Ideas needed to protect hall sensors and encoder outputs.

Hey guys I could use some ideas on this. The Prop main board has various RJ 45 ports that connect to different input sources. I like cat5 cable because installers can make up cables and it is a nice method of connecting remove devices. There is a brushless DC motor that has an encoder

https://www.usdigital.com/products/encoders/incremental/rotary/kit/E2#spec_electrical

and hall sensors

https://sensing.honeywell.com/honeywell-sensing-magnetic-sensors-line-guide-005894-21-en.pdf

The encoder output is totem pole. The hall sensor output is open collector, the BLDC driver board provides 6.35V via pullups to the hall sensor outputs.

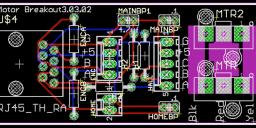

In the photo and schematic, the motor has a PCB that mounts on it that has an RJ45 that connects the motor back to the Prop main board. On the Prop main board, there are 7 other Rj45 ports for connecting other devices, and all off them vary in terms of pinout and 5v and GND will be on different pins for different ports. All the ports contain 5v, GND, and signals, and I used different pin arrangements to try to reduce noise by arranging twisted pairs on the cat5 in certain ways based on what what on that port. Unfortunately this has caused occasional problems due to people not reading the warning sticker on the motor port that says damage may occur to the motor if the cable is plugged into the wrong port! It is rare but sometimes they plug the cable in the wrong port and kill the encoder or a hall sensor. One example of a wrong port could put 5v and GND on the encoder outputs A and B.

One trick I added to the motor breakout board was 100ohm's in series with the 3 hall sensors and the 2 encoders. I think this reduced some failures but still I get a rare failure and want to try to remake the motor breakout PCB with some better protection. It is too late to change the main board pinouts. Does anyone have any ideas I could try on these signal lines ie diodes etc?

Thanks

https://www.usdigital.com/products/encoders/incremental/rotary/kit/E2#spec_electrical

and hall sensors

https://sensing.honeywell.com/honeywell-sensing-magnetic-sensors-line-guide-005894-21-en.pdf

The encoder output is totem pole. The hall sensor output is open collector, the BLDC driver board provides 6.35V via pullups to the hall sensor outputs.

In the photo and schematic, the motor has a PCB that mounts on it that has an RJ45 that connects the motor back to the Prop main board. On the Prop main board, there are 7 other Rj45 ports for connecting other devices, and all off them vary in terms of pinout and 5v and GND will be on different pins for different ports. All the ports contain 5v, GND, and signals, and I used different pin arrangements to try to reduce noise by arranging twisted pairs on the cat5 in certain ways based on what what on that port. Unfortunately this has caused occasional problems due to people not reading the warning sticker on the motor port that says damage may occur to the motor if the cable is plugged into the wrong port! It is rare but sometimes they plug the cable in the wrong port and kill the encoder or a hall sensor. One example of a wrong port could put 5v and GND on the encoder outputs A and B.

One trick I added to the motor breakout board was 100ohm's in series with the 3 hall sensors and the 2 encoders. I think this reduced some failures but still I get a rare failure and want to try to remake the motor breakout PCB with some better protection. It is too late to change the main board pinouts. Does anyone have any ideas I could try on these signal lines ie diodes etc?

Thanks

Comments

Using this type of switch will allow the cat5 from the motor to be plugged into any of 7 other ports and prevent the encoder and hall sensor outputs from getting power applied to them unless the TLP is powered on.

One thought occurred while working on this. LED's have a lifespan. So at some point of 24/7 LED ON these will diminished and fail. Then again, the encoder has an LED. So should I concern myself with extra LED's failing at some point? The goal is the longest life possible as often the motor is not accessible with some expense which can be high. I would like to find out if there is some non opto version of this idea that would remove the added failure factor. For example put mosfets in series like the TLP222a arrangement?

Any ideas appreciated.

I am looking at a mosfet option for protection versus the Diodes to reduce the voltage drop.

So... ENC-2 and HALL-2 are tied together (VCC for both) and are connected to the main supply VCC through a 47 Ohm resistor. This limits the current to slightly more than 100mA with a 5V supply. HALL-3 , HALL-4 , and HALL-5 have an additional 220 Ohm resistor in combination with the 47 Ohm resistor, the current is limited to slightly less than 20mA with a 5V supply.

Here is a part that is small, very low On resistance, very high Off. Looks like it would be fool proof if power was reversed to it.

http://www.onsemi.com/pub/Collateral/NTGD1100L-D.PDF

59 cents

http://www.ti.com/product/TPS22913

Reverse current protection in ON and OFF states. An internal reverse voltage comparator disables the power-switch when the output voltage (VOUT) is driven higher than the input voltage (VIN), by VRCP, to quickly (10 µs typ) stop the flow of current towards the input side of the switch. Reverse current protection is always active, even when the power-switch is disabled. Additionally, under-voltage lockout (UVLO) protection turns the switch off if the input voltage is too low.

http://www.ti.com/lit/ds/symlink/tps22963c.pdf

TPS22963/64

provides reverse current protection.

connect D1 to D2

connect G1 to G2 and Tie to Power (V+) with a pull up resistor(10k or so)

Your Input and Output are between S1 and S2 and can be interchanged

To enable the power mosfets, connect G1 and G2 to GND

I can solder the small BGA but that link is easier for sure.

Also if you have a non opto option for the 5 signals that would be slick.

"Also if you have a non opto option for the 6 signals that would be slick" ... I counted 5 signals... did I miss one? ... the latest BRD file was a non opto option

hall sensor A/B/C = 3 open collector. The signals are 6.35V unless the it is on that phase then the signal goes low. The 6.35V comes from the BLDC driver board, carried into to this PCB from the CAT5.

I like the opto switch idea since if it is plugged in the wrong port the switch is not turned on and any voltages 5V/GND present on any outputs will do no harm. But as mentioned I'd like to get away from LED and degradation over years.

We can do the SO-8. I have eagle on two computers, the newer version is PC and not paid so whatever you do I will re do in my older system. So if you find a generic S0-8 and use that I can redo it because I can't load your files in my older eagle professional Computer. Too lazy to upgrade and I can't get my old libraries converted for some reason. Short answer is you can use any So-8 based on the pinout of the part you like, I'll fix it easily. No need to lay out the board I just need to see a schematic. Thanks

The Ap2411 POWER SWITCH looks interesting. It is designed for hot swapping USB power. SO-08 options.

Say red for motors, green for hall sensors, something like that?

would not prevent mistakes, but make them more obvious?

Mike

sounds like the OP is using 8 pin modular plugs. No blocking pin space available.

Jim

I prefer the modular screw terminals that you can plug in, especially the more compact 3.5mm variety and they come in all configurations and make it trivial to wire a cable in the field, all you need is a screwdriver. Although they are more expensive it seems to me that trying to use modular connectors because they can be handled in the field is creating a situation where the damage they cause by wrongly connecting them cannot be handled in the field.

Circuit protection is one thing but prevention is better than a cure. Don't let those connectors get mixed up in the first place.