kicad since my Protel messes up the plotting of octagonal pads, so I exported to PCAD ASCII, imported into Kicad and saved it, then did a global search and replace on the 35mil hole pads in a text editor, then reloaded this back into Kicad.

Comments

I'd like to see how well it all fits. (am I understanding this pcb properly?)

I like through hole pads, no rippin the pad off.

That layout is freaking brilliant! Price? Shipping?

Thanks,

-Phil

Think he means the DIP40.

@"Phil Pilgrim (PhiPi)" Think cheap, think very soon in October. I will include a batch of these in the shipment to publison so he will have them "in stock".

I should have realized what i was asking, if I had thought about the size each hole would need to be, and how close, that would be hella small.

I just want everything all in one. Micro holes in micropads... that fits everything, auto adjusted, on demand, automagically!

How about a pcb that changes based on the code you program into it, lol.

(however some would have laughed at the concept of a fpga long ago)

I want an Elastomeric pcb?

https://en.wikipedia.org/wiki/Elastomeric_connector

When you get them done and have a price, I may want a few.

-Phil

Pi*(0.035/2)^2*1998 = 1.922

Pi*(0.025/2)^2*1998 = 0.98

Total area of holes = 2.9

Total are of pcb = 3.75*2.74 = 10.3

Area remaining = 7.4

Did I make a mistake?

Ground can benefit from a wider trace to lower impedance, and the boards I've used like this have GND and VCC strips on the edges, and they have also included USB sockets and regulators, so that you have easy plug-able power.

-Phil

-Phil

And as Phil said, you often want to cut down the pcb to a suitable size for your current project to suit. Same goes for mounting holes - just drill out wherever you want them which is often NOT around the edges as that is where you have connectors - easier with 0.050" (1.27mm) grid as pilot holes.

As for power supplies, easier to add a pcb on top with power as required.

There's also a photo of a tacked kynar wire matrix board. When I want a heavier ground I either run solder along the length of it or just double it up or loop it.

A 3d model would work better because you would see where the legs fit. But yes, you can squeeze a lot of parts on 0.1" pitch, and 0.050" pitch will be even better! Only last week I put SOT223 regulators and SODxxx (diodes) on a 0.1" pitch pcb easily and wired with kynar wire.

Will be even better to use 0.050" pitch headers and shunts rather than 0.1" headers and shunts for alternatives.

Fingers crossed and let's see how all these boards turn out, but these microMAT boards end up costing me around $2 USD each which is about 3 times cheaper than I pay for my standard 100mil boards the same size from Protostack. If the finish and usability is there I will order a few hundred, and then the price should come down. In fact, I just checked and even with my shipping I can get them under $1 each. Factor in handling and shipping out etc means that I could probably charge $30 for 10 boards. I checked ebay and while there are cheap boards out there ..... there are cheap boards out there. Many are single sided coated copper, and the plated through ones are only HASL, but there are no 50mil or ENIG'd ones I came across.